Professional Documents

Culture Documents

ATEX For Non-Electrical

Uploaded by

Rajesh KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ATEX For Non-Electrical

Uploaded by

Rajesh KumarCopyright:

Available Formats

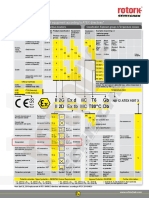

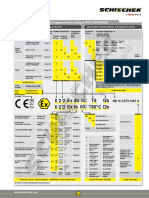

Marking of non-electrical explosion protected equipment

Potentially explosive areas Subdivisions and classification of gases and vapours

Conditions and Zone classification Required marking on the equipment Gases and vapours Assignment Temperature Maximum Permitted

of gases and vapours class surface Temperature

Flammable Temporary behaviour Classifi- Group Equipment Equipment Equipment

accordance to the temperature classes

materials of explosive atmosphere cation of as defined in category group protect level (EPL)

ignition temperature (equipment) (equipment)

hazardous directive as defined in as defined in as defined in

areas 2014/34/EU directive EN 13463-1 ff EN ISO 80079-36 Ammonia, Town gas, Hydrogen > 450 °C T1 450 °C T1 to T6

2014/34/EU EN ISO 80079-36 EN IEC 60079-0 methane, ethane, acrylnitril

Gases, is present continuously or Zone 0 II 1G II Ga propane

vapours for long periods or frequently Ethyl alcohol, Ethylene, Ethine > 300 °C ... < 450 °C T2 300 °C T2 to T6

arises in normal operation Zone 1 II 2G or 1G II Gb or Ga cyclohexane, ethylene oxide (Acetylene)

occasionally n-butane

is not likely toarise in normal Zone 2 II 3G or II Gc or Gasoline, Ethylene glycol, > 200 °C ... < 300 °C T3 200 °C T3 to T6

operation, or if it does, will 2G or 1G Gb or Ga n-hexane hydrogen

persist for a short time only sulphide

Dusts is present in the form of a Zone 20 II 1D III Da Acetaldehyde Ethyl ether > 135 °C ... < 200 °C T4 135 °C T4 to T6

cloud continuously, or for

> 100 °C ... < 135 °C T5 100 °C T5 to T6

long periods or frequently

Sulphide of

occasionally develops Zone 21 II 2D or 1D III Db or Da > 085 °C ... < 100 °C T6 85 °C T6

carbon

into a cloud during

normal operation

is not likely to develop into a Zone 22 II 3D or III Dc or

cloud during normal opera- 2D or 1D Db or Da

tion, or if it does, for a short Gas groups

time only

IIA IIB IIC

Methane, operation where there is - I M1 I Ma

carbon dust a risk of explosion Permitted Equipment groups

disconnection where there - I M2 or M1 I Mb or Ma IIA, IIB, IIC IIB, IIC IIC

is a risk of explosion

AT E X

Gases/Vapours NB1) II 1G Ex h IIC T6 Ga NB2) 18 ATEX 1234 X

Dusts II 2D Ex h IIIC T120 °C Db X

ISO (IECEx)

Gases/Vapours Ex h IIB T4 Gb IECEx ExCB3) 11.1234 X

Dusts Ex h IIIB T120 °C Dc IECEx ExCB3) 11.1234 X

Protection principle/types of protection Use of the operating equipment

Applications (examples) Flammable materials Protection principle Type of protection Marking in accordance with the equipment protection level Standards Marking Conditions

very high high level enhanced

level of protection level of protection level of protection without Equipment can be operated without

All applications Gases, vapours (G) and – General requirements + + + EN ISO 80079-36 X or U restrictions

dusts (D) EN IEC 60079-0 Specific conditions of use of the

with X

EN 13463-1 equipment

with U Component certificate (uncomple-

Coupling, belt drive, Gases, vapours (G) and This protection principle Constructional safety Ex h Ex h Ex h EN ISO 80079-37 ted), conformity is certified when

agitator, ventilator, mill dusts (D) ensures that a source of used in an overall equipment

ignition cannot occur. c c c EN 13463-5

Plain bearing, pump, agitator, Gases, vapours (G) and This protection principle Control of ignition sources Ex h Ex h Ex h EN ISO 80079-37 Max. permissible surface temperature

vacuum pump, centrifuges dusts (D) prevents a source of ignition of the equipment

from becoming effective. b b b EN 13463-6

Temperature limitation Tmax. < T5 mm - 75°C

because of dust layer

Gear Gases, vapours (G) and This protection principle Liquid immersion Ex h Ex h Ex h EN ISO 80079-37 T5 mm: Minimum ignition

dusts (D) prevents the hazardous temperature of 5 mm layer

atmosphere reaching the k k k EN 13463-8 of dust

source of ignition.

