Professional Documents

Culture Documents

537d PDF

Uploaded by

Mohammed ShazebOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

537d PDF

Uploaded by

Mohammed ShazebCopyright:

Available Formats

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 12 48

ISSN 2347-4289

Rate Of Strength Development Of Concrete Made

Using Selected Nigerian Cement Brands

Joseph A. Anejo, Raymond M. Damen

Department of Building, College of Environmental Studies, Kaduna Polytechnic, Kaduna, Nigeria.;

Department of Architecture, College of Environmental Studies, Kaduna Polytechnic, Kaduna, Nigeria.

Email: tellanejo@gmail.com

ABSTRACT: Concrete is a versatile construction material. Its most critical property is the compressive strength. The basic constituents of concrete are a

cementitious material and aggregates. The most common type of cementitious material used for concrete in Nigeria is Ordinary Portland Cement. The

strength of concrete and the rates at which it is developed depends largely on the type and quality of cement. The rates of strength development of

concrete using some selected brands of cement in the Nigerian market were investigated by means of laboratory tests. It was established that, the

concrete develops an average of 26% of the 28 day strength in 1 day and 85% in 21 days. It is concluded that concrete develop strength rapidly at early

age compared to later ages. Most cement brands in Nigeria develop strength at satisfactory rates.

Key words: Cement Brands, Concrete, Development, Rate, Strength

1 INTRODUCTION 3 REVIEW OF LITERATURE

Concrete is a versatile construction material. According to Ha- In the design of concrete structures, the characteristic strength

san and Kabir [1], it is readily available, relatively cheap, flexi- of concrete is taken to be the strength at 28 days. There is no

ble to handle and it gives shape and any desired form. The specific percentage of the ultimate strength of concrete that

compressive strength is the most critical property that gives a must be achieved at 28 days. However, concrete is believed to

very good overall idea of the quality of concrete, the tensile have attained over 70% of its full strength [8]. Also, concrete

strength being negligible in comparison. In the broad sense, develops strength rapidly at its early age and, the rate of

concrete is made of a cementitious material (cement, lime, strength development decreases with the increase in age after

pozolans etc., or any combination of these), aggregates (fine mixing. There are some factors that influence the strength of

and/or coarse) and water. There may be some additives concrete and the rate at which they develop.

and/or admixtures added to the basic constituents to vary the

properties of the concrete when it is green or hardened. Many 3.1 Cement Based Parameters in the Strength of

researchers [2], [3] and [4] have carried out works to predict Concrete

the strength of concrete at any given age using some devel- The rate of strength development, and the final strength at-

oped models. They are many factors that affect the rate at tained by concrete can be affected by the parameters relating

which strength develops in concrete after mixing [5]. Among to the composition of the cement constituents and their propor-

these factors are the richness of the mix, character and grad- tions in the cement [5]. These cement constituents include the

ing of the aggregate, the water content of the mix and the cur- following:

ing conditions [6], [7]. The porosity of concrete, changes with • Alite content (tri-calcium silicates)

the degree of cement hydration [3]. The degree of cement hy- • Belite content (di-calcium silicates)

dration which is a function of water to cement (w/c) ratio has a • Sulphate contents

direct effect on the porosity and consequently on the strength.

As stated earlier, the richness of the mix is one of the factors The strength development depends on the alite and belite

that affect the rate of strength development in concrete. The reactivity. Alite happens to be the most reactive cement miner-

richness of a concrete mix is a direct function of the quantity al which contributes significantly to the concrete strength.

and quality of the cementitious material. More of it in the cement will result in better early strength (i.e.

up to seven days). Sulphate comes into cement both from the

2 NEED FOR THE STUDY clinker and the added gypsum. Its presence in cement retards

In the Nigerian construction industry, the most commonly used the hydration phase. Insufficient sulphate in cement results in

cementitious material is the Ordinary Portland Cement (OPC). flash set (i.e. rapid hardening of freshly mixed cement paste

Of recent there has been a serious controversy as to whether with appreciable amount of heat released). If on the other

the brands of OPC used in the country can attain adequate hand there is too much sulphate content, false setting may

strength. In fact the Standard Organisation of Nigeria (SON) occur (i.e. rapid hardening of freshly mixed cement paste with

even attributes the incidences of building collapse in the coun- negligible heat released). Some physical properties of cement

try to this assumption. Concrete gains strength with increase have some effects in the strength development of concrete.

