Professional Documents

Culture Documents

Precision Tool - Zeiss CMM Training 3 Day Basic v2 PDF

Uploaded by

Nikhil K Ramesh0 ratings0% found this document useful (0 votes)

2K views1 pageOriginal Title

precision_tool_-_zeiss_cmm_training_3_day_basic_v2.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2K views1 pagePrecision Tool - Zeiss CMM Training 3 Day Basic v2 PDF

Uploaded by

Nikhil K RameshCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Metrology Services

408 774 1274

gganz@pretool.com

Basic Training for Zeiss CMM’s

Thank you for considering us to serve your Zeiss Training needs. We are dedicated to providing the highest quality

training in the industry to our Customers. Our instructors have been using Zeiss equipment and software for over 20

years, and have been successfully training customers of all experience levels since 1998. They are Zeiss Certified

Trainers and have taught classes in Calypso, Umess (300 and UX), and U-Soft. We can offer you extensive training to

cover nearly every aspect of the operation and maintenance of your Zeiss equipment and software.

Your training course will focus on everyday measuring tasks and is based on actual applications. It is balanced between

theories and practice, and will show you how to effectively use the features of your Zeiss metrology equipment.

Standard Training:

Training is for up to 2 students per available machine. Training is conducted over 3 consecutive days, each day with a

morning and afternoon session, 2 sessions per day. Our 3-Day Basic course is scheduled once per month at our facility

in Santa Clara, CA. Seats are scheduled on a first-come, first-serve basis.

Training includes a copy of reference and training materials and Certificate for all students. It also includes follow up

support via e-mail or phone.

Course Session Description:

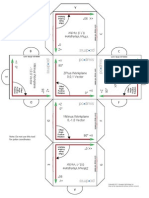

Session 1: Introduction to Calypso, CMM Fundamentals Review; Stylus Qualification-Automatic Requalification

Session 2: Calypso Fundamentals; CAD, Base Alignment, Features, Characteristics, and CNC

Session 3: Stylus Qualification-Probe Building, Qualify a New Stylus, Probe Dynamic, Force Parameters

Session 4: Intermediate Applications - Additional Features and Characteristics, Programming Techniques

Session 5: System Administration (Defaults), Stylus Qualification-CNC qualification

Session 6: Intermediate Applications – Measurement Strategies, Scanning, Filters, Outliers

Training Objectives:

Understanding of basic coordinate metrology and an introduction to the components of a CMM.

Provide students with accepted metrology practices for CMM based inspection.

Learn to create alignments, measure features, generate reports, and create programs.

Learn to apply the GD&T functionality of the software.

Provide students with the skills to begin inspecting parts in the real world.

Custom Training:

In addition to basic training, we can provide you with any level of custom training to suite your particular needs.

Advanced Probe calibration, alignments, and Scanning: algorithms, filtering, outlier elimination

basic coordinate metrology. Probe force, velocity, bending compensation

Feature measurement using trigger (ST and Curve Measurement (using Calypso curve)

RDS) and scanning (VAST and U-Type) Introduction to CAD based inspection

Control-Plan (program) creation, editing, and CAD model types (IGES, STEP, PRO-E, etc.)

execution including healing

Base alignments / Coordinate Systems Offline programming and troubleshooting.

Special alignments: Iterative, best fit, RPS, P6 , Building geometry from CAD entities (circles,

Conditional cones, etc.)

Qualification of probes Conditional Branching, Looping, Parameter

Custom outputs Control Manager (PCM) for part families

Application of ASME y14.5 to CMM Metrology Pallet programming, Autorun, One button

Bore pattern fitting and graphic plotting operation

Beyond the initial training, we offer continual support for our customers. We provide programming & application

assistance, to ensure that new users in achieve a high level of success in the utilization of their Zeiss CMM. During the

Follow-up session(s), we work with the trainee and determine if more formal training is required. If so, we can arrange for

advanced training, custom-designed with your needs and applications in mind.

