Professional Documents

Culture Documents

Rtuvgjj

Uploaded by

mangalamtestingbureaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rtuvgjj

Uploaded by

mangalamtestingbureaCopyright:

Available Formats

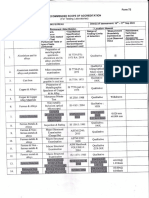

Page _01___of _03__

MANGALAM TESTING BUREAU

MATERIAL TESTING LABORATORY (HOWRAH)

TENSILE TESTING MACHINE: UTK 60

HARDNESS TESTING MACHINE: KAS

JOB CARD (Mechanical)

Job No. & Date : MTB/2020/N/0103 Date: 16.01.2020 Test to be performed : UTS, YS, %Elongation

Bend & Hardness

Description of the Sample : 07 Nos. Sample Sample Received by Lab : 16.01.2020

Heat No. : NA

Specification : Given Below Date of Testing : 03.02.2020

Sl. E% YL YS BL Hardness in HBW

No.

Sample Description G. Dia. mm Area mm² GL mm EL mm UTS

5.65√A N MPa N (10/3000/15 Sec)

Round Bar 25Ø

1. 12.52 123.16 63 79.5 26.19 43000 349.14 63400 514.78 137 (Avg.)

Foundation Bolt

Round Bar 30Ø

2. 12.42 121.20 62 78.6 26.77 42200 348.18 59800 493.40 126 (Avg.)

Foundation Bolt

Round Bar 36Ø

3. 12.46 121.98 62 78.6 26.77 36000 295.13 58800 482.05 126 (Avg.)

Foundation Bolt

Round Bar 42Ø

4. 12.42 121.20 62 78.3 26.29 41200 339.93 59800 493.40 131 (Avg.)

Foundation Bolt

Round Bar 50Ø

5. 12.30 118.87 62 80.0 29.03 35800 301.17 56200 472.79 131 (Avg.)

Foundation Bolt

Round Bar 56Ø

6. 12.18 116.56 61 78.4 28.52 33200 284.83 55200 473.58 126 (Avg.)

Foundation Bolt

Round Bar 65Ø

7. 12.44 121.59 62 78.3 26.29 36200 297.72 58800 483.59 131 (Avg.)

Foundation Bolt

Req. as per 24.00 230 MPa 430 MPa

--- --- --- --- --- 120 Min

IS : 1875/1992,Gr.2 Min (Min) (Min)

Test Method : IS : 1608/Pt-1/2018 & IS : 1500/Pt.1/2013

Remarks : The above test results obtained conform to the specified value.

___________________________ __________________________ _________________________

Witnessed by Test carried by Authorised Signature

Page _02___of _03__

MANGALAM TESTING BUREAU

MATERIAL TESTING LABORATORY (HOWRAH)

TENSILE TESTING MACHINE: UTK 60

HARDNESS TESTING MACHINE: KAS

JOB CARD (Mechanical)

Job No. & Date : MTB/2020/N/0103 Date: 16.01.2020 Test to be performed : UTS, YS, %Elongation

Bend & Hardness

Description of the Sample : 02 Nos. Sample Sample Received by Lab : 16.01.2020

Heat No. : NA

Specification : Given Below Date of Testing : 03.02.2020

Thk Width Area GL EL %Elg. YL YS BL TS Bend Test

Sl. No. Sample Description

mm mm mm² mm mm 5.65 √A N MPa N MPa (1800 at 2t)

1 Plate 12 mm Thick 11.3 12.74 143.96 68 86.2 26.76 42200 293.14 74600 518.20 Satisfactory

2 Plate 16 mm Thick 11.48 16.16 185.52 77 98.6 28.05 56800 306.17 89200 480.81 Satisfactory

Req. as per IS :

23.00 250 410

2062/2011,Amnd.No.1,nov’ --- --- --- --- --- --- --- Shall pass the test.

Min Min Min

2012,Gr.Desig.E250,Q-A

Test Method : IS : 1608/Pt-1/2018 & IS : 1599/2012,R.A.2017

Remarks : The above test results obtained conform to the specified value.

___________________________ __________________________ _________________________

Witnessed by Test carried by Authorised Signature

Page _03___of _03__

MANGALAM TESTING BUREAU

MATERIAL TESTING LABORATORY (HOWRAH)

TENSILE TESTING MACHINE: UTK 60

HARDNESS TESTING MACHINE: KAS

JOB CARD (Mechanical)

Job No. & Date : MTB/2020/N/0103 Date: 16.01.2020 Test to be performed : Hardness & Proof Load

Description of the Sample : 07 Nos. Sample Sample Received by Lab : 16.01.2020

Heat No. : NA

Specification : Given Below Date of Testing : 03.02.2020

Sl. Hardness in HRB

No.

