Professional Documents

Culture Documents

DS CT3107 en Co 63812

Uploaded by

Kevin Supho CruzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DS CT3107 en Co 63812

Uploaded by

Kevin Supho CruzCopyright:

Available Formats

Calibration

Dead-weight tester

High-pressure version

Model CPB3800HP

WIKA data sheet CT 31.07

for further approvals

see page 5

Applications

■■ Primary standard for calibrating the pressure scale in a

hydraulic range up to 2,600 bar (40,000 lb/in²)

■■ Reference instrument for factory and calibration

laboratories for the testing, adjustment and calibration of

pressure measuring instruments

■■ Complete, stand-alone system, also suitable for on-site

use

Special features

■■ Total measurement uncertainty up to 0.01 % of reading

■■ Dual-range piston-cylinder system 2,600 bar

(40,000 lb/in²) with fully automated changing between

ranges

■■ Factory calibration includes traceability to national

standards, as standard, with UKAS calibration possible as

an option Dead-weight tester, high-pressure version, model

■■ Masses manufactured from stainless steel, can be CPB3800HP

adjusted to local gravity

Description

Proven primary standard Basic principle

Pressure balances (dead-weight testers) are the most Pressure is defined as the quotient of force and area. The

accurate instruments available on the market for the core component of the CPB3800HP is therefore a very

calibration of electronic or mechanical pressure measuring precisely manufactured piston-cylinder system, onto which a

instruments. The direct measurement of the pressure mass load is applied in order to generate the individual test

(p = F/A), as well as the use of high-quality materials enable points.

a very small measurement uncertainty, in conjunction with an

excellent long-term stability. The mass load is proportional to the target pressure and

The pressure balance (dead-weight tester) has therefore this is achieved through optimally graduated masses. As

been used for years in factory and calibration laboratories in standard, these masses are manufactured to the standard

industry, national institutes and research laboratories. gravity (9.80665 m/s²), though they can be adjusted to a

specific location and also UKAS calibrated.

Stand-alone operation

Due to its integrated pressure generation and the purely

mechanical measuring principle, the model CPB3800HP is

ideal for on-site use for maintenance and service.

WIKA data sheet CT 31.07 ∙ 03/2018 Page 1 of 10

Data sheets showing similar products and accessories:

Dead-weight tester in compact design; model CPB3800; see data sheet CT 31.06

Pneumatic dead-weight tester; model CPB3500; see data sheet CT 31.22

Hydraulic pressure balance; model CPB5800; see data sheet CT 31.11

Pressure balance in high-pressure version; model CPB5000HP; see data sheet CT 31.51

CalibratorUnit; model CPU6000; see data sheet CT 35.02

Easy operation

The integrated dual-area spindle pump enables rapid filling

of the test system and smooth pressure generation up to

2,600 bar (40.000 lb/in²). At the same time, the precisely

adjustable spindle pump also enables fine pressure

adjustment. A control schematic for pressure generation on

the instrument base facilitates quick and easy operation.

As soon as the measuring system reaches equilibrium, there

is a balance of forces between the pressure and the masses.

The excellent quality of the system ensures that this pressure

remains stable over several minutes, so that the pressure

value for comparative measurements can be read without

any problems, or also so that more complex adjustments can

be carried out on the test item.

Control schematic on the CPB3800HP instrument base

Compact instrument design

The CPB3800HP is also particularly notable for its compact

dimensions, which are not altered during operation, since the Force F

spindle runs within the pump body.

With its compact dimensions, the exceptionally robust ABS

plastic case and the low weight associated with these,

the CPB3800HP is also particularly suited for on-site

applications.

The test item connection is equipped with a G ½ union nut

with metal cone. M16 x 1.5, M20 x 1.5 und 9/16-18 UNF

thread adapters with male threads are included in the scope

of delivery.

1

The piston-cylinder system 2

High accuracy over a wide measuring range

The dual-range piston-cylinder system offers two measuring

ranges in one case with automatic measuring range

switching from low-pressure to high-pressure pistons. This Pressure p

provides the user with an extremely flexible measuring

instrument that can cover a wide measuring range with high Dual-range piston-cylinder system 2,600 bar

accuracy, with only one piston-cylinder system and one (40,000 lb/in²)

mass set. Additionally two test points can automatically be

achieved by loading the masses once.

