Professional Documents

Culture Documents

Installation Fire Pumps-9

Uploaded by

Nilesh ChavanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Fire Pumps-9

Uploaded by

Nilesh ChavanCopyright:

Available Formats

GENERAL REQUIREMENTS 20–15

5.14.9.2 The following devices shall be permitted in the suc- 5.16* Valve Supervision.

tion piping where the following requirements are met:

5.16.1 Supervised Open. Where provided, the suction valve,

(1) Check valves and backflow prevention devices and assem- discharge valve, bypass valves, and isolation valves on the back-

blies shall be permitted where required by other NFPA flow prevention device or assembly shall be supervised open

standards or the authority having jurisdiction. by one of the following methods:

(2) Where the authority having jurisdiction requires positive (1) Central station, proprietary,, or remote station signaling

pressure to be maintained on the suction piping, a

m

service

pressure-sensing line for a low suction throttling valve, (2) Local signaling service that will cause the sounding of an

specifically listed for fire pump service, shall be permitted audible signal at a constantly attended point

to be connected to the suction piping. (3) Locking valves open

(3) Devices shall be permitted to be installed in the suction

o

(4) Sealing of valves and approved weekly recorded inspec-

supply piping or stored water supply and arranged to ac- tion where valves are located within fenced enclosures un-

tivate a signal if the pump suction pressure or water level der the control of the owner

falls below a predetermined minimum.

(4) Suction strainers shall be permitted to be installed in the 5.16.2 Supervised Closed. The test outlet control valves shall

c

suction piping where required by other sections of this be supervised closed.

standard.

.

5.17* Protection of Piping Against Damage Due to Movement.

(5) Other devices specifically permitted or required by this

A clearance of not less than 1 in. (25 mm) shall be provided

standard shall be permitted.

around pipes that pass through walls or floors.

5.14.10* Vortex Plate. For pump(s) taking suction from a 5.18 Relief Valves for Centrifugal Pumps.

stored water supply, a vortex plate shall be installed at the

5.18.1* General.

w

entrance to the suction pipe. (See Figure A.6.3.1.)

5.15 Discharge Pipe and Fittings. 5.18.1.1 Where a diesel engine fire pump is installed and

where a total of 121 percent of the net rated shutoff (churn)

5.15.1 The discharge components shall consist of pipe, pressure plus the maximum static suction pressure, adjusted

x

valves, and fittings extending from the pump discharge flange for elevation, exceeds the pressure for which the system com-

to the system side of the discharge valve. ponents are rated, a pressure relief valve shall be installed.

f

5.15.2 The pressure rating of the discharge components shall 5.18.1.2* Pressure relief valves shall be used only where spe-

be adequate for the maximum total discharge head with the cifically permitted by this standard.

pump operating at shutoff and rated speed, but not less than

z

the rating of the fire protection system. 5.18.1.3 Where an electric variable speed pressure limiting

control driver is installed, and the maximum total discharge

5.15.3* Steel pipe with flanges, screwed joints, or mechanical head adjusted for elevation with the pump operating at shut-

grooved joints shall be used above ground. off and rated speed exceeds the pressure rating of the system

components, a pressure relief valve shall be installed.

b

5.15.4 All pump discharge ge pipe shall be hydrostatically tested

in accordance with NFPA 13, Standard for the Installation of 5.18.2 Size. The relief valve size shall be determined by one of

.

Sprinkler Systems, and NFPA 24, Standard for the Installation of the methods specified in 5.18.2.1 or 5.18.2.2.

Private Firee Service Mains and Their Appurtenances. 5.18.2.1* The relief valve shall be permitted to be sized hy-

5.15.5* The size of pump discharge pipe and fittings shall not draulically to discharge sufficient water to prevent the pump

be less than that given in Section 5.25. discharge pressure, adjusted for elevation, from exceeding the

pressure rating of the system components.

w

5.15.6* A listed check valve or backflow preventer shall be

installed in the pump discharge assembly. 5.18.2.2 If the relief valve is not sized hydraulically, the relief

valve size shall not be less than that given in Section 5.25. (See

5.15.7 A listed indicating gate or butterfly valve shall be in- also 5.18.7 and A.5.18.7 for conditions that affect size.)

stalled on the fire protection system side of the pump dis-

charge

ge check valve. 5.18.3 Location. The relief valve shall be located between the

w

pump and the pump discharge check valve and shall be so

5.15.8 Where pumps are installed in series, a butterfly valve attached that it can be readily removed for repairs without

shall not be installed between pumps. disturbing the piping.