You might also like

- Software PolyWorks V12 Inspector Airfoil Gauge Module enDocument2 pagesSoftware PolyWorks V12 Inspector Airfoil Gauge Module entheflamebearerNo ratings yet

- Zeiss Erosion ModuleDocument13 pagesZeiss Erosion ModulepakhiddeyasNo ratings yet

- 13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Issue Number OrderDocument22 pages13-08-26 List of GPS Relevant ISO-Standards - August 2013 - Edition 25 - Issue Number OrderOmar MokhtarNo ratings yet

- ASME B89 7 3 2 2007 Technical ReportDocument30 pagesASME B89 7 3 2 2007 Technical ReportElla Celine100% (4)

- Poly Works Inspector Reference GuideDocument3,133 pagesPoly Works Inspector Reference GuidetiborNo ratings yet

- Marking Work InstructionDocument1 pageMarking Work InstructionSUBODHHNo ratings yet

- Metrology CoordinateDocument24 pagesMetrology Coordinate김상동No ratings yet

- Xyzcube PC DmisDocument1 pageXyzcube PC DmisEdgar IvanNo ratings yet

- OpenDMIS V6 EnhancementsDocument4 pagesOpenDMIS V6 EnhancementsasndmpNo ratings yet

- gpg41 CMMDocument119 pagesgpg41 CMMHelton MotaNo ratings yet

- System Center Data Protection Manager 2010 Troubleshooting GuideDocument319 pagesSystem Center Data Protection Manager 2010 Troubleshooting GuideDavid LawranceNo ratings yet

- ASME B89.4.19 Standard For Laser Tracker Verification - Experiences and OptimisationsDocument9 pagesASME B89.4.19 Standard For Laser Tracker Verification - Experiences and OptimisationsJD100% (1)

- 12l14 Bright Mild SteelDocument2 pages12l14 Bright Mild SteelStefany Carolina Chavez DavidNo ratings yet

- Temperature Uniformity Surveying For Vacuum Furnaces Optimizing Procedure ForDocument16 pagesTemperature Uniformity Surveying For Vacuum Furnaces Optimizing Procedure Foranilbabu4No ratings yet

- Mil STD 2223Document96 pagesMil STD 2223Standards IndiaNo ratings yet

- Good Practice Guide - CMM Verification NPL PDFDocument112 pagesGood Practice Guide - CMM Verification NPL PDFCDELVO1382No ratings yet

- Laser Trackers: Testing and StandardsDocument34 pagesLaser Trackers: Testing and StandardsJDNo ratings yet

- GQADocument26 pagesGQARaduz HaduzNo ratings yet

- Cad - Cam CoursesDocument19 pagesCad - Cam CoursesRagul0042No ratings yet

- Cmti Course DetailsDocument7 pagesCmti Course DetailsSudheer Kumar NNo ratings yet

- Resume For Laser Tracker OperatorDocument2 pagesResume For Laser Tracker OperatorSatish ThoratNo ratings yet

- Chapter 1Document56 pagesChapter 1om navadiyaNo ratings yet

- A Framework of A Knowledge-Based System For Predictive Characterization in Ultra-Precision Diamond TurningDocument5 pagesA Framework of A Knowledge-Based System For Predictive Characterization in Ultra-Precision Diamond TurningAli NaqviNo ratings yet

- Virtual Simulator CT QADocument10 pagesVirtual Simulator CT QAsangeetha maniNo ratings yet

- Me (Cadcam) 0708Document20 pagesMe (Cadcam) 0708భుక్య వెంకటేష్No ratings yet

- 2170 McosmosDocument12 pages2170 McosmosNguyễn HòaNo ratings yet

- Introduction To CADDocument29 pagesIntroduction To CADvalterlimawbsNo ratings yet

- IFS Academy Certified Design Engineer Program: (With 100% Placement Assistance)Document4 pagesIFS Academy Certified Design Engineer Program: (With 100% Placement Assistance)ManjotNo ratings yet

- Alignment, Mounting & Engineering ServicesDocument4 pagesAlignment, Mounting & Engineering ServicesLuisSilvaNo ratings yet

- 2020 McosmosDocument12 pages2020 McosmosRaquel RochaNo ratings yet

- Advance Diploma in Computer Aided Engineering (CAE) : (With 100% Placement Assistance)Document4 pagesAdvance Diploma in Computer Aided Engineering (CAE) : (With 100% Placement Assistance)Harshad Pawar PatilNo ratings yet

- Courses: Basic Course in Condition MonitoringDocument3 pagesCourses: Basic Course in Condition MonitoringLita SanduNo ratings yet

- Advanced Diploma in CAD/CAM: (With 100% Placement Assistance)Document4 pagesAdvanced Diploma in CAD/CAM: (With 100% Placement Assistance)Harshad Pawar PatilNo ratings yet

- Research Paper On Coordinate Measuring MachineDocument4 pagesResearch Paper On Coordinate Measuring MachineafeaoebidNo ratings yet

