Professional Documents

Culture Documents

ISO 17637 Non Destructive Examination of

Uploaded by

r afrianto0 ratings0% found this document useful (0 votes)

124 views1 pageOriginal Title

ISO_17637_Non_Destructive_Examination_of.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

124 views1 pageISO 17637 Non Destructive Examination of

Uploaded by

r afriantoCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 1

SECTION-1

(Typical duties of Welding Inspectors)

ISO 17637 (Non Destructive Examination of Fusion Welds – Visual examination)

Vision: In Accordance with EN 473 and Checked every 12 Months

Illumination: Minimum Illumination 350 lux but recommends a Min of 500 lux

Access: 600 mm view with not less than 30 degree angle.

Duties of Welding Inspector:

Before Welding: Material, WPS, Welding Equipment; Personnel; Consumables; weld fit-up and

preheat.

During Welding: Weather, Process, Preheat/ Inter-pass T, Welding Consumables, Root/Inter-run

& Welder approval/Qualification.

After Welding: Weld Identification, Weld appearance, dimensions, drawing, NDT, Repair, PWHT,

Pressure/Load Test and Documentation.

Important points to Remember

1.) ISO 17637 (Non Destructive Examination of Fusion Welds – Visual examination)

2.) BS EN 473 (Non-destructive testing. Qualification and certification of NDT personnel.

General principles)

3.) 600 mm view with not less than 30 degree angle with Min 350 Lux ( 500 Lux

recommended )

4.) Magnifying lens used shall be X2 to X5

You might also like

- BSI Standards For Welding InspectorDocument7 pagesBSI Standards For Welding InspectorAnonymous 1LrwaaONo ratings yet

- Iso 17640 2017 en PDFDocument11 pagesIso 17640 2017 en PDFTanveer Ahmed Quadri100% (1)

- WPQR3Document3 pagesWPQR3Dimitris NikouNo ratings yet

- BS 1140 PDFDocument23 pagesBS 1140 PDFjensdcvNo ratings yet

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 pagesISO - TR - 15608 - Welding Guide Line PDFDacher DanielNo ratings yet

- BS EN ISO 17637 - 2003 - WeldingDocument20 pagesBS EN ISO 17637 - 2003 - WeldingYang GaoNo ratings yet

- 25CrMo4Document1 page25CrMo4Hans GoetheNo ratings yet

- Equivalences Certified Welder According ASME EN ISO 14732 - 2013 - GleDocument1 pageEquivalences Certified Welder According ASME EN ISO 14732 - 2013 - Gleer_wenNo ratings yet

- 2 Iso 17637 PDFDocument14 pages2 Iso 17637 PDFEnggar Subagio100% (1)

- Qualification Testing of Welders - Fusion Welding: Part 1: SteelsDocument10 pagesQualification Testing of Welders - Fusion Welding: Part 1: SteelsKadri HelmiNo ratings yet

- ISO 15510 - Part 1Document5 pagesISO 15510 - Part 1Zdenko MahacekNo ratings yet

- BS en 00287-6-2010Document26 pagesBS en 00287-6-2010Shan Sandaruwan AbeywardeneNo ratings yet

- BS Uni En10204Document10 pagesBS Uni En10204Hazwan AizatNo ratings yet

- Preheat RequirementsDocument3 pagesPreheat RequirementsVJG369No ratings yet

- Comparison of BS and BSEN For Steel Simplified VersionDocument28 pagesComparison of BS and BSEN For Steel Simplified VersiondpkguptNo ratings yet

- EN 288-3xDocument38 pagesEN 288-3xSyah Reza Maulana0% (1)

- Iso 15614-13Document24 pagesIso 15614-13Marija IvanovskaNo ratings yet

- En Iso 15609Document2 pagesEn Iso 15609Wazir Shah KazmiNo ratings yet

- Qdoc - Tips Bs en Iso 19285 2017 Non Destructive Testing of WeDocument30 pagesQdoc - Tips Bs en Iso 19285 2017 Non Destructive Testing of WeDave CheungNo ratings yet

- En 10025-2Document4 pagesEn 10025-2Sebastián Araya MoraNo ratings yet

- ISO 9606-1 Cor1-2012Document1 pageISO 9606-1 Cor1-2012Flaah92No ratings yet

- Production Test CouponDocument4 pagesProduction Test CouponAbhijeet SahuNo ratings yet

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- prEN 14700-FD-2013-11-Consumiveis para Revestimentos DurosDocument15 pagesprEN 14700-FD-2013-11-Consumiveis para Revestimentos DurosRicardo FernandesNo ratings yet

- PI Tectyl-506 TE031-01Document2 pagesPI Tectyl-506 TE031-01nicusebpNo ratings yet

- BSEN2876Document30 pagesBSEN2876gawtom100% (1)