Sample Description Applied Proof Load(N)

HRB HV

1. Hex Nut M24 180000 N/15 Sec 89 180

Req. as per IS : 1367/Pt.6/1994,Cl.4 180000 N (Nominal) 117-302 HV

2. Hex Nut M30 287000 N/15 Sec 75 137

Req. as per IS : 1367/Pt.6/1994 Cl.4 286100 N (Nominal) 117-302 HV

3. Hex Nut M36 417000 N/15 Sec 68 121

Req. as per IS : 1367/Pt.6/1994 Cl.4 416700 N (Nominal) 117-302 HV

Test Method : IS : 1608/Pt-1/2018 & IS : 1586/Pt.1/2018

Remarks : The above test results obtained conform to the specified value.

Sl. Hardness in HRB

No.

Sample Description

HRB HV

1. Hex Nut M42 89 180

2. Hex Nut M48 74 135

3. Hex Nut M56 67 119

4. Hex Nut M64 71 127

Test Method : IS : 1586/Pt.1/2018

___________________________ __________________________ _________________________

Witnessed by Test carried by Authorised Signature

You might also like

- 72 MetaloDocument1 page72 MetalomangalamtestingbureaNo ratings yet

- BCS - SS-CRM 475Document2 pagesBCS - SS-CRM 475mangalamtestingbureaNo ratings yet

- Indian Coast Guard: Directorate of RecruitmentDocument6 pagesIndian Coast Guard: Directorate of RecruitmentShivam Rathor67% (3)

- Sample 1Document1 pageSample 1mangalamtestingbureaNo ratings yet

- N 4348 2Document1 pageN 4348 2mangalamtestingbureaNo ratings yet

- LA Ravi Sir NC 4Document4 pagesLA Ravi Sir NC 4mangalamtestingbureaNo ratings yet

- Mech 1024Document1 pageMech 1024mangalamtestingbureaNo ratings yet

- Is 2629Document23 pagesIs 2629Abhishek KaliaNo ratings yet

- Comparison List Copper Bronze 2011 1Document7 pagesComparison List Copper Bronze 2011 1NaldoVicenteNo ratings yet

- Gi Earth SpikeDocument5 pagesGi Earth SpikemangalamtestingbureaNo ratings yet

- Is 1979 1985 PDFDocument103 pagesIs 1979 1985 PDFmangalamtestingbureaNo ratings yet

- SAC - 8 - 3 - Build 73 - Users - Guide - 007-012449-001 - Revision C PDFDocument218 pagesSAC - 8 - 3 - Build 73 - Users - Guide - 007-012449-001 - Revision C PDFmangalamtestingbureaNo ratings yet

- Gi Earth SpikeDocument5 pagesGi Earth SpikemangalamtestingbureaNo ratings yet

- Pub 71 The Nickel Silvers PDFDocument27 pagesPub 71 The Nickel Silvers PDFmangalamtestingbureaNo ratings yet

- Thermal Power PlantDocument13 pagesThermal Power PlantThulasi RamNo ratings yet

- Gi Earth SpikeDocument5 pagesGi Earth SpikemangalamtestingbureaNo ratings yet

- Is 1757 1988 PDFDocument7 pagesIs 1757 1988 PDFkarthikkandaNo ratings yet

- Is 2486 4 1981Document21 pagesIs 2486 4 1981mangalamtestingbureaNo ratings yet

- 708M40 Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi MetalsDocument1 page708M40 Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi MetalsmangalamtestingbureaNo ratings yet

- Astm A436Document4 pagesAstm A436PaulaErikaMA80% (5)

- Mechanical EngineeringDocument14 pagesMechanical EngineeringmangalamtestingbureaNo ratings yet

- Astm A436Document4 pagesAstm A436PaulaErikaMA80% (5)

- Suspenion SystemDocument21 pagesSuspenion SystemmangalamtestingbureaNo ratings yet

- Ss MicrostructureDocument3 pagesSs MicrostructuremangalamtestingbureaNo ratings yet

- Book 1Document5 pagesBook 1mangalamtestingbureaNo ratings yet

- Xnumbers Tutorial1Document294 pagesXnumbers Tutorial1Zhichein Wong100% (1)

- Lista ProductosDocument133 pagesLista ProductosmangalamtestingbureaNo ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentmangalamtestingbureaNo ratings yet

- Din en 10293-2005 PDFDocument18 pagesDin en 10293-2005 PDFdepeche1mode100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 1MA248 2e Active Phased Ant Arr TestDocument50 pages1MA248 2e Active Phased Ant Arr TestALEXANDRE JOSE FIGUEIREDO LOUREIRONo ratings yet