- 0A RCM Workshop Program ContentDocument5 pages0A RCM Workshop Program ContentKalpeshkumar PatelNo ratings yet

- CST PresentationDocument17 pagesCST PresentationRezmerita FlorinNo ratings yet

- PROSPECTUS FOR Post Graduate Diploma in Tool Design & CAD/CAM (PGDTD & CC) - 2019Document8 pagesPROSPECTUS FOR Post Graduate Diploma in Tool Design & CAD/CAM (PGDTD & CC) - 2019simiyandcNo ratings yet

- MSC FatigueDocument24 pagesMSC FatigueintelligentloveNo ratings yet

- Powerinspect CNCDocument2 pagesPowerinspect CNCJosephRomeraloNo ratings yet

- 1st Day-2 CMMS Demo (System Description)Document24 pages1st Day-2 CMMS Demo (System Description)HamdanNo ratings yet

- CAD CAM and CAE Course OutlineDocument3 pagesCAD CAM and CAE Course Outlinedejenem398No ratings yet

- The Functional Verification Manager To Support End To End The Satellite Verification ProcessDocument7 pagesThe Functional Verification Manager To Support End To End The Satellite Verification ProcesscoralonsoNo ratings yet

- Design of An Industrial Machine Vision System For Inspection and Assembly Using Soft ComputingDocument10 pagesDesign of An Industrial Machine Vision System For Inspection and Assembly Using Soft ComputingSai NathNo ratings yet

- B.Tech. (Mech.) Fourth Year Syllabus (REVISED)Document64 pagesB.Tech. (Mech.) Fourth Year Syllabus (REVISED)bawincipetNo ratings yet

- Resume - ASHWINI PATIL - 09.12.23Document4 pagesResume - ASHWINI PATIL - 09.12.23Sumeet KaleNo ratings yet

- Cad Cam 2Document15 pagesCad Cam 2sososivar55No ratings yet

- Model Contura G2 Manufactured by Carl Zeiss Same YearDocument4 pagesModel Contura G2 Manufactured by Carl Zeiss Same YearB VarunNo ratings yet

- Finishing School BrochureDocument6 pagesFinishing School BrochureNithun DeenadayalanNo ratings yet

- Machine Vision and Metrology Workshop-08.09.2018Document2 pagesMachine Vision and Metrology Workshop-08.09.2018Ravichandran GNo ratings yet

- Brochure VAIIDocument1 pageBrochure VAIImustafaNo ratings yet

- CST MWS GPU Computing 2Document2 pagesCST MWS GPU Computing 2jochebed6010No ratings yet

- Coordianate MeasurmentDocument6 pagesCoordianate MeasurmentMilos RadovicNo ratings yet

- AM Für Space Anwedungen - "Leason Learned" Re-Design Sentinel 1 Upper SBA SupportDocument31 pagesAM Für Space Anwedungen - "Leason Learned" Re-Design Sentinel 1 Upper SBA SupportagniflameNo ratings yet

- Question Bank - Cad Cam CaeDocument12 pagesQuestion Bank - Cad Cam CaePravin DahalkeNo ratings yet

- 0YfmDqsNTy-NEW - RESUME UPDATEDDocument5 pages0YfmDqsNTy-NEW - RESUME UPDATEDWe learnNo ratings yet

- Mcosmos Manual: High-End Software For Manual Coordinate Measuring MachinesDocument12 pagesMcosmos Manual: High-End Software For Manual Coordinate Measuring MachineshonghieutrNo ratings yet

- CMM Programming TrainingDocument1 pageCMM Programming TrainingNavajyoti PandaNo ratings yet

- Resume of Karthic SDocument5 pagesResume of Karthic SKarthic MannarNo ratings yet

- ATMAE Certified in Engineering Graphics (CEG) ExamDocument14 pagesATMAE Certified in Engineering Graphics (CEG) ExamLee KimNo ratings yet

- Implementation of CAD CAM CAE SystemsDocument5 pagesImplementation of CAD CAM CAE SystemsFarhodjon AbdusamatovNo ratings yet

- D537 U49 Admit CardDocument1 pageD537 U49 Admit CardNikhil K RameshNo ratings yet

- Upsc Ese Result NameDocument83 pagesUpsc Ese Result NameNikhil K RameshNo ratings yet

- Gpmains 2011 Eng Compulsory CompressedDocument12 pagesGpmains 2011 Eng Compulsory CompressedNikhil K RameshNo ratings yet

- 2011 KAS P1 Compressed PDFDocument36 pages2011 KAS P1 Compressed PDFNikhil K RameshNo ratings yet

- Deepwater Horizon Oil SpillDocument26 pagesDeepwater Horizon Oil Spilleddy9881100% (2)

- Introduction To NFFHT: Shyam Sunder Assistant Professor Mechanical EngineeringDocument44 pagesIntroduction To NFFHT: Shyam Sunder Assistant Professor Mechanical EngineeringTAPASVI BHATTNo ratings yet

- 04 Dispersion MeasuresDocument17 pages04 Dispersion MeasuresMuhammad AbdullahNo ratings yet

- Critical Planning Issues in MTODocument2 pagesCritical Planning Issues in MTOAzhar QadriNo ratings yet

- Geo PDFDocument13 pagesGeo PDFTezera Mark TmhNo ratings yet

- 10th PET POW EM 2023 24Document6 pages10th PET POW EM 2023 24rpradeepa160No ratings yet

- Soil Resources Inventory For Land Use PlanningDocument9 pagesSoil Resources Inventory For Land Use PlanningmehNo ratings yet

- Nuclear MedicineDocument7 pagesNuclear MedicineMarco Mendoza67% (3)

- When A Migraine OccurDocument9 pagesWhen A Migraine OccurKARL PASCUANo ratings yet

- Design and Assembly Analysis of Piston, Connecting Rod & CrankshaftDocument12 pagesDesign and Assembly Analysis of Piston, Connecting Rod & CrankshaftD MasthanNo ratings yet

- An Open Letter To Annie Besant PDFDocument2 pagesAn Open Letter To Annie Besant PDFdeniseNo ratings yet

- A Green Chemistry Approach To Mercury ControlDocument7 pagesA Green Chemistry Approach To Mercury ControlDennis Daniel Condori EspilcoNo ratings yet

- 17 - MiG-19 Day Interceptor & Two-Seat VariantsDocument47 pages17 - MiG-19 Day Interceptor & Two-Seat VariantsEduardoFadul100% (1)

- Examination, June/July: ExplainDocument6 pagesExamination, June/July: ExplainSandesh KulalNo ratings yet

- Seminar Report On Hydrogen As The Future FuelDocument63 pagesSeminar Report On Hydrogen As The Future FuelMOHIT MGMNo ratings yet

- Indice Hocberg RheumatologyDocument8 pagesIndice Hocberg RheumatologyGerlando Russo IntroitoNo ratings yet

- Sealand Equipment GuideDocument5 pagesSealand Equipment GuidePool Jaime Quispe CordovaNo ratings yet

- Classification of AntibioticsDocument5 pagesClassification of AntibioticsdenaNo ratings yet

- Zener Diodes and Transient Voltage Suppressors Quarter 3, 1998 SG274 - D Rev 16Document8 pagesZener Diodes and Transient Voltage Suppressors Quarter 3, 1998 SG274 - D Rev 16Imraan RamdjanNo ratings yet

- Draconomicon 2 Metallic Dragons PDF 73Document3 pagesDraconomicon 2 Metallic Dragons PDF 73gabiNo ratings yet

- Sulphur VapoursDocument12 pagesSulphur VapoursAnvay Choudhary100% (1)

- PDFDocument110 pagesPDFBikash NayakNo ratings yet

- Reviewer 3RD Exam FinalDocument14 pagesReviewer 3RD Exam FinalReane Romblon GerozagaNo ratings yet

- Hyundai D4FB Diesel Fuel System 2Document727 pagesHyundai D4FB Diesel Fuel System 2Alexey Koshelnik100% (1)

- Nutella: Italian PronunciationDocument1 pageNutella: Italian PronunciationhbnjknwvnffkjrpaadttirvorgNo ratings yet

- Anatomy ST1Document2 pagesAnatomy ST1m_kudariNo ratings yet

- Dry-Heat Destruction of Destruction KineticsDocument5 pagesDry-Heat Destruction of Destruction KineticsFabioEspinolaNo ratings yet

- Aiwa CX jn5 ETDocument78 pagesAiwa CX jn5 ETluzmarospiNo ratings yet

- 1822 B.E Cse Batchno 154Document53 pages1822 B.E Cse Batchno 154maniuyyala65No ratings yet

- Pharmaceutics Exam 3 - This SemesterDocument6 pagesPharmaceutics Exam 3 - This Semesterapi-3723612100% (1)