Professional Documents

Culture Documents

7 Common Design Faults Causing Damage To Concrete

Uploaded by

Akshay ThakurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 Common Design Faults Causing Damage To Concrete

Uploaded by

Akshay ThakurCopyright:

Available Formats

5

7 Common Design Faults Causing

Damage to Concrete

Home / How To Guide / Detailing Guide / 7 Common Design Faults Causing Damage

to Concrete

There are number of common design faults that lead to the

damage of concrete and hence the capacity of the structural

member would be reduced. In adequate structural design,

inadequate cover, improper joint detailing, incorrect placement

of embedments in concrete, and improper connection details are

most common design faults that concrete buildings have

experienced. It is important for the designers that be aware of

these design faults in order to prevent concrete damage in the

future.

1. Inadequate Structural Design

Insufficient structural design makes structural members to

support loads that are well above the design loads. cracking of

concrete because of torsion and shear stress and spalling of

concrete due to high compression stress are indicators of

inadequate structural design. In order to specify inadequate

design as a cause of damage, it is required to compare the

location of the damage with the types of stresses that should be

present in the concrete.

For instance, if spalls are present on the underside of a simply

supported beam, high compressive stresses are not present and

inadequate design may be eliminated as a cause. However, if the

type and location of the damage and the probable stress are in

agreement, a detailed stress analysis would be required to

determine whether inadequate design is the cause or not.

Inadequate design is best prevented by thorough and careful

review of all design calculations

2. Inadequate Concrete Cover

If the cover to reinforcement is not sufficiently provided in the

construction drawing as per the environmental exposure as

suggested by the standard codes, steel reinforcement would

corrode due to permeability of moisture into the concrete. This

also becomes cause for freeze-thaw deterioration of concrete.

Due to the corrosion in steel reinforcement, the volume of

corroded steel increases inside the concrete which may cause

cracks in the concrete and spalling of concrete may take place.

ACI 318-14 section 20.6.1.3 provides minimum concrete cover

requirement for cast in place, prestressed, and precast concrete

of various structural members.

Fig. 1: Concrete Damage Due to Inadequate

Concrete Cover

3. Incorrect Placement of Embedments

in Concrete

This is also the most common type of error which may occur in

the detailing of concrete. Placement of embedment in right

location and position is important to prevent damage to

concrete.

Embedded metals, electrical conduits or outlet boxes should not

be near the exterior surfaces of the concrete structure. Cracks

may develop over and around the embedment which may lead

to damage of concrete due to corrosion and freeze thaw effect.

4. Detailing of joints

Detailing of joints in drawings for concrete structure is

substantially crucial. Joints allow the concrete to expand and

contract as temperature changes. It also allows the concrete to

transfer loads through joints. Detailing of contraction joints,

expansion joints, and construction joints for concrete structure

is needed to prevent any kind of damage that may occur.

Details of reinforcement, types of materials to be used, right

placement of joining materials shall be clearly specified to

prevent any error that may occur at site during construction.

Concrete slabs constructed with insufficient or too narrow

expansion joints can cause serious damage to bridge deck

surfaces, dam roadways, and the floors of long, steeply sloping,

south facing spillways where the large temperature changes

occur on daily and seasonal basis.

5. Improper connection details

Improper connection details between concrete members such as

beams, columns, and slabs can lead to damage of concrete

structure. If the detailing of connecting members at the junction

is not proper, the load transfer from one member to the other

may not be as expected from the design. As a result, concrete

member may deflect or suffer durability issues during the

occupancy of the structure; may cause the structure unfit for

use.

Fig. 2: Improper Connection Detail

6. Reinforcement Detailing

Reinforcement detailing errors like development length of bars,

and lapping methods of reinforcement for the given size may

also cause trouble to the concrete structure. If the contractor is

not aware of these things, then the proper placement of

reinforcement in concrete is not done which may cause damage

to the structure during its service.