- Ijsrp p7967 1Document5 pagesIjsrp p7967 1olumideNo ratings yet

- Interactive Cares Laravel Career Path Outline 1Document15 pagesInteractive Cares Laravel Career Path Outline 1Neamotullah NaimNo ratings yet

- Loyalty Program As A Customer Retention Strategy The Perspective of O2 Telefonica Limited, UK.Document7 pagesLoyalty Program As A Customer Retention Strategy The Perspective of O2 Telefonica Limited, UK.International Journal of Innovative Science and Research TechnologyNo ratings yet

- Assignment 2Document8 pagesAssignment 2Ador AkoiNo ratings yet

- FEF Welding Fabric Selection ChartDocument1 pageFEF Welding Fabric Selection Chartsalman KhanNo ratings yet

- Vessel, Jacketed Vessel, Reactor Atmospheric Tank, Storage: 7.8 Documentation ExamplesDocument7 pagesVessel, Jacketed Vessel, Reactor Atmospheric Tank, Storage: 7.8 Documentation ExamplesnmulyonoNo ratings yet

- The Unfolding of Bhopal Disaster: T.R. ChouhanDocument4 pagesThe Unfolding of Bhopal Disaster: T.R. ChouhanAyush SharmaNo ratings yet

- FullStack Cafe Interview PlanDocument6 pagesFullStack Cafe Interview PlanAnkurNo ratings yet

- 16 Common Interview Questions & Answers On Generator - Part-1Document3 pages16 Common Interview Questions & Answers On Generator - Part-1Mrinal Kanti Roy40% (5)

- LED Matrix Display Project ReportDocument81 pagesLED Matrix Display Project ReportAmar Shrestha81% (16)

- Combining Inductive and Analytical LearningDocument6 pagesCombining Inductive and Analytical LearningDr B AnjanadeviNo ratings yet

- Chapter 12Document12 pagesChapter 12Mut4nt TVNo ratings yet

- Data Protection GDPRE Short Version 5 2021Document49 pagesData Protection GDPRE Short Version 5 2021anees kausarNo ratings yet

- EdScratch Student Lesson ActivitiesDocument242 pagesEdScratch Student Lesson Activitiesلينا ابو عمرNo ratings yet

- A Survey On OLE For Process Control (OPC)Document6 pagesA Survey On OLE For Process Control (OPC)scadaprimaciptaNo ratings yet

- DaVinci Resolve 17 Fusion Visual EffectsDocument379 pagesDaVinci Resolve 17 Fusion Visual Effectsmaan ti100% (1)

- Ajit Singh Yadav Roll No 02 IIFT 2009-12-Spanish Project On TCS Latin AmericaDocument10 pagesAjit Singh Yadav Roll No 02 IIFT 2009-12-Spanish Project On TCS Latin AmericaAjit SinghNo ratings yet

- Diagnostic Report: Component Fault Codes 7 Total / 1 Active / 6 InactiveDocument2 pagesDiagnostic Report: Component Fault Codes 7 Total / 1 Active / 6 Inactivealexis nuñez hernandezNo ratings yet

- Deliver Better Customer Experiences With Machine Learning in Real-Time - HandoutDocument27 pagesDeliver Better Customer Experiences With Machine Learning in Real-Time - Handoutanil987vermaNo ratings yet

- Backflush Accounting Feb 2020: Traditional Cost Accounting SystemDocument9 pagesBackflush Accounting Feb 2020: Traditional Cost Accounting SystemMuhammad Noman AnserNo ratings yet

- EMC Aircraft PDFDocument51 pagesEMC Aircraft PDFHema SinghNo ratings yet

- Lecture 01 Introduction To Product Design and DevelopmentDocument17 pagesLecture 01 Introduction To Product Design and DevelopmentSohit Mishra100% (2)

- Conversion TablesDocument5 pagesConversion TablesFredy NavasNo ratings yet

- Digital SLR Photography Solutions, From PC Magazine - 89Document419 pagesDigital SLR Photography Solutions, From PC Magazine - 89adi22-22No ratings yet

- DBF-Proposal Final FinalDocument5 pagesDBF-Proposal Final FinalSaif RezaNo ratings yet

- Online Admission SystemDocument39 pagesOnline Admission SystemBirjoy Basumatary100% (1)

- Lamond - Tarrio Comms July 2020 To Dec 30 2020Document22 pagesLamond - Tarrio Comms July 2020 To Dec 30 2020Daily KosNo ratings yet

- Manual Dryer FD 95 PDFDocument42 pagesManual Dryer FD 95 PDFAhmad DagamsehNo ratings yet

- Sebp4321 20 00 AllDocument785 pagesSebp4321 20 00 AllNataly Mendoza100% (1)