Professional Documents

Culture Documents

Installation Fire Pumps-5

Uploaded by

Nilesh ChavanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Fire Pumps-5

Uploaded by

Nilesh ChavanCopyright:

Available Formats

GENERAL REQUIREMENTS 20–11

3.3.54.3 Pressure Control Valve. A pilot-operated pressure- 5.3 Pump Operation. In the event of fire pump operation,

reducing valve designed for the purpose of reducing the qualified personnel shall respond to the fire pump location

downstream water pressure to a specific value under both to determine that the fire pump is operating in a satisfac-

flowing (residual) and nonflowing (static) conditions. [14, tory manner.

2007]

5.4 Fire Pump Unit Performance.

3.3.54.4 Pressure-Reducing Valve. A valve designed for the

purpose of reducing the downstream water pressure under 5.4.1* The fire pump unit, consisting of a pump, driver, and

m

both flowing (residual) and nonflowing (static) conditions. controller,, shall perform in compliance with this standard as

[14, 2007] an entire unit when installed or when components have been

replaced.

3.3.54.5 Relief Valve. A device that allows the diversion of

liquid to limit excess pressure in a system. 5.4.2 The complete fire pump unit shall be field acceptance

o

tested for proper performance in accordance with the provi-

3.3.54.5.1 Circulation Relief Valve. A valve used to cool a sions of this standard. (See Section 14.2.)

pump by discharging a small quantity of water, this valve is

separate from and independent of the main relief valve. 5.5 Certified Shop Test.

c

3.3.54.6 Unloader Valve. A valve that is designed to relieve 5.5.1 Certified shop test curves showing head capacity and

brake horsepower of the pump shall be furnished by the

.

excess flow below pump capacity at set pump pressure.

manufacturer to the purchaser.

3.3.55 Variable Speed Pressure Limiting Control. A speed con-

trol system used to limit the total discharge pressure by reduc- 5.5.2 The purchaser shall furnish the data required in 5.5.1

ing the pump driver speed from rated speed. to the authority having jurisdiction.

3.3.56 Velocity Head (hv). See 3.3.23.6. 5.6 Liquid Supplies.

w

3.3.57 Wet Pit. A timber, concrete, or masonry enclosure hav- 5.6.1* Reliability. The adequacy and dependability of the wa-

ing a screened inlet kept partially filled with water by an open ter source are of primary importance and shall be fully deter-

body of water such as a pond, lake, or stream. mined, with due allowance for its reliability in the future.

x

5.6.2* Sources.

f

5.6.2.1 Any source of water that is adequate in quality, quan-

Chapter 4 Reserved tity, and pressure shall be permitted to provide the supply for a

fire pump.

z

5.6.2.2 Where the water supply from a public service main is

Chapter 5 General Requirements not adequate in quality, quantity, or pressure, an alternative

water source shall be provided.

5.1 Pumps. 5.6.2.3 The adequacy of the water supply shall be determined

b

5.1.1 This standard shall apply to centrifugal single-stage and and evaluated prior to the specification and installation of the

multistage pumps of the horizontal or vertical shaft design fire pump.

.

and positive displacement pumps of the horizontal or vertical 5.6.2.4 For liquids other than water, the liquid source for the

shaft design. pump shall be adequate to supply the maximum required flow

5.1.2 Other Pumps. rate for any simultaneous demands for the required duration

and the required number of discharges.

5.1.2.1 Pumps other than those specified in this standard and

5.6.3 Level. The minimum water level of a well or wet pit shall

w

having different design features shall be permitted to be in-

stalled where such pumps are listed by a testing laboratory. be determined by pumping at not less than 150 percent of the

fire pump rated capacity.

5.1.2.2 These pumps shall be limited to capacities of less than

500 gpm (1892 L/min). 5.6.4* Stored Supply.

5.2* Approval

oval Required. 5.6.4.1 A stored supply plus reliable automatic refill shall be

w

sufficient to meet the demand placed upon it for the design

5.2.1 Stationary pumps shall be selected based on the condi- duration.

tions under which they are to be installed and used.

5.6.4.2 A reliable method of replenishing the supply shall be

5.2.2 The pump manufacturer or its authorized representa- provided.

tive shall be given complete information concerning the liq-

w

uid and power supply characteristics. 5.6.5 Head.

5.2.3 A complete plan and detailed data describing pump, 5.6.5.1 The head available from a water supply shall be fig-

driver, controller, power supply, fittings, suction and discharge ured on the basis of a flow of 150 percent of rated capacity of

connections, and liquid supply conditions shall be prepared the fire pump.

for approval. 5.6.5.2 This head shall be as indicated by a flow test.

5.2.4 Each pump, driver, controlling equipment, power sup- 5.7 Pumps, Drivers, and Controllers.

ply and arrangement, and liquid supply shall be approved by

the authority having jurisdiction for the specific field condi- 5.7.1* Fire pumps shall be dedicated to and listed for fire pro-

tions encountered. tection service.

2007 Edition

--```,,`,,``,``,,`,,,```,`,``,,-`-`,,`,,`,`,,`---

You might also like

- Contros Desk ListDocument1 pageContros Desk ListNilesh ChavanNo ratings yet

- PLC Handbook PDFDocument119 pagesPLC Handbook PDFBudi100% (6)

- Brochure AC FIREDocument8 pagesBrochure AC FIREPablo Martin Ruiz VirruetaNo ratings yet

- 1128 Thermocouple Catalog enDocument74 pages1128 Thermocouple Catalog enNilesh ChavanNo ratings yet

- Panel EarthingDocument1 pagePanel EarthingNilesh ChavanNo ratings yet

- SymbolS VALVULAS-GuideDocument6 pagesSymbolS VALVULAS-GuideEnrique DguezNo ratings yet

- Planning The PanDocument44 pagesPlanning The PanVikash KumarNo ratings yet

- Cable Gland DetailsDocument1 pageCable Gland DetailsNilesh ChavanNo ratings yet

- Realistic IoT vs. Visionary IoTDocument10 pagesRealistic IoT vs. Visionary IoTNilesh ChavanNo ratings yet

- Junction Box HardwareDocument1 pageJunction Box HardwareNilesh ChavanNo ratings yet

- Instrument Harware Erection BOQDocument1 pageInstrument Harware Erection BOQNilesh ChavanNo ratings yet

- Legend Sheet Require For Matching The SymbolDocument1 pageLegend Sheet Require For Matching The SymbolNilesh ChavanNo ratings yet

- Panel Hardware BomDocument2 pagesPanel Hardware BomNilesh ChavanNo ratings yet

- Hydraulic Symbols TP 2015Document28 pagesHydraulic Symbols TP 2015Nilesh ChavanNo ratings yet

- Legend Sheet Require For Matching The SymbolDocument1 pageLegend Sheet Require For Matching The SymbolNilesh ChavanNo ratings yet

- Installation Fire Pumps-6Document1 pageInstallation Fire Pumps-6Nilesh ChavanNo ratings yet

- Data Sheet of CW Speed SensorDocument1 pageData Sheet of CW Speed SensorNilesh ChavanNo ratings yet

- No. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 43% 0 0Document2 pagesNo. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 43% 0 0Nilesh ChavanNo ratings yet

- Datasheet of CW Junction BoxDocument1 pageDatasheet of CW Junction BoxNilesh ChavanNo ratings yet

- MDL 2Document1 pageMDL 2Nilesh ChavanNo ratings yet

- No. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 100% 0 0Document2 pagesNo. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 100% 0 0Nilesh ChavanNo ratings yet

- Typical P&ID Arrangement For PumpsDocument12 pagesTypical P&ID Arrangement For PumpsNilesh ChavanNo ratings yet

- Installation Fire Pumps-4Document1 pageInstallation Fire Pumps-4Nilesh ChavanNo ratings yet

- Installation Fire Pumps-7Document1 pageInstallation Fire Pumps-7Nilesh ChavanNo ratings yet

- Installation Fire Pumps-8Document1 pageInstallation Fire Pumps-8Nilesh ChavanNo ratings yet

- Installation Fire Pumps-9Document1 pageInstallation Fire Pumps-9Nilesh ChavanNo ratings yet

- Installation Fire Pumps-2Document1 pageInstallation Fire Pumps-2Nilesh ChavanNo ratings yet

- Installation Fire Pumps-3Document1 pageInstallation Fire Pumps-3Nilesh ChavanNo ratings yet

- Installation Fire Pumps-1Document1 pageInstallation Fire Pumps-1Nilesh ChavanNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Nasa Corrugated Hose FlowDocument2 pagesNasa Corrugated Hose Flowpatdh1028No ratings yet

- MTC 02 W Throttle Check Valve (320BAR)Document4 pagesMTC 02 W Throttle Check Valve (320BAR)박준용No ratings yet

- Parker Valve Industrial DIN Slip-In Cartridge Valves PDFDocument130 pagesParker Valve Industrial DIN Slip-In Cartridge Valves PDFWedneslao LopezNo ratings yet

- Cylinder 81 LTRDocument2 pagesCylinder 81 LTRMarwa AlkarakiNo ratings yet

- Sostenedora Presion BERMADDocument6 pagesSostenedora Presion BERMADguzman_10No ratings yet

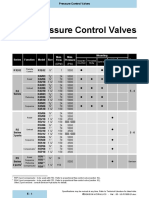

- Pressure Control Valves: Mounting Series Function Model Size Max. Flow Max. PressureDocument3 pagesPressure Control Valves: Mounting Series Function Model Size Max. Flow Max. Pressureshahrol effendy rodziNo ratings yet

- Asahi - y Sediment StrainerDocument2 pagesAsahi - y Sediment StrainerLaskar PejuangNo ratings yet

- RFI-3458 - Daily Fit Up Inspection Report-OKDocument24 pagesRFI-3458 - Daily Fit Up Inspection Report-OKnguyennamxmNo ratings yet

- 58 Lpg-Aaa A2016 SrreportDocument122 pages58 Lpg-Aaa A2016 SrreportCire Lop CastroNo ratings yet

- Agf CatalogDocument24 pagesAgf Catalogarvint_1999No ratings yet

- Inspection Checklist For: Control ValvesDocument2 pagesInspection Checklist For: Control Valvesabdelkader benabdallahNo ratings yet

- Process Line SizingDocument21 pagesProcess Line Sizingsj_scribdNo ratings yet

- 10 - Hydraulic Jump and Its Usefulness in The Design of Irrigation StructuresDocument11 pages10 - Hydraulic Jump and Its Usefulness in The Design of Irrigation StructuresSandeep sahNo ratings yet

- CV Equations Used in HysysDocument3 pagesCV Equations Used in HysysBesan LaduNo ratings yet

- Vehicle AerodynamicsDocument31 pagesVehicle AerodynamicsNimisha Singh100% (1)

- Effect of Time On Pipe RoughnessDocument11 pagesEffect of Time On Pipe Roughnessmostafa shahrabiNo ratings yet

- LF020Document6 pagesLF020Sandeep RapakaNo ratings yet

- Design Improvement of Radial Flow Submersible Pump Using CFDDocument61 pagesDesign Improvement of Radial Flow Submersible Pump Using CFDSavalia HardikNo ratings yet

- CFD Modelling and Simulation of Jet Mixed Tanks PDFDocument18 pagesCFD Modelling and Simulation of Jet Mixed Tanks PDFMohammed GallowNo ratings yet

- 02 Airfoil ADocument23 pages02 Airfoil Abecool_bcn75No ratings yet

- CFD Analysis of Pelton TurbineDocument4 pagesCFD Analysis of Pelton TurbineSanam ManutdNo ratings yet

- Gas LooplinestptDocument64 pagesGas Looplinestptniyo7No ratings yet

- Hangers and Supports For Hvac Piping and EquipmentDocument10 pagesHangers and Supports For Hvac Piping and EquipmentAmeen Mohamed Ali SanadNo ratings yet

- Naca 66 Mod A 0 - 8 PDFDocument46 pagesNaca 66 Mod A 0 - 8 PDFDerli Amaral33% (3)

- SBH 00 02c Aa DW TM 0004 Rev.01 Water SupplyDocument12 pagesSBH 00 02c Aa DW TM 0004 Rev.01 Water SupplyAnonymous NR3qZ30No ratings yet

- Tutorial 5Document13 pagesTutorial 5clarence limNo ratings yet

- Spe 176089 MS PDFDocument11 pagesSpe 176089 MS PDFatilio martinezNo ratings yet

- Kaplan Design Marko KogovsekDocument10 pagesKaplan Design Marko KogovsekIvan Batistic BeloNo ratings yet

- Basic Control ValveDocument59 pagesBasic Control ValveChiheb KaanicheNo ratings yet

- BSB-SAFETY-RELIEF-VALVE (PSV Combined With Rupture Disk)Document8 pagesBSB-SAFETY-RELIEF-VALVE (PSV Combined With Rupture Disk)LudiNo ratings yet