Temperature limitation Tmax. < 2/3 TCL

Centrifuge, compressor, Gases, vapours (G) and This protection principle Pressurised enclosure – Ex h Ex h EN ISO 80079-36 because of dust cloud

geared motor, dusts (D) prevents the hazardous – Ex pxb, pyb Ex pzc EN IEC 60079-2 TCL: Minimum ignition

complex assembly group atmosphere reaching the temperature of the

source of ignition. – p – EN 13463-8 cloud of dust

Centrifuge, compressor, Gases and vapours (G) This protection principle Protection by flow – – fr EN 13463-2 Max. permissible lowest outcome of

geared motor, prevents the hazardous restricting enclosure surface temperature the Tmax. - values

complex assembly group atmosphere reaching the of the equipment:

source of ignition.

Mill, geared motor, Dusts (D) This protection principle Protection by enclosure Ex h Ex h Ex h EN ISO 80079-36 Subdivision of dusts

complex assembly group prevents the hazardous Ex ta Ex tb Ex tc EN IEC 60079-31

atmosphere reaching the Permitted Dust groups Dusts

source of ignition. Equipment

groups

Brakes Gases and vapours (G) This protection principle Flame-proof enclosure – Ex h Ex h EN ISO 80079-36

combustible

D-D-WEG261010-01/2019-BARTECMarketing & Communications-306855

prevents flame propagation Ex db Ex dc EN IEC 60079-1 IIIA, IIIB, IIIC IIIA

flyings

through an enclosure.

d – EN 13463-3 IIIB, IIIC IIIB non-conductive

1) Identification number of the Notified Body responsible for the surveillance of the manufacturer‘s IIIC IIIC conductive

quality system (Cat. 1).

Application area (equipment)

2) Notified Body (NB) that has tested and certified the product (Cat. 1).

Zone 0/20 Zone 1/21 Zone 2/22

3) Certification Body (CB) that has tested and certified the product (EPL a, b and c). Zone 1/21 Zone 2/22

Zone 2/22

ATEX is in the European Union a mandatory and IECEx a voluntary certification procedure.

For the correct application of the certification procedures, please follow the corresponding guidelines,

regulations and standards.

BARTEC GmbH Max-Eyth-Str. 16 97980 Bad Mergentheim Germany Phone: +49 7931 597 0 info@bartec.de www.bartec.com

You might also like

- 2008 Honda ARX1500T3 T3D Aquatrax Service Repair Manual PDFDocument30 pages2008 Honda ARX1500T3 T3D Aquatrax Service Repair Manual PDFfuksekfmmdNo ratings yet

- Cat d7 3t Operatons MtceDocument98 pagesCat d7 3t Operatons MtceMilagros Pullchs AriasNo ratings yet

- CK20 WM 09 HydraulicDocument56 pagesCK20 WM 09 Hydraulicclcasal100% (2)

- Ex Poster Bartec 2019 eDocument1 pageEx Poster Bartec 2019 eSubin ThomasNo ratings yet

- Hazardous Area Classification EN PDFDocument6 pagesHazardous Area Classification EN PDFUsama IqbalNo ratings yet

- Multi Port Valve ManualDocument2 pagesMulti Port Valve ManualJithin JamesNo ratings yet

- Competence 8 Oic-Ew ReviewerDocument16 pagesCompetence 8 Oic-Ew ReviewerCristine Ann Javier100% (1)

- Motor Basico C9Document9 pagesMotor Basico C9GerardoNo ratings yet

- Marking Non Electrical Equipment ExDocument1 pageMarking Non Electrical Equipment ExTurkish Medical CareNo ratings yet

- Marking Electrical Equipment ExDocument1 pageMarking Electrical Equipment ExFendy ShirahNo ratings yet

- Marking Iecex Equipment Ex..Document1 pageMarking Iecex Equipment Ex..jerrinjNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFNicolae VisanNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFMMNo ratings yet

- Marking Non Electrical Equipment Ex PDFDocument1 pageMarking Non Electrical Equipment Ex PDFAgus RianNo ratings yet