in age, and this is regardless of the grade, but it is important to Among these properties are cement surface area and then the

know how much of this strength is gained at any particular age particle size distribution. The fineness of cement is sometimes

between the ages of 1 to 28 days. It is also important to know expressed in terms of total particle surface area. The higher

whether the cement brands produced and used in Nigeria de- the level of fineness of cement, the higher will be the rate of

velop adequate strength when used to produce concrete to hydration of the cement [3]. Particle size distribution plays an

meet the desired strength. Also it is needful to know the rate of important role in strength development in concrete. Cement

strength development to be able to decide on the time to strike which has very finely ground particles have slower rate of hy-

the formwork during construction. dration.

Copyright © 2014 IJTEEE.

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 12 49

ISSN 2347-4289

3.2 Water-Cement Ratio na, Nigeria. It was supplied in 50kg bags for each of the

The amount of water used in making concrete measured as brands. There cement brands used in the investigation were

water-cement (w/c) ratio has an impact on the strength of con- five in number, namely; Ashaka cement, Sokoto cement, Dan-

crete. Jankovic et al [3] reported that Duff Abrams established gote cement, Elephant cement and Rhino cement.

this fact since 1918. Increase in water-cement ratio increases

with the level of porosity of the concrete when it hardens. This Fine Aggregates

is because the excess water in concrete after drying up from Good quality sand is good for the production of concrete that

the concrete matrix leaves pores in the concrete. The increase will develop the desired properties. Natural clean sand ob-

in the water-cement ratio therefore, the higher the volume of tained from River Kaduna was used for fine aggregate.

voids after the concrete hardens which thereby reduces the

Coarse Aggregates

strength of the resulting concrete.

In the Nigerian construction industry, 20mm coarse aggregates

are used in most construction work. Crushed, angular granite

3.3 Aggregate

of nominal maximum size of 20mm was used for the investiga-

In normal concrete, the influence of the strength of aggregate

tion. The aggregate used was free of dust and other impurities.

is usually not appreciated. This is because the strength of the

aggregate is far greater than the concrete matrix and the inter- Water

facial transition zone inside the concrete. Therefore where The water used for producing and curing the concrete was

natural aggregates are used in concrete, their strengths are obtained directly from the tap in the laboratory.

usually not utilized as the other two phases determine failure.

Some other aggregate characteristics like size, shape, surface 4.2 Experimental Methods

texture, grading (particle size distribution) and mineralogy

have effects on the strength of the concrete. Mix Design

There was no effort aimed at designing a concrete mix to

3.4 Mixing Water achieve any specific target strength. A prescribed mix of 1:2:4

The impurities contained in mixing water may affect some with a water-cement ratio of 0.4 was used for the experiment.

properties of concrete, among which is strength. The concrete Batching of the materials was by weight.

production requirement for water is that the water should be

portable. This makes the water obtained directly from the tap Mixing

to be very suitable for concrete mixing. This does not however Dry cement and aggregates were thoroughly mixed before

mean that water that is unsuitable for drinking is not appropri- water was added. After the water was added, it was mixed for

ate for concrete production. Due to water shortage in some another four minutes to produce a concrete of homogenous

places, slightly acidic, alkaline, salty, coloured water or water consistency.

with unsuitable smell for drinking can be used for mixing con- Compaction

crete. The moulds were assembled, filled with the concrete and then

placed on a vibrating table. The moulds were properly vibrated

3.4 Curing Conditions at 1200 vibrations per minute for two minutes.

The process that involves a combination of conditions that

facilitate the hydration of cement in concrete after it has been Curing

cast is described as curing [9]. These conditions are time, The moulds with the compacted concrete were covered with

temperature and humidity conditions. For a given water- polythene sheets immediately after casting and left for twenty

cement ratio, the porosity of hydrated cement paste depends four hours. The cubes were demoulded after twenty four hours

on the degree of cement hydration. At normal temperature, and then immersed in clean water, and kept at the laboratory

some of the constituents of Ordinary Portland Cement begin temperature. They were all kept in this condition until the time

the hydration process as soon as water is added. This process just before the tests for set of the specimens.

slows down significantly when the dry cement grains become

coated with the product of hydration. This implies that hydra- Testing

tion can be achieved satisfactorily when there is saturation of A total of ninety 150mm cubes were cast for the experiment.

water. It will almost stop completely when the humidity in the Three specimens were tested for each of the five brands of

capillaries falls below 80%. This makes humidity and duration cement for any given age. The strength was taken to be the

of hydration to be of significance in the hydration process. The mean of the three values obtained for each set of three. The

rate of hydration reaction has a direct relationship with tem- tests were carried out at the ages of 1 day, 4 days, 7 days, 14

perature. Generally, the time-strength relationship in concrete days, 21 days and 28 days. The mean compressive strength

assumes moist curing conditions and temperature. Air en- was measured to the nearest 0.5N/mm2.

trainment, admixtures and additives are also some factors that

may affect the strength of concrete. 5 RESULTS AND DISCUSSION

4 MATERIALS AND METHOD 5.1 General Observations

From the tests carried out on the samples of concrete cubes

made with all five selected brands of Portland cement, the

4.1 Materials

average compressive strength are not very different from one

Cement another for four out of the five brands of cement. Compressive

Ordinary Portland Cement (OPC) of grade 32.5 was used. The strength of concrete made with Ashaka cement, Dangote ce-

cement brands were obtained from the open market in Kadu- ment and Sokoto cement at the age of 28 days have the max-

Copyright © 2014 IJTEEE.

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 12 50

ISSN 2347-4289

imum strength of 33.5N/mm2 each. Rhino cement had a value TABLE 4

of 34.5N/mm2 which was the highest compared to those of the COMPRESSIVE STRENGTH TEST RESULTS FOR RHINO

other brands of cement. Elephant cement at the age of 28 CEMENT

days had an average strength of 23.5N/mm2 which was the

least compared to other samples tested. However, all samples Age Weight Of

Compressive Rate of strength

tested met the minimum requirements of strength of concrete (Days) Cubes(kg) Strength dev. (%)

cubes in 3 days and 7 days which should not be less than (N/mm2)

8N/mm2 and 14N/mm2 respectively specified by BS EN 197- 1 7.87 8.5 25

1:2011 [10]. In determining the rate of development of 4 8.10 9.5 29

strength, the target strength is the value at 28 days which is 7 8.10 16.0 46

taken as 100%. The values for the various brands of cement 14 8.08 23.5 70

were as follows: Ashaka, Dangote and Sokoto brands had 21 7.95 29.0 86

33.5N/mm2, Rhino brand had 34N/mm2, while Elephant brand 28 8.10 34.0 100

had 23.5N/mm2. These values were used to determine the Source: Laboratory investigation.

rate of strength development in concrete made using the se-

lected brands of cement. TABLE 5

COMPRESSIVE STRENGTH TEST RESULTS FOR RHINO

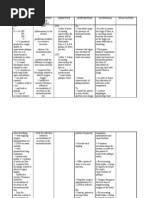

5.2 Test Results CEMENT

The results for the compressive strength tests for all the se-

lected brands of cement are given in Tables 1 to 6

Age Weight Of Compressive Rate of strength

(Days) Cubes(kg) Strength dev. (%)

TABLE 1

(N/mm2)

COMPRESSIVE STRENGTH TEST RESULTS FOR ASHAKA

1 8.25 9.0 39

CEMENT

4 8.20 9.5 41

Age Weight Of Compressive 7

Rate of strength 8.37 13.0 56

(Days) Cubes (kg) Strength (N/mm2) dev. (%) 14 8.02 15.0 65

1 7.93 8.0 25 21 8.12 19.0 81

4 8.16 10.5 37 28 8.02 23.5 100

7 8.03 15.5 47 Source: Laboratory investigation.

14 7.95 22.0 66

21 7.93 29.0 87 5.3 Discussion

28 7.97 33.5 100 From the results obtained, the strength developed at the age

Source: Laboratory investigation. of 1 day ranges from 25% to 27% of the strength of concrete

at 28 days for four out of the five brands used for the investi-

TABLE 2 gation. The value of 39% obtained for the Elephant brand of

COMPRESSIVE STRENGTH TEST RESULTS FOR SOKOTO cement is due to the comparatively low value of the strength at

CEMENT 28 days obtained. The most probable reason for this develop-

ment is that the cement batch supplied for the experiment may

Age Weight Of Compressive Rate of strengthhave been in the market for a long time. This makes this value

(Days) Cubes (kg) Strength (N/mm ) 2

dev. (%) to be an outlier from statistical point of view and therefore not

included in calculating the average rate of strength develop-

1 8.10 9.0 27

ment. From the results obtained the average rate of develop-

4 8.07 10.0 29

ment concrete for the selected brands of cement with accept-

7 8.00 15.0 45

able results are 26% for 1 day, 30% for 4 days, 46% for 7

14 8.03 21.0 63

days, 67% for 14 days, 85% for 21 days and 100% for 28

21 8.08 27.0 81

days. It is also seen that the rate of strength development is

28 8.02 33.5 100

gradual and is more rapid at the early ages and decreases as

Source: Laboratory investigation. the age of the concrete increases.

