Professional Documents

Culture Documents

PFI ES 2 2000 Method of Dimensioning Piping Assemblies

Uploaded by

edwinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PFI ES 2 2000 Method of Dimensioning Piping Assemblies

Uploaded by

edwinCopyright:

Available Formats

~

S T D n P F I ES-2-ENGL 1992 D 7 1 b 4 5 4 4 00005b3 TTb

PFI Standard ES-2

(Revised 1992)

(Reaffirmed 2000)

METHOD OF DIMENSIONING

PIPING ASSEMBLIES

Prepared by

Pipe Fabrication Institute Engineering Committee

All PFI Standards are advisory only. There is no

agreement to adhere to any PFI Standard and their

use by anyone is entirely voluntary.

Copyright by

PIPE FABRICATION INSTITUTE

Dedicnied io Technicnl Advnnceriienis and Stnndnidizntion in

the Pipe Fn6iicniion lndrrsir3~

Since 1913

CISA CANADA

PMB 323 655. 3 Y d w e . sitife 201

61 I Penns)fvnnin Aveiiire SE Lncliine, Qiie6ec

Wnshingtori. DC 20003 HST3G6

WEB SITE

ors

Iiitp://~<.,c~ic..pfi-institiiie.

COPYRIGHT Pipe Fabrication Institute

Licensed by Information Handling Services

S T D - P F I ES-2-ENGL 1772 7Lb95'49 00005b'4 732 =

PFI Standard ES-2

(Revised 1992)

(Reaffirmed 2000)

METHOD OF DIMENSIONING

PIPING ASSEMBLIES

METRIC CONVERSIONS

The conversion of quantities between systems of units involves a determination of the number of

significant digits to be retained. All conversions depend upon the intended precision of the original

quantity and are rounded to the appropriate accuracy.

Pipe sizes together with applicable wall thicknesses are not shown with metric equivalents.

The SI (metric) values where included with the customary U.S. values in this Standard are the

rounded equivalents of the U.S. values and are for reference only.

Metric units were derived utilizing the following conversion factor:

Conversion Factor

inches to 25.4

millimeter

1. Scope 2.4 While not necessary for the determination of the

pipeline geometry, it is essential that the engineer

1.1 This standard covers the recommended practices provide the fabricator with additional information

for dimensioning piping assemblies in a manner such as:

that would enable the fabricator to furnish a

product meeting the geometry intended by the (a) radius of bend

design engineer.

(b) type of elbow

2. Dimensioning (c) gasket or other allowances

2.1 Piping is normally of a circular cross section. (d) pipe size and wall thickness

Thus the geometry of a piping system can be fully

(e) type of branch connection, such as tee or nozzle

defined by the location of the centerline axis of

1 the pipe. Terminal points and points of change in (f) location of flanged or field welded joints

l direction of the pipe axis are known as working

points. Since two points determine a straight line, (g) location of attachments

it is recommended that the pipe axes be located (h) permissible tolerances (See PFI Std. ES-3)

by means of working points. Two alternate

methods of locating working points are suggested (i) material

in 2.2 and 2.3.

3. Fabrication Variables

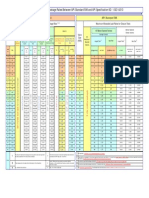

2.2 Fig. 1A illustrates location of the working points 3.1 In making the piping assemblies, the fabricator takes

along the axis of the pipe by providing into account the following factors; root opening,

information on the length and direction of each shrinkage and fitting tolerances.

consecutive segment of the axis.

3.2 In order to assure full penetration to the root of a

weld, the ends to be joined are set up with a small

2.3' Fig. 1B illustrates dimensioning by means of

gap between them called root opening. This root

location of the working points from fixed

opening may vary from O to 1/4" (6.0 mm)

reference planes, such as from ground elevation,

depending on the welding technique.

column lines, etc.

3.3 Shrinkage of the weld metal occurs in cooling. This

shrinkage varies with welding process, technique,

COPYRIGHT Pipe Fabrication Institute

Licensed by Information Handling Services

S T D - P F I ES-2-ENGL 1992 7 L b 4 5 4 4 00005b5 8 7 9

PFI Standard ES-2

(Revised 1992)

(Reaffirmed 2000j

piping material and pipe wall thickness. On steel 3.5 Due to the above factors only the fabricator is able to

the weld shrinkage usually amounts to 1/16" (2.0 correctly determine root opening. The PFI

mm) to 118" (3.0 mm). Consequently, the recommends that these root openings not be shown

fabricator must make allowances for shrinkage on the engineers' design drawings for fabricators'

(See Paragraph 3.5). assemblies.

