Professional Documents

Culture Documents

Chapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable Water

Uploaded by

kapsarcOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable Water

Uploaded by

kapsarcCopyright:

Available Formats

CHAPTER 5 DESIGN GUIDELINES

SECTION 5.7 UTILITIES

SUBSECTION 5.7.1 POTABLE WATER

a. All pumping facilities shall be equipped with a chlorine dosing system using Cl2 gas

cylinders, located in a separate room with an exhaust fan and isolated from the rest

of the pumping facility. The design of the room shall comply with the applicable

requirements of the IBC, IFC and IMC..

b. Hypochlorite generators with a dosing pump may also be used.

c. Minimum onsite chlorine storage shall be seven days.

d. All of the system components shall be according to the manufacturer’s

recommendations to insure efficient chlorination system operation.

e. Chlorine analyzers, and sample taps shall be provided both upstream and

downstream of the injection point.

f. An emergency eye wash station, shower, and appropriate signs shall also be

provided.

5. Building

a. All booster pumps, mechanical equipment, chlorination facilities, control equipment,

electrical equipment and telemetry equipment shall be enclosed in a building. See

Section 5.2 and Subsections 5.3.4 and 5.4.2 for specific building requirements.

b. All booster pumps stations shall be equipped with a manual transfer switch and

provisions for connecting a roll-up generator to operate the pump station in the event

of a prolonged power outage. Refer to Subsection 5.3.4 for specific building

requirements.

c. Pumping stations finished floor elevations shall be graded around the station so as

to lead surface drainage away from the station. The finished floor elevation of the

pump station shall be a minimum of 150 mm above finished grade.

d. Adequate provisions shall be made for removal and replacement of the motor,

discharge column, pump, and other equipment. Provisions include roof hatches,

crane-ways, hoist beams, eyebolts, or other acceptable means.

e. Suitable HVAC shall be required. Refer to Subsection 5.4.3 for HVAC requirements.

Interior temperatures shall be maintained at no more than 40°C.

f. Emergency/back-up power shall be provided for all critical pumping facilities (life

safety services). Refer to Subsection 5.5.1.E for specific back-up power

requirements.

g. Floor drains shall be provided, except in the chlorine room. The building floor shall

slope to the drains.

h. All pumping facilities shall be fenced with a minimum 2.0 m high fence. The site

access, size and layout shall provide adequate room for maintenance of the facility,

including removal of pumps; including adequate room for the removal and

replacement of all mechanical and electrical equipment.

L. Water Storage Tanks

1. General

a. Ground Surface Water Storage Tanks

1) Water storage tank design shall comply with the following AWWA Standards:

Welded Carbon Steel Tanks for Water Storage AWWA Standard D100-11

and design manual M42

RCJ Guiding Engineering Manual

Rev. 1 5.7 - 27

CHAPTER 5 DESIGN GUIDELINES

SECTION 5.7 UTILITIES

SUBSECTION 5.7.1 POTABLE WATER

2) Factory Coated bolted steel tanks for water storage - AWWA D103-09

3) Wire and Strand-wound circular pre-stressed concrete water tanks -AWWA

D110-95

4) Tendon- pre-stressed concrete water tanks - AWWA D115-95

b. Elevated Water Storage Tanks

1) Composite welded steel elevated tanks for water storage - AWWA D107-10

(a) The materials and designs used for finished water storage structures

shall provide stability and durability as well as protect the quality of the

stored water. Steel structures shall follow the current AWWA standards

concerning steel tanks, standpipes, reservoirs, and elevated tanks

wherever they are applicable.

(b) The lowest elevation of the floor of ground level reservoirs shall be

placed at least 0.5 m above the surrounding grade, and at least 2 m

above the groundwater table.

(c) A geotechnical investigation and foundation design shall be prepared for

all tank sites.

(d) Sewers, drains, standing water, and similar sources of possible

contamination shall be kept at least 15 m from the reservoir.

(e) All finished water storage structures shall have suitable watertight roofs

which exclude birds, animals, insects, and dust. The installation of

appurtenances, such as antenna, shall be done in a manner that ensures

no damage to the tank, coatings or water quality.

(f) Fencing, locks on access manholes, and other necessary precautions

shall be provided to prevent trespassing, vandalism, and sabotage.

2. Sizing

a. Storage facilities shall have sufficient capacity, as determined during preliminary

design, to meet domestic demands; and where fire protection is provided, fire flow

demands.

1) Refer to Subsection 5.7.1.G for system demand information.

2) Fire flow and storage requirements shall be established by the IFC in

conjunction with Saudi Building Code 801, Chapter 5.

3) Excessive storage capacity shall be avoided to prevent potential water quality

deterioration problems.

4) Transmission Ground Level Storage Tank(s) capacity: five days of average

daily demand.

5) District Distribution Ground Level Storage Tank(s) capacity: two days of

average daily demand and fire storage.

6) District Distribution Elevated Storage Tank(s): one day of average daily

demand and fire storage.

