Professional Documents

Culture Documents

Manufacture of Soap

Uploaded by

Sandeep Soni0 ratings0% found this document useful (0 votes)

30 views3 pagesMANUFACTURE OF SOAP

Original Title

MANUFACTURE OF SOAP

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMANUFACTURE OF SOAP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views3 pagesManufacture of Soap

Uploaded by

Sandeep SoniMANUFACTURE OF SOAP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Soap manufacturing process

1. 1. SOAP MANUFACTURING PROCESS BY BINU

2. 2. SOAP • In chemistry, soap is a salt of a fatty acid. • Consumers mainly use soaps as

surfactants for washing, bathing, and cleaning, but they are also used in textile spinning and

are important components of lubricants. • Soaps for cleansing are obtained by treating

vegetable or animal oils and fats with a strongly alkaline solution. • Fats and oils are

composed of triglycerides; three molecules of fatty acids attach to a single molecule of

glycerol. • The alkaline solution, which is often called lye (although the term "lye soap" refers

almost exclusively to soaps made with sodium hydroxide), brings about a chemical reaction

known as saponification.

3. 3. • In this reaction, the triglyceride fats first hydrolyze into free fatty acids, and then these

combine with the alkali to form crude soap: an amalgam of various soap salts, excess fat or

alkali, water, and liberated glycerol (glycerin). • The glycerin, a useful by-product, can remain

in the soap product as a softening agent, or be isolated for other uses. • Soaps are key

components of most lubricating greases, which are usually emulsions of calcium soap or

lithium soap and mineral oil. • These calcium- and lithium-based greases are widely used.

Many other metallic soaps are also useful, including those of aluminium, sodium, and

mixtures of them. • Such soaps are also used as thickeners to increase the viscosity of oils.

In ancient times, lubricating greases were made by the addition of lime to olive oil

4. 4. SOAP-MAKING PROCESSES • The industrial production of soap involves continuous

processes, such as continuous addition of fat and removal of product. Smaller-scale

production involves the traditional batch processes. • The three variations are: the 'cold

process', wherein the reaction takes place substantially at room temperature, the 'semiboiled'

or 'hot process', wherein the reaction takes place near the boiling point, and the 'fully boiled

process', wherein the reactants are boiled at least once and the glycerol is recovered. • The

cold process and hot process (semiboiled) are the simplest and typically used by small

artisans and hobbyists producing handmade decorative soaps.

5. 5. COLD PROCESS • In the cold soapmaking process, some heat is usually required; the

temperature is usually raised to a point sufficient to ensure complete melting of the fat being

used. • The batch may also be kept warm for some time after mixing to ensure the alkali

(hydroxide) is completely used up. This soap is safe to use after about 12–48 hours, but is

not at its peak quality for use for several weeks. • Cold-process soap making requires exact

measurements of lye and fat amounts and computing their ratio, using saponification charts

to ensure the finished product does not contain any excess hydroxide or too much free

unreacted fat. • Saponification charts should also be used in hot processes, but are not

necessary for the “fully boiled hot-process” soaping.

6. 6. • lye used in the cold process was made from scratch using rainwater and ashes.

Soapmakers deemed the lye solution ready for use when an egg would float in it • A cold-

process soapmaker first looks up the saponification value for each unique fat on an oil

specification sheet. • Oil specification sheets contain laboratory test results for each fat,

including the precise saponification value of the fat. • The saponification value for a specific

fat will vary by season and by specimen species. • 28] This value is used to calculate the

exact amount of sodium hydroxide to react with the fat to form soap. The saponification value

must be converted into an equivalent sodium hydroxide value for use in cold process

soapmaking. • Excess unreacted lye in the soap will result in a very high pH and can burn or

irritate skin; not enough lye leaves the soap greasy. Most soap makers formulate their

recipes with a 2–5% deficit of lye, to account for the unknown deviation of saponification

value between their oil batch and laboratory averages.

