Professional Documents

Culture Documents

Chevron EN 2018 CR PDF

Uploaded by

anon_464848664Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chevron EN 2018 CR PDF

Uploaded by

anon_464848664Copyright:

Available Formats

DUNLOP SUPERFORT CHEVRON

PROFILED BELTS

THE TOUGHEST, LONGEST LASTING CHEVRON BELTING

IN THE WORLD

EXCEPTIONALLY

STRONG MOULDED CHEVRONS

CHEVRON AND HIGH CHEVRON BELTS

Dunlop Superfort ‘super strength’ chevron belts are quite simply the

OUTSTANDING WEAR

strongest and most reliable chevron belts available today. Unlike most RESISTANCE AND DURABILITY

other manufacturers, Dunlop profiles are moulded and vulcanised in one

continuous production process together with the base belt. This creates

a single, homogeneous belt structure that is far stronger than belts that EXCELLENT TENSILE

have the chevrons attached separately. Another key advantage is that this STRENGTH WITH LOW ELONGATION

integral strength allows the use of smaller pulley diameters.

►► Exclusively manufactured in Holland

The ultra-strong Dunlop Superfort and Dunloflex carcasses with their

polyester-nylon (EP) fabric plies provide low elongation (stretch) and ►► Super-strong homogeneous belt structure

are impervious to moisture. They significantly exceed the international ►► Available in 16mm and 32mm chevron height

standards for tensile strength at break (for both the carcass and the options

covers), adhesion between the plies and adhesion between the covers and

►► Outstanding wear resistance and durability

the carcass.

►► 100% ozone and UV resistant

APPLICATIONS ►► Low elongation

There are two chevron height sizes to choose from – 16mm (low chevron)

and 32mm (high chevron). The 16mm high profile is typically suitable for ►► Available in belt widths from

500mm up to 1600mm

smaller lump sizes and conveyor angles up to 20 to 25 degrees. For larger

lump sizes and steeper inclinations the 32mm high chevron profile will ►► Safe to handle – fully compliant with REACH

provide the best results. Dunlop Superfort ‘super strength’ chevron belts regulations

can handle everything from light duty applications up to the very heaviest,

►► Two-year guarantee against faulty

toughest materials and the most challenging working environments. workmanship and/or materials

AVAILABILTY

Standard profile widths range from 400mm up to 1600mm, depending on

profile type. Dunlop ‘super strength’ chevron belts are available in RA (high

abrasion resistant), and ROS (mineral oil resistant) qualities. Other cover

grades are available on request. All Dunlop chevron belts are supplied with

moulded edges.

HELPLINE ADDITIONAL INFORMATION

+31 (0) 512 585 555 WWW.DUNLOPCB.COM

We are never more than a phone call away when our customers need our help or advice. This service is

extremely well supported by our extensive network of highly reputable Dunlop Authorised Distributors,

Vulcanisers and Approved Agents.

UNRIVALLED TECHNICAL SUPPORT

AND GUIDANCE

When you buy from Dunlop you get more than just quality conveyor

belts because we have one of the largest, most experienced and

highly trained teams of conveyor belt specialists and application

engineers in the industry.

Dunlop provide an unrivalled level of customer service — visiting

our customers on‑site, providing advice, guidance and practical

support including:

■■ Site visits and surveys

■■ Belt calculation services

LOW CHEVRON

■■ Technical training (on-site and Dunlop based)

■■ Splice training

■■ Trouble shooting and problem solving

■■ In-house research, testing and development

■■ After-sales support

HIGH CHEVRON

SUPER-TOUGH ‘LONG LIFE’

COVER GRADES OZONE & UV RESISTANCE

To provide optimum carcass protection, Dunlop RA covers are fitted as Unlike the vast majority of our competitor’s products, (especially

standard because of its excellent resistance to cutting combined with products originating from the Far East) our profiled belts are fully

outstanding resistance to abrasion. Dunlop RA significantly exceeds resistant to ozone and ultraviolet according to EN/ISO 1431 testing.

the requirements for the DIN Y abrasion resistant standard. Other

qualities, such as oil, resistant covers are available. All Dunlop cover At ground level, ozone is a pollutant. It increases the acidity of

qualities are antistatic according to EN ISO 284 and are extensively carbon black surfaces and causes reactions to take place within the

ozone tested in compliance with EN ISO 1431 ozone resistance (50 molecular structure of the rubber. The consequences include surface

pphm, strain 20%, 96 hours no cracking) and resistant to the damaging cracking (allowing moisture and small particles to penetrate) and a

effects of ultraviolet in order to avoid premature failure due to cracking decrease in the tensile strength of the rubber. Ultraviolet light from

of the belt surface. All Dunlop cover qualities perform well beyond the sunlight and fluorescent lighting accelerates the deterioration of

minimum requirements of the international standards and comply to rubber because it produces photochemical reactions that promote

REACH regulations. the oxidation of the surface of the rubber. This results in a loss in

mechanical strength creating a tendency to tear and rip much too

easily. Its excellent resistance to the effects of ozone and ultra-

violet is yet another reason why genuine Dunlop “Made in Holland”

products last so much longer.

All information and recommendations in this bulletin have been supplied to the best of our knowledge,

as accurately as possible and updated to reflect the most recent technological developments. We cannot

accept any responsibility for recommendations based solely on this document.

The Netherlands (Head Office) +31 (0) 512 585 555 • France +33 (0) 130555419 • Spain +34 (0) 93 770 45 97 • Italy +39 0363 906266 •

Poland +48 (0) 32 218 5070 • Morocco +212 (0) 522 34 65 80/85 • Russia +7 495 780 88 64 • United Arab Emirates +971 (0) 4 880 6337

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CH 7 Solution & Electrolytes UpdatedDocument50 pagesCH 7 Solution & Electrolytes UpdatedbasitaleeNo ratings yet

- Getinet TamiruDocument75 pagesGetinet TamiruMezgebu BiresawNo ratings yet

- Cipac MT - 2021Document3 pagesCipac MT - 2021Milan DamjanovicNo ratings yet

- Pharmaceutics I Theory and Practical ForDocument21 pagesPharmaceutics I Theory and Practical ForNitin SharmaNo ratings yet

- Mechanism of DBTO CatalystDocument8 pagesMechanism of DBTO Catalystsahajahan shaikhNo ratings yet

- Covalent Bonding v1.0Document45 pagesCovalent Bonding v1.0jt100% (1)

- FYP Presentation Schedule CL-R0Document5 pagesFYP Presentation Schedule CL-R0Cheau KimNo ratings yet

- 6 Chemistry of Car Ban IonsDocument17 pages6 Chemistry of Car Ban Ionsshivanagendra koya100% (1)

- DEE-920-12 - Rev 0Document3 pagesDEE-920-12 - Rev 0Karim ZahranNo ratings yet

- Taper and Deburring CountersinkersDocument33 pagesTaper and Deburring CountersinkersTuyenNo ratings yet

- Names of Fuel 20110318Document3 pagesNames of Fuel 20110318BumpyLandyNo ratings yet

- 5754 Aluminum CircleDocument2 pages5754 Aluminum Circlewei huaNo ratings yet

- Organic SolventsDocument4 pagesOrganic SolventsnewemaierlNo ratings yet

- MSDS-MDT Plus 4 2017Document2 pagesMSDS-MDT Plus 4 2017Ade IrawanNo ratings yet

- Inorganic Chemistry Deals WithDocument4 pagesInorganic Chemistry Deals WithAriel GonzalesNo ratings yet

- The Carbon FamilyDocument26 pagesThe Carbon Familygautambadgujar30No ratings yet

- Safety Data Sheet Product IdentificationDocument5 pagesSafety Data Sheet Product Identificationmazyiyatul zellviaNo ratings yet

- Shanghai Singapore International School G11 Chemistry Test - Bonding SL Mark Out of .. Name Target Grade . Best Grade 1Document10 pagesShanghai Singapore International School G11 Chemistry Test - Bonding SL Mark Out of .. Name Target Grade . Best Grade 1oscarbecNo ratings yet

- ART - Tartaric-acid-enhanced-CuFe2O4-catalyzed-heterogeneo - 2019 - Materials-ScienceDocument10 pagesART - Tartaric-acid-enhanced-CuFe2O4-catalyzed-heterogeneo - 2019 - Materials-ScienceAntonio romero de avilaNo ratings yet

- Tgs SCR 3Document9 pagesTgs SCR 3Ari SaputroNo ratings yet

- Welding 1Document115 pagesWelding 1Shanky BhatnagarNo ratings yet

- Ion Exchange Resins - Water Conditioning ManualDocument93 pagesIon Exchange Resins - Water Conditioning Manualm9m2070No ratings yet

- Brazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessDocument23 pagesBrazing, Soldering, Adhesive, Bonding & Mechanical Fastening ProcessAd Man GeTigNo ratings yet

- Discussion: Ferrous Alloys Specimen 1 (X17)Document5 pagesDiscussion: Ferrous Alloys Specimen 1 (X17)Syahirzabidi100% (1)

- Welcome To The World of VELP ScientificaDocument8 pagesWelcome To The World of VELP ScientificaDinhtrung TruongNo ratings yet

- Generalized Rackett-Type Correlations To Predict The Density of Saturated Liquids and Petroleum FractionsDocument14 pagesGeneralized Rackett-Type Correlations To Predict The Density of Saturated Liquids and Petroleum FractionsLizeth RamirezNo ratings yet

- Solutions - AIATS Medical-2020 (XI Studying) - Test-5 (Code-C & D) - (27!01!2019)Document28 pagesSolutions - AIATS Medical-2020 (XI Studying) - Test-5 (Code-C & D) - (27!01!2019)Ûdây RäjpütNo ratings yet

- Lesson 1 - Classification of MatterDocument28 pagesLesson 1 - Classification of Mattercecil tayagNo ratings yet

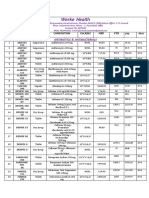

- Werke HealthDocument23 pagesWerke Healthganga ippltdNo ratings yet

- 35 48Document14 pages35 48Mohamed Saddek SalmiNo ratings yet