Professional Documents

Culture Documents

A48u PDF

A48u PDF

Uploaded by

Renny DevassyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A48u PDF

A48u PDF

Uploaded by

Renny DevassyCopyright:

Available Formats

M ARYLAND METRIC

METRI C S

P.O.Box 261 Owings Mills, MD 21117 USA

(410)358-3130 (800)638-1830 Faxes: (410)358-3142 (800)872-9329

http://mdmetric.com techinfo@mdmetric.com

TECHNICAL INFORMATION and DATA

Pre-Loading of high-strength structural bolts

Complete sets are only to be used. Hot dip galvanized nuts supplied by us are treated and

ready for assembly (coated with molykote). An additional lubrication of screws, nuts or

washers is not permissible, since it alters the preload values and leads to failures in assembly.

The preload is generally applied by tightening the nut. For this purpose, torque wrenches,

impact screwdrivers or similar devices may be used.

Tightening via the bolt head requires a free turning shank, so that no additional frictional

resistance is developed.

Torque wrench

When tightening with a torque wrench, the necessary pre-loading force is provided by

applicating a measured torque.

The wrench used must be properly adjustable or allow a reliable reading of the required

torque.

The maximum discrepancy allowed for adjusting and reading should be +0.1 Ma. Testing is to

be done before the torque wrench is used and also during use at least every six months.

Impact screwdriver

When tightening with impact screwdrivers the necessary preload force is provided by

impulses. The screwdriver is to be adjusted to the prescribed preload by tests with

suitable equipment (e.g. tensometer) on at least three screws intended for use in the

assembly.

Angle of rotation

Pre-loading the screws by the angle of rotation method is done by an alignment (“snug”)

tightening and then adding a further rotation through the angle ϕ.

A 48 copyright 1999 Maryland Metrics

M ARYLAND METRIC

METRI C S

P.O.Box 261 Owings Mills, MD 21117 USA

(410)358-3130 (800)638-1830 Faxes: (410)358-3142 (800)872-9329

http://mdmetric.com techinfo@mdmetric.com

TECHNICAL INFORMATION and DATA

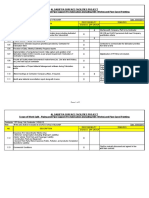

Method of tightening

Torque wrench Impact Angle of rotation method

Screwdriver

Necessary

Bolt diameter preload Pv Tightening torque Ma Preload P v Necessary

in the bolt to be applied alignment Clamping range Angle of Rotation

to be applied

torque rotation

Bolt lubricated

with MoS2 Bolt slightly oiled

(hot dip 1)

Mav 1) lk O U

galvanized)

1) 1)

kN Nm 2) Nm kN Nm mm

M 12 050 0100 0120 060 010

M 16 100 0250 0350 110 0–50 180° 1/2

050

M 20 160 0450 0600 175

M 22 190 0650 0900 210

100 51–100 240° 4/6

M 24 220 0800 1100 240

M 27 290 1250 1650 320

M 30 350 1650 2200 390 200 101–240 270° 3) 3/4 3)

M 36 510 2850 3800 560

1) Independent of lubrication of the thread or the surfaces of nut and bolt.

2) For tightening from the head, please ask for data.

3) For bolts M 12–M 22 with clamping range of 171–240 mm, an angle of rotation = 360° or U = 1 is to be applied.

Important: Tightening torques for hot dip galvanized bolts differ from those for plain. See table above.

copyright 1999 maryland metrics all rights reserved A 49

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Spare Parts Catalogue PK 11001: (S106-EK-A)Document134 pagesSpare Parts Catalogue PK 11001: (S106-EK-A)Alfred HitchcockNo ratings yet

- SM-Kobelco SK300LC-6E Szervíz (YC07U0623 )Document1,184 pagesSM-Kobelco SK300LC-6E Szervíz (YC07U0623 )Károly Vigh100% (2)

- Price List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevDocument67 pagesPrice List For Painting Works - Destination Greenfield: Project #Unit Document Code Serial #RevRenny DevassyNo ratings yet

- OGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21Document14 pagesOGASCO - ENOC Jabel Ali Refinery Expansi Technical Specification 2017-06-21Renny DevassyNo ratings yet

- Responsibility Matrix For Shop Piping WorksDocument5 pagesResponsibility Matrix For Shop Piping WorksRenny DevassyNo ratings yet

- Soudokay Strip Cladding - PrincipesDocument31 pagesSoudokay Strip Cladding - PrincipesRenny DevassyNo ratings yet

- WPS Alloy 625 Strip With Flux EST 236Document1 pageWPS Alloy 625 Strip With Flux EST 236Renny DevassyNo ratings yet

- 1250 kVA Genset Specifications PDFDocument8 pages1250 kVA Genset Specifications PDFRenny DevassyNo ratings yet

- Lincoln Strip Cladding Presentation April 2011Document26 pagesLincoln Strip Cladding Presentation April 2011Renny DevassyNo ratings yet

- Cummins C350D5 Diesel Generator Data SheetDocument3 pagesCummins C350D5 Diesel Generator Data SheetasdthuNo ratings yet

- 0400GF Amerlock 400 GF PDSDocument4 pages0400GF Amerlock 400 GF PDSRenny DevassyNo ratings yet

- 0400GF Amerlock 400 GF PDS PDFDocument4 pages0400GF Amerlock 400 GF PDS PDFRenny DevassyNo ratings yet

- Ratnamani - Manufacturing RangeDocument2 pagesRatnamani - Manufacturing RangeRenny DevassyNo ratings yet

- Garnet IDocument3 pagesGarnet IRenny DevassyNo ratings yet

- Cummins C350D5 Diesel Generator Data SheetDocument3 pagesCummins C350D5 Diesel Generator Data SheetasdthuNo ratings yet

- Cummins C350D5 Diesel Generator Data SheetDocument3 pagesCummins C350D5 Diesel Generator Data SheetasdthuNo ratings yet

- A310 TeardownDocument3 pagesA310 TeardownGaynor MorganNo ratings yet

- U-5 Boring and Jig Boring MachineDocument27 pagesU-5 Boring and Jig Boring Machineapi-271354682No ratings yet

- RMM Power Distribution & VFD CalculatorDocument12 pagesRMM Power Distribution & VFD CalculatorReymar BanaagNo ratings yet

- I - Steel Butt - Welding Pipe FittingsDocument26 pagesI - Steel Butt - Welding Pipe FittingstruongNo ratings yet

- NortonSuperabrasives NortonToolroomWheelsDocument33 pagesNortonSuperabrasives NortonToolroomWheelsarminhecimovicNo ratings yet

- CG4100Document5 pagesCG4100CarmenJuliaNo ratings yet

- Копија Датотеке FAR Slow HydraulicsDocument1 pageКопија Датотеке FAR Slow HydraulicszeljkoNo ratings yet

- Types of Air ConditioningDocument2 pagesTypes of Air ConditioningELVEVIYONA JOOTNo ratings yet

- Chapter4analysis of Clamping ForceDocument10 pagesChapter4analysis of Clamping ForceMohammad umarNo ratings yet

- Spare Part: Powder Valve TPSP, Ø63,5 LKLA-T Act.: Material No. 90517-8535Document1 pageSpare Part: Powder Valve TPSP, Ø63,5 LKLA-T Act.: Material No. 90517-8535Xuân Hòa Nguyễn100% (1)

- MCQ On Milling MachineDocument3 pagesMCQ On Milling MachineSandipkumar VhanakadeNo ratings yet

- Fittings and Valves Fittings: Building Utilities 2Document19 pagesFittings and Valves Fittings: Building Utilities 2Patty GorospeNo ratings yet

- Modified Learning Activity Sheet in CarpentryDocument14 pagesModified Learning Activity Sheet in CarpentryDonna Marie Arcangel100% (1)

- PGR Maverick 1.5 - .22 Short Revolver: Read All Instructions Carefully. Do Not Skip or Skim. It's All Here For A ReasonDocument8 pagesPGR Maverick 1.5 - .22 Short Revolver: Read All Instructions Carefully. Do Not Skip or Skim. It's All Here For A ReasonZarcano FariasNo ratings yet

- LG Washing Machine Spare Parts Price ListDocument4 pagesLG Washing Machine Spare Parts Price ListSukanta MandalNo ratings yet

- SJ-20180130092119-001-ZXDD01 P1500 (V5.0) PAD Power System Quick Installation GuideDocument9 pagesSJ-20180130092119-001-ZXDD01 P1500 (V5.0) PAD Power System Quick Installation GuideJose Samuel Alva Ancón100% (1)

- Gram HC-75 MK2 SPLDocument57 pagesGram HC-75 MK2 SPLBenito Antonio Formoso LouroNo ratings yet

- Power Rasp, Build Your OwnDocument6 pagesPower Rasp, Build Your OwnJim100% (1)

- Chap11 - Steam System Part 1Document59 pagesChap11 - Steam System Part 1Minh TranNo ratings yet

- Total Result 69,901.00Document15 pagesTotal Result 69,901.00farazNo ratings yet

- Zen Toolworks CNC Carving Machine DIY Kit User Installation ManualDocument47 pagesZen Toolworks CNC Carving Machine DIY Kit User Installation Manualchompink6900No ratings yet

- XRVS 455 - MD - ASLDocument134 pagesXRVS 455 - MD - ASLyangNo ratings yet

- Nipcib 000035Document55 pagesNipcib 000035AlfoFSNo ratings yet

- Ring Gasket Sizing Chart VFDocument11 pagesRing Gasket Sizing Chart VFjuanNo ratings yet

- SS75R Toyota Land Cruiser 75 Series 2H 3F Diesel Snorkel InstallDocument5 pagesSS75R Toyota Land Cruiser 75 Series 2H 3F Diesel Snorkel Installbodie mallettNo ratings yet

- Classification Equipment UsageDocument2 pagesClassification Equipment UsageJane PangilinanNo ratings yet

- Permafloat Dock Float Installation & ProceduresDocument1 pagePermafloat Dock Float Installation & ProceduresMichael ApplerNo ratings yet

- Book 1 Bodymaker CMB - English-7Document23 pagesBook 1 Bodymaker CMB - English-7felipe alfonso guarnizo naranjoNo ratings yet