Both the piston and cylinder are manufactured from The masses are stacked directly onto the piston shaft. This

hardened steel or tungsten carbide, respectively. This makes it easier to place the masses on and thus enables a

pairings of materials has very low pressure and temperature lower start value.

coefficients of expansion, which results in a very good

linearity for the effective area of the piston and a very high The overall design of the piston-cylinder system and the very

accuracy. precise manufacturing of both the piston and the cylinder,

ensure exceptionally low friction force, which results in

Piston and cylinder are very well protected, against excellent operating characteristics with long free-rotation time

contact, impacts or contamination from outside, in a solid and low sink rates. Thus a high long-term stability is ensured.

stainless-steel/hardened tool steel case. At the same time, Therefore, the recommended recalibration interval is two to

overpressure protection is integrated, which prevents the five years depending on the conditions of use.

piston from being forced out vertically and avoids damage to

the piston-cylinder system in the event of masses removal 1 High-pressure piston

under pressure. 2 Low-pressure piston = High-pressure cylinder

WIKA data sheet CT 31.07 ∙ 03/2018 Page 2 of 10

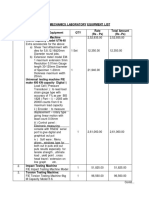

Tables of masses

The following tables show the number of masses within a For the measurement of the ambient conditions, the

mass set with their nominal mass values and the resulting CPU6000 CalibratorUnit can be used, see page 7.

nominal pressures for the respective measuring ranges.

The masses are manufactured, as standard, to the standard

Should the instrument not be operated under reference gravity (9.80665 m/s²) although they can be adjusted for any

conditions (ambient temperature 20 °C [68 °F], atmospheric local gravity.

pressure 1,013 mbar [14.69 psi], relative humidity 40 %), the

measured values must be corrected arithmetically.

Measuring range 1 … 2,600

[bar] 1 … 60 20 ... 2,600

Quantity Nominal pressure per piece Nominal pressure per piece

[bar] [bar]

Piston and make-up weight 1 1 20

Mass carrier 1 10 200

Masses (stackable on mass carrier) 7 10 200

Masses (stackable on piston shaft) 3 10 200

1 9 180

1 5 100

2 2 40

1 1 20

2 0.5 10

Set of fine increment masses 2 0.2 4

(optional)

1 0.1 2

1 0.05 1

2 0.02 0.4

1 0.01 0.2

Measuring range 10 ... 40,000

[lb/in²] 10 … 800 200 ... 40,000

Quantity Nominal pressure per piece Nominal pressure per piece

[lb/in²] [lb/in²]

Piston 1 10 200

Mass carrier 1 100 2.000

Masses (stackable on mass carrier) 14 100 2.000

Masses (stackable on piston shaft) 4 100 2.000

1 90 1.800

1 50 1.000

2 20 400

1 10 200

1 5 100

Set of fine increment masses 2 2 40

(optional)

1 1 20

1 0.5 10

2 0.2 4

1 0.1 2

WIKA data sheet CT 31.07 ∙ 03/2018 Page 3 of 10

Specifications

Model CPB3800HP

Piston-cylinder system

Measuring range 1) 1 … 60 bar / 20 … 2,600 bar

Required masses 107 kg

Smallest step 2) 0.5 bar / 10 bar

(Standard mass set)

Nominal effective area of the piston 1/8 in² / 1/160 in²

Measuring range 1) 10 … 800 lb/in² / 200 … 40,000 lb/in²

Required masses 119 kg

Smallest step 2) 5 lb/in² / 100 lb/in²

(Standard mass set)

Nominal effective area of the piston 1/8 in² / 1/160 in²

Accuracies

Standard 3) 4) 0.025 % of reading

Premium 3) 4) 0.01 % of reading

Pressure transmission medium Hydraulic fluid based on VG22 mineral oil (0.5 litre included in scope of delivery)

Material

Piston Tungsten carbide / steel

Cylinder Steel / tungsten carbide

Weight

Piston-cylinder system 2 kg [4.4 lbs]

bar mass set, box 1 43.3 kg [95.5 lbs]

bar mass set, box 2 29.7 kg [65.5 lbs]

bar mass set, box 3 29.4 kg [64.8 lbs]

bar mass set, box 4 29.4 kg [64.8 lbs]

lb/in² mass set, box 1 40.5 kg [89.3 lbs]

lb/in² mass set, box 2 33.6 kg [74.1 lbs]

lb/in² mass set, box 3 33.6 kg [74.1 lbs]

lb/in² mass set, box 4 31.6 kg [69.7 lbs]