3.4 All standard welding fittings and flanges are 3.6 In certain situations, (reference welds marked "W" in

subject to tolerances on terminal dimensions (end Fig. 1A & lB), when the design does not allow for

intervening pipe segments, it may be necessary for

to end, face to face, or center to end, etc.). The

tolerance on overall length of flanges as given in the fabricator to vary root opening or trim

components to hold overall dimensions (reference

ANSI B16.5, is k .06" (1.5 mm) for sizes up to

L'). Alternatively, and with permission from the

and including 10" and f .12" (3.0 mm) for larger

purchaser's engineer, adjustment may be made in

sizes. ANSI B 16.9 gives tolerances for butt

adjoining assemblies.

welding fittings.

For 90" & 45" elbows & tees these are:

Tol. (in.) Tol. (mm)

112" - 8" k .O6 I 2

1O" I .O9 f 2

12" - 24" k .O9 k3

26" - 30" k .12 k3

32" - 48" f .19 k5

E......EQUIPEMENT D

-I

T......TIE IN DIMENSION

R....REFERENCE DMENSK)N

G.,,,u4sKET

DIME"

wF?..wR"G POECT

FIGUREIA

FIGUREIB

COPYRIGHT Pipe Fabrication Institute

Licensed by Information Handling Services

S T D * P F I ES-2-ENGL 1772 7 L b 4 5 4 4 OOOOSbb 705

CHARTER MEMBERS

ACCORD PIPE FABRICATORS, INC. Jamaica, New York

AIR CONDITIONING COMPANY, INC. Glendale, California

FLO-RITE, INC. Riviera Beach, Florida

GEM INDUSTRIAL, INC. Walbridge, Ohio

HPI CONSTRUCTION CO., INC. Huntington, West Virginia

HUXTABLE & ASSOCIATES, INC. Lawrence, Kansas

IDEAL WELDERS, LTD. Delta, British Columbia (Canada)

INDUSTRIAL POWER SYSTEMS, INC. Toledo, Ohio

IVOR J. LEE, INC. Masury, Ohio

JOHN E. GREEN COMPANY Highland Park, Michigan

J. F. AHERN CO. Fond du Lac, Wisconsin

J. H. KELLY LLC Longview, Washington

J. S. MC KINNEY, INC. Freeport, Texas

KINETIC SYSTEMS, INC. Santa Clara, California

M & M WELDING AND FABRICATORS, INC. Gaithersburg, Maryland

MC ABEE CONSTRUCTION, INC. Tuscaloosa, A I abama

MC CARL’S, INC. Beaver Falls, Pennsylvania

MECHANICAL INCORPORATED Freeport, Illinois

MID STATES PIPE FABRICATING, INC. EI Dorado, Arkansas

MURPHY COMPANY St. Louis, Missouri

NARDE1 FABRICATORS, LTD. Calgary, Alberta (Canada)

NEWMECH COMPANIES, INC. St. Paul, Minnesota

PHILLIPS, GETSCHOW COMPANY Oconto Falls, Wisconsin

PIPING SYSTEMS, INC. New London, Wisconsin

S. A. COMUNALE COMPANY, INC. Barberton, Ohio

S&D / OSTERFELD MECHANICAL CONTRACTORS Dayton, Ohio

SCOTT CO. OF CALIFORNIA San Leandro, California

SPECIALTY PIPING CORPORATION Davisville, West Virginia

TEAM INDUSTRIES, INC. Kaukauna, Wisconsin

W. J. O’NEIL COMPANY Livonia, Michigan

A current index of the latest revised ES Standards, Technical Bulletins and Safety Training Guideline is available from

the Pipe Fabrication Institute.

PFI Safety Training Guideline, Standards and Technical Bulletins are published to serve proven needs of the pipe

fabricating industry at the design level and in actual shop operations. Hence, such needs are continually considered and

reviewed by the Engineering Committee of the Pipe Fabrication Institute to provide recommended procedures, which

have been demonstrated by collective experiences to fulfill requirements in a manner for Code compliance. However,

as the PFI Standards are for minimum requirements the designer or fabricator always has the option of specifying

supplementary conditions in the form of requirements beyond the scope of the PFI publications.

