Professional Documents

Culture Documents

Bolt Nut Locking and Knock Pin Installation PDF

Bolt Nut Locking and Knock Pin Installation PDF

Uploaded by

Fitra Vertikal0 ratings0% found this document useful (0 votes)

24 views3 pagesOriginal Title

Bolt Nut Locking and Knock Pin Installation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views3 pagesBolt Nut Locking and Knock Pin Installation PDF

Bolt Nut Locking and Knock Pin Installation PDF

Uploaded by

Fitra VertikalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

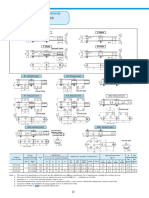

CYCLO DRIVE Parts Data

6060~6125 Bolt/Nut Locking and Knock Pin Installation

1/3

1. When with brake and when specification code is T31 (Bolt/Nut Locking)

Table of Usage (CNHM, CNH)

Bolt for Ring Gear Locktight 262 on

Housing U nut female threaded

Type Frame Size

Screw part coating Note 2 section for stud bolt

insertion

CNHM 6060, 6065 A B B

6070, 6075 A B B

6080, 6085 A B B

6090, 6095 A B B

6100, 6105 A B B

6110, 6115 A B B

6120, 6125 A B B

6060DA, 6065DA A B B

6070DA, 6075DA A B B

6090DA, 6095DA Input side B B B

Output side B A

6100DA, 6105DA Input side B B B

Output side B A

6120DA~6125DB Input side B B B

Output side B A

CNH 6060, 6065 B A

6070, 6075 B A

6080, 6085 A B B

6090, 6095 B A

6100, 6105 B A

6110, 6115 A B B

6120, 6125 B A

6060DA, 6065DA B A

6070DA, 6075DA B A

6090DA, 6095DA Input side B B

Output side B A

6100DA, 6105DA Input side B B

Output side B A

6120DA~6125DB Input side B B

Output side B A

Note: 1. A: Coating required. B: Coating not required.

2. No spring washer is used when u nut is used.

3. The table applies also when FCD horizontal casing is used.

4. When coated hexagon socket head bolt is used and bolt bearing surface is

casting surface (FC or FCD), spring washer is used.

5. Wipe tap end side of stud bolt (male) when applying Locktight 262 (gasoline

cleansing not necessary.).

August 1, 2001 Sumitomo Heavy Industries, Ltd.

CYCLO DRIVE Parts Data

6060~6125 Bolt/Nut Locking and Knock Pin Installation

2/3

Table of Usage (CNVM, CNFM, CNV, CNF)

Bolt for Ring Gear Locktight 262 on

Housing U nut female threaded

Type Frame Size

Screw part Note 2 section for stud

coating bolt insertion

CNVM 6060,6065 B A A

& 6070,6075 B A A

CNFM 6080,6085 B A A

6090,6095 B A A

6100,6105 B A A

6110,6115 B A A

6120,6125 B A A

6060DA, 6065DA B A A

6070DA, 6075DA B A A

6090DA, 6095DA Input side B B B

Output side B A

6100DA, 6105DA Input side B B B

Output side B A

6120DA~6125DB Input side B B B

Output side B A

CNV 6060, 6065 B A

& 6070, 6075 B A

CNF 6080, 6085 B A A

6090, 6095 B A

6100, 6105 B A

6110, 6115 B A A

6120, 6125 B A

6060DA, 6065DA B A

6070DA, 6075DA B A

6090DA, 6095DA Input side B B

Output side B A

6100DA, 6105DA Input side B B

Output side B A

6120DA~6125DB Input side B B

Output side B A

Note: 1. A: Coating required. B: Coating not required.

2. Do not use spring washer when using u nut. Use u nut for all locations.

3. The table applies also when FCD vertical/flange casing is used.

4. When coated hexagon socket head bolt is used and bolt bearing surface is

casting surface (FC or FCD), spring washer is used.

5. Wipe tap end side of stud bolt (male) when applying Locktight 262 (gasoline

cleansing not necessary.).

August 1, 2001 Sumitomo Heavy Industries, Ltd.

CYCLO DRIVE Parts Data

6060~6125 Bolt/Nut Locking and Knock Pin Installation

3/3

2. When Specification Code is Indicated as T30

Table of Contents for Usage

When knock bolt is used

Types Frame Size

Note 3

CNHM, 6060, 6065 B

CNH, 6070, 6075 B

CNVM, 6080, 6085 B

CNV, 6090, 6095 A

CNFM, 6100, 6105 A

CNF 6110, 6115 A

6120, 6125 A

6060DA, 6065DA B

6070DA, 6075DA B

6090DA, 6095DA Input side B

Output side A

6100DA, 6105DA Input side B

Output side A

6120DA~6125DB Input side B

Output side A

Note) 1. Bolt for ring gear housing: Screw part coating, u nut, and Locktight application for

stud bolt is the same as page 1 and 2.

2. Knock pin is not used when housing material is ADC12.

Subject models without knock pin: 6060~6085

3. Quantity of knock pin used for each unit: 2

Location of knock pin: located in diagonally between bolts on PCD of bolt for ring

gear housing.

August 1, 2001 Sumitomo Heavy Industries, Ltd.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- VG-640 SV enDocument349 pagesVG-640 SV enSupremo HaloNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- M-20iA35M Linebuilder Manual en 02Document7 pagesM-20iA35M Linebuilder Manual en 02Fitra VertikalNo ratings yet

- Class Presentation M FG 318999 Sidney Shaol ADocument28 pagesClass Presentation M FG 318999 Sidney Shaol AFitra VertikalNo ratings yet

- It's STILL All in The Details - Tips & Tricks of Detailing in InventorDocument22 pagesIt's STILL All in The Details - Tips & Tricks of Detailing in InventorFitra VertikalNo ratings yet

- 2016E 00 Full PDFDocument168 pages2016E 00 Full PDFFitra VertikalNo ratings yet

- Class Hand Out Im 473672 Demir AliDocument23 pagesClass Hand Out Im 473672 Demir AliFitra VertikalNo ratings yet

- Strength of Materials: (SI Units)Document11 pagesStrength of Materials: (SI Units)Fitra VertikalNo ratings yet

- Virtual Commissioning in The Factory: Learning ObjectivesDocument25 pagesVirtual Commissioning in The Factory: Learning ObjectivesFitra VertikalNo ratings yet

- Automation Studio P6 Brochure PDFDocument28 pagesAutomation Studio P6 Brochure PDFFitra VertikalNo ratings yet

- Bearing, Shear, and Tear-Out Stress?: What's The Difference BetweenDocument2 pagesBearing, Shear, and Tear-Out Stress?: What's The Difference BetweenFitra VertikalNo ratings yet

- Class Presentation Im 322995 Florian Wegman NDocument68 pagesClass Presentation Im 322995 Florian Wegman NFitra VertikalNo ratings yet

- Pulley Assembly 2015Document1 pagePulley Assembly 2015Fitra VertikalNo ratings yet

- Fischer RM IIDocument4 pagesFischer RM IIFitra VertikalNo ratings yet

- 2 Fluid CouplingDocument25 pages2 Fluid CouplingFitra VertikalNo ratings yet

- Kissof Manual PDFDocument1,017 pagesKissof Manual PDFFitra Vertikal100% (1)

- Bending Moment CalculationDocument39 pagesBending Moment CalculationFitra VertikalNo ratings yet

- DIN 15018-1-1984, Cranes, Steel Structures PDFDocument38 pagesDIN 15018-1-1984, Cranes, Steel Structures PDFFitra VertikalNo ratings yet

- Modelling and Stress Analysis of Column Bracket For Rotary Jib CraneDocument10 pagesModelling and Stress Analysis of Column Bracket For Rotary Jib CraneFitra VertikalNo ratings yet

- Orthoman OkDocument156 pagesOrthoman OkFitra VertikalNo ratings yet

- Technical Data For Elevator Buckets - Bucket ElevatorDocument1 pageTechnical Data For Elevator Buckets - Bucket ElevatorFitra VertikalNo ratings yet

- Reference Chain For Bucket-TsubakiDocument1 pageReference Chain For Bucket-TsubakiFitra VertikalNo ratings yet

- Wall Mounted Jib Crane (H-Type) : Mechanical System DesignDocument65 pagesWall Mounted Jib Crane (H-Type) : Mechanical System DesignFitra VertikalNo ratings yet

- Flat Belt Roller Conveyor Calculation:: Feeding DataDocument4 pagesFlat Belt Roller Conveyor Calculation:: Feeding DataFitra VertikalNo ratings yet