Poor detailing of reinforcement may lead to localized

concentration of high stress in structural member. Structural

failure, concrete cracking, and seepage through structural

element are signs of improper reinforcement detailing.

7. General and Special Notes

General and special notes on drawing shall be provided for

whatever is assumed during design. If any assumption has been

made in case of any details not available, then that should be

mentioned in the drawing, so that contractor or supervisor at

site while construction can verify the assumptions made and in

case of any changes required, structure can be redesigned and

detailed.

& % / 0

Like 580

About Madeh Izat Hamakareem

Madeh is a Structural Engineer who works as Assistant Lecturer in

Koya University. He is the author, editor and partner at

theconstructor.org.

Search here ... .

Popular Recent

∠ Compressive Strength of Concrete -Cube Test,

Procedure, Results

April 2, 2014

∠ Types of Formwork (Shuttering) for Concrete

Construction and its Properties

October 15, 2013

∠ Quantity and Rate Analysis for Reinforced Concrete

Construction

August 21, 2014

∠ Quantity of Cement and Sand Calculation in Mortar

November 3, 2014

∠ Civil Engineering Tips - Points to Remember for

Civil Site Engineer

September 4, 2014

Popular Recent

∠ What are the difference between Tender and

Contract Documents?

May 31, 2016

∠ What are Bearing Capacity Values of Different Types

of Soil?

November 18, 2017

∠ What should be Minimum Ceiling Height for a Large Bedroom?

October 23, 2017

∠ fly Ash Percentage in PPC Cements

December 20, 2018

∠ Which Softwares are used to Estimate Project Time

and Quantity in Construction?

December 2, 2017

Login

2 Username

3 Password Forget

Log in

Register

4 Remember Me

The Constructor - Civil Engineering Home

The Constructor - Civil Engineering Home provides informational

resources to Civil Engineers around the globe on various subjects

such as construction management, Structural Engineering,

Building Construction Tips, How to Guides for Civil Engineers etc.

Quick Links

- ) Popular Questions

- ) Recent Questions

- ? Ask Question

- + Write Article

- , Question Categories

- Users

POPULAR CATEGORIES

Bridges Building Materials Building Technology Concrete Admixtures

Concrete Crack Repair Concrete Cracks Concrete Technology Construction

Construction Management Construction Project Earthquake Engineering

Foundation Design Foundation Engineering Geotechnical Engineering

How To Guide Material Testing Guide Mix Design Guide Pile Foundation

Reinforcement Guide Repair/Protection Guide Special Concrete

Structural Engineering Surveying Tests on Concrete Tips Work Procedures

! Home | " About Us | # Contact Us | $ Privacy Policy

©2019 The Constructor - Civil Engineering Home

% & ' (

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Short Term Effects of DisasterDocument1 pageShort Term Effects of DisasterAkshay ThakurNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Types of Loads On Structures Buildings and Other StructuresDocument1 pageTypes of Loads On Structures Buildings and Other StructuresAkshay ThakurNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Wikipedia - EarthquakeDocument1 pageWikipedia - EarthquakeAkshay ThakurNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Effluent StandardsDocument109 pagesEffluent StandardsAkshay ThakurNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Objectives of Structural DesignDocument1 pageObjectives of Structural DesignAkshay Thakur100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Sampling of Solid WasteDocument1 pageSampling of Solid WasteAkshay ThakurNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Causes of Failures of Earthfill DamsDocument1 pageCauses of Failures of Earthfill DamsAkshay ThakurNo ratings yet

- Canal Falls - Their Types and Importance: What Is Canal Fall?Document1 pageCanal Falls - Their Types and Importance: What Is Canal Fall?Akshay ThakurNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Wikipedia - Natural DisastersDocument1 pageWikipedia - Natural DisastersAkshay ThakurNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Subscribe 'Decode BD' YouTube channel for structural design tutorialsDocument13 pagesSubscribe 'Decode BD' YouTube channel for structural design tutorialsPre Sheet100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- SpillwayDocument1 pageSpillwayAkshay ThakurNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Gravity Dams: Design, Galleries and Joints - Irrigation - AgricultureDocument1 pageGravity Dams: Design, Galleries and Joints - Irrigation - AgricultureAkshay ThakurNo ratings yet