COPYRIGHT Pipe Fabrication Institute

Licensed by Information Handling Services

You might also like

- Pip Vefv1100-Jan. 2009 - Part1Document28 pagesPip Vefv1100-Jan. 2009 - Part1Ionut FloricaNo ratings yet

- Client Guide For The Inspection of Steel ChimneysDocument28 pagesClient Guide For The Inspection of Steel Chimneysdeptiranjan mohapatra100% (1)

- Guideline Lifting Lug DesignDocument10 pagesGuideline Lifting Lug Designye-kyaw-aung80% (10)

- Loads On FlangesDocument16 pagesLoads On Flangesccoollest100% (3)

- API 570 in Service Inspection Piping System 1643295114Document32 pagesAPI 570 in Service Inspection Piping System 1643295114DeepakNo ratings yet

- PipesDocument37 pagesPipesGautam BhardwajNo ratings yet

- SOP - FRP Pipe Jointing Procedure.Document10 pagesSOP - FRP Pipe Jointing Procedure.Ali Mari BalochNo ratings yet

- Duplex Stainless Steels: Properties and Welding TechniquesDocument25 pagesDuplex Stainless Steels: Properties and Welding Techniqueskdsenipah6667No ratings yet

- GasketsDocument20 pagesGasketsParthiban NagarajanNo ratings yet

- Implementation of PSM in Capital Projects DuPontDocument11 pagesImplementation of PSM in Capital Projects DuPontmb1981No ratings yet

- Esab, Ok 309L (29.12.16)Document1 pageEsab, Ok 309L (29.12.16)RodrigoNo ratings yet

- AIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01Document20 pagesAIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01faraz_muslimNo ratings yet

- Inspection OF Fired Heaters: For Restricted CirulationDocument59 pagesInspection OF Fired Heaters: For Restricted Cirulationasif rahim100% (1)

- BLADDER TANK PROPORTIONING SYSTEMDocument12 pagesBLADDER TANK PROPORTIONING SYSTEMakshay MahajanNo ratings yet

- INSPECT HEAT EXCHANGERDocument82 pagesINSPECT HEAT EXCHANGERBalaji VenkatesanNo ratings yet

- PROJECT UNITS DATA SHEETDocument7 pagesPROJECT UNITS DATA SHEETHatem ShawkiNo ratings yet

- Pfi Es-24Document10 pagesPfi Es-24wdwweNo ratings yet

- Piping-Progress-Measurement - (In Dia and in Meter)Document6 pagesPiping-Progress-Measurement - (In Dia and in Meter)Jiso Thomas100% (1)

- Sop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Document10 pagesSop-miqa-Attk-001 - Pressure Vessel Inspection For Migas Re-Certification (2007)Iksan Adityo MulyoNo ratings yet

- Pressure Vessels Carbon Steel: Standard Specification 3-11-6Document26 pagesPressure Vessels Carbon Steel: Standard Specification 3-11-6minh nguyenNo ratings yet

- Installing Mechanical Seals GuideDocument3 pagesInstalling Mechanical Seals GuideLaxman Singh SankhlaNo ratings yet

- Coating Structural Steel SystemsDocument28 pagesCoating Structural Steel SystemsSaud PathiranaNo ratings yet

- FRP Procedure Rev DDocument13 pagesFRP Procedure Rev DDaengkulle Firmansyah PuteraNo ratings yet

- Comparison of Leakage Rates in API and ISO Valve StandardsDocument0 pagesComparison of Leakage Rates in API and ISO Valve StandardsZoebair0% (1)

- Determining The Remaining Strength of Corroded Pipelines ASME B31G-1991Document30 pagesDetermining The Remaining Strength of Corroded Pipelines ASME B31G-1991ravi00098No ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- Mechanical SealDocument1 pageMechanical SealVaibhav KaleNo ratings yet

- B31.3 and B31.1 Code Safety Factor ComparisonDocument4 pagesB31.3 and B31.1 Code Safety Factor ComparisonJohn AlvarezNo ratings yet