TABLE 3 6 CONCLUSION

COMPRESSIVE STRENGTH TEST RESULTS FOR DAN- At a range of between 33.5N/mm2 to 34.0N/mm2, the strength

GOTE CEMENT of concrete made using most of the selected brands of cement

meet the minimum strength requirement of 32.5 N/mm2 for

Age Weight Of Compressive Rate of strength

grade 32.5 cement used for the investigation. The rate of

(Days) Cubes(kg) Strength dev. (%) strength development for the concrete is adequate for the

(N/mm2) supports for such concrete made using these brands of ce-

1 7.89 8.5 26 ment to be removed at 21 days. The strength of 85% is ade-

4 8.10 9.5 28 quate to carry construction loads before the structure will be

7 8.10 15.5 46 fully loaded. For the Elephant brand of cement, it is required

14 8.08 23.5 70 that the supports for such strucutres be kept in place for a

21 7.95 29.0 87 longer period than 21 days specified for the other brands. The

28 8.10 33.5 100 rate of strength development of concrete made using most of

Source: Laboratory investigation. the cement brands available in the Nigerian market is enough

Copyright © 2014 IJTEEE.

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 12 51

ISSN 2347-4289

for safe construction. It should however be pointed out that

high quality materials in themselves do not produce safe struc-

tures without adequate professional input at all levels.

REFERENCES

[1] M.M. Hasan and Kabir, Prediction of Compressive

Strength of Concrete from Early Age Test Result. 4th An-

nual Paper Meet and 1st Civil Engineering Congress, De-

cember 22-24, Dhaka, Bangladesh, 2011.

[2] C. Yeh., Generalisation of Strength versus Water-

Cementitious Ratio Relationship to Age. Cement and

Concrete Research 36, pp. 1865-1873, 2006.

[3] K. Jankovic, D.Nikolic, D. Bojovic, L. Loncar and Z. Ra-

makov, The Estimation of Compressive Strength of Nor-

mal and Recycled Aggregate. Facta Univerzitates– Archi-

tecture and Civil Engineering Vol. 9, No 3, pp. 419-431,

2011.

[4] M. a.a. Abd elaty, Compressive Strength Prediction of

Portland Cement Concrete with Age Using a New Model.

HBRC Journal (2013).

[5] Anonymous, Rate of Strength of Concrete.

www.aboutcivil.org/concrete-strength-gain-rate.html. Ac-

cessed 26/07/2014.

[6] K.F El-Nemri, Effect of Different Curing Systems on the

Mechanical and Physico-Chemical properties of Acryloni-

trile Butadiene Rubber Vulvcanizates. Material and De-

sign, Vol. 32, No 6, pp. 3361-3369, 2011.

[7] F. Bruce, C.A. Davy, F. Skoczylas, N. Burlion and X. Bour-

bon., Effect of Temperature on the Water Retention Prop-

erties on Two High Performance Concretes. Cement Con-

crete Research, Vol. 42, No. 2, pp. 384-396, 2012.

[8] G. Mishra, Why do we Test Concrete Compressive

Strength after 28 Days? www.theconstructor.org/why-we-

test-concrete-after-28-days. Accessed 25/07/2014.

[9] A.A.J. Yahia, The Maturity Method: Modification to Im-

prove Estimation of Concrete Strength at Later Ages.

Construction and Building Materials, Vol. 20, pp. 893-900,

2006.

[10] British Standard Institutio, BS EN 197-1:2000 Cement.

Part 1: Composition, Specifications and Conformity Crite-

ria for Common Cements. London, British Standard Insti-

tution, 2000.

Copyright © 2014 IJTEEE.

