Professional Documents

Culture Documents

Coc 19s1-2016-Saipem-Po-1283374 PDF

Coc 19s1-2016-Saipem-Po-1283374 PDF

Uploaded by

Fahad Ahmad0 ratings0% found this document useful (0 votes)

216 views24 pagesOriginal Title

COC 19S1-2016-SAIPEM-PO-1283374..pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

216 views24 pagesCoc 19s1-2016-Saipem-Po-1283374 PDF

Coc 19s1-2016-Saipem-Po-1283374 PDF

Uploaded by

Fahad AhmadCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 24

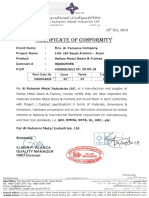

Global Anti-Corrosion Techniques FORM | GBRF-Oon

1

Revision

14981-2016

CERTIFICATE OF CONFORMITY | seqne: | 49-11-2019

Date: 10f4

‘Sheet Ne

Customer: SAUDI ARABIAN SAIPEM CO. LTD. PO No 1283374

TTEW-007

[Description COATING DATE

16, NOV 2019, N/IS

10 IN X 0.438 N WT GR X60

TOTALS:

) See attached print out for details

‘COATINGS APPLIED:

INTERNAL FBE + Fusion Bonded Epoxy Coating with Primer

FBE Thickness 20-30 mils (600-760 microns) APCS-102C

WATERIALS:

INTERNAL FBE - Primer 3M 500 N

Fusion Bonded Epoxy Powder 3M XC-6174 (APCS 1020)

‘STATEMENT OF CONFORMITY:

‘Statement of We confirm that the coatings and services provided by GLOBETECH have

conformity: been supplied in accordance with the Customer speci

deviations shown below.

‘APPLICABLE SPECIFICATIONS:

‘09-SAMSS-091 | Qualification Requirements for Shop-Applied Internal FBE Coatings

Procedure for Plant Application of Intornal FBE Coatings to the internal

FNP SE nev 6: Surfaces of Carbon Steel Line Pig

ITP-P.INT-FBE- | ITP for Plant Application of FEE Coatings to the Internal Surfaces of Carbon

002-SAIPEM Rev. | Stoo! Line Pipes (APCS-1020)

8

GLOBETECH CERTIFYING AUTHORITY: ‘SAIPEM CERTIFYING AUTHORITY:

Reviewed by Hamid Nkrumah,

Peston, Wane, Signatre Psion, Name, Signature

Date: 1814-2079 T Dave

Disclaimer: (Coated pipes, spools & Titings are dispatched ftom GLOBETECHYs coating facility only

having passed holiday detection testing. GLOBETECH will not beheld responsible for any subsequent holiday

testing carried out by the Client or its Contactors inthe field t shouldbe noted that holiday detection should not be

carried out in the fel, particularly on items that have been exposed to moisture since holiday detection in such

cases may cause holiday in otherwise sound coating. Ref. NACE Standard SP0188-2006,)

Prepared By: MOHAMED

Snayei

isvezZins ‘90 =1un09

‘soyewung

u eoee | vaves6 | srowans naan oso | 1 | wicca: | OaXHDIMNeErOXNIO | ZlO0-INaSHLEY

3 ‘awee | wosizs | econana wavs ssovx | + | weter | osXHOIMNeErOXNIOL

Lu ocee | sovess | ieonana waa ssovx | + | weteer | 0sX¥OIMNBEYOXNIOL

a ‘avec | 00126 | ooNaHa wave ssovx | + | wecscs | ogxuoIMNecroxNIOL

ou ever | noize | cinerea wav ssovx | + | wicca | 0X YO IMN@CFOXNIOL

43 zee | nosis | seonana wavs osovx | + | wicca | 0oX¥OIMN@CPOXNIOL

‘emseonyown | wus | onve=H | enacts | vonenaiqay wong | on wen | ounoa | qunN OG wond9800

710 1 Beg -

FeageLld 1020 2208:9/10=1NOO ‘PUPaAONA "FEAIEAS Jo ROHSOO SEUPLO MOYO

‘pea PeM=ONA‘snop=30NOD ‘2s6ing pomLSd WENEAUATS WedeLNaG "98eUeg [shog-C LS LH34 ‘eBEWEG EIg~OS VOREUUE HHT sioasaa

