Professional Documents

Culture Documents

Installation Fire Pumps-7

Uploaded by

Nilesh ChavanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Fire Pumps-7

Uploaded by

Nilesh ChavanCopyright:

Available Formats

GENERAL REQUIREMENTS 20–13

plosion, fire, flood, earthquake, rodents, insects, windstorm, 5.12.5 Ventilation. Provision shall be made for ventilation of a

freezing, vandalism, and other adverse conditions. pump room or pump house.

5.12.1.1* Indoor Fire Pump Units. 5.12.6* Drainage.

5.12.1.1.1* Indoor fire pumps in high-rise buildings shall be 5.12.6.1 Floors shall be pitched for adequate drainage of es-

physically separated or protected by 2-hour fire-rated con- caping water away from critical equipment such as the pump,

struction. driver, controller, and so forth.

m

5.12.1.1.2 Indoor fire pumps in non-high-rise buildings shall 5.12.6.2 The pump room or pump house shall be provided

be physically separated or protected by fire-rated construction with a floor drain that will discharge to a frost-free location.

in accordance with Table 5.12.1.1.2.

5.12.7 Guards. Couplings and flexible connecting shafts shall

o

be installed with a coupling guard in accordance with Section

8 of ANSI B15.1, Mechanical Power Transmission Apparatus.

Apparatus.

Table 5.12.1.1.2 Equipment Protection

5.13 Pipe and Fittings.

c

Building(s) 5.13.1* Steel Pipe.

Pump Required

Exposing Pump

Room/House Separation 5.13.1.1 Steel pipe shall be used above ground except for

.

Room/House

connection to underground suction and underground dis-

Not sprinklered Not sprinklered 2 hour fire-rated charge piping.

Not sprinklered Fully sprinklered or 5.13.1.2 Where corrosive water conditions exist, steel suction

Fully sprinklered Not sprinklered 50 ft (15.3 m) pipe shall be galvanized or painted on the inside prior to in-

stallation with a paint recommended for submerged surfaces.

w

1 hour fire-rated

Fully sprinklered Fully sprinklered or 5.13.1.3 Thick bituminous linings shall not be used.

50 ft (15.3 m) 5.13.2* Joining Method.

x

5.13.2.1 Sections of steel piping shall be joined by means of

screwed, flanged mechanical grooved joints or other ap-

f

5.12.1.1.3 Location and access to the fire pump room shall proved fittings.

be pre-planned with the fire department. 5.13.2.2 Slip-type fittings shall be permitted to be used where

5.12.1.1.4 Rooms containing fire pumps shall be free from installed as required by 5.14.6 and where the piping is me-

z

storage and penetrations not essential to the operation of the chanically secured to prevent slippage.

pump and related components. 5.13.3 Concentrate and Additive Piping.

5.12.1.2 Outdoor Fire Pump Units. 5.13.3.1 Foam concentrate or additive piping shall be a ma-

b

5.12.1.2.1 Fire pump units located outdoors shall be located terial that will not corrode in this service.

at least 50 ft (15.3 m) away from any exposing building. 5.13.3.2 Galvanized pipe shall not be used for foam concen-

.

5.12.1.2.2 Outdoor installations also shall be required to be trate service.

provided with protection against possible interruption in ac- 5.13.4* Cutting and Welding. Torch-cutting or welding in the

cordance with 5.12.1. pump house shall be permitted as a means of modifying or

5.12.1.3 Firee Pump Buildings or Rooms with Diesel Engines. repairing pump house piping when it is performed in accor-

Fire pump buildings or rooms enclosing diesel engine pump dance with NFPA 51B, Standard for Fire Prevention During Weld-

w

drivers and day tanks shall be protected with an automatic ing, Cutting, and Other Hot Work.

sprinkler system installed in accordance with NFPA 13, Stan- 5.14 Suction Pipe and Fittings.

dard for the Installation of Sprinkler Systems.

Systems

5.14.1* Components.

5.12.2 Heat.

5.14.1.1 The suction components shall consist of all pipe,

w

5.12.2.1 An approved or listed source of heat shall be pro- valves, and fittings from the pump suction flange to the con-

vided for maintaining the temperature of a pump room or nection to the public or private water service main, storage

pump house, where required, above 40°F (5°C). tank, or reservoir, and so forth, that feeds water to the pump.

5.12.2.2 The requirements of 11.6.5 shall be followed for 5.14.1.2 Where pumps are installed in series, the suction

higher temperature requirements for internal combustion pipe for the subsequent pump(s) shall begin at the system side

w

engines. of the discharge valve of the previous pump.