- BS en 12668-1-2010Document48 pagesBS en 12668-1-2010lamhuu quangNo ratings yet

- Application DIN 2303Document8 pagesApplication DIN 2303Marcelle Poll100% (1)

- Catalog Tevi - Van Leeuwend-Slatina PDFDocument62 pagesCatalog Tevi - Van Leeuwend-Slatina PDFBara SebastianNo ratings yet

- En 764-4-2002Document44 pagesEn 764-4-2002Marija IvanovskaNo ratings yet

- Tech Manual MVP Series 2017.1 WIP 3Document73 pagesTech Manual MVP Series 2017.1 WIP 3Chav HoangNo ratings yet

- WPQR SBM 029Document3 pagesWPQR SBM 029HoJienHauNo ratings yet

- Drop Weight Tear Testing of High Toughness Pipeline MaterialDocument8 pagesDrop Weight Tear Testing of High Toughness Pipeline MaterialKK SinghNo ratings yet

- Final Draft Pren Iso 15607: European Standard Norme Européenne Europäische NormDocument19 pagesFinal Draft Pren Iso 15607: European Standard Norme Européenne Europäische Normunnamed90100% (1)

- Method Statement For In-Situ Metallography Test: DCSM Project 2019Document5 pagesMethod Statement For In-Situ Metallography Test: DCSM Project 2019Thinh NguyenNo ratings yet

- Iso 14344 2010Document9 pagesIso 14344 2010MOHAMEDNo ratings yet

- En 12517Document15 pagesEn 12517Nguyen Huu TriNo ratings yet

- A Comparison of BS en 287 Part 1 9606Document2 pagesA Comparison of BS en 287 Part 1 9606Amin ThabetNo ratings yet

- 4 Gerry McCarthy PDFDocument42 pages4 Gerry McCarthy PDFbharani dharanNo ratings yet

- En 10164-2005 PDFDocument15 pagesEn 10164-2005 PDFUmut HızırNo ratings yet

- CEN ISO TR 14745 (2015) (E) CodifiedDocument4 pagesCEN ISO TR 14745 (2015) (E) CodifiedacampanellajoaquimamNo ratings yet

- ArcelorMittal Energy Projects - EN10225-2019 Plates - Feb 2020Document2 pagesArcelorMittal Energy Projects - EN10225-2019 Plates - Feb 2020Vinoth Kumar PothuvudaiNo ratings yet

- 0526 16 2004 07 en - enDocument6 pages0526 16 2004 07 en - envtsusr fvNo ratings yet

- Trim Material Valve PlugDocument4 pagesTrim Material Valve Plugalexmontell100% (1)

- JIS Z2241-1993 Method of Tensile Test For Metallic MaterialsDocument12 pagesJIS Z2241-1993 Method of Tensile Test For Metallic MaterialsBui Chi TamNo ratings yet

- ILNAS-EN 14917:2021: Metal Bellows Expansion Joints For Pressure ApplicationsDocument9 pagesILNAS-EN 14917:2021: Metal Bellows Expansion Joints For Pressure ApplicationsRyan FisherNo ratings yet

- Din en Iso 15614 - 5 - 2004Document28 pagesDin en Iso 15614 - 5 - 2004Alfalloy Testing and Inspection Services Pvt. Ltd.No ratings yet

- Specification For The Qualification of Welding Inspectors: AWS B5.1:2013-AMD1 An American National StandardDocument28 pagesSpecification For The Qualification of Welding Inspectors: AWS B5.1:2013-AMD1 An American National StandardRodolfo MartinezNo ratings yet

- ISO 1579-1 (Part Only)Document5 pagesISO 1579-1 (Part Only)sn200709100% (1)

- Section 1 Typical Duties of Welding InspectorsDocument13 pagesSection 1 Typical Duties of Welding InspectorsMohd Farid OsmanNo ratings yet

- BS EN 17637 Requirement/ Guidance For Welding Visual Insp. BS EN 9712 Qualification & Certfication For NDT PersonelDocument3 pagesBS EN 17637 Requirement/ Guidance For Welding Visual Insp. BS EN 9712 Qualification & Certfication For NDT PersonelTuTuy AnNo ratings yet

- 1 Typical Duties of Welding InspectorsDocument7 pages1 Typical Duties of Welding InspectorspandimrNo ratings yet

- Cwi Twi 2006Document333 pagesCwi Twi 2006Lajit SubramanianNo ratings yet

- Welding InspectionDocument317 pagesWelding InspectionQualidade QualidadeNo ratings yet

- Cswip 3.1 2011Document400 pagesCswip 3.1 2011Anonymous SA40GK6No ratings yet

- 1 Typical Duties of Welding InspectorsDocument7 pages1 Typical Duties of Welding InspectorsSamerNo ratings yet

- WHO 2019 Ncov IPC - Masks 2020.4 Eng PDFDocument16 pagesWHO 2019 Ncov IPC - Masks 2020.4 Eng PDFSyed DanishNo ratings yet