Dimensions (W x D x H)

Carrying case 1 for mass set (optional) 400 x 310 x 310 mm

[15.8 x 12.2 x 12.2 in]

Carrying case 2 - 4 for mass set (optional) 215 x 310 x 310 mm

[8.5 x 12.2 x 12.2 in]

1) Theoretical starting value; corresponds to the pressure value generated by the piston or the piston and its make-up weight (by their own weight). To optimise the operating

characteristics more masses should be loaded.

2) The smallest pressure change value that can be achieved based on the standard mass set. To reduce this, a set of fine increment masses is also available.

3) The accuracy from 10 % of the measuring range is based on the measured value. In the lower part the accuracy is 0.025 % of reading.

4) Measurement uncertainty assuming reference conditions (ambient temperature 20 °C [68 °F], atmospheric pressure 1,013 mbar [14.69 psi], relative humidity 40 %). For operation

without a CalibratorUnit, corrections must be made if required.

Base

Connections

Connection for piston-cylinder system G ¾ B (male)

Test connection G ½ union nut with metal cone, with three thread adapters as standard

M16 x 1.5 / M20 x 1.5 and 9/16-18 UNF

Material

Wetted parts Austenitic stainless steel, high tensile brass, nitrile rubber

Pressure transmission medium Hydraulic fluid based on VG22 mineral oil (0.5 l included in scope of delivery) 5)

Reservoir 170 cm³

WIKA data sheet CT 31.07 ∙ 03/2018 Page 4 of 10

Base

Weight

Base 13.5 kg [29.8 lbs]

Permissible ambient conditions

Operating temperature 18 ... 28 °C [64 ... 82 °F]

Dimensions (W x D x H)

Base 401 x 397 x 155 mm [15.8 x 15.7 x 6.1 in], for details, see technical drawings

5) Other pressure transmission media on request.

Approvals

Logo Description Country

EU declaration of conformity European Union

Pressure equipment directive (Module A)

EAC Eurasian Economic Community

■■EMC directive

■■Pressure equipment directive

■■Low voltage directive

■■Machinery directive

UkrSEPRO Ukraine

Metrology, measurement technology

- MTSCHS Kazakhstan

Permission for commissioning

Certificates

Certificate

Calibration

CPB3800HP Standard: Calibration certificate

Option 1: UKAS calibration certificate (pressure calibration with a mass set)

Option 2: UKAS calibration certificate (area and mass calibration)

Set of fine increment masses Standard: Calibration certificate

Option 1: UKAS calibration certificate (pressure calibration with a piston-cylinder system)

Option 2: UKAS calibration certificate (mass calibration)

Recommended recalibration interval 2 to 5 years (dependent on conditions of use)

Approvals and certificates, see website

Transport dimensions for complete instrument

The complete instrument, in its standard version and standard scope of delivery, is shipped on two pallets.

The dimensions are 1.200 x 800 x 500 mm [47.2 x 31.5 x 19.7 in] and 800 x 600 x 500 mm [31.5 x 23.6 x 19.7 in].

The overall weight is dependent on the measuring range.

Version Weight

net gross

1 … 60 / 20 … 2,600 bar 169 [372.6 lbs] 207 kg [456.4 lbs]

10 … 800 / 200 … 40,000 lb/in² 177 [390.3 lbs] 215 kg [474.1 lbs]

WIKA data sheet CT 31.07 ∙ 03/2018 Page 5 of 10

Dimensions in mm [in]

(without masses)

3

1

1

]

.09

2

17

8[

35

Ø

203 [7.99]

183 [7.20]

171 [3.73]

22 [0.87]

4

401 [15.79] 1 Piston connection

108 [4.25]

5

2 Test connection

A 3 Dual-area spindle pump with star handle

6

4 Rotatable feet

7

8 5 High-pressure shut-off valve

6 Reservoir with plug screw

397 [15.63]

CPB3800HP

7 Low-pressure shut-off valve

R

B

8 Pressure generation control schematic

P

133 [5.24]

R

A B P P

9 Oil collecting tray

0-140bar

83 [3.27]

B A P

0-2000lb/in²

140bar +

A B P

2000lb/in² +

P A B

0

10 Adapter, see scope of delivery

145 [5.71] 143 [5.63]

93 [3.66]

Standard connection piston-cylinder system Test connection

10

9

9

WIKA data sheet CT 31.07 ∙ 03/2018 Page 6 of 10

CalibratorUnit model CPU6000

The models of the CPU6000 series are compact tools for use

with a pressure balance (dead-weight tester). In particular

when highly accurate measuring values, with measurement

uncertainties of less than 0.025 %, are required, complicated

mathematical calculations and corrections are necessary.