5.15.9 Low Suction Throttling Valves. 5.18.4 Type.

5.18.4.1 Pressure relief valves shall be either a listed spring-

w

5.15.9.1 Low suction throttling valves that are listed for fire

pump service and that are suction pressure sensitive shall be loaded or pilot-operated diaphragm type.

permitted where the authority having jurisdiction requires 5.18.4.2 Pilot-operated pressure relief valves, where attached

positive pressure to be maintained on the suction piping. to vertical shaft turbine pumps, shall be arranged to prevent

relieving of water at water pressures less than the pressure

5.15.9.2 Where required, the low suction throttling valves

relief setting of the valve.

shall be installed between the pump and the discharge check

valve. 5.18.5* Discharge.

5.15.10 No pressure-regulating devices shall be installed in 5.18.5.1 The relief valve shall discharge into an open pipe or

the discharge pipe except as permitted in this standard. into a cone or funnel secured to the outlet of the valve.

2007 Edition

You might also like

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineFrom EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineRating: 5 out of 5 stars5/5 (1)

- NFPA-20-fire Pump ReliefDocument3 pagesNFPA-20-fire Pump ReliefhossameldeenNo ratings yet

- Muc 5-14.2 NFPA13-1999 PDFDocument3 pagesMuc 5-14.2 NFPA13-1999 PDFambition1340cnNo ratings yet

- Nfpa 20 (Fire Pump and Piping Components On Suction Side)Document3 pagesNfpa 20 (Fire Pump and Piping Components On Suction Side)design sseNo ratings yet

- Nfpa 20 ReviewedDocument6 pagesNfpa 20 Reviewedakill3rNo ratings yet

- Fire Pum Installation Checklist S.No. Check Points Ok Not Ok Remarks GeneralDocument4 pagesFire Pum Installation Checklist S.No. Check Points Ok Not Ok Remarks GeneralSSO SAFETYNo ratings yet

- Automatic Sprinkler (Control, Gauges & Alarms)Document6 pagesAutomatic Sprinkler (Control, Gauges & Alarms)rmaffireschoolNo ratings yet

- Tank Interior: Annex ADocument1 pageTank Interior: Annex AMd. Fozlul Korim SumonNo ratings yet

- Foam System Specification PDFDocument22 pagesFoam System Specification PDFpequenita34No ratings yet

- Lessons Learned-FINAL-NEW PDFDocument8 pagesLessons Learned-FINAL-NEW PDFImtinan MohsinNo ratings yet

- HD 247 Alarm Valve Model-HDocument16 pagesHD 247 Alarm Valve Model-HAjjuParmarNo ratings yet

- Installation Fire Pumps-6Document1 pageInstallation Fire Pumps-6Nilesh ChavanNo ratings yet

- Application Data - Fire Pump Fittings: Minimum Fitting SystemDocument2 pagesApplication Data - Fire Pump Fittings: Minimum Fitting Systemاحمد الجزار2007No ratings yet

- Model Umc Faq'S: 4077 Airpark Dr. Standish, MI 48658 - 989-846-4583 - Technical Support 989-414-2600Document6 pagesModel Umc Faq'S: 4077 Airpark Dr. Standish, MI 48658 - 989-846-4583 - Technical Support 989-414-2600Mark Louie GuintoNo ratings yet

- Standard For The Inspection, Testing, and Maintenance of Water-Based Fire Protection SystemsDocument2 pagesStandard For The Inspection, Testing, and Maintenance of Water-Based Fire Protection SystemsBarkat UllahNo ratings yet

- I & M Mark 57: Ideal InstallationDocument4 pagesI & M Mark 57: Ideal Installationbenzerga karimNo ratings yet

- I & M 6800HP Series: Ideal Installation SchematicDocument4 pagesI & M 6800HP Series: Ideal Installation SchematicMultilibros VillamontesNo ratings yet

- Trimpac™ Pneumatically Operated Deluge SystemDocument1 pageTrimpac™ Pneumatically Operated Deluge SystemmamunfauziNo ratings yet

- Digital Control Valve (Brodie, BV88) - ENGDocument28 pagesDigital Control Valve (Brodie, BV88) - ENGKovalyk DmitriyNo ratings yet

- Installation, Operation and Maintenance Manual: CRANE® Cast Steel ValvesDocument44 pagesInstallation, Operation and Maintenance Manual: CRANE® Cast Steel ValveszumrottNo ratings yet

- T NFPA 20 T Chapter 4 General Requirements: Section 4.28Document2 pagesT NFPA 20 T Chapter 4 General Requirements: Section 4.28AnoirNo ratings yet