- IJEEGS - Comparison Between Seismic Analysis and Non-SeismicDocument6 pagesIJEEGS - Comparison Between Seismic Analysis and Non-SeismicTJPRC PublicationsNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SpillwayDocument1 pageSpillwayAkshay ThakurNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- RetrofittingDocument61 pagesRetrofittingBala GopalNo ratings yet

- (PPT) Earthquake Resistant Construction PDFDocument36 pages(PPT) Earthquake Resistant Construction PDFAkshay ThakurNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Design of Reinforced Concrete Structures Prof. Nirjhar Dhang Department of Civil Engineering Indian Institute of Technology, Kharagpur Lecture - 01Document32 pagesDesign of Reinforced Concrete Structures Prof. Nirjhar Dhang Department of Civil Engineering Indian Institute of Technology, Kharagpur Lecture - 01Ahmed FayedNo ratings yet

- Specification For Industrial Helmets As Per Is CodeDocument3 pagesSpecification For Industrial Helmets As Per Is CodeAkshay ThakurNo ratings yet

- 01 SeismologyDocument29 pages01 SeismologyGirish YumnamNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Is 801 1975 SpecificationsDocument1 pageIs 801 1975 SpecificationsAkshay ThakurNo ratings yet

- (IRJET-V4I7224) To Study Earthquake Resistance Design of StructuresDocument12 pages(IRJET-V4I7224) To Study Earthquake Resistance Design of StructuresAkshay ThakurNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Reinforced Concrete StandardsDocument1 pageReinforced Concrete StandardsAkshay ThakurNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- (IRJET-V4I7224) To Study Earthquake Resistance Design of Structures PDFDocument3 pages(IRJET-V4I7224) To Study Earthquake Resistance Design of Structures PDFAkshay ThakurNo ratings yet

- Is 875-1 DescriptionDocument2 pagesIs 875-1 DescriptionAkshay ThakurNo ratings yet

- Is 432-1 TerminologyDocument1 pageIs 432-1 TerminologyAkshay ThakurNo ratings yet

- Is 432-1 Types & Grade, Manufacture & Chemical CompositionDocument1 pageIs 432-1 Types & Grade, Manufacture & Chemical CompositionAkshay ThakurNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- 4.63 ME Civil Engg Strutural EnggDocument139 pages4.63 ME Civil Engg Strutural Enggshivaji_sarvadeNo ratings yet

- Is 800Document4 pagesIs 800Akshay ThakurNo ratings yet

- Is 875-1 DescriptionDocument2 pagesIs 875-1 DescriptionAkshay ThakurNo ratings yet

- Assignment 2 CA3703.2016Document6 pagesAssignment 2 CA3703.2016wilsonNo ratings yet

- Roofing Handbook 2ed 2000 - Scharff & KennedyDocument552 pagesRoofing Handbook 2ed 2000 - Scharff & KennedyCarl Williams100% (1)

- Building Construction V: Architectural Finishing SystemsDocument21 pagesBuilding Construction V: Architectural Finishing SystemsSajay PajarillagaNo ratings yet

- ACI 117 - Specifications For Tolerances For ConcreteDocument88 pagesACI 117 - Specifications For Tolerances For ConcreteRhonzkie GapuzNo ratings yet

- Moderate Mary Ma ThewDocument4 pagesModerate Mary Ma ThewShyam Kumar0% (2)

- 3) Method of StatementDocument10 pages3) Method of StatementZiaul HaqNo ratings yet

- MS Samsung Cassette InverterDocument2 pagesMS Samsung Cassette InverterMacSparesNo ratings yet