With the CPU6000 in combination with the WIKA-Cal (PC

software) all critical ambient parameters can be registered

and automatically corrected.

The CPU6000 series is made up of three

instruments

Weather station, model CPU6000-W

The CPU6000-W provides measured values such as

atmospheric pressure, relative humidity and the ambient CPU6000 series

temperature of the laboratory environment.

Pressure balance sensor box, model CPU6000-S

The CPU6000-S measures the piston temperature and

displays the floating position of the masses.

Digital multimeter, model CPU6000-M

The CPU6000-M fulfils the function of a digital multimeter

and power supply unit when electronic pressure transmitters

must be calibrated.

Typical application

WIKA-Cal PC software - Weight calculator

With the demo version of the WIKA-Cal software and a CPB

series pressure balance (dead-weight tester), the masses to

be applied and the corresponding reference pressure can be

determined. The pressure balance data (dead-weight tester

data) can be entered into the database manually or imported Model CPU6000-W, CPU6000-S, CPB5800 and PC with

automatically via an XML file available online. WIKA-Cal software

All ambient parameters and piston temperature can be

entered manually into WIKA-Cal or can be measured

automatically with the CPU6000 series, so that the highest

accuracy can be achieved. WIKA-Cal demo version can be

downloaded free of charge from the WIKA website.

Further specifications on the CPU6000 series can be found

in data sheet CT 35.02.

For details of the WIKA-Cal calibration software see data

sheet CT 95.10.

WIKA-Cal PC software - Weight calculator

WIKA data sheet CT 31.07 ∙ 03/2018 Page 7 of 10

Further pressure balances (dead-weight testers) within our calibration technology

programme

Dead-weight tester, model CPB3800

Measuring ranges:

Hydraulic 1 ... 120 to 10 ... 1.200 bar

(10 ... 1.600 to 100 ... 16.000 lb/in²)

Accuracy: 0.05 % of reading

0.025 % of reading (optional)

For specifications see data sheet CT 31.06 Dead-weight tester, model CPB3800

Dead-weight tester, model CPB3500

Measuring ranges:

Pneumatic -0.015 ... -1 to +1... +120 bar

(1 ... 100 to 10 ... 1,600 lb/in²)

Accuracy: 0.015 % of reading

up to 0.006 % of reading (optional)

For specifications see data sheet CT 31.22 Dead-weight tester, model CPB3500

Pressure balance, model CPB5800

Measuring ranges:

Hydraulic Single-piston measuring ranges:

1 ... 120 to 2 ... 300 bar

(10 ... 1,600 to 30 ... 4,000 lb/in²)

Dual-piston measuring ranges:

1 ... 60 bar / 10 ... 700 bar to

1 ... 60 bar / 20 ... 1,400 bar

(10 ... 800 lb/in² / 100 ... 10,000 lb/in² to

10 ... 800 lb/in² / 200 ... 20,000 lb/in²)

Accuracy: 0.015 % of reading

up to 0.006 % of reading (optional)

For specifications see data sheet CT 31.11 Pressure balance, model CPB5800

Pressure balance for high pressure, model CPB5000HP

Measuring ranges:

Hydraulic 25 ... 2,500, 25 ... 4,000 or 25 ... 5,000 bar

(350 ... 40,000, 350 ... 60,000 or

350 ... 70,000 lb/in²)

Accuracy: 0.025 % of reading

0.02 % of reading (optional)

Pressure balance for high pressure,

For specifications see data sheet CT 31.51 model CPB5000HP

WIKA data sheet CT 31.07 ∙ 03/2018 Page 8 of 10

Mass sets

Set of fine increment masses M1 and F1

The masses included in the standard mass set are ideally

suited for everyday use. If even smaller intermediate values

need to be generated, using one of the class M1 or F1

set of fine increment masses with the following masses is

recommended:

1 x 50 g, 2 x 20 g, 1 x 10 g, 1 x 5 g, 2 x 2 g, 1 x 1 g,

1 x 500 mg, 2 x 200 mg, 1 x 100 mg, 1 x 50 mg, 2 x 20 mg, Set of fine increment masses

1 x 10 mg, 1 x 5 mg, 2 x 2 mg, 1 x 1 mg

Accessories Bestellcode

Fine increment masses in bar (smallest step 0.1 / 2 lb/in²) CPB-A-CC-ZZ7ZZZ-Z

Fine increment masses in bar (smallest step 0.01 / 0.2 bar) CPB-A-CC-ZZ6ZZZ-Z

1 storage case for instrument base (and CPB3800HP piston-cylinder system) CPB-A-CC-ZZ8ZZZ-Z

Four flight cases for mass set CPB-A-CC-ZZ9ZZZ-Z

Adapter for connection column, G ½ female thread with o-ring, max. 1,600 bar, mat.: 1.4571 CPB-A-CC-ZZFZZZ-Z

Adapter for connection column, 9/16-18 UNF male thread with sealing cone, mat.: hardened stainless steel CPB-A-CC-ZZEZZZ-Z

Adapter for connection column, M20 x 1.5 male thread with sealing cone, mat.: hardened stainless steel CPB-A-CC-ZZDZZZ-Z

Adapter for connection column, M16 x 1.5 male thread with sealing cone, mat.: hardened stainless steel CPB-A-CC-ZZCZZZ-Z

Dual range piston-cylinder system 1 … 50 / 20 … 2,600 bar CPB-A-CC-ZZ2ZZZ-Z

Dual range piston-cylinder system 10 … 600 / 200 … 40,000 lb/in² CPB-A-CC-ZZ3ZZZ-Z

Sealing and maintenance set for instrument base CPB-A-CC-ZZBZZZ-Z

Hydraulic fluid based on VG22 mineral oil in plastic bottle, content 0.5 litre CPB-A-CC-ZZAZZZ-Z

Tool set consisting of open-ended spanners, replacement seals, pointer remover and pointer punch CPB-A-CC-ZZGZZZ-Z

WIKA data sheet CT 31.07 ∙ 03/2018 Page 9 of 10

Scope of delivery Options

■■ Base ■■ Systems with increased accuracy to 0.01 %

■■ Dual-area spindle pump for filling, pressure generation ■■ Further pressure transmission media

and fine pressure adjustment ■■ Further pressure units

■■ Piston connection with G ¾ B male thread ■■ Masses manufactured to local gravity

■■ Test connection with G ½ union nut with metal cone ■■ Set of fine increment masses

and three thread adapters M16 x 1.5 / M20 x 1.5 and ■■ Further tools:

9/16-18 UNF -- G ½ (½" BSP) angle connection

■■ Piston-cylinder system -- Pointer punch

■■ Masses manufactured to standard gravity -- Pointer remover

(standard value: 9.80665 m/s²) -- Test item connection

■■ VG22 mineral oil (0.5 litre) ■■ UKAS calibration certificate

■■ Tool and maintenance set consisting of:

-- 1 hexagon wrench key 3 mm A/F

-- 2 x 30 mm A/F open-ended spanners

-- 1 spirit level

-- 4 level plates

-- 1 set of hardened steel sealing rings

-- 1 set of replacement seals for base

■■ Operating instructions

■■ Factory calibration certificate

Ordering information

Model / Package / Accuracy / Gravity value g / Fine increment masses / Storage case / Calibration for dead-weight tester /

Calibration for fine increment masses / Accessories / Further approvals / Additional ordering information

© 02/2015 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials

WIKA data sheet CT 31.07 ∙ 03/2018 Page 10 of 10

03/2018 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- Wika CPB3800 DatasheetDocument9 pagesWika CPB3800 DatasheetHatem RagabNo ratings yet

- Catalog Hydraulic Pressure Balance Cpb5800Document11 pagesCatalog Hydraulic Pressure Balance Cpb5800Fulbert SuriatmadjaNo ratings yet

- Pneumatic Pressure Balance Model CPB5000: ApplicationsDocument12 pagesPneumatic Pressure Balance Model CPB5000: ApplicationsEliseo PardoNo ratings yet