+ yn

id ¥ ¥ ou | iw os one 2 | omnasvce|

vy v | eeze v vs oz a 00- aSrLe |

oe v v sez v evs omIz a L00-L ISLEY |

v ¥ wee v we oe a 00-LMESPLEY |

v v onze. v vs ‘000 a ‘S000 INaSPLEV

v ¥ ¥ evs a F ay

veeeszt| LTO

yewsopea [| rewiowy |»

PO'ASY VLO0AL ‘ON WO ANVId ONILVOD 384 LNIYOdS1OOdS Fadid = *

oee'60 ou,

etoziet/t ‘area (LONNId) odey Burwosy edig

ANVdINO9 SNDINHDAL NOISONYOS-ILNY Tv8019

= 2402 08eq -

naa ‘sseuuieas 6 MO=G00 eUUNEY P O-LOO

18208 Lg L4e34 ebeuing ong-OS YOREURIET=HYT siai0

vit oon arava mad

190/20 PINA-aNN sBhop=30NDD ‘sels pouseSd! HOMES-RATS HE0=1N3O "abe

e1ozvou/Lt syenbo aa 96

z sjenbe “oNn300uS,

L stenbo ound

weeez sjenbo Joquny Od

euoiuo youees

uwodaai jo pug

Ananuuvesa ATW: sawooz 40 onrits

‘yorneu vro041“14o4s4 ONINOONT 3414 3NTT GNY ONISYD ANaHAMVaaa 90: wansst

'$t02-1006 OSI (WaLSAS ANAHDWNYH ALTTYND) SHO

ae 2 | sls

ALLVANaSauaTY SuaHOLSND wostawadns 90 sousadsNr 20

QP see

GLOBAL ANTI-CORROSION TECHNIQUE COMPANY.

|

| SURFACE PREPARATION REPORT

1 exren

Sos) ee ae

WG-2 ole

ise 242) | 12103) w2

ans Te = oy

WeLo2s) 94261 — Pao rssmnes [2.0080

‘ac inspector OAiseR

Seq. pipe Nef Tine

|Faney

poe

Testex PRESS-O-FILM™ HT

Bie Cham

faa Sa ae TOE

mowrnigyee Of

aeseo-rim™, jr

ene cara

Testhe ‘Sea, pipe Ne on Tce

Testex PRESS-O-FILM™ HT

(ZS)

7 a aT ART TTT SOOO ——|

Goa anicomaaca agama coletax Fomen, [erm

SURFACE PREPARATION REPORT See fa

Dl emmormes faeries Cerootsrnrmmos ae = rian

9 —

a ee eS

wore (MIC-3 12 Jos}2do Se a

= = = [ae Sz1 Ly z rh Tr

mows | 467-8 Ol /ox]worm =

=a L24in] | 12103) are

aE TET snes amore jo = a

W4_ #025 | )194261 Sonim Pro eae

a Sa

Sc harecron ousen

Teste ea. piste Tims D7 —

PioeiFiing ef

lasers let NE aes

Testes PRESS-o-FiLM~ fr

Teste

a pipe Neo Tine

Peering

Test he

'S0q. plpe Noa Ti

Periting he

‘SIWUS PROFLEMETER RESULT

[rm Ccten

ewes Eras

vot sore

fae Supervisor: Customrs Roprosontal Son x

Eien

) § ow

SS Se ee

INFNO1

| SAIPEM

INTERNAL COATING REPORT - HEADER

Page 1/1

111192019

9:33:56 AM

PO LINE / ITEM NUMBER: - 1

‘CUSTOMER ]

ITEM TYPE

PO NUMBER | t28s376

DATE 1 |

SHIFT NiGHT |

| SHEET# [2

[ CALIBRATION

[a ns : nero

Tecwesscuace | Tos | Tea : ora

| : =i |

oun’ T t

ou vow) a TF - verre

Se = — =

MATERIALS

| Tre pRopUCT ] aro

I ae t ancem Tee

| eter Pak se ‘08

I epson = aa

CHECK ITEMS | REQUIREMENTS | RESULTS

‘COATING LINE SPEED 180) min ~ | Na

ee

REGIA rowan Nocreomrman eo Korwnon o*

| POWDER PRESSURE Te, | st

I cai anor mmosiauaans 9 |

Global An Coron Tne COMPINY

Ferm, “F008 Rex o8

Ganomer SAPPEM

REPAIR REPORT ete sam

Dae | 18-Nov-19

Pipa/tem Description: 10°X 0.438" WT API SL GRX6O PSL-Z sae DAY

oom. lof

ie ia aaa Oo peniroee

arr a oa ae

roarrmererrat we Cc wi Teeth a ET TTR

Eauipment Calibration:

Teliay Datecior OT albration Time Tatoo

Logends: Ace Accop, Reet, H- Hold

Notations

LEGEND = OH Over Heat; OP - Orange Peet SAGS-Syg5: LUMPS Lumps: OT -Over Thickness; UT- Under Thicknass: PD - Powder Drops

‘CONT-Contamination;PC-Part Coated: AF- Adhesion Failure; HOUDAY - Holidays; BUB Bubbles, OS Over Spray; CBC -Cut Back Carin:

SPL- Spr: Dc - Discoloration; BLS lsteing PH-Pin Hoe; FISHEYE Flsn Eye

coating

Remarks

Status

Seq Length

Pipe/item Na.

Ses | Grn. pert 7

1 | os | pie Baty | Pepare ¢ Qu Wp. 2eP{wl-| AW | terenp

Repair Description Coating Date |p

(inspector Ac Superisor

Sey

ised

Aner Department

‘GLOUAL ANTLCORROSION TECHNIOUE COMP Foun OF ee

aT ST

PRODUCTION TEST RING f= Tea

far : iit

ra

iP DESCRIPTION 8° K0.344" WT APLSL GR. X60 TD pew Pox cotng rns

FE NAME / ATC BM XCEI7I BHBAZIA Of attr coring rat

‘SAMPLE NUMBER GT-05 custom shop yin) custom shop (eT)

> | acceprance crrreria | ._ EST RESULTS CONCLUSION

vest TEST METHO os

ss |

‘ omer wacesris20 neces naimnen,| 2 |} ———— tras Cat

eaten rn

| worwarenaonesion sce sree ao, see 1 1 | eos Craw

(24 hours) 75 £3°C | eeete -

| wrerraceconramnanion Are: 2016 1 | Lessthan 10% a Ora

caren osonoment

t| Gterewressy azz, sti ° wa | Grass Cran

(orearte ning

| eosssecnonrorosy cans, raigatta 2 | hes Coa

ee ee Boss Or

si i daueiz7322 | S86: a PASS vss rat

3

3

pocsamae

| onrmaeneenes sce 1 | fos Con

”

TaOUTSR GAT TRENTON CAGE mm

rooehicx wonaa

“GS QUALITY MANAGEMENT SVETEM] SO SOOT OES TT EY

= — eee

lu1uy9 00°02 ¥€ 9,00 S82 01 9.00°08 WONT (y

UIW/D,00 02 I D.00°0E 0} 9,00°0S) WOH JooD (L UlW/D,00°02 18 D.00°0€ 01 9.00°021 Woy 10D (e_

UlWy.00°02 18 D.00°0S! 0} 9.00°0 Woy IeeH (9 0.00°021 ¥8 UI O'L 40} PIOH (Z

__UUirD,00'02 8 9.00°08 01.9,00'S82 WOH eo _(S _____uuyo,00°02 18 9.00'021 01 9,00'08 wou eH (L |

(0.) eumeredwe,

Sir yoo-eLese 2

gt ost ort ozk 001 og 08 oy

: — $892

9

=H Bed - sz

PUECOOO = ERY yyy) 5, _

DOE abe ee . LUSLL = payejodenxa do sleH “81 ee

‘O.s6/r 8610 = do B18 3

2

a

eg

8

5

r we

De LOPLI = parejodenxg do yjeH “6, =

‘De6/P 1610 = do Bue |

lz |

oz

ost

VeeveHa 12180X sio¥uDIODg We "aas ewe,

SIN 6102 ‘91 AON ‘@1eq payeoo

%66'88 =9 ‘Sir Z000'0- =LH elPG ‘Or L2'z9- =H eNea

2, O21 =6L E80 ‘Ds LOPE =P61'D, L/'SHt =€6L

ONY 1SALS0-19 queuwog

Wadi¥S :al aidwes

1. ABRASIVE ANALYSIS

OUE. Fomine. FOO Fov08

oo 18374

Daily Laboratory Report bo TNO

i aaa

Poe i

MATERIALS Teerowoa Tan TE tera FE Pine coating Pat

a =e a enlace cog

Bare Ne. wan sae Dl customsropanm) C1 custom shop

custom hop ev)

TEST REQUIREMENT RESULTS ‘CONCLUSION

A (SSPCAB? Cause 46)

a a Fines 0.425mm - 16% Max metas, Oras Orat

B [011 Contamination on the Re-circulated Abrasive ee — Gis Draw

Oil/ grease free ‘iu raee Diss Oat

€ |ater Solute contaminant arcana som Ks Orn

2. BEND TEST Method: NACE SP0394-2013 (App.H)

no.| tem. | oxoneerro | Sete _—____rulenes> | wisua_ | wounav | concwusion

ages = a2 | 2 | a | a | 2 | 2 ACC o Brass Oran

2m [a [a | = | ace ass Craw

Brass Orat

Deass Oran

Doeass Oran

Orsss Oran

Orass Oran

Oeass Oran

Drass Ora

| Crass Oran

Choass Oran

OQrass Oran

3. POWDER MOISTURE CONTENT

TEST REQUIREMENT RESULTS CONCLUSION

’& [PowoER MOISTURE CONTENT (FLUIDIZED BED) (0.5% Maximum eam Eives Oran

4 DIFFERENTIAL SCANNING CALORIMETRY (DSC) Method: CSA Z.245.20-14

REQUIREMENT == ‘Te3, Ted > 93°C HBC < ATR < 23°C ‘C> 95%

RESULTS

INo.| SAMPLENO. ‘oncwusion

Te Te ate, a ant c

1 GF- 005 116.16 *c [11426 -c | 19 -c | 62.21 i/g| 00010 ¥/e| 99.99 % Btrss Oran,

2 c “c 6 we Ye * Dass Oran

3 *e *e * Ys. We % | Crass Cran

4 c c < Je ve % Drass Ora

TaBORATORY EEHNNCAN TABORATORY W-CHARGE FRENTE

AMMAR ALHOUL heen ‘ei

be. | Messin) aston [32 a4

TY RST ESTE

Updates ofa 8 2

osz

‘ujuy’9,00°02 ¥8 9.00°0 04 9.00°0S1 Woy [009

Iuy/9.00'02 18 9.00°0S1 0} 9,00'0¢ Wow 19H

‘uluy'9,00°07 18 9.00'0 01 9,00'¢8z Woy jog _(¢

(9) eunjexedwe

ove, ozz o0z ost 09)

‘uuuy9,00'08 3 9,00 S82 4 9.00°0e wos} 22H

‘u9,00°02 12 9.00'08 04

‘2.00°021 12 UIW 0'1 40} PO

______ulWu/9,00°0Z 18 9,00°0Z} 0} D.00°0E Woy EH (1)

e

1 ee

6/r 0L.00'0- = H Buea.