5.12.3 Normal Lighting. Artificial light shall be provided in a

5.14.2 Installation. Suction pipe shall be installed and tested

pump room or pump house.

in accordance with NFPA 24, Standard for the Installation of Pri-

5.12.4 Emergency Lighting. vate Fire Service Mains and Their Appurtenances.

5.12.4.1 Emer

Emergency lighting shall be provided in accordance 5.14.3 Suction Size.

with NFPA 101, Life Safety Code.

5.14.3.1 Unless the requirements of 5.14.3.2 are met, the size

5.12.4.2 Emergency lights shall not be connected to an of the suction pipe for a single pump or of the suction header

engine-starting battery. pipe for multiple pumps (operating together) shall be such

2007 Edition

--```,,`,,``,``,,`,,,```,`,``,,-`-`,,`,,`,`,,`---

You might also like

- Technical Submittal - LV DBDocument766 pagesTechnical Submittal - LV DBsamirNo ratings yet

- Reverse Cycle Ducted Split Systems R32 Installation & MaintenanceDocument8 pagesReverse Cycle Ducted Split Systems R32 Installation & MaintenanceFilipNo ratings yet

- Vitodens 300 PDFDocument148 pagesVitodens 300 PDFAlbert ButanNo ratings yet

- Chapter 11 - Storm DrainageDocument6 pagesChapter 11 - Storm DrainageGino TironiNo ratings yet

- Chapter 12 Underground Electrical SystemsDocument21 pagesChapter 12 Underground Electrical Systemsywa00No ratings yet

- Section 15910 Ductwork AccessoriesDocument9 pagesSection 15910 Ductwork AccessorieskdpmansiNo ratings yet

- Aspirante 4Document28 pagesAspirante 4nexy bNo ratings yet

- 400 Series Instructions 051118 WebDocument4 pages400 Series Instructions 051118 Webzidan080606No ratings yet

- Pt C, Ch 3, Sec 5 Installation RequirementsDocument2 pagesPt C, Ch 3, Sec 5 Installation RequirementsJon LopezNo ratings yet

- National Electrical Code (2017) - GFCI & AFCIDocument2 pagesNational Electrical Code (2017) - GFCI & AFCIpurit83No ratings yet

- DAT'Air Installation GuideDocument8 pagesDAT'Air Installation GuideDemetrios GkikasNo ratings yet

- User's ManualDocument36 pagesUser's ManualMalliebooNo ratings yet

- MANUAL 2ttb3 - SeriesDocument8 pagesMANUAL 2ttb3 - SeriesingeNo ratings yet

- Electrical Standards: Marine ProductsDocument1 pageElectrical Standards: Marine ProductsHumberto PaniaguaNo ratings yet

- Trane TWE-In-2A 18-GE02D1-3 TWE030P130B0 Air Handler Installer's Guide Installation Manual (November 2001) OcrDocument12 pagesTrane TWE-In-2A 18-GE02D1-3 TWE030P130B0 Air Handler Installer's Guide Installation Manual (November 2001) OcrPatrickHenryNo ratings yet

- Ele ElsDocument28 pagesEle ElscasaNo ratings yet

- Part 1 - Design: Water Supply Code of Australia Agency RequirementsDocument12 pagesPart 1 - Design: Water Supply Code of Australia Agency RequirementsTailieukythuat DataNo ratings yet

- InstallationDocument10 pagesInstallationJon LopezNo ratings yet

- NDT & Corrosion Control Services: Standard Operating ProcedureDocument6 pagesNDT & Corrosion Control Services: Standard Operating Procedurem_armoutiNo ratings yet

- Laying A New Water Supply Pipe: DuctingDocument4 pagesLaying A New Water Supply Pipe: DuctingvictorNo ratings yet

- Installation, Start-Up and Service Instructions: 50TJQ008-012 Single-Package Rooftop Heat Pump UnitsDocument36 pagesInstallation, Start-Up and Service Instructions: 50TJQ008-012 Single-Package Rooftop Heat Pump UnitsMouradNo ratings yet

- Installation of Gypsum Products in Concealed Radiant Ceiling Heating SystemsDocument2 pagesInstallation of Gypsum Products in Concealed Radiant Ceiling Heating SystemsINARQ1979No ratings yet

- Method Statement Mechanical SystemDocument181 pagesMethod Statement Mechanical SystemOsama Ali100% (1)

- Install HVAC Ductwork EfficientlyDocument5 pagesInstall HVAC Ductwork EfficientlyBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Specifications For Underground Water Storage Tanks For Fire ProtectionDocument5 pagesSpecifications For Underground Water Storage Tanks For Fire ProtectionkirmaniNo ratings yet

- Miscellaneous EquipmentDocument2 pagesMiscellaneous EquipmentJon LopezNo ratings yet

- Astm F 1290Document3 pagesAstm F 1290محمود أبو الحسنNo ratings yet

- 50TFF-008 014Document44 pages50TFF-008 014adolfomarcNo ratings yet

- BLS Design FinalDocument29 pagesBLS Design FinalMark GonzalesNo ratings yet

- Triton Madrid IIDocument28 pagesTriton Madrid IIdani datoadNo ratings yet

- Chapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable WaterDocument2 pagesChapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable WaterkapsarcNo ratings yet

- BKI Vol2 - Section38Document5 pagesBKI Vol2 - Section38Erwin Paulian SihombingNo ratings yet

- The Home of Fresh Air: MVHR & Quiet-Vent Radial Ductwork Installation ManualDocument16 pagesThe Home of Fresh Air: MVHR & Quiet-Vent Radial Ductwork Installation ManualMarius BabosNo ratings yet

- EN81 lift pit safety requirementsDocument2 pagesEN81 lift pit safety requirementsSupri AdiNo ratings yet

- FRP Guide SpecificationDocument9 pagesFRP Guide SpecificationkuhomikzNo ratings yet

- FD Series IomDocument7 pagesFD Series IomdasdaNo ratings yet

- Samsung MW1150WA - SMDocument23 pagesSamsung MW1150WA - SMEdwin CastilloNo ratings yet

- Important Safety Instructions Important Safety InstructionsDocument8 pagesImportant Safety Instructions Important Safety InstructionsBeer RedbullNo ratings yet

- AvidaOneAntonio - Design and Construction GuidelinesDocument18 pagesAvidaOneAntonio - Design and Construction GuidelinesKevin Perez ValenzuelaNo ratings yet

- IMG - 0088 PSME Code 2012 86Document1 pageIMG - 0088 PSME Code 2012 86Bugoy2023No ratings yet

- SYSVRF AIR EVO C HP Q Installation ManualDocument18 pagesSYSVRF AIR EVO C HP Q Installation ManualTomás ArrebolaNo ratings yet

- Intermediate PDFDocument6 pagesIntermediate PDFRIGOBERTO PONCENo ratings yet

- 3828a30038d e LG Package Instsllation ManualDocument23 pages3828a30038d e LG Package Instsllation ManualGeneza Del RosarioNo ratings yet

- Earthing: 5.4.2 - Protective Conductor TypesDocument2 pagesEarthing: 5.4.2 - Protective Conductor Typeswaleed_mohamed_10No ratings yet

- Nfpa 850Document5 pagesNfpa 850MAHMUDNo ratings yet

- Fire pump requirements overviewDocument1 pageFire pump requirements overviewNilesh ChavanNo ratings yet

- Process Pressure Vessels and Piping SystemsDocument5 pagesProcess Pressure Vessels and Piping SystemsEn NdyNo ratings yet

- LPG Systems Design and Installation RequirementsDocument2 pagesLPG Systems Design and Installation Requirementsjerin santoshNo ratings yet

- Wet Pipe Sprinkler SystemDocument6 pagesWet Pipe Sprinkler Systemamir shokrNo ratings yet

- Project design construction programme supervision facilitiesDocument1 pageProject design construction programme supervision facilitiesRamadan RashadNo ratings yet

- Combi Port / Aqua Port INS: Quick Guide Guía Rápida LynguideDocument11 pagesCombi Port / Aqua Port INS: Quick Guide Guía Rápida Lynguidejamppajoo2No ratings yet

- AEL Comments On STP Punch PointsDocument14 pagesAEL Comments On STP Punch PointsEphrem GizachewNo ratings yet

- Prepared By:: Engr. Mark Roger R Huberit Ii Civil / Structural Engineer PRC NO. 072279Document9 pagesPrepared By:: Engr. Mark Roger R Huberit Ii Civil / Structural Engineer PRC NO. 072279Mark Roger Huberit IINo ratings yet

- PowlVac 5-15kV Metal-Clad Switchgear Guide Specification v7Document8 pagesPowlVac 5-15kV Metal-Clad Switchgear Guide Specification v7ahmadgce04No ratings yet

- Cap 5Document22 pagesCap 5DIOGENES HERNANDEZNo ratings yet

- 201123-1609-HMR Fire Scheme ReportDocument4 pages201123-1609-HMR Fire Scheme ReportMine FollowerNo ratings yet

- Colged ManualDocument168 pagesColged ManualSinisa MalesevicNo ratings yet

- Bipcui 02#120216Document3 pagesBipcui 02#120216Marlon CayabyabNo ratings yet

- PDFDocument14 pagesPDFظفر حسین چوٹیال اعوانNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- 1128 Thermocouple Catalog enDocument74 pages1128 Thermocouple Catalog enNilesh ChavanNo ratings yet

- Panel EarthingDocument1 pagePanel EarthingNilesh ChavanNo ratings yet

- PLC Handbook PDFDocument119 pagesPLC Handbook PDFBudi100% (6)

- Contros Desk ListDocument1 pageContros Desk ListNilesh ChavanNo ratings yet

- Brochure AC FIREDocument8 pagesBrochure AC FIREPablo Martin Ruiz VirruetaNo ratings yet

- Planning The PanDocument44 pagesPlanning The PanVikash KumarNo ratings yet

- Cable Gland DetailsDocument1 pageCable Gland DetailsNilesh ChavanNo ratings yet

- Panel Hardware BomDocument2 pagesPanel Hardware BomNilesh ChavanNo ratings yet

- SymbolS VALVULAS-GuideDocument6 pagesSymbolS VALVULAS-GuideEnrique DguezNo ratings yet

- Datasheet of CW Junction BoxDocument1 pageDatasheet of CW Junction BoxNilesh ChavanNo ratings yet

- Junction Box HardwareDocument1 pageJunction Box HardwareNilesh ChavanNo ratings yet

- Realistic IoT vs. Visionary IoTDocument10 pagesRealistic IoT vs. Visionary IoTNilesh ChavanNo ratings yet

- No. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 43% 0 0Document2 pagesNo. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 43% 0 0Nilesh ChavanNo ratings yet

- Instrument Harware Erection BOQDocument1 pageInstrument Harware Erection BOQNilesh ChavanNo ratings yet

- Hydraulic Symbols TP 2015Document28 pagesHydraulic Symbols TP 2015Nilesh ChavanNo ratings yet

- Legend Sheet Require For Matching The SymbolDocument1 pageLegend Sheet Require For Matching The SymbolNilesh ChavanNo ratings yet

- Legend Sheet Require For Matching The SymbolDocument1 pageLegend Sheet Require For Matching The SymbolNilesh ChavanNo ratings yet

- Installation Fire Pumps-6Document1 pageInstallation Fire Pumps-6Nilesh ChavanNo ratings yet

- MDL 2Document1 pageMDL 2Nilesh ChavanNo ratings yet

- Typical P&ID Arrangement For PumpsDocument12 pagesTypical P&ID Arrangement For PumpsNilesh ChavanNo ratings yet

- KIRLOSKAR BROTHERS COOLING WATER PUMP DATASHEETSDocument1 pageKIRLOSKAR BROTHERS COOLING WATER PUMP DATASHEETSNilesh ChavanNo ratings yet

- Installation Fire Pumps-5Document1 pageInstallation Fire Pumps-5Nilesh ChavanNo ratings yet

- No. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 100% 0 0Document2 pagesNo. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 100% 0 0Nilesh ChavanNo ratings yet

- Install Fire Pump SystemsDocument1 pageInstall Fire Pump SystemsNilesh ChavanNo ratings yet

- Fire pump requirements overviewDocument1 pageFire pump requirements overviewNilesh ChavanNo ratings yet

- Installation Fire Pumps-8Document1 pageInstallation Fire Pumps-8Nilesh ChavanNo ratings yet

- Installation Fire Pumps-1Document1 pageInstallation Fire Pumps-1Nilesh ChavanNo ratings yet

- Installation Fire Pumps-4Document1 pageInstallation Fire Pumps-4Nilesh ChavanNo ratings yet

- Installation Fire Pumps-3Document1 pageInstallation Fire Pumps-3Nilesh ChavanNo ratings yet

- Minolta - Parts Manual Di251-PmDocument62 pagesMinolta - Parts Manual Di251-Pmnos218No ratings yet

- A Backpacking ChecklistDocument1 pageA Backpacking ChecklistTom Termini100% (1)

- VCP-W Vacuum Circuit Breakers (5/15 KV) : Price List PL01301006E1Document40 pagesVCP-W Vacuum Circuit Breakers (5/15 KV) : Price List PL01301006E1vanhalenfernando123100% (1)