- DHBudenberg CPB3500 DatasheetDocument9 pagesDHBudenberg CPB3500 DatasheetLeandroNo ratings yet

- Dead Weight Testers: Industrial Pressure CalibratorDocument8 pagesDead Weight Testers: Industrial Pressure CalibratorKhezzari MerwenNo ratings yet

- Dead Weight TesterDocument5 pagesDead Weight Testersanjaysingh2013100% (3)

- Avery Hardoll BM Series BulkmeterDocument8 pagesAvery Hardoll BM Series BulkmeterLismanNo ratings yet

- Celda de CargaDocument18 pagesCelda de CargaronainteNo ratings yet

- Summary of Choke Valve API 6A 21 EditionDocument52 pagesSummary of Choke Valve API 6A 21 EditionInChy Rencarnation Poseidon100% (1)

- Elastic Recovery, Consistency and Stiffness of Polymer Modified Binders (ARRB Elastometer)Document13 pagesElastic Recovery, Consistency and Stiffness of Polymer Modified Binders (ARRB Elastometer)तिप्लोकाची तिरुनचिपल्ली केरकेट्टाNo ratings yet

- M0627Document24 pagesM0627subhransubaral1No ratings yet

- Calibration of A Pressure GaugeDocument8 pagesCalibration of A Pressure GaugeRashmika Uluwatta100% (1)

- Dicks Oilfield Satellite Auto DrillerDocument16 pagesDicks Oilfield Satellite Auto Drillertoxa0707100% (1)

- Hand-Held Pressure Calibrator With Integrated Pump Model CPH6600Document6 pagesHand-Held Pressure Calibrator With Integrated Pump Model CPH6600Nabeel AhmedNo ratings yet

- Flanged Ball Valves ANSI CLASS 150 & 300: Full BoreDocument20 pagesFlanged Ball Valves ANSI CLASS 150 & 300: Full BoreBayu Aji100% (1)

- AUTOMATIC Cement Compression and Flexural Tester CONTROLSDocument4 pagesAUTOMATIC Cement Compression and Flexural Tester CONTROLSadegis100% (1)

- Ap LucDocument12 pagesAp LuchNo ratings yet

- 00 PROV CalculationReportBifurcazioneFinalDocument18 pages00 PROV CalculationReportBifurcazioneFinalJosé Hernández BarrientosNo ratings yet

- Common - Folder CGT PDFDocument12 pagesCommon - Folder CGT PDFrjca100No ratings yet

- Product Data Sheet Micro Motion cng050 Compressed Natural Gas Flow Meters en 64042Document16 pagesProduct Data Sheet Micro Motion cng050 Compressed Natural Gas Flow Meters en 64042ElcioNo ratings yet

- SM Lab Manual Part 1-1Document78 pagesSM Lab Manual Part 1-1Uneeb RamzanNo ratings yet

- Compression Testing Machine PDFDocument5 pagesCompression Testing Machine PDFBudi MaryantoNo ratings yet

- Avery Hardoll CM Series BulkmeterDocument8 pagesAvery Hardoll CM Series Bulkmeterhendro saputroNo ratings yet

- 400-10 (Meters & Accessories 49093) PDFDocument52 pages400-10 (Meters & Accessories 49093) PDFmetal_dung2No ratings yet

- Design and Analysis of Pressure Vessel Using PV Elite SoftwareDocument8 pagesDesign and Analysis of Pressure Vessel Using PV Elite SoftwareVitor OlivettiNo ratings yet

- dsb10x BrodieBirotorDocument2 pagesdsb10x BrodieBirotordleonarenNo ratings yet

- VACUTAP® VVS® Technical Data 5789182 01 enDocument42 pagesVACUTAP® VVS® Technical Data 5789182 01 enChandrashekhar KhambekarNo ratings yet

- MECH Lab RequirementDocument4 pagesMECH Lab RequirementJaishree ChauhanNo ratings yet

- Complete Fluid Mechanics Lab ManualDocument113 pagesComplete Fluid Mechanics Lab ManualRayhan SaeedNo ratings yet

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter Specificationsjimbo2032No ratings yet

- Bop 2FZ18-21 Rig202Document23 pagesBop 2FZ18-21 Rig202marthos ericson muñoz castilloNo ratings yet