7. 7. • The lye is dissolved in water. • Then oils are heated, or melted if they are solid at room

temperature. Once the oils are liquefied and the lye is fully dissolved in water, they are

combined. • This lye-fat mixture is mixed until the two phases (oils and water) are fully

emulsified. Emulsification is most easily identified visually when the soap exhibits some level

of “trace”, which is the thickening of the mixture. • After much stirring, the mixture turns to the

consistency of a thin pudding. “Trace” corresponds roughly to viscosity. Essential oils and

fragrance oils can be added with the initial soaping oils, but solid additives such as

botanicals, herbs, oatmeal, or other additives are most commonly added at light trace, just as

the mixture starts to thicken.

8. 8. • The batch is then poured into moulds, kept warm with towels or blankets, and left to

continue saponification for 12 to 48 hours. (Milk soaps or other soaps with sugars added are

the exception. They typically do not require insulation, as the presence of sugar increases

the speed of the reaction and thus the production of heat.) • During this time, it is normal for

the soap to go through a “gel phase”, wherein the opaque soap will turn somewhat

transparent for several hours, before once again turning opaque. • After the insulation period,

the soap is firm enough to be removed from the mould and cut into bars. At this time, it is

safe to use the soap, since saponification is in essence complete. • However, cold-process

soaps are typically cured and hardened on a drying rack for 2–6 weeks before use. • During

this cure period, trace amounts of residual lye are consumed by saponification and excess

water evaporates. • During the curing process, some molecules in the outer layer of the solid

soap react with the carbon dioxide of the air and produce a dusty sheet of sodium carbonate.

• This reaction is more intense if the mass is exposed to wind or low

9. 9. HOT PROCESSES• In the hot process, the hydroxide and the fat are heated and mixed

together at 80–100 °C, a little below boiling point, until saponification is complete, which,

before modern scientific equipment, the soapmaker determined by taste (the sharp,

distinctive taste of the hydroxide disappears after it is saponified) or by eye; the experienced

eye can tell when gel stage and full saponification has occurred. • An advantage of the fully

boiled hot process in soapmaking is the exact amount of hydroxide required need not be

known with great accuracy. • They originated when the purity of the alkali hydroxides were

unreliable, as these processes can use even naturally found alkalis, such as wood ashes

and potash deposits. • In the fully boiled process, the mix is actually boiled (100+ °C), and,

after saponification has occurred, the “neat soap” is precipitated from the solution by adding

common salt, and the excess liquid is drained off. • This excess liquid carries away with it

much of the impurities and color compounds in the fat, to leave a purer, whiter soap, and

with practically all the glycerine removed. • The hot, soft soap is then pumped into a mould.

The spent hydroxide

10. 10. PURIFICATION AND FINISHING • In the fully boiled process on an industrial scale, the

soap is further purified to remove any excess sodium hydroxide, glycerol, and other

impurities, colour compounds, etc. These components are removed by boiling the crude

soap curds in water and then precipitating the soap with salt. • At this stage, the soap still

contains too much water, which has to be removed. This was traditionally done on chill rolls,

which produced the soap flakes • The dry soap (about 6–12% moisture) is then compacted

into small pellets or noodles. These pellets or noodles are then ready for soap finishing, the

process of converting raw soap pellets into a saleable product, usually bars.

11. 11. • Soap pellets are combined with fragrances and other materials and blended to

homogeneity in an amalgamator (mixer). • The mass is then discharged from the mixer into a

refiner, which, by means of an auger, forces the soap through a fine wire screen. • From the

refiner, the soap passes over a roller mill (French milling or hard milling) in a manner similar

to calendering paper or plastic or to making chocolate liquor. • The soap is then passed

through one or more additional refiners to further plasticize the soap mass. Immediately

before extrusion, the mass is passed through a vacuum chamber to remove any trapped air.

• It is then extruded into a long log or blank, cut to convenient lengths, passed through a

metal detector, and then stamped into shape in refrigerated tools. • The pressed bars are

packaged in many ways.

