Professional Documents

Culture Documents

Indcoil Brochure 2013

Indcoil Brochure 2013

Uploaded by

Vikaas Jain0 ratings0% found this document useful (0 votes)

76 views8 pagesIndcoil Brochure

Original Title

INDCOIL_BROCHURE_2013

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIndcoil Brochure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

76 views8 pagesIndcoil Brochure 2013

Indcoil Brochure 2013

Uploaded by

Vikaas JainIndcoil Brochure

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

&

INDCOIL

|

be eMac SO yaan off Senvice:and

Our Mission

To be the leaders in Transformers for Special Applications, Instrument Transformers and Reactors and achieve

consistency in Quality, Customer satisfaction, Profitability and growth by:

Strict adherence to specifications and documented procedures,

Proper identification and understanding of the needs of customers before acceptance of contracts.

Training and motivating our team to adhere to procedures and to bring out the best in them.

Positive attitude towards a disciplined work culture.

Optimize Designs and production costs by regular Re-Engineering

INDCOIL was founded in 1968 for manufacture of

Instrument Transformers and Control Transformers.

Presently the unit is strategically located in Thane, an

Industrial Area in the outskirts of Mumbai

The Company grew steadily with the help and team-

work of well qualified and experienced Engineers and

Technicians who played very important roles in bringing

up its product range and reputation to the present level.

The name INDCOIL, is a very powerful brand now for

quality Transformers within its range of Production.

INDCOIL is a pioneer in Dry Type Transformers in India.

"Turnover of the Company has been almost doubling

every 2 years since 2003-04. The Company is poised for

a major increase in turnover with the introduction of a

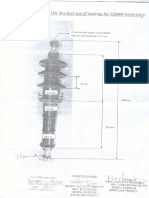

new range of products - Oil Immersed Cts & PTs for 11

kv, 22 Kv and 33 Kv systems. Similar products for 66 Kv

and 136 Kv class are under development and will be

introduced in the market soon. At present nearly 40% of

the Company's production is exported"

We have offices/agents in Bangalore, Kolkota New Delhi

and Kochi.

Resin Cast CTs Reactor

High Current Transformer (Out Door CT

696

Current Transformers

Dry type with enclosure

PRODUCT RANGE

‘LT Current and Potential Transformers Tape

Wound and Cast Resin Types.

+ Cast resin Current Transformers for 11/ 22/ 33

KV systems

+ LT Control and Lighting Transformers including

Cast Resin Types

+ Oil cooled Transformers up to 2500 KVA and

Dry Type Transformers up to 2500 KVA, for;

> Power and distribution

> Converter applications

> Slip-Power Recovery Systems,

> Rectifier Applications,

Multi-Winding Transformers for Phase Conversion,

and Rectification,

Furnace Duty Transformers.

Air and Iron cored Reactors

Dry Type Transformers

oe

Computerized design and testing methods streamline

the manufacturing process and cut down on lead time te

make our products cost effective to our customers.

INDCOIL products have found acceptance in all

steel plants, cement plants, petrochemicals and

other major Industries. Our Transformers are in

continuous use during the past four decades in

Bhilai, Bokaro and Rourkela Steel Plants and

various other Industries in the country and overseas.

We are approved by most of the leading consultants

in the country-MECON, NTPC, ElL, TCE, DusturCo

. to name a few.

General

Electric power generation is the index of Industrial

and Economic development of any country. As on

date, India, with its 1.2 billion people, generates less

than 20% of its electric power requirement.

‘Ambitious plans for additional power generation

are being discussed and many are under various

stages of finalization J implementation. By the end of

2014, the country is expected to double its installed

capacity as of 2012

Though 90% of our villages are supposed to be elec-

trified, only less than half of the House-holds have

access to Electricity

Every GW of power generated will require 4 GW of

transformers for transmission, Receiving, distribution

and utilization of the generated power (1 GW = 1000

Mw).

