Professional Documents

Culture Documents

Antirotation and Centering Devices

Antirotation and Centering Devices

Uploaded by

Roopesh S Acharya0 ratings0% found this document useful (0 votes)

150 views1 pageANTIROTATION AND CENTERING DEVICES

The internal floating roof shall be centered and restrained

from rotating. A guide pole with rollers, two or more seal

centering cables or other suitable device(s) shall be provided

as required for this purpose. The internal floating roof shall

not depend solely on the peripheral seals or vertical penetration

wells to maintain the centered position or to resist rotation.

Any device used for either purpose shall not interfere

with [he ability of the internal flo

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentANTIROTATION AND CENTERING DEVICES

The internal floating roof shall be centered and restrained

from rotating. A guide pole with rollers, two or more seal

centering cables or other suitable device(s) shall be provided

as required for this purpose. The internal floating roof shall

not depend solely on the peripheral seals or vertical penetration

wells to maintain the centered position or to resist rotation.

Any device used for either purpose shall not interfere

with [he ability of the internal flo

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

150 views1 pageAntirotation and Centering Devices

Antirotation and Centering Devices

Uploaded by

Roopesh S AcharyaANTIROTATION AND CENTERING DEVICES

The internal floating roof shall be centered and restrained

from rotating. A guide pole with rollers, two or more seal

centering cables or other suitable device(s) shall be provided

as required for this purpose. The internal floating roof shall

not depend solely on the peripheral seals or vertical penetration

wells to maintain the centered position or to resist rotation.

Any device used for either purpose shall not interfere

with [he ability of the internal flo

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

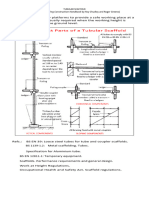

ANTIROTATION AND CENTERING DEVICES

The internal floating roof shall be centered and restrained

from rotating. A guide pole with rollers, two or more seal

centering cables or other suitable device(s) shall be provided

as required for this purpose. The internal floating roof shall

not depend solely on the peripheral seals or vertical penetration

wells to maintain the centered position or to resist rotation.

Any device used for either purpose shall not interfere

with [he ability of the internal floating roof to travel within

the full operating elevations in accordance with H.4.1.1.

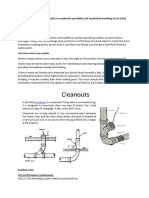

H.5.5 MANHOLES AND INSPECTION HATCHES

H.5.5.1 Fixed-Roof Man holes

At least one fixed roof manhole, with a nominal opening

of 600 mm (24 in.) or larger, shall be provided in the fixed

roof for maintenance ventilation purposes. If used for access

to [he tank inlerior, the minimum clear opening shall be

750mm (30 in.).

H.5.5.2 Floating-Roof Manholes

At least one internal floating roof deck manhole shall be

provided for access to and ventilation of the tank when the

floating roof is on its supports and the tanlc is empty. The

manhole shall have a nominal opening of 600 mm (24 in.) or

larger and shall be provided with a bolted or secured and gasleted

manhole cover. The manhole neck dimensions shall

meet the requirements of H.4.l.4 and H.4.1.5.

H.5.5.3 Inspection Hatches

When specified by the purchaser, inspection hatches shall

be located on the Gxed roof to permil visual inspection of [he

seal region. The maximum spacing between inspection

hatches shall be 23 m (75 it), but there shall not be fewer than

four equally spaced hatches. Designs that combine inspection

hatches with tank-shell circulation vents (located on the tanlc

roof) are acceptable.

You might also like

- Specification KONE ECO3000 EscalatorDocument5 pagesSpecification KONE ECO3000 EscalatorRohit JainNo ratings yet

- Storm Choke K Safety ValveDocument2 pagesStorm Choke K Safety ValveHIPAP100% (5)

- Part 8 - Exhaust Fan PDFDocument7 pagesPart 8 - Exhaust Fan PDFhvacsriniNo ratings yet

- Inside BopDocument5 pagesInside BopNigin Parambath100% (1)

- GuardrailsDocument2 pagesGuardrailsRose AlcantaraNo ratings yet

- General:: Means of Egress AnalysisDocument1 pageGeneral:: Means of Egress AnalysisBahaa MohamedNo ratings yet

- Floating Roof Check PointsDocument3 pagesFloating Roof Check PointsSajeev NarayananNo ratings yet

- Annex H (Summary API 650) : 1. MaterialDocument6 pagesAnnex H (Summary API 650) : 1. MaterialnjkasdncjkdNo ratings yet

- SECTION 1213, 1214, 1215: Report By: Elibado T. MaureenDocument19 pagesSECTION 1213, 1214, 1215: Report By: Elibado T. MaureenJohnFred CativoNo ratings yet

- Material Specification For FLANGED RUBBER SEATED BUTTERFLY VALVESDocument4 pagesMaterial Specification For FLANGED RUBBER SEATED BUTTERFLY VALVESMASOUDNo ratings yet

- ANSUL Aircraft HangarsDocument8 pagesANSUL Aircraft Hangarsاحمد الجزار2007100% (1)

- KPR 53 2018 SpecDocument7 pagesKPR 53 2018 SpecABDELKADER BENABDALLAHNo ratings yet

- CFS Controlled Flow Storage Silo: Highly Reliable Extraction Low Air and Specific Power ConsumptionDocument4 pagesCFS Controlled Flow Storage Silo: Highly Reliable Extraction Low Air and Specific Power ConsumptionSamehibrahemNo ratings yet

- 3 and 4 1Document3 pages3 and 4 1Lyca Agelica BalonggaNo ratings yet

- SCAFFOLDSDocument16 pagesSCAFFOLDSMohamadou NdjiddaNo ratings yet

- C-2107499 - KONE - ESCALATOR - TM110 - Technical - Specification en - USDocument13 pagesC-2107499 - KONE - ESCALATOR - TM110 - Technical - Specification en - USSabeeh KhanNo ratings yet

- Bottom OutletsDocument3 pagesBottom OutletsJezylu Jireh Lasola AnitoNo ratings yet

- VELMATIC Well Service Air ValveDocument2 pagesVELMATIC Well Service Air Valvecarlos37No ratings yet

- Laws For UniversityDocument17 pagesLaws For UniversityPatricia DeniegaNo ratings yet

- Fire Exits - Mark EdmineDocument39 pagesFire Exits - Mark EdmineMark GonzalesNo ratings yet

- Camfil Farr Slimline HEPADocument2 pagesCamfil Farr Slimline HEPAkalmech2003No ratings yet

- Tubular ScaffoldingDocument17 pagesTubular Scaffoldingfoxsins226100% (1)

- Infrastructure GadDocument14 pagesInfrastructure Gaderik francis laurenteNo ratings yet

- IMG - 0052 PSME Code 2012 50Document1 pageIMG - 0052 PSME Code 2012 50Bugoy2023No ratings yet

- InletDocument31 pagesInletArul PrakashNo ratings yet

- 0004 Lesson API RP-576Document65 pages0004 Lesson API RP-576tayyab aliNo ratings yet

- Automatic Sprinkler (Drenchers)Document2 pagesAutomatic Sprinkler (Drenchers)rmaffireschool89% (9)

- Completion Equipment1Document32 pagesCompletion Equipment1MUHAMMAD AKRAMNo ratings yet

- Scope of Load Line SurveyDocument5 pagesScope of Load Line SurveyMuhammed Mudafi ElhaqNo ratings yet

- Albert AST RegulationsDocument105 pagesAlbert AST RegulationsxnbsxNo ratings yet

- Nbs-Rule-Xii-Xv 2Document36 pagesNbs-Rule-Xii-Xv 2Reymar MungcalNo ratings yet

- Air Admittance ValveDocument3 pagesAir Admittance ValvejituplanojrNo ratings yet

- 04 Watertight and Weather Tight DoorsDocument12 pages04 Watertight and Weather Tight DoorsLucky Boat100% (1)

- Ontario Electrical Safety Code Section 75 Proposed Changes (PDFDrive)Document145 pagesOntario Electrical Safety Code Section 75 Proposed Changes (PDFDrive)Skariah MathewsNo ratings yet

- Private Residence Lift For Disabled PersonsDocument6 pagesPrivate Residence Lift For Disabled PersonsDuarte OliveiraNo ratings yet

- Stack Maintenance Access Residential Dwellings July 2019Document5 pagesStack Maintenance Access Residential Dwellings July 2019Moren AlfonsoNo ratings yet

- Standards Update Notice (SUN) : Standard InformationDocument5 pagesStandards Update Notice (SUN) : Standard InformationGENIE CIVIL BLIDA BEREPNo ratings yet

- TMS / ITS Approved Products ListDocument6 pagesTMS / ITS Approved Products ListRaj RamachandranNo ratings yet

- LCVDocument6 pagesLCVricio10No ratings yet

- SSG App C Des Con Guide - pdf4Document7 pagesSSG App C Des Con Guide - pdf4Shohidul IslamNo ratings yet

- Massachusetts Pool RegulationsDocument5 pagesMassachusetts Pool RegulationsAnonymous Q4eW6c2ON100% (1)

- Planning For ElevatorsDocument6 pagesPlanning For ElevatorsFERNSNo ratings yet

- Sample Specification of FansDocument5 pagesSample Specification of Fanscashlover100% (1)

- Sample Specification For Air Handling UnitsDocument4 pagesSample Specification For Air Handling UnitscashloverNo ratings yet

- GatesDocument49 pagesGatesPrem Singh RawatNo ratings yet

- Passenger & Freight Elevator Pre-Inspection Checklist 2014 - FinalDocument3 pagesPassenger & Freight Elevator Pre-Inspection Checklist 2014 - FinalMostafa MohmmedNo ratings yet

- Technical Requirements - Commercial Escalators 1.00 Scope of WorkDocument8 pagesTechnical Requirements - Commercial Escalators 1.00 Scope of WorkAbd Malek RosediNo ratings yet

- SCAFFOLDSDocument12 pagesSCAFFOLDSBolupe TaiwoNo ratings yet

- BS FIRE FinalDocument18 pagesBS FIRE FinalManav JoshiNo ratings yet

- FADAEI SSD Version2 (1398 02 04)Document28 pagesFADAEI SSD Version2 (1398 02 04)mehdiNo ratings yet

- Reviewer NBC 9-12Document1 pageReviewer NBC 9-12Eugene Fernando BelmonteNo ratings yet

- New SSIV InstallationDocument12 pagesNew SSIV InstallationDidiNo ratings yet

- Vertical Openings Prevention: Means of EgressDocument23 pagesVertical Openings Prevention: Means of EgressAhmed SowilemNo ratings yet

- Safety BarrierDocument5 pagesSafety BarrierKC PangNo ratings yet

- Elevator CodeDocument31 pagesElevator Codeelevatorman7No ratings yet

- 2003 IBC 1007 Accessible Means of EgressDocument3 pages2003 IBC 1007 Accessible Means of EgressVince Anuta SalanapNo ratings yet

- The Forming ForceDocument1 pageThe Forming ForceRoopesh S AcharyaNo ratings yet

- Agitator FINITE ELEMENT METHODDocument5 pagesAgitator FINITE ELEMENT METHODRoopesh S AcharyaNo ratings yet

- Trolley Bom: SL - No Description Specification WT in Kgs Qty Total WT in Kgs RemarksDocument1 pageTrolley Bom: SL - No Description Specification WT in Kgs Qty Total WT in Kgs RemarksRoopesh S AcharyaNo ratings yet

- The Potential Applications of DOE in Manufacturing Processes IncludeDocument2 pagesThe Potential Applications of DOE in Manufacturing Processes IncludeRoopesh S AcharyaNo ratings yet

- DevelopmentDocument1 pageDevelopmentRoopesh S AcharyaNo ratings yet

- Experimental DesignDocument1 pageExperimental DesignRoopesh S AcharyaNo ratings yet

- Concrete Masonry CorporationDocument1 pageConcrete Masonry CorporationRoopesh S AcharyaNo ratings yet

- Experimental DesignDocument1 pageExperimental DesignRoopesh S AcharyaNo ratings yet

- HISTORYDocument1 pageHISTORYRoopesh S AcharyaNo ratings yet

- Stress Concentration FactorsDocument1 pageStress Concentration FactorsRoopesh S AcharyaNo ratings yet

- The Peters Company ProjectDocument1 pageThe Peters Company ProjectRoopesh S AcharyaNo ratings yet