- 09 IRC Fuel Gas Piping ChecklistDocument3 pages09 IRC Fuel Gas Piping ChecklistMochammad Nur HidayatNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- HighRiseSafety PDFDocument1 pageHighRiseSafety PDFmelitoNo ratings yet

- Essence 160x320cm Slab E-Catalogue Feb 23Document54 pagesEssence 160x320cm Slab E-Catalogue Feb 23chiragressenceNo ratings yet

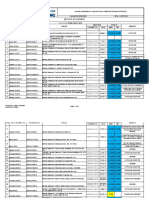

- Bill of Materials: Description Quantity Unit Cost Amount I Layout / Stakeout and EarthworksDocument35 pagesBill of Materials: Description Quantity Unit Cost Amount I Layout / Stakeout and EarthworksJm BarangcoNo ratings yet

- ASKIN XFLAM Performance Panel CladdingDocument5 pagesASKIN XFLAM Performance Panel CladdingDanusha EgodawatteNo ratings yet

- Guardhouse 1-2Document2 pagesGuardhouse 1-2dawitgggNo ratings yet

- Cold Room Refrigeration System Full SpecificationDocument3 pagesCold Room Refrigeration System Full SpecificationmelkuNo ratings yet

- Mision 8 9 12Document419 pagesMision 8 9 12auweia1No ratings yet

- Improvement of Jaglot-Skardu Road Project Cost EstimatesDocument6 pagesImprovement of Jaglot-Skardu Road Project Cost EstimatesAhmad Javed WarraichNo ratings yet

- SECTION 07310 Asphalt Shingle Roofing Gaf Design Line: Prepared byDocument18 pagesSECTION 07310 Asphalt Shingle Roofing Gaf Design Line: Prepared byRafael Ramirez CasateNo ratings yet

- Dire Dawa University Institute of Technology (Dduiot)Document7 pagesDire Dawa University Institute of Technology (Dduiot)SemNo ratings yet

- DesignBuilder Simulation TrainingDocument170 pagesDesignBuilder Simulation TraininghoangpalestineNo ratings yet

- Pm210011-Nui900-Rf2-00005 - 02 - Raft Foundation Layout - (261-B203) Operator...Document1 pagePm210011-Nui900-Rf2-00005 - 02 - Raft Foundation Layout - (261-B203) Operator...MOHAMMAD JAKARIA HASANNo ratings yet

- Technical Specifications For Construction of Futsal Play GroundDocument4 pagesTechnical Specifications For Construction of Futsal Play Groundpujan77No ratings yet

- EC - Quick ReferenceDocument3 pagesEC - Quick ReferencevanamgouthamNo ratings yet

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDocument1 page4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFshawonscribdNo ratings yet

- Spancast Site Visit Report on Precast Concrete ProductsDocument20 pagesSpancast Site Visit Report on Precast Concrete ProductsAddrien DanielNo ratings yet

- Prefabricated Structures: Benefits and UsesDocument26 pagesPrefabricated Structures: Benefits and Usessakshi meherNo ratings yet

- RDMP Project Fmar Shop DWG Fabrication Estimated Delivery (On Site)Document12 pagesRDMP Project Fmar Shop DWG Fabrication Estimated Delivery (On Site)Bintang DwiPutraNo ratings yet

- Is: 3414-1968Document29 pagesIs: 3414-1968Gandem Mohan KrishnaNo ratings yet

- Skyscrapers: Construction TechnologyDocument12 pagesSkyscrapers: Construction TechnologyGrigore StNo ratings yet

- ST OBC Supplementary Standard SB-12 (2011!12!05)Document27 pagesST OBC Supplementary Standard SB-12 (2011!12!05)simonsahiNo ratings yet

- Instruction Sheet W10322578Document10 pagesInstruction Sheet W10322578Lyle WeischwillNo ratings yet

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet