Professional Documents

Culture Documents

Intake System

Uploaded by

Miguel Ángel RodríguezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intake System

Uploaded by

Miguel Ángel RodríguezCopyright:

Available Formats

DI03-1

SECTION

00 DI03

INTAKE SYSTEM

Table of Contents

AIR FLOWS ................................................................. DI03-3

INTAKE SYSTEM LAYOUT ......................................... DI03-4

Components locator ............................................... DI03-4

Air cleaner ............................................................... DI03-5

Air flow sensor

(hot film air mass sensor) ....................................... DI03-8

Intercooler ............................................................. DI03-14

Intake manifold assembly ..................................... DI03-16

SPECIAL TOOLS AND EQUIPMENT ........................ DI03-17

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI03-3

AIR FLOWS

Intake Valve

(in combustion chamber)

Intake Manifold

Air Cleaner

Turbo

Charger Engine

HFM Sensor

Intake Air Outlet Hose Intercooler Intake Air Inlet Hose

Y220_03001

Work Flow of Intake System

Combustion

Air HFM Turbo Intake

Intercooler Chamber in

Cleaner Sensor Charger Manifold

Engine

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI03-4

INTAKE SYSTEM LAYOUT

COMPONENTS LOCATOR

Air cleaner Intake manifold

HFM sensor Intercooler

Y220_03002

CHANGED BY INTAKE SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI03-5

AIR CLEANER

Cover

Element

Housing

Y220_03003

Specifications

Element Type Dry-Element Type

* Initial cleaning: 5,000 km, Clean or change every 10,000 km as required.

However, change every 30,000 km.

Service Interval

* If the vehicle is operated under severe condition (short distance driving, extensive

idling or driving in dusty condition): More frequent maintenance is required.

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI03-6

Air Cleaner Element - Replacement

Preceding Work: Disconnection of negative battery cable

1. Disconnect the HFM sensor connector.

2. Loosen the locking clamp and remove the intake duct.

Y220_03004

3. Unscrew the screws and remove the air cleaner cover.

Y220_03005

4. Remove the air cleaner element. Clean or replace the

element as required.

Y220_03006

CHANGED BY INTAKE SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI03-7

Air Cleaner Housing

- Removal and Installation

Preceding Work: Removal of air cleaner cover

1. Set aside the return hose and remove the coolant reservoir

bolts.

Y220_03007

2. Remove the air cleaner housing bolts.

3. Install in the reverse order of removal.

Y220_03008

Air Cleaner Housing/Element - Check

1. Check the air cleaner body, cover and packing for

deformation, corrosion and damage.

2. Check the air duct for damage.

Y220_03009

3. Check the air cleaner element for clogging, contamination

and damage. If the element is partially clogged, remove

the dust or foreign materials with the compressed air. If

the contamination is severe, replace it with new one. Also,

be careful not to contaminate during the replacement.

4. Check the air cleaner housing for clogging, contamination

and damage.

5. If the inside of housing is contaminated, remove the

contaminants.

Notice

When cleaning the air cleaner with compressed air,

direct the air from inside (engine) to outside (ambient

air). Otherwise, contaminants can get into the engine. Y220_03010

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI03-8

AIR FLOW SENSOR (HOT FILM AIR MASS SENSOR)

Change history

inner tube added + grid (No.3)

added + sensing chip changed +

sensing section design changed

Results

Durability has enhanced 60

times (lab test results)

<CI type HFM sensor structure>

Y220_03011

1. Plug-in sensor 7. Hybrid

2. Cylinder housing 8. Sensor

3. Protection grid 9. Mounting plate

4. Hybrid cover 10. O-ring

5. Measuring duct cover 11. Temperature sensor

6. Housing

Air flow sensor is locating on the air intake passage between air cleaner and intake manifold and measures air volume

flows to engine combustion chamber and intake air temperature.

And intake temperature sensor built-in the sensor detects intake temperature.

Internal circuit of the air flow sensor is being used to control the voltage value to control the temperature to maintain the

heating resistance (Rh) to 160°C that is higher temperature than intake air temperature that is measured by resistance

(RI).

Temperature sensor of the heating resistance (Rh) is measured by resistance (Rs).

If temperature changes occur due to increasing/decreasing intake air volume, voltage of the heating resistance changes

to maintain the intake air temperature changes to set value (160°C).

Control unit computes intake air volume based on voltage changes of heating resistance.

Intake air temperature is measured by NTC integrated in the sensor.

CHANGED BY INTAKE SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI03-9

Intake air temperature sensor is a part of HFM sensor and a thermister and resister and detects air temperature

changes that flow into the engine. There occurs high resistance when temperature is low and low resistance when high

(NTC type).

ECU supplies 5 V to intake air temperature sensor and then measures voltage changes to determine the intake air

temperature. When air in the intake manifold is cold, the voltage is high and air is hot, the voltage is low.

The reason for using HFM sensor is that this sensor is most proper in controlling accurate air-fuel ratio to meet the legal

emission regulations. This sensor measures actual intake air mass into engine very accurately during specific instant

acceleration and deceleration, and determines engine loads and detects intake air pulsation and air flows.

Main functions of HFM sensor are:

• Using for EGR feedback control

• Using for turbocharger booster pressure control valve control

• Using for fuel injecting compensation

CI type HFM sensor: The air flowing the sensor does not directs toward sensing section but flows along with lower wall

after passing protection grid to enhance durability of the sensor. Oil, water and dust less damage the sensor.

Air outlet Air inlet

<Structure of CI type HFM sensor>

Y220_03012

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

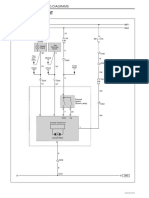

DI03-10

Power supply

Intake air

flow

sensor

Ground

Ground

Signal

Intake air temperature

sensor

HFM sensor

<Circuit diagram of HFM sensor>

Y220_03013

CHANGED BY INTAKE SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI03-11

HFM Sensor - Removal and Installation

HFM sensor

Y220_03014

Preceding Work: Disconnection of negative battery cable

1. Disconnect the negative battery cable.

2. Loosen the clamps on the air cleaner and the turbo

charger and remove the duct.

Y220_03015

3. Unscrew the bolts and remove the HFM sensor assembly.

Tightening torque 10 ± 1.0 Nm

Y220_03016

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI03-12

4. Install in the reverse order of removal.

Y220_03017

Intake Air Outlet Hose (Turbo Charger)

- Removal and Installation

1. Remove the radiator grille.

Y220_03018

2. Loosen the clamp at both sides and remove the outlet

hose.

Y220_03019

3. Loosen the clamp on the intake air hose and remove the

intake air hose.

Installation Notice

Tightening torque 6 ~ 7 Nm

4. Install in the reverse order of removal.

Notice

Securely fasten the clamps on the pipes and hoses.

Y220_03020

CHANGED BY INTAKE SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI03-13

Intake Air Inlet Duct (Air Cleaner)

- Removal and Installation

1. Loosen the clamp at intercooler side.

2. Loosen the clamp at turbo charger side.

Y220_03021

3. Separate the hose from the oil separator and remove the

intake duct.

4. Install in the reverse order of removal.

Y220_03022

Intake Air Inlet Duct (Intake Manifold)

- Removal and Installation

1. Loosen the clamp on the inlet hose in intercooler.

Y220_03023

2. Loosen the clamp at the intake manifold and remove the

inlet hose.

Installation Notice

Tightening torque 6 ~ 7 Nm

3. Install in the reverse order of removal.

Y220_03024

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI03-14

INTERCOOLER

The turbo charger is designed to improve the engine power by introducing more air (oxygen) into the engine. However,

the intake air is heated (100 ~ 110°C) during the compression process in turbo charger compressor and the density is

lowered.

The intercooler is the device which cools (50 ~ 60°C) the air entering the engine. Colder air has more oxygen molecules

than warm air. Thus cooler air gives more power and better fuel economy.

Y220_03025

1. Intercooler

CHANGED BY INTAKE SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI03-15

Intercooler - Removal and Installation

1. Remove the radiator grille.

Y220_03018

2. Loosen the clamp at both sides (inlet and outlet) of the

intercooler.

Installation Notice

Tightening torque 6 ~ 7 Nm

Y220_03027

3. Remove the intercooler mounting bolts.

Installation Notice

Tightening torque 10 ± 1.0 Nm

Y220_03028

4. Remove the air duct in intake manifold and the intercooler

assembly.

5. Install in the reverse order of removal. Y220_03029

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI03-16

INTAKE MANIFOLD ASSEMBLY

Y220_03030

System Characteristics

• Shape that delivers the required capacity of compressed air from turbo charger to inlet port

• Optimized EGR gas mixture in inlet chamber

• Maximized intake efficiency with helical and tangential inlet port

- Improving the swirl ratio in low and mid operating range

- Improving the acceleration/fuel economy and reducing the maintenance in low and mid operating range

• Integrated inlet port and coolant outlet port

CHANGED BY INTAKE SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI03-17

SPECIAL TOOLS AND EQUIPMENT

Name and Part Number Application

Intake manifold locking guide pin Installation of intake manifold

Y220_03031 Y220_03032

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI03-18

Intake Manifold - Removal/Installation

Preceding Work: Disconnection of negative battery cable

1. Lift up the vehicle and remove the skid plate.

Y220_03033

2. Open the coolant reservoir cap and remove loosen the

drain cock to drain the coolant.

Y220_03034

3. Remove the air inlet hose (1) from intake manifold.

4. Loosen the clamp and remove the coolant inlet hose (2).

Y220_03035

5. Remove the coolant inlet port housing.

6. Remove the vacuum hose from EGR valve.

7. Remove the EGR valve mounting bolts and gasket.

Remove the EGR exhaust pipe (primary) mounting bolts

and gasket.

Notice

• Replace the pipes (2, 3) at both sides of EGR cooler

(1) and gaskets with new ones.

• Make sure that the convex surface of gasket is facing

to the pressurized direction.

Y220_03036

CHANGED BY INTAKE SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

DI03-19

8. Remove the brackets and connectors from top section of

the engine.

- Vacuum hose bracket in turbo charger

- Booster pressure sensor

- Main wiring bracket

- Ground cable bracket

- Fuel pressure sensor connector

9. Unscrew the bolts and remove the vacuum modulator

bracket.

Tightening torque 9.0 Nm

Y220_03037

10. Remove the HP pump fuel supply line bolts.

11. Remove the HP pump fuel supply line mounting bracket.

12. Remove the HP pump fuel return line at fuel filter.

Notice

• Plug the openings of pipes and ports with sealing

caps to keep the cleanness of the fuel system.

• Replace the pipes with new one once removed.

Y220_03038

13. Remove the injector return line at HP pump.

Notice

• Be careful not to damage the pipes to HP pump.

• Plug the fuel return port of the HP pump with a

sealing cap.

Y220_03039

INTAKE SYSTEM CHANGED BY

DI ENG SM - 2004.4 EFFECTIVE DATE

AFFECTED VIN

DI03-20

14. Remove the intake manifold mounting bolts.

Notice

1. Check the length of the bolts before installation.

M8 x 45: 6EA

M8 x 130: 6EA

Tightening torque 25 ± 2.5 Nm

Y220_03040

15. Lift up the vehicle and remove the propeller shaft joint

bolts.

16. Unscrew the bolt in oil filter and remove the intake

manifold and gasket.

Notice

• Replace the gasket with new one.

• Make sure that the residual coolant in intake

manifold gets into the inside of inlet port.

Y220_03041 17. Install in the reverse order of removal.

Notice

• Replace the gasket with new one.

• If replaced only gasket without any other service

operation, completely remove the coolant and other

contaminants from the engine before installation.

CHANGED BY INTAKE SYSTEM

EFFECTIVE DATE DI ENG SM - 2004.4

AFFECTED VIN

You might also like

- Section5 3Document41 pagesSection5 3Miguel Ángel RodríguezNo ratings yet

- Lubrication SystemDocument19 pagesLubrication SystemCorsaDelEjeNo ratings yet

- Electric Devices and SensorsDocument19 pagesElectric Devices and SensorsMiguel Ángel RodríguezNo ratings yet

- SST List (1) HTTA ESPECIALDocument7 pagesSST List (1) HTTA ESPECIALMiguel Ángel RodríguezNo ratings yet

- Engine AssemblyDocument30 pagesEngine AssemblyEdinson Ariel Chavarro QuinteroNo ratings yet

- Diagnosis 2Document45 pagesDiagnosis 2CorsaDelEjeNo ratings yet

- Engine HousingDocument26 pagesEngine HousingMiguel Ángel RodríguezNo ratings yet

- Cooling System PDFDocument32 pagesCooling System PDFMiguel Ángel RodríguezNo ratings yet

- Fuel System PDFDocument61 pagesFuel System PDFMiguel Ángel RodríguezNo ratings yet

- Exhaust SystemDocument42 pagesExhaust SystemMiguel Ángel RodríguezNo ratings yet

- Diagnosis 4Document47 pagesDiagnosis 4Miguel Ángel RodríguezNo ratings yet

- Engine AssemblyDocument30 pagesEngine AssemblyEdinson Ariel Chavarro QuinteroNo ratings yet

- Electric Devices and SensorsDocument19 pagesElectric Devices and SensorsMiguel Ángel RodríguezNo ratings yet

- Catalogo Pajero - Manual Do Motor 4m40 PDFDocument0 pagesCatalogo Pajero - Manual Do Motor 4m40 PDFgargwlas86% (7)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Inventory Spare Part Tb. TP2Document14 pagesInventory Spare Part Tb. TP2Rohmananda ValdaNo ratings yet

- D24NAPDocument265 pagesD24NAPdbnfkz100% (4)

- Manual Viewer JU4 HNL54Document9 pagesManual Viewer JU4 HNL54KarelNo ratings yet

- UTB 650 Service Manual SmallDocument201 pagesUTB 650 Service Manual Smallrom100% (3)

- Detroit Diesel SERIES 60 Parts Catalog Diesel Rebuild Kits PDFDocument16 pagesDetroit Diesel SERIES 60 Parts Catalog Diesel Rebuild Kits PDFnicolaspinzon97GNo ratings yet

- Engine Knocking: DetonationDocument16 pagesEngine Knocking: Detonationm abdullahNo ratings yet

- VNX - Su Master Propulsion 2003Document469 pagesVNX - Su Master Propulsion 2003cvn2100% (3)

- BURITDocument1 pageBURITMuhammad Sya'RaniNo ratings yet

- G3304Document8 pagesG3304carlucido247970No ratings yet

- Choosing A Turbo - For TurbojetDocument4 pagesChoosing A Turbo - For TurbojetavinashmenonNo ratings yet

- Pionjar 120Document40 pagesPionjar 120Igor Halterbeck HalterbeckNo ratings yet

- CNG Kit ComponentsDocument5 pagesCNG Kit ComponentsAnisha VyasNo ratings yet

- Pectel C2 ECU: ECU Offload Tool SoftwareDocument7 pagesPectel C2 ECU: ECU Offload Tool SoftwareJorge Arilio Gonzalez ArangoNo ratings yet

- Gen Subj 2Document199 pagesGen Subj 2Stabin MathewNo ratings yet

- 32-40-Project Guide-Stationary (For - Information - Only) - 2 PDFDocument348 pages32-40-Project Guide-Stationary (For - Information - Only) - 2 PDFRhaanzah67% (3)

- Cosechadora - Ch570 - Sugarcane Harvester - Manual de PartesDocument1,004 pagesCosechadora - Ch570 - Sugarcane Harvester - Manual de PartesManuales De Maquinaria Jersoncat100% (1)

- Lovol Phaser SeriesDocument87 pagesLovol Phaser SeriesGerman O.No ratings yet

- RTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitDocument7 pagesRTA-59 Procedures and Relevant Information For RTA Engines To Comply With The Annex VI NOx LimitCatalin CataNo ratings yet

- 3TN84L RBS-B37 1Document49 pages3TN84L RBS-B37 1sasaNo ratings yet

- Carb - Mikuni Carbs and Mikuni Carb PartsDocument7 pagesCarb - Mikuni Carbs and Mikuni Carb PartsPajaroloco Carpintero100% (1)

- F4MHH F4amh'09Document33 pagesF4MHH F4amh'09GermanDarioRussoNo ratings yet

- VarioCam - Engine Power Plus PDFDocument4 pagesVarioCam - Engine Power Plus PDFjoop1231177No ratings yet

- SS FG230 enDocument2 pagesSS FG230 entolisNo ratings yet

- RSA Fuel Injection Training Manual CompleteDocument26 pagesRSA Fuel Injection Training Manual CompleteIan WhitingNo ratings yet

- Chevrolet Racing Engine Bill JenkinsDocument10 pagesChevrolet Racing Engine Bill Jenkinsnaomi100% (49)

- Ecu-Pinouts PDFDocument6 pagesEcu-Pinouts PDFDavid Solis100% (1)

- LEKQ7518 G3500 Engine BasicsDocument50 pagesLEKQ7518 G3500 Engine BasicsJaime Calmet100% (8)

- C11 Acert: Industrial Caterpillar Engine SpecificationsDocument4 pagesC11 Acert: Industrial Caterpillar Engine SpecificationsTamer MoustafaNo ratings yet

- Fuel System Installation: GY6 150, CN250Document6 pagesFuel System Installation: GY6 150, CN250Claudio Eduardo Di NassoNo ratings yet