You might also like

- Trainers, Explainers, Sustainers - The Human Workers Behind AI SystemsDocument1 pageTrainers, Explainers, Sustainers - The Human Workers Behind AI Systemsee sNo ratings yet

- Attention-Original Licence in Hard ITwebsiteDocument1 pageAttention-Original Licence in Hard ITwebsiteMohammed ShazebNo ratings yet

- Think Comp ScientistDocument288 pagesThink Comp ScientistDaniel RubioNo ratings yet

- IEUK21On Demand EngineeringDocument6 pagesIEUK21On Demand EngineeringMohammed ShazebNo ratings yet

- Computer Programming For Everyone Glossary: D H J Q R T VDocument5 pagesComputer Programming For Everyone Glossary: D H J Q R T VRazzNo ratings yet

- Econ 2Document16 pagesEcon 2ediabcNo ratings yet

- Improve Efficiency, Accuracy & Customer ExperiencesDocument1 pageImprove Efficiency, Accuracy & Customer Experiencespriyakanthr5883No ratings yet

- Activity Pack: AccentureDocument12 pagesActivity Pack: AccentureMohammed ShazebNo ratings yet

- To Estimating: 1-1 General IntroductionDocument11 pagesTo Estimating: 1-1 General IntroductionMark Lester Brosas TorreonNo ratings yet

- Computer Programming For Everyone Glossary: D H J Q R T VDocument5 pagesComputer Programming For Everyone Glossary: D H J Q R T VRazzNo ratings yet

- UG CE-2017 (Sec-A) : Programme - Fall Semester 2019 (Wef 23 Sep 2019)Document3 pagesUG CE-2017 (Sec-A) : Programme - Fall Semester 2019 (Wef 23 Sep 2019)Rafia AbidNo ratings yet

- Course OutineDocument2 pagesCourse OutineMohammed ShazebNo ratings yet

- Hypo TheDocument73 pagesHypo TheMohammed ShazebNo ratings yet

- 2021 GKS-G Application Guidelines (English)Document42 pages2021 GKS-G Application Guidelines (English)Katrin R.No ratings yet

- TRG Prog UG CE-2017, Fall-19 (23-12-19)Document3 pagesTRG Prog UG CE-2017, Fall-19 (23-12-19)Mohammed ShazebNo ratings yet

- 5000 TOEFL Words PDFDocument36 pages5000 TOEFL Words PDFPrudhveeraj Chegu100% (2)

- Synesthesia and Its TyoesDocument8 pagesSynesthesia and Its TyoesMohammed ShazebNo ratings yet

- UG CE-2017 (Sec-A) : Programme - Spring Semester 2019 (Wef 28 Jan, 2019)Document3 pagesUG CE-2017 (Sec-A) : Programme - Spring Semester 2019 (Wef 28 Jan, 2019)Mohammed ShazebNo ratings yet

- The Making of An Expert Engineer (Marked)Document591 pagesThe Making of An Expert Engineer (Marked)Fransisco Padilla AlmadaNo ratings yet

- Cheat SheetDocument2 pagesCheat SheetCmpt CmptNo ratings yet

- How Fast? Rates of Chemical Change 4.3Document2 pagesHow Fast? Rates of Chemical Change 4.3Mohammed ShazebNo ratings yet

- 6CH04 01 Pef 20110309Document46 pages6CH04 01 Pef 20110309Ashani0001No ratings yet

- Reviews: Fluid Mechanics With Engineering Applications. Fluid DynamicsDocument8 pagesReviews: Fluid Mechanics With Engineering Applications. Fluid DynamicsMohammed ShazebNo ratings yet

- Eng BTSDocument62 pagesEng BTSKamleshNo ratings yet

- 15 6 BoundaryDocument25 pages15 6 BoundaryMaggieNo ratings yet

- Saumsung TabS2 Quick User GuideDocument96 pagesSaumsung TabS2 Quick User GuideMohammed ShazebNo ratings yet

- Edexcel International AS/A level grade boundaries January 2015Document6 pagesEdexcel International AS/A level grade boundaries January 2015Amorn JiralucksanawongNo ratings yet

- OrganicDocument9 pagesOrganicMohammed ShazebNo ratings yet

- 4.9 Spectroscopy & ChromatographyDocument6 pages4.9 Spectroscopy & ChromatographyMohamed ZaidhanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Law of One Study Guide - Section 4Document16 pagesThe Law of One Study Guide - Section 4Kyle Ordway100% (2)

- Civil Rights Web-QuestDocument5 pagesCivil Rights Web-Questapi-367833271No ratings yet