rw £100" = ely

9. 09612 = Heed

0. 92'vLL = peieiodenxg do sleH ‘61

DosB/0 8810 = do eHIeG

‘Oe SF ObE = payejodenxg do sey BL |

‘DerBir 2020 = dO e1I8a

az

—— — (mw) umog opug moj jee

fez

le

‘VeZ¥BHE LLLSOX eIOIYDIDS We “Sad [ELIE IU

SIN 6102 ‘9 AON :@1eG pa1209

'%66'66 =9 ‘B/r 0100°0- =1H eu8C ‘B/r }eZ9- =H eNEC

‘2. 06'I- =61 8180 ‘0. 92'PL1 =¥6L ‘9. 91-91

261

00-19 quewwiog

WA3dI¥S :G) e\dwes

(GLOBAL ANTI-CORROSION TECHNIQUE COMPANY [FORM NO. Q-004_sev.08

oe 2.00010

Virgin Abrasive Testing Report ‘shit DAY

ase aotar

"ABRASIVE NAME [ABRASIVE TYPE ‘ABRASIVE BATCH

WINOA

W GLO25 1192

WHEELABRATOR _ mee

ANALYSIS

DESCRIPTION TEST METHOD CRITERIA TEST RESULT

are

‘SULFATE CONTENT MSMR Oba ney 02 less than SOPPM. 14 PPM

paragraph 6.14

CHLORIDE CONTENT AASBLTE* 002 ran. 02: less than SOPPM 16 PPM

paragraph 6.14

MS8L7P-001 rev.02

cava wei 499% by wei

IM CARBONATE 7. 1.0% by weight 0.49% by weight

OIL CONTENT Matin cutee 02 oll free erPass FAIL

paragraph 6.14

MS<P-001 rev.02 not more than

CONDUCTIVITY paragraph 6.14 1150uS/em 22 uS/em

LABORATORY TECHNICIAN

oviensd

Etwitnessye

UD, Yn [Sa

astnon | pate: \y

ron osauoA assaaTACASOUR 7

aE (A HARRGEENT STO BODO

ee TRGRATORT TRG ASRS TSTRGWETOR FOO Ra

ungerneconos _Lusonavony Updated one 1,20

Yau

W Abrasives’

CERTIFICATE OF ANALYSIS.

Certificat d'analyse - Analysen zertifikat - Certificato di analysi

INFEN 10204 (od 9,1)

‘CUSTOMER (cient Kunde lars)

GLOBAL ANTI CORROSION

TECHNIQUES CO P.o. SOX:10823

ALIUEALL 33961, KSA TEL. +966133,

1 Peclng Lit (Avis exp, Liteachla, As specins).

34610

4000: Fax: -S66i33¢oass5

SATEHIe aiet Bne ) PRODUCT (Pod Produ roto)

119261 W cuo2s

rer (Cmdetrg/Comands) —____Net Wel (ais Ht Gel) DATE (Cale / Dam Ota)

st 08507 54.000 Ke 25 09 2019

HARDNESS (Oust Hante/Ouressay§

Spectaten(Speteaten | Spetaton Spacteaone)

“Ansiyeyraniométiqu! KorgBe! Anais ranuoetia)

WISCREENSZE SPECIFICATION % ‘REFUSED

me Spon Rave stony <4 < 6s0Hy

Witirenereseucdo Spetenionss gu est (Reuss / Rests)

i $95 wy

a4] 40 O13 °

lo ee . carr ese) conan)

38/3100 i to SesteaonSpttenton/ Spstiton/Spsteaton)

aol ae | oe seemiacr a

25) 0.72 8s 85 ena Risa rests)

dole S| ” Sit

35] 0,50 |

ae | SHAPE (Coca dame Fenkolien

Coie toma) ———

Spesteaton(Splatcaton /Spessieaton! Spacesione)

S>= N/A not Applied

.cHetcat couposiTion eras (esate Rots)

(Conga cine Chara zisiasnng / Conga IAS) :

‘Specifications %

spootrsenn ‘MICROSTRUCTURE (Merostucne [Mio zoxntea)

0,e0< c < 2,20

0.40¢ six 2,20

0,60< Nn< 2,00

0,00< s < 0,05

0,00< P< 0,08

State Spleen eptein pieces)

ete (Rees Rests)

MARTENSITE

PINE EP HONOGENE

‘Tiered isin atcorsoce with he dla sheet speiiaens. hase rest star hm the apeatan of x cont lan,

Ce pect et cones aux speteatons de rete fee ecnige. Ces esas tote spicaon co wot pane cetle, "|

‘leses Prout ertpen den Speiatonen Dies Dan wucengenassvasten Pstonesongon eat

Questo pads @cantome ae speciche dela shedaecvice. Queal ruler cent con fpgtesine Sel nos pang

LsoearoRY uanceR comencil \ q

sent etre respi Wt

Uabcrter

capo geleserseno

SBu— \Winoa - BP 3 - 38570 Le Cheylas - France

Tél, 133 476 929 270- Fax ¥83 476-929 2

NIHOA - $A. au capital de 30,811-008 EUR - RCS Grenoble 8 06: 500 864

528, avenue de Savoie - 38570 Le Cheylas - FRANCE - Tel: 04.76.92.92.70 / Fax: 04-76.92.92.49

Locataire-gerant du fonds de commerce de la gociete AMP Grenailles §.A.

