Professional Documents

Culture Documents

Beaconenglish

Uploaded by

Bhakti Mahbubani0 ratings0% found this document useful (0 votes)

27 views1 pageprocess safety

Original Title

201904beaconenglish

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentprocess safety

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views1 pageBeaconenglish

Uploaded by

Bhakti Mahbubaniprocess safety

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

This issue sponsored by

http://www.aiche.org/CCPS/Publications/Beacon/index.aspx

www.aiche.org/ccps

Messages for Manufacturing Personnel http://www.dekra-process-safety.com/

What if that “wrong” instrument reading is correct? April 2019

An explosion at a large US chemical manufacturing site caused 16 fatalities and more than 300 injuries.

There were significant property damage and business interruption losses as well. The explosion occurred

during startup of a distillation column. It is believed that the trays in the column were damaged early in the

startup. The tray damage caused poor separation. There was an abnormally high nitrobenzene concentration in

the bottom of the column – a concentration which was unstable.

There are many lessons from this incident (see references). This Beacon focuses on one – a “bad”

temperature indication in the distillation column. Hours before the explosion, the column was put on total

reflux because of startup difficulties. Later, a control system technician was asked to replace a thermocouple

on a tray in the column below the feed tray. The reason – it was reading 121°C when it “should have been

reading 102 °C.” The conclusion at the time was that the thermocouple had failed. In hindsight, the

thermocouple was probably Before After

reading correctly. Computer Plant location

modeling of the column,

done many years after the

incident and assuming

damage to the trays in the

bottom of the column,

predicted increased

nitrobenzene concentration.

This would account for the

observed temperature of

121°C.

What Can You Do?

How often do we dismiss readings that are not normal as “erroneous?” While this may be the case, shouldn’t

we first assume that the instrument is reading correctly? Then, try to understand why the reading is not normal.

Use other process instruments and related information to perform a more comprehensive assessment of what

is happening in your process.

What else can you do to understand if the instrument is failed or correct? For example, can you take a process

sample for analysis to help understand the situation? Can you look at local temperature or pressure gages in

the field? Can you look through a sight glass on top of a tank to see the level?

Get help from your co-workers, supervisors, and engineering support.

Ask “What are the possible consequences if this reading is correct?” Asking the question may lead to reviews

that could uncover unexpected hazards.

If the “erroneous” reading warns of a significant threat, work with your supervisors and technical support

engineers. Understand what action you should be taking to prevent a possible incident if it turns out that the

instrument reading is correct.

In a good process safety culture, everybody should believe instruments, unless a thorough assessment

indicates that an instrument reading is wrong.

References: Process Safety Progress 23 (3), September 2004, pp. 221–228, and Process Safety Progress 35 (1), March 2016, pp. 103–106.

Think about what an “abnormal” instrument reading could mean!

©AIChE2019. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for any

commercial purpose without express written consent of AIChE is strictly prohibited. Contact us at ccps_beacon@aiche.org or 646-495-1371.

The Beacon is usually available in Afrikaans, Arabic, Catalan, Chinese, Czech, Danish, Dutch, English, Filipino, French, German, Greek, Gujarati, Hebrew, Hindi, Hungarian, Indonesian,

Italian, Japanese, Korean, Malay, Marathi, Mongolian, Persian (Farsi), Polish, Portuguese, Romanian, Russian, Spanish, Swedish, Telugu, Thai, Turkish, Urdu, and Vietnamese.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Worthy - Elevation WorshipDocument1 pageWorthy - Elevation WorshipSabine J.100% (1)

- Monthly Fire Extinguisher Inspection ChecklistDocument2 pagesMonthly Fire Extinguisher Inspection ChecklistisaacbombayNo ratings yet

- Idioms and Phrases MCQs - English Grammar For Competitive ExamsDocument6 pagesIdioms and Phrases MCQs - English Grammar For Competitive ExamsgeologistlakhanNo ratings yet