Dry type Transformers:

The recent trend is to install Dry Type Transformers in

high-rise buildings and Public Utiity areas, due to its

high fire safety qualities. The higher cost for this kind

of transformer is due to the Thermal and Insulation

schemes which require use of costlier materials.

‘The savings due to lower losses and maintenance

costs more than offset this initial high cost within 3

years of operation.

‘Apart from the failure- proofness of the design , Dry

Type Transformers are known for their low inflamma-

bility and least smoke generation properties in the

unlikely event of a fire. These types of our Transform-

ers have a, track record of zero failures,

Resin Cast Control Transformer

Reactors:

‘We are one of the very few manufacturers in India for

Reactors. This product goes into Power saving

devices and Converter applications. The design of

this product is challenging when it comes to use in

revamping distribution networks in order to increase

efficiency.

INDCOIL Range covers both Iron core and Air core

rectors for various applications

Instrument Transformers:

We are one of the earliest manufactures of instrument

transformers in the country. The Company has devel-

oped a full range of Cast Resin Current Transformers

for 11 and 22 KV systems,

Oil Insulated Instrument Transformers for up to and

including 136 KV systems is being introduced by us in

the market

Lv coil

Dise Winding

Routine & Type Tests:

Transformers and Reactors are tested for following

Routine tests wherever applicable. Type Tests are

carried out in Standard Laboratories on representa-

tive ratings and Certificates are available:

Turns Ratio Test

Polarity Test

Terminal Markings

Overall Dimensions

Load and No-Load Losses Measurement

Impedance Measurement

Insulation Resistance Test

Power Frequency High Voltage Withstand Test

Induced Over Voltage withstand Test

Oil Break down Voltage Test

Pressure Test for Oil Cooled Transformers

‘Temperature Rise Test (Proto Types only)

Lightning Impulse Withstand (Type test)

Short Circuit Dynamic Withstand (Type Test)

Quality Control

Input Materials are checked for conformation to our

specifications. Wherever required, our QC Engineers:

visit Supplier's factories to witness their routine test.

ur Transformers have been Type Tested in Central

Power Research Institute, Bangalore (CPRI) and

ERDA Vadodara. We have in-house facilities for

performing all the routine tests and some of the Type

Tests as per Indian and International Standards.

Our Manufacturing practices are certified by EURO

VERITAS under ISO 9001:2008.

1-Ph Step Down

Transformer

LT Lighting Transformer

Cenificat of Registration

(ag TECH

Se

i 180 9001: 2008

, cote 6

‘ ee

i nt

BB) tears RARER oy wre Hs BR

CURRENT TRANSFORMERS ‘(Way

3606

INDCOIL covers a full range of Current Transformers

both for Metering as well as for protection, manufac-

tured conforming to Indian and International Specifi-

cations. These transformers are recommended for

use in Busbar Chambers, Control Cubicles, Circuit

Breakers, Relays and so on, The type, Accuracy

class and Burden should be selected to suit the

particular requirement

Metering Current Transformers

‘These Transformers are meant for feeding measuring

Instruments. The accuracy requirements of the

Instruments will decide the Class of accuracy of the

CTs whereas the internal impedance of the Instru-

ments expressed in VA (Volt Amperes) will decide the

BURDEN of the CTs, Above 100 A Primary Current, it

will be economic to use Bushing type or Ring type

CTs. On lower than 100 A Primary current ring type

construction will not give good accuracy for measure-

ments, In such cases Wound Primary CTs should be

selected.

Example: Current to be measured = 400 Amps,

‘ammeter Available =O to 1 Amps.

Impedance of Meter = 4 Ohms.

Selecta CT of 500/18, § VA Accuracy class 1

‘Aring ype CT ean be selected, The Bus bar size wil decide the 1D

Teajired forthe CTA Bushing ype CT = sufiet.