- Astm C109 (2005)Document5 pagesAstm C109 (2005)kimberly solisNo ratings yet

- Prime 4 PD MeterDocument4 pagesPrime 4 PD Metertiualbert8729100% (1)

- Thincylind PDFDocument2 pagesThincylind PDFPriyanshuNo ratings yet

- Thincyl PDFDocument2 pagesThincyl PDFPriyanshuNo ratings yet

- Automatic Compression Testers For Cylinders: SeriesDocument4 pagesAutomatic Compression Testers For Cylinders: SeriesJosé Fco. Cerda M.No ratings yet

- Civil Lab Equipment Details1Document17 pagesCivil Lab Equipment Details1ANKESH SHRIVASTAVANo ratings yet

- Fuel Oil Meter ManualDocument89 pagesFuel Oil Meter ManualbouguerraNo ratings yet

- Pressure Sensor ModulesDocument3 pagesPressure Sensor Modulesphani22No ratings yet

- Ultrasonic Flow Meter'sDocument4 pagesUltrasonic Flow Meter'sFer TiscoNo ratings yet

- Pipe Rack Erection Modified and PresentationDocument34 pagesPipe Rack Erection Modified and PresentationRojan Baby75% (4)

- Cat - UTMDocument4 pagesCat - UTMDeb RoyNo ratings yet

- Bettis CBA-300 Series: Pneumatic ActuatorsDocument18 pagesBettis CBA-300 Series: Pneumatic Actuatorsbatu shaudaNo ratings yet

- SS2 8110 0600 07Document4 pagesSS2 8110 0600 07rullycosta85No ratings yet

- Fatigue AnalysisDocument14 pagesFatigue AnalysisAndrei Ionut UtaNo ratings yet

- Komatsu PumpDocument64 pagesKomatsu PumpAhmed Rezk98% (40)

- ROCS Umbilical-Less Control SystemDocument2 pagesROCS Umbilical-Less Control SystemWilliam EvansNo ratings yet

- BGH1200Document2 pagesBGH1200Muhammad Afzal MirzaNo ratings yet

- Differential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsDocument8 pagesDifferential Pressure Gauges Cryo Gauge Model 712.15: ApplicationsdhaktodesatyajitNo ratings yet

- Hydraulic Comparison Test Pump Model CPP1200-X: ApplicationsDocument5 pagesHydraulic Comparison Test Pump Model CPP1200-X: ApplicationsToy HeartNo ratings yet

- Datasheet TachogeneratorDocument4 pagesDatasheet TachogeneratorNurulHidayatNo ratings yet

- Universal Testing Machine: Model: TUF-C-1000 KN (SERVO)Document4 pagesUniversal Testing Machine: Model: TUF-C-1000 KN (SERVO)Intan PuspitariniNo ratings yet

- SM TM 1.5-4 Guardsman (G) Series02002Document4 pagesSM TM 1.5-4 Guardsman (G) Series02002Paola Arevalo RinconNo ratings yet

- YokogawaDocument32 pagesYokogawadcperfectNo ratings yet

- Danfoss KPS 31Document12 pagesDanfoss KPS 31ikan11No ratings yet

- Calculating CC10P6inCC17cupDocument12 pagesCalculating CC10P6inCC17cupdsargoarnowoNo ratings yet

- Gauges and Ancillary EquipmentDocument26 pagesGauges and Ancillary EquipmentAlbertoNo ratings yet

- Constant Rate of Strain ConsolidationDocument2 pagesConstant Rate of Strain ConsolidationDương NguyễnNo ratings yet

- 6203 Eng D WDocument5 pages6203 Eng D WKevin Supho CruzNo ratings yet

- Excavadora 336DL CAT Manual de Partes PDFDocument1,179 pagesExcavadora 336DL CAT Manual de Partes PDFJuan Paco100% (7)

- Dead Weight Tester ManualDocument4 pagesDead Weight Tester ManualAliNo ratings yet

- Sip 01 GBDocument3 pagesSip 01 GBAnonymous FZs3yBHh7No ratings yet

- Sip 01 GBDocument3 pagesSip 01 GBAnonymous FZs3yBHh7No ratings yet

- Data Sheet 74LS86Document3 pagesData Sheet 74LS86Tejo YuliantoNo ratings yet

- Datasheet 74ls83 PDFDocument3 pagesDatasheet 74ls83 PDFLioni Dávila AguilarNo ratings yet