- CascadingDocument1 pageCascadingDenzo RyugaNo ratings yet

- Cu400mrd Cu500mrd Cu580mrdDocument4 pagesCu400mrd Cu500mrd Cu580mrdAndres Isaac Salvatierra LauraNo ratings yet

- 003-119e 06.14Document4 pages003-119e 06.14Girlane Matos Dos AnjosNo ratings yet

- Boletin Enfriamiento de Mack EgrDocument25 pagesBoletin Enfriamiento de Mack Egrcristian picado100% (1)

- 876JJ6P722 - Partner 200 12-4 (Fini)Document5 pages876JJ6P722 - Partner 200 12-4 (Fini)LefialgaNo ratings yet

- Imports of Ammunition by Zim Shipping, 2013-2014Document12 pagesImports of Ammunition by Zim Shipping, 2013-2014darwinbondgrahamNo ratings yet

- NM Half Inch Connector Preparation InstructionsDocument2 pagesNM Half Inch Connector Preparation Instructionssandeep bagulNo ratings yet

- Frameless09072012C PampDocument8 pagesFrameless09072012C PampLeandro Francisco da SilvaNo ratings yet

- Quick Installation and Start-Up Guide: Safety InstructionsDocument15 pagesQuick Installation and Start-Up Guide: Safety InstructionsTonyNo ratings yet

- SDLG LG933 Parts CatalogDocument65 pagesSDLG LG933 Parts CatalogMithlesh KumarNo ratings yet

- MDFu 74Document47 pagesMDFu 74Rhishidas PuthiyavalappilNo ratings yet

- Rt540E Operator'S Manual Operating Controls and ProceduresDocument27 pagesRt540E Operator'S Manual Operating Controls and ProceduresYuri FaroNo ratings yet

- Fisher Paykel Gw612 Au FP WH Parts ListDocument17 pagesFisher Paykel Gw612 Au FP WH Parts ListPaul WilsonNo ratings yet

- Hir Purchase List CSDDocument57 pagesHir Purchase List CSDAbdullah ShabbirNo ratings yet

- ATA-83 Accessory Gear BoxDocument11 pagesATA-83 Accessory Gear BoxMeda100% (2)

- Destiny - Max - SM - GB SMV2.3 - 110930 (2020 - 08 - 20 02 - 50 - 44 UTC)Document458 pagesDestiny - Max - SM - GB SMV2.3 - 110930 (2020 - 08 - 20 02 - 50 - 44 UTC)Arnoldo FelixNo ratings yet

- 360 Degree Flexible Drilling Machine Ed Project ReviewDocument15 pages360 Degree Flexible Drilling Machine Ed Project ReviewAbdul mujeeb25% (4)

- 4 HydraulicsDocument63 pages4 HydraulicsDiego BernalNo ratings yet

- Altistart 22: Selection GuideDocument8 pagesAltistart 22: Selection GuideFrancisco Mozart B. MeirellesNo ratings yet

- Ps 202Document4 pagesPs 202AgnewNo ratings yet

- PDF Mercedes Benz Sensotronic Brake Control SBC CompressDocument21 pagesPDF Mercedes Benz Sensotronic Brake Control SBC CompressArga PRNo ratings yet

- User Manual For ConnectingDocument5 pagesUser Manual For ConnectingMassimo BalvisNo ratings yet

- Manual Dong DMT 400HLDocument39 pagesManual Dong DMT 400HLcmendezNo ratings yet

- Nedis AIPU300CWT Air PurifierDocument76 pagesNedis AIPU300CWT Air Purifierjose antonio vilar bravoNo ratings yet

- Wat - QRSDocument2 pagesWat - QRStemplecloud1No ratings yet

- FUNAI Chassis FL14.10 Service ManualDocument143 pagesFUNAI Chassis FL14.10 Service ManualAchim F.No ratings yet

- Installation Fire Pumps-7Document1 pageInstallation Fire Pumps-7Nilesh ChavanNo ratings yet

- CRJ 700 - 900 - 1000 Thrust Reverser OperationDocument23 pagesCRJ 700 - 900 - 1000 Thrust Reverser OperationN ANo ratings yet

- Datasheet UTC MCR100Document2 pagesDatasheet UTC MCR100kenongomulyoNo ratings yet