- Is Audit Report 14489 (07-03-2018-122522)Document37 pagesIs Audit Report 14489 (07-03-2018-122522)Bhakti Mahbubani100% (4)

- Analog Layout Design (Industrial Training)Document10 pagesAnalog Layout Design (Industrial Training)Shivaksh SharmaNo ratings yet

- Floating Roof TanksDocument123 pagesFloating Roof TanksSalman BhattiNo ratings yet

- Maternity Leave and Paternity LeaveDocument6 pagesMaternity Leave and Paternity LeaveBhakti Mahbubani0% (1)

- 23MSDS ZDBC (C)Document11 pages23MSDS ZDBC (C)Bhakti MahbubaniNo ratings yet

- ApolloDocument2 pagesApolloikesh mNo ratings yet

- BeaconenglishDocument1 pageBeaconenglishBhakti MahbubaniNo ratings yet

- Late Coming NoticeDocument4 pagesLate Coming NoticeBhakti MahbubaniNo ratings yet

- Annexure BDocument1 pageAnnexure BBhakti MahbubaniNo ratings yet

- Order IndiatimesDocument1 pageOrder IndiatimesBhakti MahbubaniNo ratings yet

- SWIFTDocument2 pagesSWIFTManu BhardwajNo ratings yet

- Silica SpecificationsDocument2 pagesSilica SpecificationsBhakti MahbubaniNo ratings yet

- JD Head SheDocument2 pagesJD Head SheBhakti MahbubaniNo ratings yet

- CalculationsDocument4 pagesCalculationsBhakti MahbubaniNo ratings yet

- DlinkDocument5 pagesDlinkBhakti MahbubaniNo ratings yet

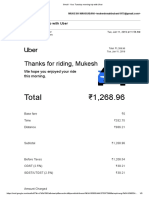

- Tuesday Morning Trip With UberDocument3 pagesTuesday Morning Trip With UberBhakti MahbubaniNo ratings yet

- Production Jan18Document1 pageProduction Jan18Bhakti MahbubaniNo ratings yet

- 032Document3 pages032Bhakti MahbubaniNo ratings yet

- July'18-Opg Minutes of MeetingDocument2 pagesJuly'18-Opg Minutes of MeetingBhakti MahbubaniNo ratings yet

- Invoice 1393070181Document1 pageInvoice 1393070181Bhakti MahbubaniNo ratings yet

- Factory Worker Muster Roll FormDocument30 pagesFactory Worker Muster Roll FormBhakti MahbubaniNo ratings yet

- MSE Paper Format SEM III VDocument2 pagesMSE Paper Format SEM III VBhakti MahbubaniNo ratings yet

- M Iv PDFDocument2 pagesM Iv PDFBhakti MahbubaniNo ratings yet

- You BroadDocument1 pageYou BroadBhakti MahbubaniNo ratings yet

- IATF - International Automotive Task Force: IATF 16949:2016 - Frequently Asked Question (FAQ)Document19 pagesIATF - International Automotive Task Force: IATF 16949:2016 - Frequently Asked Question (FAQ)Arvin BabuNo ratings yet

- A Presentation On: Code of ConductDocument8 pagesA Presentation On: Code of ConductBhakti MahbubaniNo ratings yet

- National & International Standards Master ListDocument2 pagesNational & International Standards Master ListBhakti MahbubaniNo ratings yet

- Membership Application Form: Gujarat Safety CouncilDocument2 pagesMembership Application Form: Gujarat Safety CouncilBhakti MahbubaniNo ratings yet

- M IvDocument2 pagesM IvBhakti MahbubaniNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityBhakti MahbubaniNo ratings yet

- Material ManagementDocument106 pagesMaterial ManagementRomi AfriansyahNo ratings yet

- GREEN AIR CONDITIONER Mechanical Presentation TopicsDocument9 pagesGREEN AIR CONDITIONER Mechanical Presentation TopicsCerin91No ratings yet