- 매설배관 건전성평가 PDFDocument169 pages매설배관 건전성평가 PDF이선엽No ratings yet

- DVS 2207-3Document12 pagesDVS 2207-3gura9054No ratings yet

- JHF 610-Xgat-Mm (2006 Ac)Document1 pageJHF 610-Xgat-Mm (2006 Ac)Arya Bayu WibisonoNo ratings yet

- Prepare for GATE Metallurgy exam with this study guideDocument4 pagesPrepare for GATE Metallurgy exam with this study guidedrashokyvuceNo ratings yet

- ES.0.08.0002 Rev.B - Engineering Data Request Form PDFDocument1 pageES.0.08.0002 Rev.B - Engineering Data Request Form PDFSaravanan VaradarajanNo ratings yet

- Commenly Used Materials: Rolta Training Center, Mumbai - IndiaDocument1 pageCommenly Used Materials: Rolta Training Center, Mumbai - IndiaTAMIZHKARTHIKNo ratings yet

- I Object: Repair Procedure For Tank BottomDocument6 pagesI Object: Repair Procedure For Tank BottomZouhair BenmabroukNo ratings yet

- Shielded Metal Arc Welding: by Lakhveer SinghDocument77 pagesShielded Metal Arc Welding: by Lakhveer Singhਲਖਵੀਰ ਸਿੰਘ ਖਾਨਾNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Mcnichols GratingsCat09Document21 pagesMcnichols GratingsCat09jasonvigilNo ratings yet

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Document8 pagesInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaNo ratings yet

- Inspection RoleDocument18 pagesInspection Rolesribd9128No ratings yet

- 01-B. - API STD 510 10th Ed (May 2014) + (Addendum 2 March 2018)Document3 pages01-B. - API STD 510 10th Ed (May 2014) + (Addendum 2 March 2018)PelifullHDNo ratings yet

- Pipeline integrity program assessmentDocument51 pagesPipeline integrity program assessmentCris Gaucho100% (1)

- API 650 12th - 2013Document4 pagesAPI 650 12th - 2013mohamedNo ratings yet

- Procedimientos TecnicosDocument10 pagesProcedimientos TecnicosDomingo esteban perez ceballoNo ratings yet

- Maintanance of Spring Hanger by PTDocument2 pagesMaintanance of Spring Hanger by PTRagu NathanNo ratings yet

- RT API 650 12th - 2013Document1 pageRT API 650 12th - 2013Đỗ Thị HuyềnNo ratings yet

- Guide To Prepare WPQR According To Asme Section IxDocument5 pagesGuide To Prepare WPQR According To Asme Section IxHoque AnamulNo ratings yet

- Welding of Ferritic CreepDocument3 pagesWelding of Ferritic CreepMuhammed SulfeekNo ratings yet

- Wrapping MethodDocument5 pagesWrapping Methodnnuek67% (3)

- Boroscope InspectiónDocument14 pagesBoroscope InspectiónXiomara Hurtado FloresNo ratings yet

- Install, operate and maintain microfinish ball valvesDocument14 pagesInstall, operate and maintain microfinish ball valvesrajputashiNo ratings yet

- Attach-13 Work Procedure For Static Equipment InstallationDocument9 pagesAttach-13 Work Procedure For Static Equipment InstallationSukalyan BasuNo ratings yet

- PFI ES 16 - 2013 EditionDocument11 pagesPFI ES 16 - 2013 EditionArcadio Duran100% (1)

- ABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGDocument1 pageABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGPrabu KumarNo ratings yet

- Engrasadora NEUMATICAFLOWSERVERDocument16 pagesEngrasadora NEUMATICAFLOWSERVERLuis E. Barcelo TovarNo ratings yet

- TripleeeeDocument12 pagesTripleeeeDomingo esteban perez ceballoNo ratings yet

- 6 MFL Tool Spec Rev 3.5Document1 page6 MFL Tool Spec Rev 3.5fadialkasrawiNo ratings yet

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingDocument14 pagesMobile Offshore Drilling Units 2008: Rules For Building and ClassingmfazioliNo ratings yet

- QR2 - Mechanical Maintenance Question RecordDocument2 pagesQR2 - Mechanical Maintenance Question RecordMicky PlumbNo ratings yet

- AnsiDocument4 pagesAnsiHendrie NMcNo ratings yet

- Previews - 2033457 PIP VEFV1100MDocument5 pagesPreviews - 2033457 PIP VEFV1100Mabdulloh_99100% (1)