- NCP For Ineffective Airway ClearanceDocument3 pagesNCP For Ineffective Airway ClearanceJennelyn BayleNo ratings yet

- An Umbrella For Druvi: Author: Shabnam Minwalla Illustrator: Malvika TewariDocument12 pagesAn Umbrella For Druvi: Author: Shabnam Minwalla Illustrator: Malvika TewariKiran Kumar AkulaNo ratings yet

- Salah or Prayer Is One of The Pillars of Islam and It Is AnDocument7 pagesSalah or Prayer Is One of The Pillars of Islam and It Is AnSitti Nauhar AukasaNo ratings yet

- B&A Performance AnalysisDocument16 pagesB&A Performance AnalysisNathalia Caroline100% (1)

- EGNTDocument6 pagesEGNTTida Nicholas NyahunzviNo ratings yet

- Exam On Multiculturalism: - Acculturation Process of Immigrants From Central and Eastern Europe in SwedenDocument60 pagesExam On Multiculturalism: - Acculturation Process of Immigrants From Central and Eastern Europe in SwedenMarta santosNo ratings yet

- Hubspot Architecture Practicum Workbook: ObjectiveDocument4 pagesHubspot Architecture Practicum Workbook: Objectivecamilo.salazarNo ratings yet

- Statistical PhysicsDocument4 pagesStatistical PhysicsRenan ZortéaNo ratings yet

- MM Im Pi PiDocument19 pagesMM Im Pi Pim0use-outNo ratings yet

- Christmas Elf NPCDocument4 pagesChristmas Elf NPCDrew CampbellNo ratings yet

- MHC-GPX33 55 77 88Document1 pageMHC-GPX33 55 77 88Juliana Ribeiro100% (6)

- Juice in PakistanDocument9 pagesJuice in Pakistanrize1159100% (1)

- JAWABAN UTS Bahasa Inggris II Keperawatan Dewi YuniarDocument3 pagesJAWABAN UTS Bahasa Inggris II Keperawatan Dewi Yuniarovan maysandyNo ratings yet

- Design Portfolio (Priyal)Document30 pagesDesign Portfolio (Priyal)PRIYAL SINGHALNo ratings yet

- Wireless Local LoopDocument8 pagesWireless Local Loopapi-3827000100% (1)

- Increased Demand of Parcels For Residential Experts' Interest To Have New Parcelation Map Drainage ProblemDocument23 pagesIncreased Demand of Parcels For Residential Experts' Interest To Have New Parcelation Map Drainage ProblemTesfuGebreslassieNo ratings yet

- Stranger Things Episode Script 2 05 Chapter Five Dig DugDocument67 pagesStranger Things Episode Script 2 05 Chapter Five Dig Dugyonas123No ratings yet

- 2.visual ArtsDocument78 pages2.visual ArtsNelson VergaraNo ratings yet

- Operon NotesDocument3 pagesOperon NotesanithagsNo ratings yet

- Antianginal Student222Document69 pagesAntianginal Student222MoonAIRNo ratings yet

- Philips NTRX505Document28 pagesPhilips NTRX505EulerMartinsDeMelloNo ratings yet

- G3335-90158 MassHunter Offline Installation GCMSDocument19 pagesG3335-90158 MassHunter Offline Installation GCMSlesendreNo ratings yet

- SCC800-B2 SmartSite Management System V100R002C00 Installation GuideDocument190 pagesSCC800-B2 SmartSite Management System V100R002C00 Installation GuideHamza OsamaNo ratings yet

- Language Learning Enhanced by Music and SongDocument7 pagesLanguage Learning Enhanced by Music and SongNina Hudson100% (2)

- Speidel, M. O. (1981) - Stress Corrosion Cracking of Stainless Steels in NaCl Solutions.Document11 pagesSpeidel, M. O. (1981) - Stress Corrosion Cracking of Stainless Steels in NaCl Solutions.oozdemirNo ratings yet

- The Carb Cycling Codex ThibaudeuDocument30 pagesThe Carb Cycling Codex ThibaudeuOrlando Paez Cortazar100% (1)

- Swift Group Technical HandbookDocument8 pagesSwift Group Technical HandbookLukasz WilkNo ratings yet

- Self Unbound Ego Dissolution in PsychedelicDocument11 pagesSelf Unbound Ego Dissolution in Psychedelicszucsanna123456789No ratings yet