- Factors to Consider in Reactor Design for Industrial ProcessesDocument3 pagesFactors to Consider in Reactor Design for Industrial Processesuma villashini100% (2)

- Theoretical Development of The Brooks-Corey CapillDocument7 pagesTheoretical Development of The Brooks-Corey CapillDiana Vanessa PedrazaNo ratings yet

- Surat Kecil Untuk TuhanDocument9 pagesSurat Kecil Untuk TuhanAsgarPurnamaNo ratings yet

- TCB E-F 015cukDocument2 pagesTCB E-F 015cukTempcoNo ratings yet

- Image Processing Based Leaf Rot Disease, Detection of Betel Vine (Piper Betlel.)Document7 pagesImage Processing Based Leaf Rot Disease, Detection of Betel Vine (Piper Betlel.)ManiNo ratings yet

- Stabil Drill Roller ReamersDocument2 pagesStabil Drill Roller ReamersIMEDHAMMOUDANo ratings yet

- Philips HD5 enDocument5 pagesPhilips HD5 enmohamed boufasNo ratings yet

- PTC Document Status: (Updated 11 November 2015)Document5 pagesPTC Document Status: (Updated 11 November 2015)AndersonGabriel23No ratings yet

- SaponificationDocument2 pagesSaponificationK.SaravananNo ratings yet

- Preventive Maintenance Service Concept For SPACOM Product FamilyDocument27 pagesPreventive Maintenance Service Concept For SPACOM Product FamilyMiguel MarquesNo ratings yet

- Bandari 2015 Exact SER Expressions of GFDM in Nakagami-M and Rician Fading ChannelsDocument6 pagesBandari 2015 Exact SER Expressions of GFDM in Nakagami-M and Rician Fading Channelssameer khan100% (1)

- Practical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDocument3 pagesPractical 7 - Angiosperms Marking Guide Exercise 1: Class DicotyledonsDitiro Maletsanake50% (2)

- Regulation 1 Regulation 2 Regulation 3 Regulation 4 Regulation 5 Regulation 6 Regulation 7 Regulation 8 Regulation 9 AppendixDocument10 pagesRegulation 1 Regulation 2 Regulation 3 Regulation 4 Regulation 5 Regulation 6 Regulation 7 Regulation 8 Regulation 9 AppendixAnonymous 7gJ9alpNo ratings yet

- Mec 323Document68 pagesMec 323VINAY B.SNo ratings yet

- Imsa Catalog Imsa CatDocument16 pagesImsa Catalog Imsa CatDaniel TelloNo ratings yet

- Juxtaposition and Non Motion Varese BridDocument13 pagesJuxtaposition and Non Motion Varese BridIvan Eiji Yamauchi SimurraNo ratings yet

- Wemco Depurator 2003Document2 pagesWemco Depurator 20031mmahoneyNo ratings yet

- Entrepreneurship Macro Environment ForcesDocument26 pagesEntrepreneurship Macro Environment ForcesSivaNo ratings yet

- Ex 2013 1 (Recurrent)Document30 pagesEx 2013 1 (Recurrent)alh basharNo ratings yet

- MUSCULAR SYSTEM WORKSHEET Slides 1 To 4Document4 pagesMUSCULAR SYSTEM WORKSHEET Slides 1 To 4kwaiyuen ohnNo ratings yet

- Definisi, Karakteristik dan Contoh Aplikasi SIGDocument28 pagesDefinisi, Karakteristik dan Contoh Aplikasi SIGtoyota taaNo ratings yet

- TheologicalDiscipleship English 2011-1Document144 pagesTheologicalDiscipleship English 2011-1bilnyangnatNo ratings yet

- LP PG Conversion To Thar CoalDocument3 pagesLP PG Conversion To Thar CoalRaja Zeeshan100% (1)

- Logicroof V-RP enDocument1 pageLogicroof V-RP enCristina DogariNo ratings yet