Professional Documents

Culture Documents

Ice New Now

Uploaded by

Jikni NobleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ice New Now

Uploaded by

Jikni NobleCopyright:

Available Formats

A carburetor (American English) or carburettor (British English) is a device that mixes air and fuel

for internal combustion engines in the proper air–fuel ratio for combustion. It is sometimes

colloquially shortened to carb in the UK and North America or carby in

Australia.[1] To carburate or carburet (and thus carburation or carburetion, respectively) means to

mix the air and fuel or to equip (an engine) with a carburetor for that purpose.

Carburetors have largely been supplanted in the automotive and, to a lesser extent, aviation

industries by fuel injection. They are still common on small engines for lawn mowers, rototillers and

other equipment

Basics

A carburetor consists of an open pipe through which the air passes into the inlet manifold of the

engine. The pipe is in the form of a venturi: it narrows in section and then widens again, causing the

airflow to increase in speed in the narrowest part. Below the venturi is a butterfly valve called the

throttle valve — a rotating disc that can be turned end-on to the airflow, so as to hardly restrict the

flow at all, or can be rotated so that it (almost) completely blocks the flow of air. This valve controls

the flow of air through the carburetor throat and thus the quantity of air/fuel mixture the system will

deliver, thereby regulating engine power and speed. The throttle is connected, usually through

a cable or a mechanical linkage of rods and joints or rarely by pneumatic link, to the

accelerator pedal on a car, a throttle lever in an aircraft or the equivalent control on other vehicles or

equipment.

Fuel is introduced into the air stream through small holes at the narrowest part of the venturi and at

other places where pressure will be lowered when not running at full throttle. Fuel flow is adjusted by

means of precisely calibrated orifices, referred to as jets, in the fuel path.

Fuel injection Diesel engines rely on internal mixture formation,[132] which means that they require a

fuel injection system. The fuel is injected directly into the combustion chamber, which can be either a

segmented combustion chamber or an unsegmented combustion chamber. Fuel injection with the

latter is referred to as direct injection (DI), whilst injection into the former is called indirect injection

(IDI).[145] In diesel engine terminology, indirect injection does not mean fuel injection into the inlet

manifold or anywhere else outside the cylinder or combustion chamber: in fact, the definition of the

diesel engine excludes such injection methods. For creating the fuel pressure, diesel engines usually

have an injection pump. There are several different types of injection pumps and methods for

creating a fine air-fuel mixture. Over the years many different injection methods have been used.

These can be described as the following: Air blast, where the fuel is blown into the cylinder by a

blast of air. Solid fuel / hydraulic injection, where the fuel is pushed through a spring loaded valve /

injector to produce a combustible mist. Mechanical unit injector, where the injector is directly

operated by a cam and fuel quantity is controlled by a rack or lever. Mechanical electronic unit

injector, where the injector is operated by a cam and fuel quantity is controlled electronically.

Common rail mechanical injection, where fuel is at high pressure in a common rail and controlled by

mechanical means. Common rail electronic injection, where fuel is at high pressure in a common rail

and controlled electronically. Torque controlling

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Building's Heat Gain: Air Conditioning DesignDocument19 pagesBuilding's Heat Gain: Air Conditioning DesignJikni NobleNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Developing An Environment Conducive To LearningDocument23 pagesDeveloping An Environment Conducive To LearningJikni NobleNo ratings yet

- Metal ShredderDocument4 pagesMetal ShredderJikni NobleNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Decision Making in Engineering ManagementDocument23 pagesDecision Making in Engineering ManagementJikni NobleNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Iron Ore CrusherDocument1 pageIron Ore CrusherJikni NobleNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Jikni MaintenanceDocument4 pagesJikni MaintenanceJikni NobleNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Assignment FinalsDocument5 pagesAssignment FinalsJikni NobleNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Manager: Renard Y. SienesDocument2 pagesThe Manager: Renard Y. SienesJikni NobleNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Building's Heat Gain: Air Conditioning DesignDocument18 pagesBuilding's Heat Gain: Air Conditioning DesignJikni NobleNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

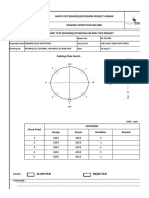

- Final SurveyDocument1 pageFinal SurveyJikni NobleNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Características de Potencia de Compresores de AireDocument9 pagesCaracterísticas de Potencia de Compresores de AireDavid ParraNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Against The Death PenaltyDocument3 pagesAgainst The Death PenaltyCassie E. ZernaNo ratings yet

- Jasper Van B. Arrieta: ObjectiveDocument2 pagesJasper Van B. Arrieta: ObjectiveJikni NobleNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- When Cutting Operations Are Performed On The MachineDocument5 pagesWhen Cutting Operations Are Performed On The MachineJikni NobleNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Figure 1. Rankine CycleDocument17 pagesFigure 1. Rankine CycleJikni NobleNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Chapter 1 HeatDocument10 pagesChapter 1 HeatJikni NobleNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Refrigerating MachineDocument5 pagesRefrigerating MachineJikni NobleNo ratings yet

- WAY. Don't Move Forward or Back While Doing This!Document2 pagesWAY. Don't Move Forward or Back While Doing This!Jikni NobleNo ratings yet

- Joyful Mysteries of The Holy RosaryDocument1 pageJoyful Mysteries of The Holy RosaryJikni NobleNo ratings yet

- Chapter 1 HeatDocument10 pagesChapter 1 HeatJikni NobleNo ratings yet

- Underline The Word That Rhymes With The First WordDocument1 pageUnderline The Word That Rhymes With The First WordJikni NobleNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Introduction ReginDocument22 pagesIntroduction ReginJikni NobleNo ratings yet

- Figure 1. Rankine CycleDocument17 pagesFigure 1. Rankine CycleJikni NobleNo ratings yet

- Ice FormulaDocument1 pageIce FormulaJikni NobleNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- ASEN3113 HW5 Solutions PART1Document7 pagesASEN3113 HW5 Solutions PART1Jikni NobleNo ratings yet

- Introduction ReginDocument22 pagesIntroduction ReginJikni NobleNo ratings yet

- HttpelDocument1 pageHttpelJikni NobleNo ratings yet

- ARPAN 2nd Periodic ExaminationDocument4 pagesARPAN 2nd Periodic ExaminationJikni NobleNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Wall and Floor Power Socket Outlet SymbolsDocument2 pagesWall and Floor Power Socket Outlet SymbolsJikni NobleNo ratings yet

- 4000 Series PM SchedulesDocument3 pages4000 Series PM SchedulesSoubhik MishraNo ratings yet

- L4103A, B, C Combination Aquastat and High Limit Controller: FeaturesDocument4 pagesL4103A, B, C Combination Aquastat and High Limit Controller: Features94splashmanNo ratings yet

- 2E TsisarDocument6 pages2E TsisarsemenyukNo ratings yet

- 8th Sem - Assignment - MD II (2962108)Document5 pages8th Sem - Assignment - MD II (2962108)rishabhk28995No ratings yet

- Carbon Residue TestDocument34 pagesCarbon Residue TestJerico Llovido50% (2)

- ZF BW 2050Document7 pagesZF BW 2050Yahya Moughlia100% (2)

- Pipline Cleaning ServicesDocument4 pagesPipline Cleaning Servicesbagus adhitiawarman100% (1)

- Mechanic Sample CV No 3Document2 pagesMechanic Sample CV No 3Patrick AidooNo ratings yet

- Jacobs Consultancy Lca Report Exec SummaryDocument17 pagesJacobs Consultancy Lca Report Exec SummaryCyril BorleNo ratings yet

- AIRPORETDocument131 pagesAIRPORETTrang DoNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Complete PFDDocument5 pagesComplete PFDAriff FikriNo ratings yet

- Passat No. 43/1: Air-ConditioningDocument6 pagesPassat No. 43/1: Air-ConditioningLuix TiradoNo ratings yet

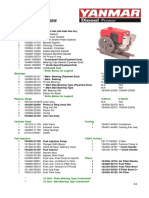

- Yanmar TS 80 PDFDocument2 pagesYanmar TS 80 PDFAhmad Ali Nursahidin100% (3)

- Backhoe Loader: Cat® 3054C Naturally Aspirated Diesel Engine Standard Optional Backhoe Digging DepthDocument20 pagesBackhoe Loader: Cat® 3054C Naturally Aspirated Diesel Engine Standard Optional Backhoe Digging DepthOutmane Lakhlili100% (1)

- Hydrogen Fuel CellsDocument7 pagesHydrogen Fuel CellshimanshuNo ratings yet

- Loco Comparison Chart Diesel LocosDocument6 pagesLoco Comparison Chart Diesel LocosJohan KrugerNo ratings yet

- Maintenance Manual 1400 HP DEMUsDocument556 pagesMaintenance Manual 1400 HP DEMUsKaushal Shrivastava100% (1)

- Lube Oil SystemDocument4 pagesLube Oil SystemSudhanshu ShekharNo ratings yet

- Joy T - Petr. Ref.-Introduction-Chapter 1 &2-Session 2Document47 pagesJoy T - Petr. Ref.-Introduction-Chapter 1 &2-Session 2ali aljifriNo ratings yet

- D155ax-5 Japan (Eng) Sebd0016205Document1,154 pagesD155ax-5 Japan (Eng) Sebd0016205walter vasquez100% (8)

- Home Materials Top 10 Companies in Automotive Lubricants MarketDocument6 pagesHome Materials Top 10 Companies in Automotive Lubricants Marketarman chowdhuryNo ratings yet

- Slime PsiDocument1 pageSlime PsiCameron RiosNo ratings yet

- Course ObjectivesDocument5 pagesCourse ObjectivesHyjan JacobNo ratings yet

- LG4JJED-WE-VN53 - Engine Control System 4JJ1Document402 pagesLG4JJED-WE-VN53 - Engine Control System 4JJ1tuannholtt92% (12)

- M-12C-003 Padding Plate Fuel Gas Cold Vent StackDocument4 pagesM-12C-003 Padding Plate Fuel Gas Cold Vent StackYurizal FirmansyahNo ratings yet

- Mec2249 P3 2017 2 PDFDocument4 pagesMec2249 P3 2017 2 PDFRonald V. Nina VelizNo ratings yet

- Now, LNG Can Drive Your ProjectsDocument4 pagesNow, LNG Can Drive Your ProjectsgatutNo ratings yet

- Soundpaint SP150: Water Based Vibration Damping CompoundDocument5 pagesSoundpaint SP150: Water Based Vibration Damping CompoundMarhadi AdiNo ratings yet

- ADocument64 pagesAjuanca_eduNo ratings yet

- Bitumen AsphaltDocument4 pagesBitumen AsphaltSrinivasan AlagarNo ratings yet

- Automotive Electronic Diagnostics (Course 1)From EverandAutomotive Electronic Diagnostics (Course 1)Rating: 5 out of 5 stars5/5 (6)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]From EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Rating: 5 out of 5 stars5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceFrom EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVFrom EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVRating: 5 out of 5 stars5/5 (2)

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)