- Method of Dimensioning Piping Assemblies: Prepared Pipe Fabricatioll Imtitute Engineering CommitteeDocument4 pagesMethod of Dimensioning Piping Assemblies: Prepared Pipe Fabricatioll Imtitute Engineering CommitteeAlfian LeoanakNo ratings yet

- Celex:02014l0068 20140717:en:txtDocument118 pagesCelex:02014l0068 20140717:en:txtedwinNo ratings yet

- Economic and Engineering Considerations in The Design of Stacks For Good Gas DispersionDocument7 pagesEconomic and Engineering Considerations in The Design of Stacks For Good Gas DispersionedwinNo ratings yet

- PIP VEFV1100 Vessel/S&T Heat Exchanger Standard Details (U.S. Customary Units)Document9 pagesPIP VEFV1100 Vessel/S&T Heat Exchanger Standard Details (U.S. Customary Units)edwinNo ratings yet

- Ped Pressure Equipment Certification PDFDocument8 pagesPed Pressure Equipment Certification PDFProkopNo ratings yet

- PV ProcessDocument48 pagesPV Processkisan singhNo ratings yet

- Ped Pressure Equipment Certification PDFDocument8 pagesPed Pressure Equipment Certification PDFProkopNo ratings yet

- Vessel Example PDFDocument35 pagesVessel Example PDFedwinNo ratings yet

- VEFV1100 - Vessel S&T Heat Exchanger Standard DetailsDocument39 pagesVEFV1100 - Vessel S&T Heat Exchanger Standard DetailsYogi YuganNo ratings yet

- Vessel Example PDFDocument35 pagesVessel Example PDFedwinNo ratings yet

- PV ProcessDocument48 pagesPV Processkisan singhNo ratings yet

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel Constructionpreds1717No ratings yet

- VEFV1100 - Vessel S&T Heat Exchanger Standard DetailsDocument39 pagesVEFV1100 - Vessel S&T Heat Exchanger Standard DetailsYogi YuganNo ratings yet

- How To Measure Fastener LengthDocument4 pagesHow To Measure Fastener LengthedwinNo ratings yet

- Weld Cost CalculationDocument27 pagesWeld Cost Calculation-Abdul Khodir Van Java-100% (7)

- Pip PLC00002Document8 pagesPip PLC00002romerobernaNo ratings yet

- PIP VEFV1100 Vessel/S&T Heat Exchanger Standard Details (U.S. Customary Units)Document9 pagesPIP VEFV1100 Vessel/S&T Heat Exchanger Standard Details (U.S. Customary Units)edwinNo ratings yet

- Engineering Drawing ManualDocument128 pagesEngineering Drawing Manualadnan100% (6)

- AvancesDocument2 pagesAvancesedwinNo ratings yet

- NORSOK M-601 (2016) - Welding and Inspection of Piping PDFDocument34 pagesNORSOK M-601 (2016) - Welding and Inspection of Piping PDFchfontes100% (2)

- VDPDocument27 pagesVDPAppleuk SudarNo ratings yet

- VDPDocument27 pagesVDPAppleuk SudarNo ratings yet

- Astm A530 A530m 12Document9 pagesAstm A530 A530m 12edwinNo ratings yet

- NORSOK M-601 (2016) - Welding and Inspection of Piping PDFDocument34 pagesNORSOK M-601 (2016) - Welding and Inspection of Piping PDFchfontes100% (2)

- Pip PLC00002Document8 pagesPip PLC00002romerobernaNo ratings yet

- Astm A530 A530m 12Document9 pagesAstm A530 A530m 12edwinNo ratings yet

- Effect of Water Immersion On Mechanical Properties of Polyurethane ...Document8 pagesEffect of Water Immersion On Mechanical Properties of Polyurethane ...konshoeNo ratings yet

- Dog Cake Recipe For Dozer's Birthday! - RecipeTin EatsDocument36 pagesDog Cake Recipe For Dozer's Birthday! - RecipeTin EatsZyreen Kate CataquisNo ratings yet

- Friends of Hursley School: Late Summer NewsletterDocument6 pagesFriends of Hursley School: Late Summer Newsletterapi-25947758No ratings yet