“Tape-Wound CTs

INDCOIL

Wherever Instrumentation needs to be done far

away from the Busbar location, itis recommended

to use 1 Amp instead of the usual 5 Amps for the

secondary rating of the CT. Impedance of the

connecting leads will have to be included in order

to arrive at the Burden of the CT. It is possible to

provide more than one range in both Primary side

as well as secondary side. This is achieved by

providing suitable taps on the windings,

"Wound Pri, C75

‘Rectangular construction of core for bushing type

CTs can give considerable saving of space when

Rectangular Bus Bars are used

Protection Current Transformers

‘These Transformers are mainly for operation with

Circuit Breakers, Relays and other Protection

devices. The main characteristics of these CTs are

their ability to remain without saturation in the

event of a short circuit. The fault current may be

many times the rated current and the CTs should

be designed to drive this high current through the

relays and its connected circuit. Normally they are

specified as Class 5P or 10P to indicate their accu-

racy at fault current, followed by the fault current

limit at which the accuracy required, expressed as

a multiple of the rated CT secondary current.

gs 5p10, 10°15 and s0 on. SP or 10P are the accuracy class and

10, 15., are the multiples, snows as the sccuracy limit factor.

Cts for Diteretial Protection shouldbe specified with their Kneepaint

votage (Vk) requirements along withthe permissible resistance ofthe

CT secondary winding (Ret). The parameters for selection of CTs are

‘ion in tha Rela catalogues. By a careful selection of Vk and Ret

‘reat economy can be achieved in selection of the ight ype of CTs for

these applications

Typical values:

1000/5 A. Vi > 0 Vals, Ret < 0:2 Ohms

300001 A. Vk > 250 v Rel «5.5 Ohms,

Note: 18-800 Cts with higher Vic and ct

‘Summation Current Transformers

These are used to measure sum of the currents in

more than one line from the same phase of the system,

Normally used for monitoring total current/power

drawn from a system. Input to a Summation CT should

be from the individual line CTs. It is necessary for the

Line CTs to have same secondary currents. The out

puts from Line CTs 500/5 A, 200/5A, 150/5A ...(not

150/1A...) can be connected to a summation CT

Primary windings. Egs: 5+5#5..../5A. The Secondary

can be designed for 5A or 1A.

—_

‘Summation CTs

Interposing Current Transformers

Mainly used for differential protection in order to match

the ratios of main feeder CTS. These can also be used

as saturation CTs, which can protect sensitive Instru-

ments and devices during a fault. These C7s will satu-

rate and limit their secondary currents within specified

values,

Cable Mounting Type CTs

Cast Resin Types

Recommended for higher mechanical strength and

safely. Ideal for use in a corrosive atmosphere. All the

above mentioned types of CTs can be supplies in Cast

Resin construction also.

Cast Resin CTs

Neutral Current Transformers

Used for measuring unbalance current in the neu-

tral of a three phase system. Since the neutral

current should be zero in a balance three phase

system, the primary of these CTs are rated for a

fraction of the line currents in that system.

The output of the CTs can feed relays or metering

instruments. Bar Primary Bushing Types or wound

primary Types can be manufactured

Enquiries

The following details if furnished with enquiries can help us to

quote the right type of Transformers for your specific require-

ment.

Type Purpose,

Ratio Burden

Ret vie

Accuracy, System Vollage

Timing Dimensions and 1D requirements

(CFor Protection class CTs only)

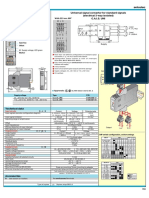

Standard Ranges and Dimensions

Bar Primary Tape Wound

Ratio | Rated ‘Ace _ [Dimensions In mn.

Amps | VA Class DOD DEPT]

506 | 6 30 | 85] 50

10s | 5 1+ | 30| 85 | 50

1505 | 5 1 | 30] a5] 50

2005 | 5 1 | 30] 85| 50

3005 | 10 1 | 50 | 100 | 50

4005 | 15 1 | 50 | 100} 50

5005 | 18 1 | 50 | 100 | 50

6005 | 15 1 | 50 | 100 | 50

800s | 15 1 | 75 | 120} 50

1,000! | 15 1 | 75 | 120] 40

45005 | 15 1 | 85 | 130 | 40

20005 | 15 1 |100 | 140 | 40

3.0005 | 15 1 | 125 | 170 | 40

formore informations vist www.electrical4u.com

INDCOIL TRANSFORMERS PRIVATE LIMITED

Poe ae)

conse

General

INDCOIL Power & Distribution Transformers incorpo-

rate modern Engineering concepts and high quality

materials processed under expert supervision and

quality control. The factory is equipped with all

required machinery and Testing Equipment to

produce transformers for a variety of applications.

Standard ratings from 15 kVA to 2000 KVA in close

steps as per IS 2026 for all Input Voltages of 3.3, 6.6,

11, 22 & 33 KV and Out-put voltages of 380, 400, 415

or 433 Volts are available. Transformers manufac-

tured by us conform to IS 2026 or IEC 60076.

Ratings

Transformers are designed for maximum Efficiencies

at following load- factors unless otherwise specified:

Power Transformers- 0.45 to 0.65. Distribution Trans-

formers- 0.4 to 0.5. We can supply transformers with

non-standard Voltage Ratios, capacities and

Efficiency Load Factors, for special applications. Our

speciality is in design and manufacture of Transform-

ers with multiple phases for use in variable speed

drives and other converter applications. Prices will be

available on request. Please send us details of your

use with specifications of the Transformer.

Design & Constructional Features

Prime quality Cold Rolled Grain Oriented Silicon

Steel (CRGO) of grade M4/M3 are used as core

materials, depending on specific applications for the

Transformer.

INDCOIL

Windings

Windings are normally made with electrolytic grade

Copper soft annealed and insulated with paper or

enamel depending on ratings as well as voltage

class. Special designs with Nomex covered

conductors can be supplied. HV and LV windings

are provided with end-turn reinforcement for

protection under short circuits and lightning

Impulse. The windings are dried and pre-shrunk

before assembling them in to the core. Windings

with Copper or Aluminum or a combination of both

can be supplied as per customer preferences.

Sufficient radial and axial ducts provided, ensure

proper insulation levels and avoid hot spots during

surge voltages and shor time over loads

Tanks,

Tanks are designed with ample clearances for

minimum stray losses. Local heating and eddy

current losses are also kept minimal with

non-magnetic welding at High Current areas. The

tanks are of sturdy design to prevent even cil

sweating during the thermal cycles while in use.

Tanks are pressure tested initially and the com-

pleted Transformer pressure tested with all fitings.

Cooling

Normally pressed steel radiators are used for cool-

ing. Each bank of Radiators will be provided with

air release plugs, drain cocks and lifting eyes.

Transformers up to 500 kVA are provided with

radiators welded to the tank. Higher ratings can be

provided with Flanged type with or Without Radia-

tor valves.

Taps and Terminals

HV and LV sides can be provided with cable box type

‘or Qut-door type terminations with or without palms for

connections to cables or OH lines.

Standard ratings will have taps at -5% to +5% in steps

of 2.5% on the HV side connected through off-circuit

tap changer with indicator and locking device. Addi-

tional taps and On Load Tap changing devices with

remote Control can be provided at extra cost,

HY Dise Winding

Testing

Accessories

INDCOIL is an 1S0 9000 Certified company.

Our experienced Quality Assurance Engineers carry 1. Flat / Flanged Rollers 4.Nos

cut stage inspection during the manufacturing process. 2. Earthing Terminals 2Nos

Al insramens used tes are of Presion Grade. cng Pals ‘ok

: : 4. Radiator Valves* 4 set

All Routine tests as per IS 2026 are performed on 5. Filter Valves* 1 set

every Transformer manufactured, before they are 6, Double Float Buchholz Relay with ATC* 1 set.

dispatched from our works. We are also equipped to. 7. Conservator Shutoff valve 1No

conduct few Type tests at our works. Impulse and

Dynamic Short circuit withstand tests are carried out at_-® Oil Temp. Indicator ine

CPRI/ERDA. Kindly inform us at order stage itself, in 9 Explosion Vent with Diaphragm 1 No.

case you wish to witness routine/type tests. 10.Alir release plugs 1 set

‘Test results are stored for 5 years for analysis. 11. Pressed steel Radiators 1set

Dimensions and Details 12.Liting Lugs / hooks 1 set

— ol ai nw 13.Conservator 1 No.

L |B] Ht) We il i lc} Z

wa] ALB TRE RS [SE LM) LNG |Z] t4ottcircit Lockable Tap-changer 1 No

35 |tilos| 421 a0 1 70} 01 foes] 2] 1:Raling & Diagram Plate 1 set

60 |12|08| 14] s90 | 100 [ore] 1.10| 4] 12 Fercum bran vave

i Level Gau

63 | 1.2| 0.9] 1.4] 610 | 1120} 0.22) 1.25] 4

400 711 15| goo | 135 | 029117614 18. Thermometer Pocket 1No.

0 419,Silica gel Breather 11No.

160, 1.1] 1.5 | 1050| 230 | 0.41] 2.55] 4 20.HV Terminals 4 Set

an 1.1] 1.6 | 1200} 245 | 0.55] 320 4 | 94. Lv Terminals with neutral 1 Set.

250 [15] 12] +.7| 1360] 320 [0.65] 3.20] 4 | 29 additonal Neutral Terminal to

315 | 1.5| 1.3 | 1.7| 1850] 360 | 0.85|4.50| 4) 23. wriwitAlarm & Trip Contacts* 1 Set.

400 | 1.6| 1.4| 1.8 | 1800) 425 | 1.00] 5.50| 4 | 24. Marshalling Box with spare terminals* 1 Set.

500 | 7.8 | 1.6] 2.0| 2300] 490 | 1.20] 6.60| 4 | “at aditonal cost

630 | 2.0] 1.7| 2.1| 2700] 550 | 1.35] 7.80/ 4] ores

1. Detaled OmensionalOrawigs along wi ctl pro

S007 22 [ete [2 19160 | 760. seo 2-406. parameters wl be submited witin to 3 weeks fom

1000| 2.3 1.9| 2.3| 3700| 1130] 1.65] 11.0| § Contre oe

2, Tanstomer wth pefomance values ar han tna

1250| 2.4| 1.9| 2.4| 4200} 1700| 1.75] 12.5] 5 ‘values can be made against specific enquiries.

1600| 2.6| 2.2| 2.6| 4900] 2000| 7.90| 15.0] 6 | * sersanders poner and Betton aplestons cy ae

Senda vote and equony Butuan is

Fee 4, Tanstomer tbl fr Contr an vert ues and with

‘Transformers with copper windings. multwincings can be supplied on request.

INDCOIL TRANSFORMERS PRIVATE LI

ach

ITED

cones

Perna

Sree

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5808)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (843)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chino Chartless Recorder CatalogDocument6 pagesChino Chartless Recorder CatalogVikaas JainNo ratings yet

- LED FLood Light-Specification SheetDocument10 pagesLED FLood Light-Specification SheetVikaas JainNo ratings yet

- Miniature Linear Guideway: MSC Stainless Steel SeriesDocument10 pagesMiniature Linear Guideway: MSC Stainless Steel SeriesVikaas JainNo ratings yet

- Digitally Signed by NADIM Nasir Ghanchi Date: 22.12.2020 12:30:16Document1 pageDigitally Signed by NADIM Nasir Ghanchi Date: 22.12.2020 12:30:16Vikaas JainNo ratings yet