W Abrasives”

ATTESTATION de CONFORMITE

Conductivité / Chlorures / sulfates

CONFORMITY Report (Conductivity / Chlorides / Sulfates)

CLIENT : GLOBAL ANTI CORROSION DATE: 25-sept-10

Customer TECHNIQUES CO P.O. BOX:10823 Date

ALJUBAIL 31961,KSA TEL:+966133

40001 FAX:+986% 33408555,

PRODUIT : WeLo2s AR: 3507

Product ore

N° de Lor Avis:

Batch nr aa9261 Packing ts: pari

Poids Net Transaction:

ae 54 tonnes, Trangagtion: 90010292

1°) conouctiviTe 9 Siem Exigence habtuelle: Maxi SoyS/em

Conductivity:

Méthode d'essai conforme &:

Measurment in accordance with

2°) CHLORURES :

Cchlerides:

2,0 mgil

Méthode d'essai conforme &:

Measurment in accordance with

3°) SULFATES

Sutfates:

3 mall

Méthode d'essai conforme 8:

‘Measurment in accordance with

Usual requirement:

ASTM 04940 (2010)

Exigence habituelle: Maxi 10 mg/l

Usual requirement:

EPA 0325.1 (1973)

Exigence habituelle: Maxi 10 mg/l

Usual requirement:

ASTM DS16 (2011) / EPA 0375.4 (1978)

WS

Ces résultats sont compatibles avec les exigences habituellement rencontrées sur le marché we

cece

Page 1 of

Certificate of Analysis

3M CORDOVA

22614 ROUTE 84 N

CORDOVA IL 61242-9779, USA

GLOBAL ANTI CORROSION TECHNIQUES LTD(GLOBETECH

‘SUPPORT INDUSTRIES NO.3 ROAD # 106. PO.BOX 10823,

‘SAUDI ARABIA,JUBAIL 31961

Date certificate is prepared: Oct-06-2017 Order Ship Date: Sep-11-2017

‘The 3M product listed below was produced in accordance with standard manufacturing processes for the product in

effect at the time of manufacture and is certified to meet the specifications displayed below.

‘3M Invoice Number ‘Customer PO Number Customer Part Number

1000865 ACBZ4

‘3M Stock Number Product Description

80-6107-4933-7 SCOTCHKOTE SOON WATERBASED PRIMER (5 GALLONS)

UPC Number

00051138361297

Shelf Life ‘Storage Condition for this Product

4. YEARS FROM DATE OF MFG DO NOT FREEZE (>0C/32F)

Lot Number: 20086 Date of Manufacture: Sept-05-2017

‘Test Property [Comments] “Test Method Nor | MinSpec | MaxSpec Units Rete

‘Weiht pr Gallon 1026 Tegal TS

‘Appearance BHC PASS

Please contact your 3M Customer Service Representative if you have any questions.

‘Wann Limits Remesy: Unless stated otherwise in 3M produc literature, packaging insets or product packaging for individual prc,

3M arn Hat each 3M product meets the applicable 3M specifications atthe time 3M ships the product. Iraividul products may have

‘ddivonal or dierent avanies 26 saled on product erature. package inserts or product packages, 3M MAKES NO OTHER

WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY

(OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OR

CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE OF TRADE. Use is responsible for determining

‘voce te 3M produc i it fora particular purpose and stable for uses application IF te 3M products shown to be nonconforming with

the waany pertod, your exclusive remedy and 3Ms sole obligation wil be, at 3M option, to replace the nonconforming 3M product refund

the purchase rice

Except where prohibited by ln, 3M wil ote liable for any os or damage arising fom the 3M produc, whether det,

{nde speci, cena or consequent, regalsso he legal theory aseted eluding Warranty, conc, negligence or sc ibility

“This certfcmte or any iteration contained in it doesnot amend or change any applicable 3M tems and conditions of ae

Esra nr Poy one pny ang Sal Ps =

associated Fittings and Couplings: Reale) glia

ESRETET

VIRGIN FBE POWDER TESTING

MAR 31,2006

sige ae

Materials:

[Virgin FBE Powder Type and Batch No BA22/ T

bu scorcnwore rae xctrt

Analysis:

Pepe Toate Crier =

Fiaws,bubbio,

Bees ae

appari ry wacesemssecoriapeny | scotiniten, |p

cae |

Dena (Specie Gravy) 2842248 Ciauae 120 Manufacturer |

" CRATE C ame ee | oeteton | tase OFA

‘Maximum 3.0 % |

erie Sie 60 ym) c5Az245Ciauee 125 ‘ove 220mm too %

ps

D ‘Maximum 0.2% *

Parle Sze (150 um) 542245 Clee 128 Se ea

neon

=

Get Tne, 2040 842245 Clause 122 saree 188%

Speciation

| Moots i

Cure Time CSA 2265 Clause 12.4 ‘Manufacturer 80 mins ||

|

|

Moisture Content 0842248 Cause 125 05 Mexinum o2a%

| 3 Moots

| 8 {tot CSA.Z245 Clause 12.7 ‘Manufacturer

25 Specification

a3 Meets

2 Elta CSA 2245 Clause 127 Manufacturer 4oa7acc |!

i Speen :

#8 = !

igs Meets: 1

Br hai racciona GAZ cuneate ‘anne 221 40

Spocteaton

us Tecewci pentck

anna Rap Easiongr Rapes

Sr rs

fappanore cae acase wane

2.0082 019,0082 woe CZ

9.00'9/ 019,002 WOHEEH

oe « erre

. = ann

VIR 16 ypomeenra do HoH 6

‘On6ir €22'0 = do e180

Sir $202 79 = H HPC

fw tze 082i = Bary

On GLH = HI

9. #2°801 = Pareiodennxa doe :6,

w6ir o0z'0 = do eea

9M Seotchkote™ 6171 Pipe Grade Cortilicale of Analysis

[Cor Number [Bate of Manufacturer

lsazza lJanuary 22, 2018 ‘1

‘Specifications,

Test Property Test Method |-,-

You might also like

- Inspection &test Report: 08572-TRHT-AQ-QC-00-OO-206 FRM 02Document4 pagesInspection &test Report: 08572-TRHT-AQ-QC-00-OO-206 FRM 02Fahad AhmadNo ratings yet

- Inspection &test Report: P.O. Item Tag No. Description QuantityDocument8 pagesInspection &test Report: P.O. Item Tag No. Description QuantityFahad AhmadNo ratings yet

- Lion KingsDocument32 pagesLion KingsFahad AhmadNo ratings yet

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitDocument3 pagesInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadNo ratings yet

- Inspection Flash Report: ITP No. & SL No: W20015-ITP-001& 12,13Document2 pagesInspection Flash Report: ITP No. & SL No: W20015-ITP-001& 12,13Fahad AhmadNo ratings yet

- Inspection Flash Report: RFI NO & Date: 1.0 Type of VisitDocument2 pagesInspection Flash Report: RFI NO & Date: 1.0 Type of VisitFahad AhmadNo ratings yet

- Islamiat CSS Paper 2010: Part-IiDocument1 pageIslamiat CSS Paper 2010: Part-IiFahad AhmadNo ratings yet

- Motor Abdul Latif Jameel TPL Schedule - : Policy Number P1216-ALT-ALJ-000003/R3 - / 79711Document2 pagesMotor Abdul Latif Jameel TPL Schedule - : Policy Number P1216-ALT-ALJ-000003/R3 - / 79711Fahad AhmadNo ratings yet

- Valves & Fittings PDFDocument24 pagesValves & Fittings PDFFahad AhmadNo ratings yet

- XCBXCBXCBX B ,.M..NDocument23 pagesXCBXCBXCBX B ,.M..NFahad Ahmad0% (1)

- Dasdadasd ZC AsvDocument11 pagesDasdadasd ZC AsvFahad AhmadNo ratings yet

- GASKET Aramco Exam QuestionsDocument1 pageGASKET Aramco Exam QuestionsFahad AhmadNo ratings yet

- Coc 19s1-2019-Saipem-Po-1283374.Document28 pagesCoc 19s1-2019-Saipem-Po-1283374.Fahad AhmadNo ratings yet

- ISYDADocument12 pagesISYDAFahad AhmadNo ratings yet

- Latest 9COM Regulated Vendors List PDFDocument105 pagesLatest 9COM Regulated Vendors List PDFFahad AhmadNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)