12. 12. • Sand or pumice may be added to produce a scouring soap. The scouring agents serve

to remove dead cells from the skin surface being cleaned.This process is called exfoliation. •

Many newer materials that are effective, yet do not have the sharp edges and poor particle

size distribution of pumice, are used for exfoliating soaps. • To make antibacterial soap,

compounds such as triclosan or triclocarban can be added. • There is some concern that use

of antibacterial soaps and other products might encourage antibiotic resistance in

microorganisms

13. 13. STRUCTURE OF A MICELLE, A CELL-LIKE STRUCTURE FORMED BY THE

AGGREGATION OF SOAP SUBUNITS (SUCH AS SODIUM STEARATE): THE EXTERIOR

OF THE MICELLE IS HYDROPHILIC (ATTRACTED TO WATER) AND THE INTERIOR IS

LIPOPHILIC (ATTRACTED TO OILS).

14. 14. Than k you

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Jeremy A. Greene-Prescribing by Numbers - Drugs and The Definition of Disease-The Johns Hopkins University Press (2006) PDFDocument337 pagesJeremy A. Greene-Prescribing by Numbers - Drugs and The Definition of Disease-The Johns Hopkins University Press (2006) PDFBruno de CastroNo ratings yet

- 6 Kuliah Liver CirrhosisDocument55 pages6 Kuliah Liver CirrhosisAnonymous vUEDx8100% (1)

- Psychological Effects of Cell Phone AddictionDocument5 pagesPsychological Effects of Cell Phone AddictionSandeep SoniNo ratings yet

- SOAPDocument3 pagesSOAPSandeep SoniNo ratings yet

- History of SoapDocument5 pagesHistory of SoapSandeep SoniNo ratings yet

- 7 Scary Things You Never Knew About Cell Phone AddictionDocument3 pages7 Scary Things You Never Knew About Cell Phone AddictionSandeep SoniNo ratings yet

- Cef1 07102019011033Document4 pagesCef1 07102019011033Sandeep SoniNo ratings yet

- Smartphone Addiction SymptonsDocument3 pagesSmartphone Addiction SymptonsSandeep SoniNo ratings yet

- Cef1 07102019041047Document4 pagesCef1 07102019041047Sandeep SoniNo ratings yet

- PROFFESIONALDocument2 pagesPROFFESIONALSandeep SoniNo ratings yet

- Education SystemDocument1 pageEducation SystemSandeep SoniNo ratings yet

- Cef1 14102019101013 PDFDocument4 pagesCef1 14102019101013 PDFSandeep SoniNo ratings yet

- BankDocument1 pageBankSandeep SoniNo ratings yet

- Motivation For Workout PDFDocument1 pageMotivation For Workout PDFSandeep SoniNo ratings yet

- Cef1 07102019011033Document4 pagesCef1 07102019011033Sandeep SoniNo ratings yet

- Cef1 06112019031123Document4 pagesCef1 06112019031123Sandeep SoniNo ratings yet

- Worker ParticipationDocument2 pagesWorker ParticipationSandeep SoniNo ratings yet

- GYMINGDocument3 pagesGYMINGSandeep SoniNo ratings yet

- Child LabourDocument1 pageChild LabourSandeep SoniNo ratings yet

- ConstitutionDocument1 pageConstitutionSandeep SoniNo ratings yet

- GYMINGDocument3 pagesGYMINGSandeep SoniNo ratings yet

- Child FoeticideDocument2 pagesChild FoeticideSandeep SoniNo ratings yet

- Caa PDFDocument1 pageCaa PDFSandeep SoniNo ratings yet

- Yoga (: Yoga Sutras of PatanjaliDocument1 pageYoga (: Yoga Sutras of PatanjaliDanescu MarilenaNo ratings yet

- Business DevelopmentDocument1 pageBusiness DevelopmentSandeep SoniNo ratings yet

- Earth From The Makers of Deep Blue PDFDocument1 pageEarth From The Makers of Deep Blue PDFSandeep SoniNo ratings yet

- Managememt SkilldDocument2 pagesManagememt SkilldSandeep SoniNo ratings yet

- Motivation in ManagementDocument1 pageMotivation in ManagementSandeep SoniNo ratings yet

- Cef1 14102019101013 PDFDocument4 pagesCef1 14102019101013 PDFSandeep SoniNo ratings yet

- Internet BankingDocument1 pageInternet BankingSandeep SoniNo ratings yet

- Business DevelopmentDocument1 pageBusiness DevelopmentSandeep SoniNo ratings yet