- Construction Technology Training Institute Islamabad (Ctti)Document3 pagesConstruction Technology Training Institute Islamabad (Ctti)Tariq QaisraniNo ratings yet

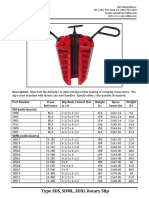

- Type SDS SDML SDXL Rotary Slip Cut SheetDocument2 pagesType SDS SDML SDXL Rotary Slip Cut SheetJose Barrero100% (1)

- Technical Offer - SQIP22039-00 30Document1 pageTechnical Offer - SQIP22039-00 30bmanojkumar16No ratings yet

- Posonic HomeAlarm EX10 & EX18 Installation Manual - Rev1.0Document54 pagesPosonic HomeAlarm EX10 & EX18 Installation Manual - Rev1.0Vlad Florescu100% (3)

- Áð. Áð. Pcs Pcs St. Piezas: Öåïü Ïëàñòèí÷àòàÿ Cha Ne Laminaire Cadena de L MinaDocument5 pagesÁð. Áð. Pcs Pcs St. Piezas: Öåïü Ïëàñòèí÷àòàÿ Cha Ne Laminaire Cadena de L MinaSergo SergoNo ratings yet

- Section 3 Hydraulic SystemDocument3 pagesSection 3 Hydraulic SystemRafał DworakNo ratings yet

- Balanced vs Unbalanced audio cablesDocument9 pagesBalanced vs Unbalanced audio cablesDreamdraft FilmsNo ratings yet

- 2 Chapter 2 Design of LocatorDocument39 pages2 Chapter 2 Design of LocatorKhaled HamdyNo ratings yet

- Inspiration Mood Board and Test PhotographsDocument7 pagesInspiration Mood Board and Test Photographsapi-483055750No ratings yet

- Abb Brake MotorDocument22 pagesAbb Brake MotorAmitesh DindaNo ratings yet

- Quick Checking of Earth LoopsDocument2 pagesQuick Checking of Earth Loopsbudi0251No ratings yet

- Cable Schedules SamplesDocument26 pagesCable Schedules SamplesansarNo ratings yet

- Caterpillar Advance Training Power Train Works WearsDocument10 pagesCaterpillar Advance Training Power Train Works Wearsjustin100% (49)

- B.4.9 S4850G1 Solar Power Module User ManualDocument4 pagesB.4.9 S4850G1 Solar Power Module User ManualGrover David Perez Huanca100% (1)

- Graphtec CE6000Document179 pagesGraphtec CE6000Christian ZepedaNo ratings yet

- Wiremold Tele-Power PolesDocument16 pagesWiremold Tele-Power PolesNathan MillerNo ratings yet

- Pp2526 Intelligent Manual Call Point Issue 1 Locked - UnlockedDocument2 pagesPp2526 Intelligent Manual Call Point Issue 1 Locked - UnlockedbluesierNo ratings yet

- Installation Manual for Two-way Cassette Type Digital Scroll and DC/AC Inverter Commercial Air-conditionerDocument15 pagesInstallation Manual for Two-way Cassette Type Digital Scroll and DC/AC Inverter Commercial Air-conditionerwalter cruzNo ratings yet

- Evolution Series E9000: Motor Control CentersDocument44 pagesEvolution Series E9000: Motor Control CentersArslan ILServicesNo ratings yet

- Orbis I.S.: Optical/Heat Multisensor DetectorDocument2 pagesOrbis I.S.: Optical/Heat Multisensor DetectorbluesierNo ratings yet

- 25RH Manual GB 2011 02 22 PDFDocument54 pages25RH Manual GB 2011 02 22 PDFSaulius KlimkeviciusNo ratings yet

- Test Mode ProceduresDocument8 pagesTest Mode ProceduresRheana DomingoNo ratings yet

- Fbs-Plc User'S Manual【Hardware】Document67 pagesFbs-Plc User'S Manual【Hardware】Igal GalilNo ratings yet

- Mingazzini-Brochure-PB EU 4pg ENGDocument4 pagesMingazzini-Brochure-PB EU 4pg ENGBelgacem ArramiNo ratings yet

- SocomecDocument18 pagesSocomecl1f3b00kNo ratings yet

- Eh tw480Document12 pagesEh tw480fefotroncitoNo ratings yet

- Ansul - Core O&imDocument64 pagesAnsul - Core O&imAmeen Hamed AlwseyNo ratings yet