- Prevention, Identification and Management of Health Worker Infection in The Context of COVID-19Document13 pagesPrevention, Identification and Management of Health Worker Infection in The Context of COVID-19Ioana SuciuNo ratings yet

- Considerations in The Investigation of Cases and Clusters of COVID-19Document5 pagesConsiderations in The Investigation of Cases and Clusters of COVID-19Mark Anthony MadridanoNo ratings yet

- WHO Bio-Safety ManualDocument186 pagesWHO Bio-Safety ManualrggefrmNo ratings yet

- WHO 2019 NCoV PPE Specifications 2020.1 EngDocument40 pagesWHO 2019 NCoV PPE Specifications 2020.1 EngHervian LanangNo ratings yet

- Understanding The Difference: Surgical Mask N95 RespiratorDocument1 pageUnderstanding The Difference: Surgical Mask N95 RespiratorRichard BarakNo ratings yet

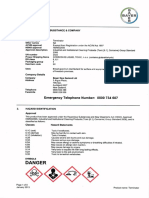

- Terminator - Safety Data SheetDocument8 pagesTerminator - Safety Data Sheetr afriantoNo ratings yet

- How To Wash A Cloth Face Covering - CDCDocument3 pagesHow To Wash A Cloth Face Covering - CDCr afriantoNo ratings yet

- WHO 2019 NCoV SAGE Framework Evidence 2020.1 EngDocument9 pagesWHO 2019 NCoV SAGE Framework Evidence 2020.1 Englea mae andoloyNo ratings yet

- OSHA Quick Card - Portable Ladder SafetyDocument2 pagesOSHA Quick Card - Portable Ladder Safetyr afriantoNo ratings yet

- Probable Case of Sars-Cov-2 Infection A B C DDocument1 pageProbable Case of Sars-Cov-2 Infection A B C Dkezivana10No ratings yet

- 1910.23-OSHA Ladders StandardsDocument10 pages1910.23-OSHA Ladders Standardsr afriantoNo ratings yet

- Readiness For Influenza During The COVID-19 Pandemic: Policy Brief 6 November 2020Document6 pagesReadiness For Influenza During The COVID-19 Pandemic: Policy Brief 6 November 2020r afriantoNo ratings yet

- WHO 2019 Ncov IPC - Masks 2020.5 Eng PDFDocument22 pagesWHO 2019 Ncov IPC - Masks 2020.5 Eng PDFNielsen MedínNo ratings yet

- Ansi A14 2 1990 PDFDocument83 pagesAnsi A14 2 1990 PDFAndres Antonio Moreno Castro100% (1)

- Stairways & Ladders - A Guide To OSHA RulesDocument15 pagesStairways & Ladders - A Guide To OSHA Ruleseafarmihar2554100% (3)

- BSC OEB Sept2015 McKernanDocument61 pagesBSC OEB Sept2015 McKernanafra1870No ratings yet

- Pre-Lift Check List: A Toshiba America Energy Systems CompanyDocument2 pagesPre-Lift Check List: A Toshiba America Energy Systems Companyr afriantoNo ratings yet

- NIOSH Ruido Ocupacional PDFDocument126 pagesNIOSH Ruido Ocupacional PDFUltrich CarrascoNo ratings yet

- Hazard Communication Standard - Safety Data Sheets - OSHA 3514 - Occupational Safety and Health AdministrationDocument11 pagesHazard Communication Standard - Safety Data Sheets - OSHA 3514 - Occupational Safety and Health Administrationr afriantoNo ratings yet

- Ansi A14 1 1990 PDFDocument81 pagesAnsi A14 1 1990 PDFdiegoNo ratings yet

- NFPA Labeling Information PDFDocument2 pagesNFPA Labeling Information PDFGeorge AniborNo ratings yet

- OSHA Combustible DustDocument13 pagesOSHA Combustible Dustdannymay95No ratings yet

- Correspondence Between ISO 9001 2015 ISODocument4 pagesCorrespondence Between ISO 9001 2015 ISONoranierahNohoNo ratings yet

- SCAT OriginalDocument2 pagesSCAT OriginalFuadNo ratings yet

- The Nioh Band ExposureDocument141 pagesThe Nioh Band ExposureSOLANGEL ARISTIZÁBAL CÓRDOBANo ratings yet

- Lifting Plan GuidelinesDocument45 pagesLifting Plan GuidelinesFerry H. Sitohang100% (5)

- Lifeline Harness Inspection GuideDocument7 pagesLifeline Harness Inspection GuideaustinrajaNo ratings yet

- Tumpa Bucket Chemical Spill KitDocument1 pageTumpa Bucket Chemical Spill Kitr afriantoNo ratings yet

- Scatchart 1299012452484 Phpapp01Document1 pageScatchart 1299012452484 Phpapp01KhanNo ratings yet