Professional Documents

Culture Documents

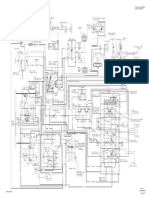

Esquema SCR Scania

Uploaded by

claudioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esquema SCR Scania

Uploaded by

claudioCopyright:

Available Formats

03:26-01 Issue 1 en-GB

EXHAUST GAS AFTERTREATMENT EU4, EU5 and EEV

© Scania CV AB 2016, Sweden

NOx sensor control unit NOx sensor control unit

Detail A Side venting for Injection nozzle - 4A connected to NOx sensor - 4E connected to NOx sensor - 4D V117 1. Reductant tank 6. EMS control unit

refilling

Only on DC1621. Reductant doser - 3

1E

See Detail B 1D

ECU

T113 EMS

Exhaust gas temperature

sensor upstream of the SCR

catalytic converter - 4B 1A

Approx. 3.5 bar

Q

CAN connection

Cover/venting - 1D 1B

From 2.9 to 4.2 bar See Detail A °t

7B

1C

T116

T131

Magnet

Reductant pick-up unit 7. Heating

NOx sensor - 4E 2. Main unit

with integrated level and system

temperature sensor - 1A and 1B

Detail B V117 See Detail E

Reductant doser - 3 2A

23

2H

Reductant

Reductant tank - 1E 2D

2L 2F ECU

7A M SCR

Winding

°t

2B 2E

11

Chemical reaction that

reduces the NOx level

See Detail D 2G P

12 2K

Prefilter - 1C

Engine coolant 2C

Compressed 5B

air

2J

5A P

T115 2I

Valve NOx sensor - 4D V118 Air 2J

Coolant valve for 8.4 bar P

Mixing chamber - 3B Manifold fitting - 5B

coolant flow (heater) - 7A

See Detail F 21

22

To exhaust pipe 5. Air supply

23 21

12 4E 4B 4C 4D

Detail C E67

Marking of connections on the main unit - 2 °t °t

25 Nm

Auxiliary

Marking in the diagram Marking on the unit

Main filter - 2E

11 tank - 5A 3B

11....................................Reductant IN 22

Renewal intervals: 3. Reductant doser 4A

12....................................Air IN

21....................................Reductant OUT M and L inspection

E67

22....................................Air OUT 3A

23....................................Reductant RETURN FLOW Ref: See Multi Main unit -2

4 Nm See Detail C Air 4. SCR catalytic converter

8.4 bar

Detail D Key

Reductant Detail E T116 Level sensor - 1A Temperature Level

Detail F V118 1. Reductant tank 1A - Level sensor............... Engine cooling circuit

1B - Temperature sensor.... T116

Ammonia Carbon Activation conditions for 1C - Prefilter Reductant supply circuit

Urea Water C = Carbon reductant heating: 1D - Bleed cover

dioxide Reductant return circuit

1E - Reductant tank

O = Oxygen • Ambient temperature is between

12°C and 8°C 2. Main unit 2A - Solenoid valve for recirculation to the tank Air

N = Nitrogen 2B - Prefilter

• Engine is running and the coolant 2C - Air control valve Pipes gathered in one hose

250-400°C H = Hydrogen temperature exceeds 60°C 2D - Pump

Generates an operating temperature 2E - Main filter

Resistor for the SCR system of approx. 15°C 2F - Reductant temperature sensor

NH2- CO - NH2 H2O 2 NH3 CO2 2G - Reductant pressure sensor

At an ambient temperature of approx. 2H - SCR control unit

-10°C or lower, the SCR system stops 2I - Restriction valve

x 19 injecting reductant 2J - Pressure sensor

Nitrogen Ammonia Oxygen Nitrogen Water 2K - Integrated heating pad

Oxide 2L - Pressure fluctuation damper

(NOx) 2M - Overflow valve

3. Reductant doser 3A - Injection valve..........

Test instrument for reductant content

3B - Mixing chamber..... V117

in the reductant tank:

Catalytic 588 226 4. SCR catalytic converter 4A - Injection nozzle

converter + Magnetic switch Value in % of weight: 32,5% (30-34%) 4B - Exhaust gas temperature sensor upstream of the SCR catalytic converter...... T113

temperature 4C - Exhaust gas temperature sensor downstream of the SCR catalytic converter (discontinued 2007)

4D - NOx sensor...... T115

200 to 600°C Float with Test strips for detection of diesel

4E - NOx sensor upstream of the silencer...... T131 Only on DC1621.

integrated magnet in the reductant: 588 876

The darker blue 5. Air supply 5A - Auxiliary tank

the colour of the 5B - Manifold fitting

6. EMS control unit

Temperature sensor - 1B paper, the higher

367 253

4 NO 4 NH3 O2 4 N2 6 H2O NTC: ≈ 2 kΩ to 25°C the diesel content 7. Heating system 7A - Solenoid valve for water flow......V118

in the reductant 7B - Heating duct

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Nitrogen & PhosphorusDocument30 pagesNitrogen & PhosphorusSachin KumarNo ratings yet

- 8.acids, Bases and Salts PDFDocument20 pages8.acids, Bases and Salts PDFHakim Abbas Ali PhalasiyaNo ratings yet

- Natural Sciences Know Nothing of EvolutionDocument205 pagesNatural Sciences Know Nothing of EvolutionBlackShadowSnoopy100% (2)

- New Holland B110 B115 en Service Manual PDFDocument993 pagesNew Holland B110 B115 en Service Manual PDFdobas100% (9)

- Ship Stability Yuk BilgisiDocument342 pagesShip Stability Yuk BilgisiHasan CosalevNo ratings yet

- Keane-Technical Methods of Chemical Analysis Vol 2 PT 1 1908Document648 pagesKeane-Technical Methods of Chemical Analysis Vol 2 PT 1 1908RonLaytonNo ratings yet

- XPI Fuel System: en-GBDocument26 pagesXPI Fuel System: en-GBclaudio100% (2)

- XPI Fuel System: en-GBDocument26 pagesXPI Fuel System: en-GBclaudio100% (2)

- WA 470-5H 50051&upDocument1,297 pagesWA 470-5H 50051&upclaudio100% (14)

- Disgrama Hidraulico 24 MDocument16 pagesDisgrama Hidraulico 24 Mdanielito_lajoNo ratings yet

- Plano Elect D155AX-6Document13 pagesPlano Elect D155AX-6claudio50% (4)

- Field Assembly D155AX-6Document127 pagesField Assembly D155AX-6claudio100% (1)

- Installation Scania MultiDocument1 pageInstallation Scania Multiclaudio100% (1)

- Operations Report-PAKARAB FertilizersDocument27 pagesOperations Report-PAKARAB Fertilizersiqrakhan007100% (6)

- Plano Hidráulico WA470-6 (Imprimir Formato A1)Document1 pagePlano Hidráulico WA470-6 (Imprimir Formato A1)Roy Goyzueta PumaNo ratings yet

- Plano Hidráulico WA470-6 (Imprimir Formato A1)Document1 pagePlano Hidráulico WA470-6 (Imprimir Formato A1)Roy Goyzueta PumaNo ratings yet

- German Problems 2005Document123 pagesGerman Problems 2005Paul AdrianNo ratings yet

- Casale Advanced Ammonia TechnologiesDocument35 pagesCasale Advanced Ammonia TechnologiesMaribel ParragaNo ratings yet

- Desmontaje Mando Final D155AX-6Document3 pagesDesmontaje Mando Final D155AX-6claudioNo ratings yet

- Flash Code Circuit Index 466EDocument5 pagesFlash Code Circuit Index 466EclaudioNo ratings yet

- Module 8Document14 pagesModule 8let's skip thisNo ratings yet

- Chapter 3: Synthesis Gas Production and Derived ChemicalsDocument78 pagesChapter 3: Synthesis Gas Production and Derived ChemicalsFadhli JapryNo ratings yet

- Measuring Food Quality With InstrumentDocument17 pagesMeasuring Food Quality With InstrumentMay Ann Malo VmobileNo ratings yet

- Successful and Safe De-And Recommissioning: Continental Engineers BVDocument11 pagesSuccessful and Safe De-And Recommissioning: Continental Engineers BVvaratharajan g rNo ratings yet

- Grade 11 Chemistry Review With AnswersDocument15 pagesGrade 11 Chemistry Review With AnswersRiham ElhabyanNo ratings yet

- ChitosanDocument7 pagesChitosanYonatan AdiNo ratings yet

- Final Report For Doe Sensors Contract Ut RCDocument243 pagesFinal Report For Doe Sensors Contract Ut RCprash_13No ratings yet

- Nitriding DatasheetDocument4 pagesNitriding DatasheetamitNo ratings yet

- Buku Program IConCEES2017 - With AbstractDocument97 pagesBuku Program IConCEES2017 - With AbstractMuhamad Azani YahyaNo ratings yet

- Chemistry P22 F - M 2024Document16 pagesChemistry P22 F - M 2024mharis0903No ratings yet

- Balanced Equations & Associated Calc's 05 MSDocument7 pagesBalanced Equations & Associated Calc's 05 MSlmao lmaoNo ratings yet

- Gaseous Emissions From Management of Solid Waste: A Systematic ReviewDocument15 pagesGaseous Emissions From Management of Solid Waste: A Systematic ReviewIslem Ben ChaifaNo ratings yet

- Preparation of Salts: Suitable For FORM 2,3, AND 4Document44 pagesPreparation of Salts: Suitable For FORM 2,3, AND 4Richard NestorNo ratings yet

- Major Ammonia Leak From HP Ammonia Feed Pump2Document3 pagesMajor Ammonia Leak From HP Ammonia Feed Pump2Rana ImtiazNo ratings yet

- 9132 7491 W A3 Ammonia Refrigeration RagagepDocument108 pages9132 7491 W A3 Ammonia Refrigeration RagagepArdago LenggaNo ratings yet

- Composting of Poultry Manure and Wheat Straw in A Closed Reactor Optimum Mixture Ratio and Evolution of ParametersDocument11 pagesComposting of Poultry Manure and Wheat Straw in A Closed Reactor Optimum Mixture Ratio and Evolution of ParametersivanpetricNo ratings yet

- Nitrogen SourcesDocument3 pagesNitrogen SourcesRoque VirgilioNo ratings yet

- Lectura 2. The Yin and Yang in The Development of Catalytic Processes. Catalysis Research and Reaction EngineeringDocument18 pagesLectura 2. The Yin and Yang in The Development of Catalytic Processes. Catalysis Research and Reaction EngineeringTRIANA FORERO GABRIEL RICARDONo ratings yet

- Ammonium Test: MquantDocument1 pageAmmonium Test: MquantMarco M.No ratings yet

- Msds Npk01 August 2013Document7 pagesMsds Npk01 August 2013Ardhy LazuardyNo ratings yet

- EA11210E DetectorsDocument8 pagesEA11210E DetectorsJustin SiNo ratings yet

- SBP Trial SPM 2011 Chemistry Kertas 1,2,3 With Answer For K1, K2 and K3Document18 pagesSBP Trial SPM 2011 Chemistry Kertas 1,2,3 With Answer For K1, K2 and K3Adroit MemberNo ratings yet