- CrewmgtDocument36 pagesCrewmgtDoddy HarwignyoNo ratings yet

- IsoTherming® Hydroprocessing TechnologyDocument4 pagesIsoTherming® Hydroprocessing Technologyromi moriNo ratings yet

- NRF Nano EthicsDocument18 pagesNRF Nano Ethicsfelipe de jesus juarez torresNo ratings yet

- Bai Tap Tieng Anh Lop 8 (Bai 13)Document4 pagesBai Tap Tieng Anh Lop 8 (Bai 13)nguyenanhmaiNo ratings yet

- Cargador de BateríaDocument34 pagesCargador de BateríaBenNo ratings yet

- Valve Material SpecificationDocument397 pagesValve Material Specificationkaruna34680% (5)

- DyslexiaDocument19 pagesDyslexiaKeren HapkhNo ratings yet

- Transfer and Business Taxation SyllabusDocument5 pagesTransfer and Business Taxation SyllabusamqqndeahdgeNo ratings yet

- Riber 6-s1 SP s17-097 336-344Document9 pagesRiber 6-s1 SP s17-097 336-344ᎷᏒ'ᏴᎬᎪᏚᎢ ᎷᏒ'ᏴᎬᎪᏚᎢNo ratings yet

- EIL Document On Motor, PanelDocument62 pagesEIL Document On Motor, PanelArindam Samanta100% (1)

- Long Term Effects of Surgically Assisted Rapid Maxillary Expansion Without Performing Osteotomy of The Pterygoid PlatesDocument4 pagesLong Term Effects of Surgically Assisted Rapid Maxillary Expansion Without Performing Osteotomy of The Pterygoid PlatesAngélica Valenzuela AndrighiNo ratings yet

- Soalan 9 LainDocument15 pagesSoalan 9 LainMelor DihatiNo ratings yet

- Topic of Assignment: Health Wellness and Yoga AssignmentDocument12 pagesTopic of Assignment: Health Wellness and Yoga AssignmentHarsh XNo ratings yet

- Method StatementDocument29 pagesMethod StatementZakwan Hisyam100% (1)

- How McDonald'sDocument2 pagesHow McDonald'spratik khandualNo ratings yet

- DT 2107Document1 pageDT 2107Richard PeriyanayagamNo ratings yet

- 208-Audit Checklist-Autoclave Operation - FinalDocument6 pages208-Audit Checklist-Autoclave Operation - FinalCherry Hope MistioNo ratings yet

- DX340LC: Crawler ExcavatorDocument20 pagesDX340LC: Crawler ExcavatorFeristha Meriani TabitaNo ratings yet

- Bio411 C1Document1 pageBio411 C1Aqiena BalqisNo ratings yet

- Those With MoonDocument1 pageThose With MoonRosee AldamaNo ratings yet

- Registration Statement (For Single Proprietor)Document2 pagesRegistration Statement (For Single Proprietor)Sherwin SalanayNo ratings yet

- 7-Multiple RegressionDocument17 pages7-Multiple Regressionحاتم سلطانNo ratings yet

- Pengaruh Kualitas Anc Dan Riwayat Morbiditas Maternal Terhadap Morbiditas Maternal Di Kabupaten SidoarjoDocument9 pagesPengaruh Kualitas Anc Dan Riwayat Morbiditas Maternal Terhadap Morbiditas Maternal Di Kabupaten Sidoarjohikmah899No ratings yet

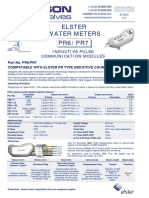

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleDocument1 pageData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaNo ratings yet

- ArticleDocument5 pagesArticleJordi Sumoy PifarréNo ratings yet

- Fast FashionDocument9 pagesFast FashionTeresa GonzalezNo ratings yet

- Service Bulletins For Engine Model I0360kb.3Document6 pagesService Bulletins For Engine Model I0360kb.3Randy Johel Cova FlórezNo ratings yet

- 204-04B - Tire Pressure Monitoring System (TPMS)Document23 pages204-04B - Tire Pressure Monitoring System (TPMS)Sofia AltuzarraNo ratings yet