- Marking Electrical Equipment Ex PDFDocument1 pageMarking Electrical Equipment Ex PDFrakacyuNo ratings yet

- ATEX Marking Electrical Equipment Ex PDFDocument1 pageATEX Marking Electrical Equipment Ex PDFBinhvvNo ratings yet

- WWW - schischek.com:pdf:ATEX Classification Labelling of Electric EquipmentDocument1 pageWWW - schischek.com:pdf:ATEX Classification Labelling of Electric EquipmentfrancisNo ratings yet

- Marking IECEx Equipment ExDocument1 pageMarking IECEx Equipment Exadirocks89No ratings yet

- Comparison FM Vs ATEX Flow Chart PDFDocument1 pageComparison FM Vs ATEX Flow Chart PDFGoogool YNo ratings yet

- Explaining ATEX & IECEx Certifications NotesDocument3 pagesExplaining ATEX & IECEx Certifications Notes何吉飞No ratings yet

- Intrinsic Safety: A Technical Seminar OnDocument32 pagesIntrinsic Safety: A Technical Seminar OnGobinath BalasubramanianNo ratings yet

- Ex Motor PresentationDocument72 pagesEx Motor PresentationsanatikalaNo ratings yet

- Labelling of Explosion Proof Equipment: Ii2Gexdiict6 Ii 2D Ex TB Iiic T80°C GB DB GB DB GB T80°C T80°C DBDocument1 pageLabelling of Explosion Proof Equipment: Ii2Gexdiict6 Ii 2D Ex TB Iiic T80°C GB DB GB DB GB T80°C T80°C DBChirack Singh Tony AntonyNo ratings yet

- ATEX Electric Equipment Classification Labelling PDFDocument1 pageATEX Electric Equipment Classification Labelling PDFRamius HamdaniNo ratings yet

- Haz Area GuideDocument4 pagesHaz Area GuideBoz Van DuynNo ratings yet

- ATEX StandardDocument4 pagesATEX StandardharmlesdragonNo ratings yet

- ATEX Explosive AtmospheresDocument3 pagesATEX Explosive AtmospheresrakicbgNo ratings yet

- Ex Selection - 5 Des 2022Document8 pagesEx Selection - 5 Des 2022Alex van dykNo ratings yet

- ATEX Classification Labelling of Electric EquipmentDocument1 pageATEX Classification Labelling of Electric EquipmentLudi D. LunarNo ratings yet

- 986 07 1006 031 - ManDocument8 pages986 07 1006 031 - ManFernando Ledesma RamirezNo ratings yet

- Ashrae D 86142Document1 pageAshrae D 86142ดั๊มพ์ วาสนาทิพย์No ratings yet

- Classification Labelling o EquipmentDocument1 pageClassification Labelling o EquipmentAbdul RahmanNo ratings yet

- A Guide To The Use Of... : Electrical Equipment in Potentially Explosive AtmospheresDocument4 pagesA Guide To The Use Of... : Electrical Equipment in Potentially Explosive AtmospheresAsif Ullah KhanNo ratings yet

- Atexor ATEX GUIDELINESDocument1 pageAtexor ATEX GUIDELINESDhiven VesNo ratings yet

- Standards, Zone DefinitionsDocument3 pagesStandards, Zone DefinitionsKhalifa AljahawiNo ratings yet

- Atex ClassificationDocument1 pageAtex ClassificationDANE80No ratings yet

- 8.bartec Non-Electrical PosterDocument1 page8.bartec Non-Electrical PosteraungwinnaingNo ratings yet

- Flame Detector Comparison Item Spectrex Net Safety Talentum: Atex and Iecex CSA - Class IDocument2 pagesFlame Detector Comparison Item Spectrex Net Safety Talentum: Atex and Iecex CSA - Class IhomaNo ratings yet

- 50H Earlier Hygienic Flow MeterDocument24 pages50H Earlier Hygienic Flow MeterShishir JhaNo ratings yet

- Control Boxes (Pilih)Document18 pagesControl Boxes (Pilih)Shihabudin QolyubiNo ratings yet

- Temperature Classes - How They Work and How To Use ThemDocument1 pageTemperature Classes - How They Work and How To Use Themdeepak kumarNo ratings yet

- Ver2-0 Part 01 Ignition PropertiesDocument24 pagesVer2-0 Part 01 Ignition PropertieschewbaccyNo ratings yet

- Ex-Poster GBDocument1 pageEx-Poster GBNarendra BabuNo ratings yet

- ATEX Explained EX PDFDocument1 pageATEX Explained EX PDFZal RizalNo ratings yet

- Svacina Larson - Understanding Hazardous Area Sensing - Intrinsic Safety - Part2Document10 pagesSvacina Larson - Understanding Hazardous Area Sensing - Intrinsic Safety - Part2AbdelRahmanNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Eckerle EIPH2 - 3 - 6 Series PDFDocument12 pagesEckerle EIPH2 - 3 - 6 Series PDFOleg080No ratings yet

- Minwei Sun, Abbas Firoozabadi: HighlightsDocument5 pagesMinwei Sun, Abbas Firoozabadi: HighlightsFajar AnggaraNo ratings yet

- NFPA Liquefied Petroleum Gas Code 58 Fire Safety Analysis Plan and O&M Instructions For Propane Storage SystemsDocument42 pagesNFPA Liquefied Petroleum Gas Code 58 Fire Safety Analysis Plan and O&M Instructions For Propane Storage Systemsquiron2014No ratings yet

- Causes of Global WarmingDocument3 pagesCauses of Global Warmingjohnangel_22No ratings yet

- An Atmospheric Crude Tower RevampDocument6 pagesAn Atmospheric Crude Tower RevampMarlon ArteagaNo ratings yet

- Chapter 1: Chemistry and MeasurementDocument13 pagesChapter 1: Chemistry and MeasurementSusan ChanNo ratings yet

- Kilns Khaled PDFDocument16 pagesKilns Khaled PDFbulentbulut100% (1)

- 08 GRP04 All EnginesDocument32 pages08 GRP04 All Engineseurospeed2No ratings yet

- Bulletin 60 AFQRJOS Issue 27 Feb 2013 PDFDocument6 pagesBulletin 60 AFQRJOS Issue 27 Feb 2013 PDFpersadanusantaraNo ratings yet

- Seal Presentation SasolDocument27 pagesSeal Presentation Sasolkhadeejah-hasmad-1981No ratings yet

- Hydrogen CAR: Govt Polytechnic, PuriDocument22 pagesHydrogen CAR: Govt Polytechnic, PuriKrishnaNo ratings yet

- Citroen C4 B7 Edition BrochureDocument4 pagesCitroen C4 B7 Edition BrochureJéferson BischoffNo ratings yet

- Omnivore Dilemma CH 2Document2 pagesOmnivore Dilemma CH 2api-235750525No ratings yet

- Fire Technology and Arson InvestigationDocument146 pagesFire Technology and Arson InvestigationClarito LopezNo ratings yet

- 2H 102 94 0 00Document122 pages2H 102 94 0 00yudi handoko0% (1)

- Corken PZ10 Detail Sales CatalogDocument12 pagesCorken PZ10 Detail Sales Catalogsiapakahdiriku100% (1)

- Stoichiometric Calculations Using The Table MethodDocument3 pagesStoichiometric Calculations Using The Table MethodJavian CampbellNo ratings yet

- How A Jet Engine Creates ThrustDocument4 pagesHow A Jet Engine Creates ThrustRossNo ratings yet

- VW - tb.01!07!64 Mil On DTC P129F and or P310B SStored in ECM Fault MemoryDocument6 pagesVW - tb.01!07!64 Mil On DTC P129F and or P310B SStored in ECM Fault MemorySlobodanNo ratings yet

- Paper 6 Log Interpretation Hakeem DahoDocument6 pagesPaper 6 Log Interpretation Hakeem DahoSadiq JalalNo ratings yet

- Electronic Ignition Systems: CM WP ME HA AP LG EP CS IN EL AV TO PS BVDocument1 pageElectronic Ignition Systems: CM WP ME HA AP LG EP CS IN EL AV TO PS BVRaju GuptaNo ratings yet

- Gas Lift Installation DesignDocument6 pagesGas Lift Installation DesignsukunsurNo ratings yet

- 1.1 FivesPillard - UK 02-2011 (English)Document29 pages1.1 FivesPillard - UK 02-2011 (English)Jackson VuNo ratings yet

- Carbone Lorraine PresentationDocument128 pagesCarbone Lorraine PresentationDebarati Bhattacharjee100% (1)