- 35-Information Center Commands HuaweiDocument25 pages35-Information Center Commands HuaweitorradoedgardoNo ratings yet

- M1 - Introduction To Data EngineeringDocument65 pagesM1 - Introduction To Data EngineeringEdgar SanchezNo ratings yet

- A Mini Project On Human Resource Management in Wipro TechnologiesDocument10 pagesA Mini Project On Human Resource Management in Wipro TechnologiesnithyakalakNo ratings yet

- İstanbul Aydın University: 1. Project ProposalDocument11 pagesİstanbul Aydın University: 1. Project ProposalSafouh AL-HelwaniNo ratings yet

- Cutting Room FloorDocument17 pagesCutting Room FloorMarko KcNo ratings yet

- SQL CodesDocument23 pagesSQL Codeseanandan_be4041No ratings yet

- NURSING INFORMATICS Review NotesDocument4 pagesNURSING INFORMATICS Review Notespoleene de leonNo ratings yet

- Assigment No 1 - AnnDocument3 pagesAssigment No 1 - AnnVaishnavi GuravNo ratings yet

- En - stm32l4 WDG Timers RTCDocument22 pagesEn - stm32l4 WDG Timers RTCThế PhươngNo ratings yet

- Agora: Bringing Our Voting Systems Into The 21st CenturyDocument46 pagesAgora: Bringing Our Voting Systems Into The 21st CenturypokechoNo ratings yet

- Comparison Chart: Curriculum Vitae RésuméDocument7 pagesComparison Chart: Curriculum Vitae Résumérr48843No ratings yet

- FIL0814 DavaoDocument27 pagesFIL0814 DavaoangelomercedeblogNo ratings yet

- Visualsoft Suite User Manual Visual: Overlay 10.4Document60 pagesVisualsoft Suite User Manual Visual: Overlay 10.4cristianocalheirosNo ratings yet

- Py101 PDFDocument548 pagesPy101 PDFafalonso100% (1)

- Hy-Lite 2 System: Operating Instructions ManualDocument33 pagesHy-Lite 2 System: Operating Instructions ManualIrfan NurdiansyahNo ratings yet

- Rab CCTVDocument10 pagesRab CCTVMjska rakaNo ratings yet

- Idc4 Car 54 en 3 PDFDocument13 pagesIdc4 Car 54 en 3 PDFMasmas Mas100% (1)

- User Interface Design: by Roger S. Pressman and Bruce R. MaximDocument26 pagesUser Interface Design: by Roger S. Pressman and Bruce R. MaximKimberly GonzalesNo ratings yet

- Optimal Placement of PMUs by Integer Linear ProgrammingDocument2 pagesOptimal Placement of PMUs by Integer Linear Programmingwvargas926No ratings yet

- Windows AD Top20 Questions and AnswerDocument47 pagesWindows AD Top20 Questions and AnswerSeenivasan Srirangadhamu0% (1)

- Rancher Com Docs k3s Latest en Backup RestoreDocument8 pagesRancher Com Docs k3s Latest en Backup RestoreJose BoullosaNo ratings yet

- 3.6 Digitalized Oil and Gas FieldsDocument25 pages3.6 Digitalized Oil and Gas FieldsHamid Souliman100% (2)

- THE DOSE Magazine - Issue 3 (Paris) TEASERDocument10 pagesTHE DOSE Magazine - Issue 3 (Paris) TEASERthedosemag100% (1)

- Oracle Partitioning For DevelopersDocument70 pagesOracle Partitioning For DevelopersLewis CunninghamNo ratings yet

- Items ObjectDocument23 pagesItems ObjectAsur100No ratings yet

- Rehva: Federation of European Heating and Air-Conditioning AssociationsDocument57 pagesRehva: Federation of European Heating and Air-Conditioning AssociationsmradiliNo ratings yet

- Shipping Container Homes Book 7Document35 pagesShipping Container Homes Book 7Radu Gheorghe Ciortescu100% (2)

- Quality Requirements InterpretationDocument76 pagesQuality Requirements InterpretationMauro MLRNo ratings yet

- Lesson 14-Audio MediaDocument51 pagesLesson 14-Audio MediaCatherine Concrenio100% (1)

- AN2399Document20 pagesAN2399Drew AlbaneseNo ratings yet