Professional Documents

Culture Documents

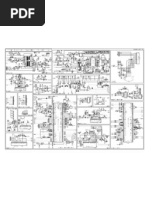

A2010-A Explosive View L3 Repair

Uploaded by

todorloncarskiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A2010-A Explosive View L3 Repair

Uploaded by

todorloncarskiCopyright:

Available Formats

NOTES:

、Assembly with dust-free workshop assembly, process material transfer must ensure cleanliness, including the turnover box

、Assembly before the shell must ensure that, by means of air rifle clean monomer dust-free dot, hair silk, or white dots

、Pay attention to avoid hair silk and residue in the process of assembly, pay attention to use finger sets of operation, pay

attention to request mold factory exhaust direction of foam and burr in the same direction of the steel, avoid scratching around

hair silk or points behind the front shell of dust and LCD

Foam cavity side, if there is still a risk of dustfall, suggested after back glue, foam joint strength of air gun small blow try

adding appropriate component

、Package are prohibited flaky materials, such as pearl cotton, or monomer cleanness not enough air bubble bags or plastic

bags, static electricity is recommended for the blister tray and a plastic disc placed cleanliness higher isolation film form,

Under the specific packing layer: anti-static tray - transparent film on the transparent film - product - - anti-static tray, and

so on.Anti-static tray need to be used now in vitro after removal lon-izing blow dry, transparent film to ensure is that the new

film (may not be reused)

、Focuses on the purity of the packing and warehousing, transportation process for shell pollution risk, avoid dirt from the

back-end links to product hidden trouble

You might also like

- BK 2831D Calibration ProcedureDocument3 pagesBK 2831D Calibration ProceduretodorloncarskiNo ratings yet

- 4 Digit and 50,000 Count Bench Multimeters: ModelDocument78 pages4 Digit and 50,000 Count Bench Multimeters: ModeltodorloncarskiNo ratings yet

- Ersa i-CON 1V & i-CON 2V: Soldering StationDocument58 pagesErsa i-CON 1V & i-CON 2V: Soldering StationtodorloncarskiNo ratings yet

- BK 2831D Service ManualDocument26 pagesBK 2831D Service ManualtodorloncarskiNo ratings yet

- B&K Digital Bench Multimeter Model 2831 Users ManualDocument15 pagesB&K Digital Bench Multimeter Model 2831 Users ManualtodorloncarskiNo ratings yet

- PDTA124E Series: 1. Product ProfileDocument18 pagesPDTA124E Series: 1. Product ProfiletodorloncarskiNo ratings yet

- Ersa Soldering Station PDFDocument22 pagesErsa Soldering Station PDFtodorloncarskiNo ratings yet

- Samsung Le23r86bd Le26r86bd Le32r86bd Le32r82bx Le37r86bd Le37r81bx Le40r86bd Le40r82bx PDFDocument157 pagesSamsung Le23r86bd Le26r86bd Le32r86bd Le32r82bx Le37r86bd Le37r81bx Le40r86bd Le40r82bx PDFtodorloncarskiNo ratings yet

- Toshiba 42pw33q - S Ch. Pw33 SchematicsDocument18 pagesToshiba 42pw33q - S Ch. Pw33 SchematicstodorloncarskiNo ratings yet

- Onkyo tx-7430 SM PDFDocument34 pagesOnkyo tx-7430 SM PDFtodorloncarskiNo ratings yet

- Ak37 ManualDocument29 pagesAk37 Manualdanielstancu883296No ratings yet

- Roadstar Hif-7119rc PDFDocument8 pagesRoadstar Hif-7119rc PDFtodorloncarskiNo ratings yet

- Ersa Werkzeugkatalog Eng Web PDFDocument52 pagesErsa Werkzeugkatalog Eng Web PDFtodorloncarskiNo ratings yet

- 11AK19P5 SCHDocument44 pages11AK19P5 SCHtodorloncarskiNo ratings yet

- TV operating instructions documentDocument25 pagesTV operating instructions documenttodorloncarskiNo ratings yet

- LNK304 PDFDocument20 pagesLNK304 PDFtodorloncarskiNo ratings yet

- Loewe q2500Document52 pagesLoewe q2500todorloncarskiNo ratings yet

- TV Orion-Sinudyne Chassis - 2550 - Professional - SCH, Service - ModeDocument13 pagesTV Orion-Sinudyne Chassis - 2550 - Professional - SCH, Service - ModetodorloncarskiNo ratings yet

- Akira Ct-21cqs5cpt Ete-2 Vivax Imago 2105Document44 pagesAkira Ct-21cqs5cpt Ete-2 Vivax Imago 2105Pedro Jose Paucar ValleNo ratings yet

- Loewe q4100 Chassis SMDocument93 pagesLoewe q4100 Chassis SMtodorloncarskiNo ratings yet

- Tauras Beko Tv2k Ag Bk2 20 St92195 Stv2248 Chassis K Bomann Ctv577v Chassis Pm2tv2k SCHDocument1 pageTauras Beko Tv2k Ag Bk2 20 St92195 Stv2248 Chassis K Bomann Ctv577v Chassis Pm2tv2k SCHtodorloncarskiNo ratings yet

- 3Y11 FullDocument24 pages3Y11 FulltodorloncarskiNo ratings yet

- Chassis - px20045 Pow (V1513)Document2 pagesChassis - px20045 Pow (V1513)todorloncarskiNo ratings yet

- Service Mode Orion t2129mtx 163Document6 pagesService Mode Orion t2129mtx 163todorloncarskiNo ratings yet

- Sony Chas - BG 1s KV g21m1Document4 pagesSony Chas - BG 1s KV g21m1todorloncarskiNo ratings yet

- PT11 ChassisDocument2 pagesPT11 Chassiserez01No ratings yet

- Elite 21es55 57 58 67 14es31 37 SCH (ET)Document13 pagesElite 21es55 57 58 67 14es31 37 SCH (ET)todorloncarskiNo ratings yet

- Samsung Chassis S51aDocument49 pagesSamsung Chassis S51aAlan BurnNo ratings yet

- KarcherSD PT92-2Document1 pageKarcherSD PT92-2Stana PetruNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)