- Section 19: Plumbing Work 02: Water Distribution: 2.6.2 Drain TapsDocument3 pagesSection 19: Plumbing Work 02: Water Distribution: 2.6.2 Drain TapsAfnanMuhammadNo ratings yet

- RP Is 009 009 FS+2214Document8 pagesRP Is 009 009 FS+2214Prabath KNo ratings yet

- WaterWorker Vertical Well Tank Installation ManualDocument12 pagesWaterWorker Vertical Well Tank Installation ManualS100% (1)

- Fire Pump, Motor and ControllerDocument3 pagesFire Pump, Motor and Controllerعامر شیخNo ratings yet

- Fire Nfpa 20Document25 pagesFire Nfpa 20BRANDON100% (2)

- Deluge Valve ADocument14 pagesDeluge Valve APatel MehulkumarNo ratings yet

- QCP-10 Hydrotest and Flushing ProcedureDocument15 pagesQCP-10 Hydrotest and Flushing ProcedureIbrahim67% (3)

- Fire Water Pump Rules Nfpa 20Document8 pagesFire Water Pump Rules Nfpa 20kenoly123No ratings yet

- Operational and Installation Guidelines "CDP" Series Booster PumpDocument2 pagesOperational and Installation Guidelines "CDP" Series Booster PumpEliana GuzmanNo ratings yet

- Model ZW209FP: Installation Start-Up Maintenance InstructionsDocument5 pagesModel ZW209FP: Installation Start-Up Maintenance InstructionsRanses RomanNo ratings yet

- hd127 Double Interlock Elec Elec Release - 2Document6 pageshd127 Double Interlock Elec Elec Release - 2Benny Kurniawan LimNo ratings yet

- Deluge Valve ADocument14 pagesDeluge Valve ASiddharth GupteNo ratings yet

- Section 15F Sprinkler System: Construction Master Specifications Fitout WorksDocument6 pagesSection 15F Sprinkler System: Construction Master Specifications Fitout WorksMark Roger II HuberitNo ratings yet

- Trainer GuideDocument16 pagesTrainer GuideCrystal DavisNo ratings yet

- 11 Weekly Inspection of Pump System ConditionsDocument9 pages11 Weekly Inspection of Pump System Conditionsm.sofiqur rahmanNo ratings yet

- Text Section 5Document11 pagesText Section 5Jorge ValdezNo ratings yet

- Equipment Descriptions, Operating Characteristics, and Requirements PDFDocument50 pagesEquipment Descriptions, Operating Characteristics, and Requirements PDFHKHKBOOKSNo ratings yet

- Re 07700Document2 pagesRe 07700Ahmed Abd ElhakeemNo ratings yet

- Model ZW209FP: Installation Start-Up Maintenance InstructionsDocument4 pagesModel ZW209FP: Installation Start-Up Maintenance InstructionsTomer RosenNo ratings yet

- The Piping Engineering WorldDocument4 pagesThe Piping Engineering WorldHrishikesh PatilNo ratings yet

- Chapter 05Document4 pagesChapter 05Rajkumar MaruthaiNo ratings yet

- Condensate SystemDocument2 pagesCondensate SystemAriNdoloeNo ratings yet

- p100 - 13 Could BeDocument4 pagesp100 - 13 Could BeEudaldo SaltosNo ratings yet

- Multiple Foam Deluge SystemDocument10 pagesMultiple Foam Deluge SystemTrần VânNo ratings yet

- Fire PumpsDocument46 pagesFire PumpsMd. Biplob HossainNo ratings yet

- Installation Fire Pumps-8Document1 pageInstallation Fire Pumps-8Nilesh ChavanNo ratings yet

- Procurement and Installation: Approved: H. Zoghbi Signed Original On FileDocument9 pagesProcurement and Installation: Approved: H. Zoghbi Signed Original On Filed r hardyNo ratings yet

- Chemgaurd Bladder Tank Design and System Installation PDFDocument7 pagesChemgaurd Bladder Tank Design and System Installation PDFVignesh WaranNo ratings yet

- Im 306Document10 pagesIm 306Iwan SetiawanNo ratings yet

- Valvula de Diluvio-TycoDocument14 pagesValvula de Diluvio-TycoAlejandro JoseNo ratings yet

- 9/27/01 AC 43.13-1B CHG 1: Figure 12-5. Pitot/static System For A Small AircraftDocument5 pages9/27/01 AC 43.13-1B CHG 1: Figure 12-5. Pitot/static System For A Small Aircraftaerogem618No ratings yet

- Fire Sprinkler System DesignDocument3 pagesFire Sprinkler System DesignAhrian BenaNo ratings yet

- Rupk 78Document39 pagesRupk 78puccio78No ratings yet

- Suction Pressure NFPA ClauseDocument1 pageSuction Pressure NFPA Clausebhima irabattiNo ratings yet

- 90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControlDocument2 pages90G-21/90A-21 UL: UL Listed Pilot-Operated Pressure ControllesterNo ratings yet

- BPRVDocument18 pagesBPRVPatel UsamaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsFrom EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsNo ratings yet

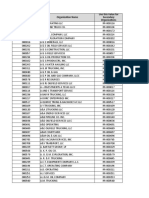

- Contros Desk ListDocument1 pageContros Desk ListNilesh ChavanNo ratings yet

- PLC Handbook PDFDocument119 pagesPLC Handbook PDFBudi100% (6)

- Brochure AC FIREDocument8 pagesBrochure AC FIREPablo Martin Ruiz VirruetaNo ratings yet

- 1128 Thermocouple Catalog enDocument74 pages1128 Thermocouple Catalog enNilesh ChavanNo ratings yet

- Panel EarthingDocument1 pagePanel EarthingNilesh ChavanNo ratings yet

- SymbolS VALVULAS-GuideDocument6 pagesSymbolS VALVULAS-GuideEnrique DguezNo ratings yet

- Planning The PanDocument44 pagesPlanning The PanVikash KumarNo ratings yet

- Cable Gland DetailsDocument1 pageCable Gland DetailsNilesh ChavanNo ratings yet

- Realistic IoT vs. Visionary IoTDocument10 pagesRealistic IoT vs. Visionary IoTNilesh ChavanNo ratings yet

- Junction Box HardwareDocument1 pageJunction Box HardwareNilesh ChavanNo ratings yet

- Instrument Harware Erection BOQDocument1 pageInstrument Harware Erection BOQNilesh ChavanNo ratings yet

- Legend Sheet Require For Matching The SymbolDocument1 pageLegend Sheet Require For Matching The SymbolNilesh ChavanNo ratings yet

- Panel Hardware BomDocument2 pagesPanel Hardware BomNilesh ChavanNo ratings yet

- Hydraulic Symbols TP 2015Document28 pagesHydraulic Symbols TP 2015Nilesh ChavanNo ratings yet

- Legend Sheet Require For Matching The SymbolDocument1 pageLegend Sheet Require For Matching The SymbolNilesh ChavanNo ratings yet

- Installation Fire Pumps-6Document1 pageInstallation Fire Pumps-6Nilesh ChavanNo ratings yet

- Data Sheet of CW Speed SensorDocument1 pageData Sheet of CW Speed SensorNilesh ChavanNo ratings yet

- No. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 43% 0 0Document2 pagesNo. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 43% 0 0Nilesh ChavanNo ratings yet

- Datasheet of CW Junction BoxDocument1 pageDatasheet of CW Junction BoxNilesh ChavanNo ratings yet

- MDL 2Document1 pageMDL 2Nilesh ChavanNo ratings yet

- No. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 100% 0 0Document2 pagesNo. of Drawings Submitted To Client For Approval 0 0% 0 0% 3 100% 0 0Nilesh ChavanNo ratings yet

- Typical P&ID Arrangement For PumpsDocument12 pagesTypical P&ID Arrangement For PumpsNilesh ChavanNo ratings yet

- Installation Fire Pumps-4Document1 pageInstallation Fire Pumps-4Nilesh ChavanNo ratings yet

- Installation Fire Pumps-7Document1 pageInstallation Fire Pumps-7Nilesh ChavanNo ratings yet

- Installation Fire Pumps-8Document1 pageInstallation Fire Pumps-8Nilesh ChavanNo ratings yet

- Installation Fire Pumps-5Document1 pageInstallation Fire Pumps-5Nilesh ChavanNo ratings yet

- Installation Fire Pumps-2Document1 pageInstallation Fire Pumps-2Nilesh ChavanNo ratings yet

- Installation Fire Pumps-3Document1 pageInstallation Fire Pumps-3Nilesh ChavanNo ratings yet

- Installation Fire Pumps-1Document1 pageInstallation Fire Pumps-1Nilesh ChavanNo ratings yet

- Lab Experiment: Viscosity and Density: September 18, 2018Document15 pagesLab Experiment: Viscosity and Density: September 18, 2018Luqman HakimNo ratings yet

- D6M Test Hydraulic SystemDocument21 pagesD6M Test Hydraulic SystemTeresa Marina Peralta100% (3)

- Castrol Seamax Super Plus Is A SAE 15W-40 Using Castrol Seamax Super PlusDocument2 pagesCastrol Seamax Super Plus Is A SAE 15W-40 Using Castrol Seamax Super PlusKaly7No ratings yet

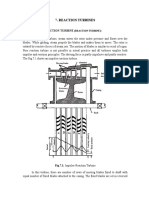

- Unit 4 (Reaction Turbines.) 1Document12 pagesUnit 4 (Reaction Turbines.) 1amarparimiNo ratings yet

- 9 - Horizontal Flare Knock Out Drum Sizing1Document2 pages9 - Horizontal Flare Knock Out Drum Sizing1Anonymous APc7I7100% (1)

- Hydraulic Cartridge Logic Valves - Hydraulic ValveDocument2 pagesHydraulic Cartridge Logic Valves - Hydraulic Valveasif bashaNo ratings yet

- Centrifugal Flow CompressorDocument20 pagesCentrifugal Flow CompressorJohnNo ratings yet

- Listings of Texas A&M Pump Users Symposiums Proceedings From 1984 To 2013Document116 pagesListings of Texas A&M Pump Users Symposiums Proceedings From 1984 To 2013jehodgsonNo ratings yet

- Hydroelectric System DesignDocument113 pagesHydroelectric System DesignMichael Joseph Beltran Samson100% (1)

- Ec 0411 PDFDocument7 pagesEc 0411 PDFmhasansharifiNo ratings yet

- AMSOIL 5W-40 Premium API CJ-4 Synthetic Diesel Oil - DEODocument2 pagesAMSOIL 5W-40 Premium API CJ-4 Synthetic Diesel Oil - DEOamsoildealerNo ratings yet

- Water Treatment System-Iit NoteDocument14 pagesWater Treatment System-Iit NoteBhaswar MajumderNo ratings yet

- Open Channel FlowDocument161 pagesOpen Channel FlowJuan HeroNo ratings yet

- Lecture-3 Crude Oil PropertiesDocument61 pagesLecture-3 Crude Oil PropertiesMrHemFun100% (1)

- WCSA Catalogue2019 EmailDocument96 pagesWCSA Catalogue2019 EmailjuniNo ratings yet

- 222 34-10-7 Well Testing Report DST2Document62 pages222 34-10-7 Well Testing Report DST2evio guierrezNo ratings yet

- Reservoir Module Reservoir EvaluationDocument7 pagesReservoir Module Reservoir EvaluationSean MiddletonNo ratings yet

- Arab Gulf FOB Mean PricesDocument2 pagesArab Gulf FOB Mean PricesRASHID AHMED SHAIKHNo ratings yet

- Water DisadvantagesDocument2 pagesWater DisadvantagesHoy Seng KokNo ratings yet

- Goulds Residential Pump Guide PDFDocument44 pagesGoulds Residential Pump Guide PDFSyed Muztuza Ali100% (1)

- Piston and Bladder Type Safety Note: Applications: Hydraulic AccumulatorsDocument3 pagesPiston and Bladder Type Safety Note: Applications: Hydraulic AccumulatorsconimecNo ratings yet

- Gas Dynamics and Jet Propulsion - NewDocument12 pagesGas Dynamics and Jet Propulsion - NewShanmugam SNo ratings yet

- Basics of Lattice Boltzmann Method For Fluid FlowsDocument27 pagesBasics of Lattice Boltzmann Method For Fluid FlowsSajjad Rasool ChaudhryNo ratings yet

- Hague Water Max Technical SpecsDocument1 pageHague Water Max Technical Specskshepard_182786911No ratings yet

- 2014 - 001 Introduction To House PlumbingDocument16 pages2014 - 001 Introduction To House PlumbingRon Julienne RebugioNo ratings yet

- Activity No. 4 Oblique Shock WavesDocument12 pagesActivity No. 4 Oblique Shock WavesFe Rosales Montante DizonNo ratings yet

- Exp 4 and Data ShammaDocument4 pagesExp 4 and Data ShammaAhmed ShammaNo ratings yet

- JNTU Old Question Papers 2007Document7 pagesJNTU Old Question Papers 2007Srinivasa Rao G100% (1)

- Tutorial 3 - jan2015.PDF (Fluid Mech)Document4 pagesTutorial 3 - jan2015.PDF (Fluid Mech)pijechadNo ratings yet

- RR Orgs Ramp IdmDocument268 pagesRR Orgs Ramp IdmJack deFRAUDSTERNo ratings yet