- SMART Transmitter Power Supply KCD2-STC-Ex1: FunctionDocument6 pagesSMART Transmitter Power Supply KCD2-STC-Ex1: FunctionVikaas JainNo ratings yet

- Low Resistance Ohmmeter: Ducter D007Document2 pagesLow Resistance Ohmmeter: Ducter D007Vikaas JainNo ratings yet

- KSH International-WEB SolutionsDocument8 pagesKSH International-WEB SolutionsVikaas JainNo ratings yet

- KPM On Load Tap Changer Analyzer: FunctionalityDocument1 pageKPM On Load Tap Changer Analyzer: FunctionalityVikaas JainNo ratings yet

- Dimensions of MSC-M / MSC-LM: M M M L C H ØD LDocument2 pagesDimensions of MSC-M / MSC-LM: M M M L C H ØD LVikaas JainNo ratings yet

- Entrelec Signal ConverterDocument2 pagesEntrelec Signal ConverterVikaas JainNo ratings yet

- Assembly Features: Removable Terminals GreenDocument4 pagesAssembly Features: Removable Terminals GreenVikaas JainNo ratings yet

- R58E Series Expert Registration Mark Sensors: DatasheetDocument11 pagesR58E Series Expert Registration Mark Sensors: DatasheetVikaas JainNo ratings yet

- Product Data Sheet: SPD VT2 VT2 M TT 320 FM (955 325)Document1 pageProduct Data Sheet: SPD VT2 VT2 M TT 320 FM (955 325)Vikaas JainNo ratings yet

- 25KVA Greaves DG GeneratorDocument3 pages25KVA Greaves DG GeneratorVikaas JainNo ratings yet

- Belt Sway Switch:: Emergency Safety Switch: SpecificationsDocument1 pageBelt Sway Switch:: Emergency Safety Switch: SpecificationsVikaas JainNo ratings yet

- Biovibez - Motion Sensor - Model - Mp-Ac1-R2: Save Energy and AutomateDocument8 pagesBiovibez - Motion Sensor - Model - Mp-Ac1-R2: Save Energy and AutomateVikaas JainNo ratings yet

- Ck5 0 Seri Si / Ck5 0 Seri EDocument5 pagesCk5 0 Seri Si / Ck5 0 Seri EVikaas JainNo ratings yet

- Ck5 0 Seri Si / Ck5 0 Seri EDocument5 pagesCk5 0 Seri Si / Ck5 0 Seri EVikaas JainNo ratings yet

- Solid Solution To Liquid Level Problems !: MumbaiDocument10 pagesSolid Solution To Liquid Level Problems !: MumbaiVikaas JainNo ratings yet

- 11 KV Bus DuctDocument1 page11 KV Bus DuctVikaas JainNo ratings yet

- Contactors SchaltbauDocument16 pagesContactors SchaltbauVikaas JainNo ratings yet

- Ducati Energia-Capacitors PDFDocument68 pagesDucati Energia-Capacitors PDFVikaas JainNo ratings yet

- Der Mat Ol Ogy: Der Ma Rol L ErDocument1 pageDer Mat Ol Ogy: Der Ma Rol L ErVikaas JainNo ratings yet

- D2MPR2 D2MPR3 S2CMR1 S2CTSDocument1 pageD2MPR2 D2MPR3 S2CMR1 S2CTSVikaas JainNo ratings yet

- Viscosity Compensated Flow Controller, MetallicDocument2 pagesViscosity Compensated Flow Controller, MetallicVikaas JainNo ratings yet

- AO2 Sensor PDFDocument3 pagesAO2 Sensor PDFVikaas JainNo ratings yet

- Abb S2C-H6RDocument3 pagesAbb S2C-H6RVikaas JainNo ratings yet

- ABB Surge Arrester POLIM-H..N - Data Sheet 1HC0075856 EN AF PDFDocument9 pagesABB Surge Arrester POLIM-H..N - Data Sheet 1HC0075856 EN AF PDFVikaas JainNo ratings yet