3. Piping

a. Inlet: a dedicated supply line from the distribution booster pump station to the district

distribution elevated storage tank(s) is required.

RCJ Guiding Engineering Manual

Rev. 1 5.7 - 28

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesFrom EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesRating: 4.5 out of 5 stars4.5/5 (5)

- Chapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable WaterDocument1 pageChapter 5 Design Guidelines Section 5.7 Utilities Subsection 5.7.1 Potable WaterkapsarcNo ratings yet

- Chapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingDocument4 pagesChapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingkapsarcNo ratings yet

- Section 2.5 Water SupplyDocument31 pagesSection 2.5 Water SupplyDaryl BadajosNo ratings yet

- STP SpecsDocument9 pagesSTP SpecsNakclean Water SolutionsNo ratings yet

- Sewer Pump Stations and AppurtenancesDocument9 pagesSewer Pump Stations and AppurtenancesMussa ElbarraniNo ratings yet

- Specifications For Underground Water Storage Tanks For Fire ProtectionDocument5 pagesSpecifications For Underground Water Storage Tanks For Fire ProtectionkirmaniNo ratings yet

- LPG NG - Gas Malaysia Requirement - 19 06 2014Document3 pagesLPG NG - Gas Malaysia Requirement - 19 06 2014SashiNo ratings yet

- Part Eight Water Supplyand ReticulationDocument7 pagesPart Eight Water Supplyand ReticulationMacdonald FuniNo ratings yet

- Bangladesh Power Plant Cooling System TenderDocument447 pagesBangladesh Power Plant Cooling System TenderRohit GoyalNo ratings yet

- Cathodic Protection Clarifier Specification-Jun 2010Document7 pagesCathodic Protection Clarifier Specification-Jun 2010656665665No ratings yet

- HDC Engineering Code of Practice for Water SupplyDocument31 pagesHDC Engineering Code of Practice for Water SupplySharon LambertNo ratings yet

- 11/29/19 Design No. - SECTION 15580 Feedwater EquipmentDocument20 pages11/29/19 Design No. - SECTION 15580 Feedwater EquipmentJhoNo ratings yet

- Caltrain Dewatering SpecificationsDocument4 pagesCaltrain Dewatering SpecificationsHamza MamiNo ratings yet

- Iii P2Document2 pagesIii P2rizamryNo ratings yet

- Airport PlumbingDocument11 pagesAirport Plumbingquanghai1301No ratings yet

- LAX airport plumbing standardsDocument1 pageLAX airport plumbing standardsquanghai1301No ratings yet

- requirements for plumbingDocument185 pagesrequirements for plumbingpoon.davonnaNo ratings yet

- Design Manual For Fire Protection: 1. Acts & RegulationsDocument12 pagesDesign Manual For Fire Protection: 1. Acts & RegulationsgugueNo ratings yet

- Laois County Council Water Services SectionDocument7 pagesLaois County Council Water Services SectionjarrydNo ratings yet

- GRP Tank SpecDocument5 pagesGRP Tank SpecRamesh arumugamNo ratings yet

- Raw Water System Technical SpecsDocument11 pagesRaw Water System Technical SpecsChandraNo ratings yet

- P5 Draft Technical SpecificationDocument385 pagesP5 Draft Technical SpecificationScalperNo ratings yet

- SBBC Cooling Tower StandardsDocument6 pagesSBBC Cooling Tower StandardsNoushad P HamsaNo ratings yet

- 33 16 13 - Ground Storage TankDocument6 pages33 16 13 - Ground Storage TankBelford AbuhNo ratings yet

- Appendix 3.01 - M1 Technical Specification For Field Erection Tank - 120727Document15 pagesAppendix 3.01 - M1 Technical Specification For Field Erection Tank - 120727htanhNo ratings yet

- pn93 5Document26 pagespn93 5XCNo ratings yet

- Jumbo Nozzle DocumentDocument80 pagesJumbo Nozzle DocumentashishtanjeaaNo ratings yet

- Stormwater Design RequirementsDocument11 pagesStormwater Design RequirementsVinh DuongNo ratings yet

- SSG App C Des Con Guide.pdf4Document7 pagesSSG App C Des Con Guide.pdf4Shohidul IslamNo ratings yet

- Water System Design Criteria GuideDocument5 pagesWater System Design Criteria Guidejkhgvdj mnhsnjkhgNo ratings yet

- Waterproofinganddamp-Proofing Ofwbtareasin Building-RecommendationsDocument14 pagesWaterproofinganddamp-Proofing Ofwbtareasin Building-RecommendationsAnvit GadkarNo ratings yet

- Standards Followed in Design of Oil JettyDocument12 pagesStandards Followed in Design of Oil JettyMugeshNo ratings yet

- Public Water Well SpecificationsDocument5 pagesPublic Water Well SpecificationsSilvioCarrilloNo ratings yet