- Bandari 2015 Exact SER Expressions of GFDM in Nakagami-M and Rician Fading ChannelsDocument6 pagesBandari 2015 Exact SER Expressions of GFDM in Nakagami-M and Rician Fading Channelssameer khan100% (1)

- Resume Curt JerromeDocument5 pagesResume Curt JerromeAashish MuraliNo ratings yet

- 978 613 8 91055 8 PDFDocument309 pages978 613 8 91055 8 PDFEr Sayan ParamanikNo ratings yet

- Engineering Services for Abadan Petrochemical Plant VCM Unloading Station Piping DesignDocument28 pagesEngineering Services for Abadan Petrochemical Plant VCM Unloading Station Piping DesignMehdi NouriNo ratings yet

- HymssheetDocument4 pagesHymssheettoby_wardmanNo ratings yet

- Pres. Quirino Treasured Child School, Inc.: Grade 8-St. Joseph & ST MatthewDocument2 pagesPres. Quirino Treasured Child School, Inc.: Grade 8-St. Joseph & ST MatthewChristian jade QuijanoNo ratings yet

- IRIScan Book Executive 3 PDFDocument86 pagesIRIScan Book Executive 3 PDFssamplingNo ratings yet

- Determining The Thickness of Glass in Airport Traffic Control Tower CabsDocument17 pagesDetermining The Thickness of Glass in Airport Traffic Control Tower CabsAdán Cogley CantoNo ratings yet

- Singaporean Notices To Mariners: Section ContentDocument35 pagesSingaporean Notices To Mariners: Section ContentGaurav SoodNo ratings yet

- Ic M802 UDocument79 pagesIc M802 Uharis_fikriNo ratings yet

- LP PG Conversion To Thar CoalDocument3 pagesLP PG Conversion To Thar CoalRaja Zeeshan100% (1)

- Philips HD5 enDocument5 pagesPhilips HD5 enmohamed boufasNo ratings yet

- Cefiget-Range-Leaflet-PakistanDocument2 pagesCefiget-Range-Leaflet-PakistanZafran KhanNo ratings yet

- Types of swords from around the worldDocument4 pagesTypes of swords from around the worldДмитрий МихальчукNo ratings yet

- Physical Activity Guidelines Advisory Committee ReportDocument683 pagesPhysical Activity Guidelines Advisory Committee Reportyitz22100% (1)

- Air Sentry - Energy Statement App 3 Dessicant and Filters PDFDocument20 pagesAir Sentry - Energy Statement App 3 Dessicant and Filters PDFEsteban Fernando Meza IbacetaNo ratings yet

- Column FootingDocument57 pagesColumn Footingnuwan01100% (7)

- Vitamin and Mineral Contents of Gongronema Latifolium LeavesDocument3 pagesVitamin and Mineral Contents of Gongronema Latifolium LeavesFrida Febriani IsnanisafitriNo ratings yet

- Fiber Crops - FlaxDocument33 pagesFiber Crops - Flaxmalath bashNo ratings yet

- Solar Collectors Final WordDocument14 pagesSolar Collectors Final WordVaibhav Vithoba NaikNo ratings yet

- Fesh S A0001171549 1Document7 pagesFesh S A0001171549 1ismuNo ratings yet

- DM3xxx Accessory List LeafletDocument2 pagesDM3xxx Accessory List LeafletAdvantec SrlNo ratings yet

- CHAPT 12a PDFDocument2 pagesCHAPT 12a PDFindocode100% (1)

- Ahmed Ali Alshehri Mobile 00966-508-217284 Address: P.O.Box 70132 Zipcode:31952 Riyadh Street, Al-Khobar, Saudi ArabiaDocument9 pagesAhmed Ali Alshehri Mobile 00966-508-217284 Address: P.O.Box 70132 Zipcode:31952 Riyadh Street, Al-Khobar, Saudi ArabiaShah KhalidNo ratings yet

- TCB E-F 015cukDocument2 pagesTCB E-F 015cukTempcoNo ratings yet

- Systems Design: Job-Order Costing and Process Costing: MANAGEMENT ACCOUNTING - Solutions ManualDocument16 pagesSystems Design: Job-Order Costing and Process Costing: MANAGEMENT ACCOUNTING - Solutions ManualBianca LizardoNo ratings yet

- Reading Test 7 - PassageDocument12 pagesReading Test 7 - PassageĐinh Quốc LiêmNo ratings yet