- Particular SpecificationsDocument5 pagesParticular SpecificationsMohammed HammadNo ratings yet

- 22 00 00PlumbingGeneralDocument4 pages22 00 00PlumbingGeneralle minhNo ratings yet

- Rfp-Keoh-2016-006 - Section V - Annex C (Iii) - Mechanical SpecificationsDocument13 pagesRfp-Keoh-2016-006 - Section V - Annex C (Iii) - Mechanical SpecificationsSam KibonNo ratings yet

- Cathodic Protection Galvanic Sacrificial SpecificationDocument6 pagesCathodic Protection Galvanic Sacrificial SpecificationMohamed Alkhawaga100% (1)

- SPEC D-Type TraducidoDocument16 pagesSPEC D-Type TraducidoOscar TapiaNo ratings yet

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-93Document14 pagesBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-93Dave LiNo ratings yet

- Marion-Howell-Oceola-Genoa Sewer and Water Design StandardsDocument14 pagesMarion-Howell-Oceola-Genoa Sewer and Water Design StandardsMarllon LobatoNo ratings yet

- 857 Fiberglass Reinforced Pipe For Gravity Sanitary SewerDocument13 pages857 Fiberglass Reinforced Pipe For Gravity Sanitary Sewershahidy9211No ratings yet

- Section 10 Specs For Cooling TowerDocument13 pagesSection 10 Specs For Cooling Towermjmehta81No ratings yet

- Plumbing - Technical Specifications PDFDocument18 pagesPlumbing - Technical Specifications PDFEdzon LacayNo ratings yet

- Elevated Water Storage Tank Specification Composite Pedestal DesignDocument11 pagesElevated Water Storage Tank Specification Composite Pedestal DesignashwiniNo ratings yet

- Code Sanitation of The PhilippinesDocument7 pagesCode Sanitation of The PhilippinesAljay ManejaNo ratings yet

- Supply & Install RO Water MakerDocument10 pagesSupply & Install RO Water MakerjrladduNo ratings yet

- HDC Engineering Code of Practice for Water Supply DesignDocument31 pagesHDC Engineering Code of Practice for Water Supply DesignUpali KarunarathneNo ratings yet

- Chennai Port Trust Notice Inviting Budgetary Offer MEE/V3/289/2020/Dy - CME (OH)Document16 pagesChennai Port Trust Notice Inviting Budgetary Offer MEE/V3/289/2020/Dy - CME (OH)Gurpreet KaurNo ratings yet

- Specs for Underground Fire TanksDocument5 pagesSpecs for Underground Fire TanksTeguh SetionoNo ratings yet

- Tank DesignDocument7 pagesTank Designbektiwidi1060No ratings yet

- Multi-Column Water Tank Construction SpecificationsDocument8 pagesMulti-Column Water Tank Construction SpecificationsJorge León IllanesNo ratings yet

- Appendix - 33A Requirements For Underground Water Tank and Fire PumpsDocument1 pageAppendix - 33A Requirements For Underground Water Tank and Fire PumpsBasil OguakaNo ratings yet

- MS 8 Diaphragm Wall Barrettes Using Hydraulic GrabDocument12 pagesMS 8 Diaphragm Wall Barrettes Using Hydraulic GrabMarwa FaroukNo ratings yet

- Mesan MXR-KM (F-K) Guide Specs r2Document4 pagesMesan MXR-KM (F-K) Guide Specs r2Renu TekumudiNo ratings yet

- Domestic Water Filtration EquipmentDocument10 pagesDomestic Water Filtration EquipmentElie HajjNo ratings yet

- Spec - Insulation Requirements For PlumbingDocument1 pageSpec - Insulation Requirements For PlumbingImtiyaz KhanNo ratings yet

- DM Section 7, Automatic Irrigation Work - 230919 - 092613Document79 pagesDM Section 7, Automatic Irrigation Work - 230919 - 092613Akhil VijaiNo ratings yet

- Chemical EngineeringDocument4 pagesChemical EngineeringAbdulvasea SaaitNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

- Specification For PumpsDocument29 pagesSpecification For PumpsEmad Rakat100% (1)

- Inch to mm Conversion Chart: Fractional and Decimal InchesDocument1 pageInch to mm Conversion Chart: Fractional and Decimal InchesIvan SimeonNo ratings yet

- Summary of Changes To ASME Section IX, 2021 Edition As Published in The Welding Journal, July, 2021Document6 pagesSummary of Changes To ASME Section IX, 2021 Edition As Published in The Welding Journal, July, 2021Menad SalahNo ratings yet

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

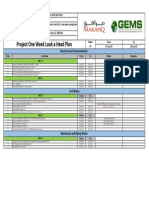

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Pump SealDocument1 pagePump SealkapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Icp-Pd-102 - CPD - 202203Document22 pagesIcp-Pd-102 - CPD - 202203HalimNo ratings yet

- Typical ARC Valve Bypass For PumpDocument1 pageTypical ARC Valve Bypass For PumpkapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet