Professional Documents

Culture Documents

DY Catalogue EN

Uploaded by

Nguyễn Linh0 ratings0% found this document useful (0 votes)

129 views88 pagesDY_Catalogue_EN, chain conveyor

Original Title

DY_Catalogue_EN

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDY_Catalogue_EN, chain conveyor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

129 views88 pagesDY Catalogue EN

Uploaded by

Nguyễn LinhDY_Catalogue_EN, chain conveyor

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 88

DYC

DONGYANG CHAIN INDUSTRY CO., LTD.

DYC

Your Needs, Our Solutions

DYC has been producing conveyor chains and sprockets for 30 years. a

With continuous investment into R&D and technical innovation in

conveyor chain field, DYC has become a promising venture company

chosen and financially sponsored by Korean government. From this

honorable milestone, the remarkable growth in company history has

started and the prosperity is still going up to now.

Overcoming several economic crisis in domestic and worldwide

market, DYC has sustained its growth momentum and has cooper-

ated with invaluable customers all over the world, DYC has tracked

ona rough way of manufacturing conveyor chains with a firm belief,

and finally ranked in a dominant position in Asian market.

DYC believes that advanced technology is top priority and has built

up a complete set of technological knowledge. With this technology

and exclusively perfect know-hows in controlling from materials,

machining, welding, heat-treatment to assembling, DYC is manu-

facturing conveyor chains of best quality. Now DYC is keeping close

ties with worldwide customers, putting high value on relationship

with partners.

DYC Products

DYC is manufacturing conveyor chains and conveyor equipment of

various industrial fields. We also provide rollers chains, sprockets,

and other accessories as well. Our products are strictly controlled

by quality management system [ISO 9001:2000 certificate) and are

KS (Korean Standard) certificate acquired.

For more information about materials, chain types, and other spec-

ification of our products, please contact us by e-mail or website.

dychain@dongyangchain.co.kr

www.dongyangchain.co, kr

Contents DYC conveyor chain & sprocket ove nso) ie} Ama

04 Structure of DYC chain ove»

05 Types of DYC chain ove neie) a=

06 YC Conveyor Chain Guide 227202

17 Average Tensile Strength anv

DYC Standard Conveyor Chains ove us ewoioi se

18 Standard Conveyor Chain == eisoii si

20 Standard Conveyor Chain Attachment si coo) 21 oat

2B Standard Conveyor Chain Sprocket 112% nojoloj nel AS 7)

DYC Specialty Conveyor Chains ove 5 zs0\ net

33 Bucket Elevator Chain 7! seiwo\ ste

35 Flow Conveyor Chain jr e4oj0\ ale

a“ Side Roller Chain 1s ae

42 Top Roller Chain = s=: 42)

43 DYD Type Chain ovo! a9

Mh DSCT Type Chain 2

45 Slat Chain (Automobile Assembly Line] saj= xe) xja <2)

46 Heavy Duty Offset Side Bar Chain asiss aie)

47 Bushed Elevator Chain 9 aoicj ie

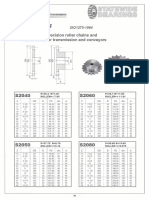

52 DYNB Type Bucket Elevator Chain pvnast 72 weisoiss te

53 DY Type Highspeed Bucket Elevator Chain 0%} 14142" selsoles 12)

5h Plant Bucket Conveyor Chain sete wi coo se

37 Sugar Mill Chain 7/2212

6 Palm Oil Mill Chain 23220! 49

68 Parking Building Chain *siu318 2121

8 Escalator Chain o\naj018 5

“9 Water Treatment Plant Chain x/ex18 aie

B Carrying Chain canying 42)

B Steel Drag Chain a9 5240)

76 Installation & Maintenance sx

78 —_ErrorHandling ost ss

80 _DYCroller chain & sprocket oye #3

82 DC Accessories pyc sua)

DONGYANG CHAIN INDUSTRY CO., LTD.

Structure of DYC chain ovc aie) z=

Link plate

Heat treated carborValoy stels are used for high tensie strength.

¥ ss Pin tink plate A

Shot peening process to improve fatigue resistance

Bush link plate

Roller

Hardened carbon/alloy steels are used for excellent

‘wear resistance and rgiity Pe

Shot peening process to improve fatigue resistance.

Bushing

Bushing Case hardened allay stects with external

and internal hardened surfaces are used

for high wear resistance, and are then ac-

curately set into the link plates.

Bush link plate

Pin ink plate 8

Pin

ea Allo sees are used fr high wear resistance and toughness.

@ Surface hardening is applicable upon request.

Types of DYC chain

DYC Al2!9] SR

\

S-roller chain

Roller diameters smaller than the height of the link plate, to pro-

tect the sprocket teeth and the chain bushing. S-rller chain is

extensively used in bucket elevator systems and other applica-

tions involving the handling of abrasive materials.

\

R-roller chain

Roller diameter's bigger than the height af the link plate, R-rller

chain is basic type of conveyor chain, and is extensively used for

small and medium size horizontal or inclined conveyors.

\

F-roller chain

Rollers are flanged, making it possible to use a ral to guide the

chain. roller chain s mainly used for large horizontal or inclined

conveyors.

\

Bushed chain

Bushed chain isthe chain without roller, which is used in trolley

conveyors and pusher chain conveyors in which the ehain only has

to transmit the pull. can be used for carrying heavy loads by at-

taching separate roller car

DYC, The Solution

A-attachment.

‘Acattachments have a bent link plate on one side. They are called

Ay. Ahn oF Ay according ta the number of bolt holes,

K-attachment

attachments have a bent link plate an both sides, They are

called Ky or Kz according to the number of bolt holes.

G, attachment

6G; attachments have two bot holes in one side ofthe link plate

G, attachment

6, attachments have four bolt holes inane side ofthe ink plate.

r

Flow conveyor chain attachment

They are caledL type, KL pe, U ype, W type, 8 type and many

ather types according tothe shape ofallachments, The alach-

rents are welded tthe lnk pate.

05

DYC Conveyor Chain Guide avwz7iac2

Selecting a conveyor chain

Chain selection requires comprehensive knowledge and experi-

tence. However, the folowing isa basic and general selection pro-

cedure for conveyor chains of your applications.

©

eo

@

e e&

Ht]

4

°

eo © &82 ® & @

HH

eo

eg

@ Basic layout of conveyor chains

(Lay-Out)

(1) Horizontal conveyor

@ Basic type

The lower side is supported by rails. But there is catenary on the

drive sprocket side, Lubrication atthe catenaryis the mast effec-

tive way.

@Catenary type

‘Some orall ofthe ower sideis catenary. You can use itat relatively

(ow speed conveyor. The catenary is usually 10% of the span. You

can’tuse it for reverse drive

@ Catenaryis on the upper side.

(2) Vertical conveyor

the conveyor stops while loaded, itis

necessary to install a brake, back-stop,

fr cam clutch to prevent reverse oper

ation.

@ Determine a conveyor type

‘When solecting a conveyor type, it is necessary to identify the physical properties of the material being conveyed. You can find below types

and applications.

(1) Lubricate chain to provent elongation during use. Use a drip or brush method and ensure lubricant penetrates between pins, bushes,

rollers, and other parts to prevent metal-on metal contact.

(2) n case of powdery of liquid conveying material, try to use loading type conveyor, which has lower running resistance. This will also

minimize the size of conveyor chain and drive parts.

(3) the conveying materials hight abrasive, avoid the irect contact with the chain conveyor.

(4) Use a seated conveyor such as a flow conveyor, to prevent loose material from flying during conveyance.

(5) Fors highty corrosive conveying material or in highly corrosive environments, select proper and suitable chain material, and stow down

the conveyor speed,

Slat conveyor, pron conveyor Bucket elevator Drag conveyor, Seraper conveyor

‘The conveying material isteaded on | The conveying matrilisin the [Chain has contact wit the aang

the rollers. bucket ‘the canveying material

ta

ine

Durigeprsen Slee rton tea Chnrascmacwineguce | Tetnredshanconah

nails. *

Sipe

Rolerype Roan Fe Sie ope Ne 2 chon

ue damer sues arama

asl weet a Inner diameter of rollers Inner diameter of bushes Chain Unk contacts

China dtc

. Srl ion ine tahun sang paris and_| cg rater

Sosa ‘Smaller povie required anti resistance. Bigge friction resistance

Bigger power requires

07

© Determine the chain specification

The following table shows the chain conveyor types and chain se-

ries for typical bulk materials.

Table 1. Material and Chain Specifications

‘eiles

Chuceal

is

a]

Biase

ce

Eason

a

Bay |

E

a

A

ere

lear

8

cere

Prue

8

eb

‘coal

Teed

ca

Dato

®

a

eae

anne 8

Sse

@ Determine the chain pitch

(1) More sprocket teeth, smoother chain operation.

With the given outer diameter of the sprocket, using shorter

pitch chain would make more sprocket teeth, And this willre-

duce the polygonal speed luetuation and articulating angle of

chain on the sprocket. This also results in less wear between

pin and bush.

(2) Generally, longer pitch chain would be more expensive per link,

but would be more affordable for a unit length(conveyor ine

length]. Chain pitch s also determined by unit size andor at-

tachment spacing

(Ex) Ifthe conveying material is every 2 meters, you can

choose the chain pitch( 100,200,250] with no remainder when

you divide it by even number

(3) The chain pitch for bulk conveyors is determined by sizes of

conveying material, Bucket, apron, scraper and et.

(4) The chain pitch is also influenced by the sprocket space.

(5) Chain pitch is related with the number of sprocket teeth and

‘the chain speed

Refer to table 2,

ane ©

"ae.

Duchy [8

120

Dyess

fume |g

‘ior

terse

2

Tair

Dy Lresore a

Dy Sowa

Dey Se

ne

Brot

hind N= Number of teeth

3

Dre

Fey Se

oe

habe Sh

‘SPROCKET (RPM)

Pabtioe

Fees

Sos an

2

‘Sie

Sint

‘ole|e|e|3/a|ala)alele)-}slelelelele| =

Ti tae

Syihee

Dre

nse

Wacoal

“ety,

‘aeons

Wes

Ws

Wealfiw | C @ fe =

Note 1. Abrasiveness : ABC

2. Corresiveness : A [Strong acid, B [Moderate ac),

Ineutral),D (Moderate alkali, E (Strong alkali)

08

yoo 200 30D aD 800

CHAIN PITCHimm)

@ Determine attachment type

DYC, The Solution

Using one side lnk plate, ou can use A or SA type attachment.

Or you could choose K of SK type altachment using both link plates.

Atype attachment

The loads on the rollers, And the rollers are onthe rails.

K type attachment

The loads equally spread out tothe chain. Ifthe slatwieth

's big, or the load is high, ths is suitable, However, you

need more study for the return parts because the rollers,

‘ofthe chain will be concealed on the return side,

Alype attachment K type attachment

@ Determine roller type

There are 3 standard roller types.

Roller types

Roller ype Structure of guide rail, Special features

‘Simalyprverts wavering movement

Faller Suitable for slat conseyor

Using Ktype attachment, beware ofthe posible contac.

TLL MT ‘The basic and ypial ype

Reiter Load capaciyis high

Friction resistance iow

a

{ Vertical comyance

Relatively inter conveying materia

See = Relatively shorter conseying distance

The aad onthe ink plate

09

@ Calculating the chain tension

‘Maximum static tension tothe chain during operation, Tcan be calculated using the formulas in Table 3. Basically itis masslweight] x co-

efficient of friction.

In case of sudden start, stop, orn case of using the pusher conveyor, inertial force is extremely large. You should be very aware of inertial

forces when calculating the tension and required power.

Table 3. Tension formulas

idl remeron eed

‘The conveying mate- 7

mnvsnnnsta

Horizontal cemveyer a pvt

oe reverSenwney wed

mace ret Byramye wed

soon

wevinal ows 4

rewenee Eu

vert

oe

oes oes Boot

seem Bot

wea reenter estos wee Loreen

mnistnrenan

Costar

rion | commer 5 vo

Ss oss ram aminonmetn wee Loewe

ee 5 va

rial is conveyed by TSG. 7S (Lt SHMIL- fy H)HIMIL AH) KW «= (T-MIHL fi)

‘scraper conveyor v S805 9

* In the formulas, i (Lh-Hl¢0, then (Lf\-H)=0 And if (H-L(}<0, then (H-L-l=0

* When calculating the tension for bucket elevator, considering weight increase when loading, calculate withthe center distance 1 meter

10

Maximum static tension on chain (kgf

Maximum conveying quantity th (teh

Ve Chain speed (ovmin}

Center distance between sprockets (vertical (mi

enter distance between sprockets horizontal) (ra

Cx=Center distance between sprockets [inclined] (ml

M=Mass (weight) of conveying device (Chain x strands, buckets,

aprons, etc] Ukgtfm)

Incase of Rand F type rollers,

Inclined angle is less than 7° : Use the weight of the whole

lengthlinclucing return)

Inclined angle is more than 7°: Use the weight of the conveying

part

oefficient of friction between chain and guide ral (Tables &

ands}

‘r= Coefficient of friction between material conveyed and casing

{able 6)

Uirthereis no contact, then f=)

n= Efficiency of driving parts

We Mass Conveyed Item [maximurn weight) (gf

c

Individual tem Wa

Mass of iter tkgf/each)

“Table 4, Rolling friction factor fy between chain and ait

Tables

iver

mT ae Sia one sun

a6

oe | 016 | 018 | O26

@so(i00 os [01s | om | 02

i000 oe [ou | os | a2

Dzialexceptiond ow | oi | 01 | a2

Lubricate with SAE30-40

‘lean and roam temperature condition

Tabled-2

Plastic roller series

Plastic sleeve series 908

arng roller sri 8

Neediesushseries | OT

‘Table Sliding coeficient of friction f1 between chain and rat

Table 51

Room temperature ~ 600, 020 | 030

“0-600 a3 | 035

$00 800 035 | 040

200 1000 048

Table5-2,

Table 6. Coctcient of rction fs between material conveyed and casing

‘Alm 063 Tor

est05

acum carbonate

pareoat

vorne powder

ay

Tee

ie

:

wad ore powier

Tmpestone

fagnesia

Mixed feed

Texel ore powder

ag

‘Soybean

arc

gar

(harated calcarn

Note: The above values may change depending on dryness and hum,

"

DONGYANG CHAIN INDUSTRY CO., LTD.

@ Determine chain size

Multiply tension T calculated with formulas in Table 3, by Safety

Factors in Table 7 for required tensile strength, and then select

chain vihich satisfies the strength,

Irthe operating time is 10-24 hours per day, have the safety fa

1.2 times.

And in case of plastic roller, plastic sleeve, bearing roller, needle

bush, EPC78, select the chain according tothe allowable tension.

Table 7. Safety factor for standard series and reinforced series

Chain speed Safety factor

“aievmin oratove | 7

30-0 mimin 3

0-50 mimin 3

50-80 m/min 0

Itis also required to consider proper environmentsicleanness,

temperature, lubrication) other than the strength ofthe chain,

In the following applications, chain life is reduced to 1/2to 1/10.

1) Short distance conveyance of heavy loads

(2} Exposure of chain to abrasive, adhesive, and corrosive mate~

al

(3) High temperature environments

(4) High humidity

'5] No lubrication

In case of 200, 400 series, refer to table 12 forthe safety factor

Example] Chan selection by the simplitied selection graph

Simplified selection graph.

Allowable sox

loading ramen

massforfor SS Bree

Teetot 32 race

chain 88 menoe

Conveyor angle“

Simplified selection graph is used under the fllowing conditions.

Itis used for DY type standard conveyor chain and the basie se-

@ The safety factoris 7.

[BUsing R or F type ralier and supporting the (oad

[At room temperature, with (ubrication,

12

(11 Calculating the total mass of conveying material

aq Mass ofitemgtea)

a

Loose partic lg = 16.7 2 engthim!

(= Maximum conveying quantity (A

= Chain sped [m/min]

(2) Calculating the total mass of slat, bucket, and ete

Ifthe conveyor angle is more than 7”, then the mass

Legit). srachment weights

Toad spacial arihaveal

Incase the angle is less than 7°, multiply it by two

(3] Based on the mass of slat or bucket and the conveying mate-

rial, choose the chain model using the simplified selection

graph.

Mass of

cjng material Mass ofl bucket

Mass of et chain=

‘numberof chain set used

Now, using the simplified selection graph, select one that satisfies

allowable leading mass fort set of chain

(6) Calculating mass of 1 set ofthe selected chain

lf the conveyor angle is more than 7”, then the mass

tlh eight gn

ational ight for attachment geal.

attachment seacinglm

Incase the angle is less than 7°, multiply it by two

5] Compare the simplified selection graph and the total sur of

conveying material, slat or bucket, and the chain,

Total mass of 1 set of chain conveyor: (3 + (4

Make sure this sum is smaller than the allowable loading mass

for for 1 set of chain, And if not, choose a bigger chain and go

back to (al

‘Incase ofverlical conveyance, adjust the length (please refer

totable 3)

(6) Required power (KW)

Kwe

Total mass of set ofchain number of chan sets chain speed)

Coefficientitable 8) 5865

‘Dring efficiency

Table 8, Coefficient for required powerlKW)

Angle 9 5 |7 10 20 30 40 50 60 70 80 90

Coeff.

ciont

'0.08/0.17|0,25]0.25|042|0.97|0,0|0.82/0.01|0.95|1.00|1 00

Example (1)

Comayripe | Harmonia dat anveyor

[Mass of conveying material | 450 kgilea

ead spacing 15m

Tonvejrlenath om

Chan speed Omvmn

Mass lt Diales

Chain peh 50mm

Chain ype

‘lattachment or every Unk

@ Mass of conveying material

Solr)

=a * soles

8,0001kf)

@ Mass of sat

__2xbolrn) .

= Sister *20letleal = 16,0001kgH

@ Load for chain 1 set

: = =

a eee

1 cee [fe eT -

low nd rage ne ont ol seer oe:

Ean Mae aun OC = = >

@ Chain speed is less than 20m/mir ‘Sudphurous heid Gar Dry 2 = = = =

‘®t operating hour is 10-24 hours/day, multiply it by 1.2 Sips Aas zs = =

@ Over 400°C environment, please contact us. gees z . = =

=a peer

Rin apenas

i

15

(4) Abrasiveness

Refer to Table 1, Material and chain specifications,

The followings are key points for abrasive conditions

© Installa chain cover to avoid exposure to abrasive materia

@ Slow down chain speed as muchas possbi.

( Increase the chain size to reduce pin-bush bearing pressure.

@ Lubricate using a grease nipple

@® Other details

(1) Lubricate to prevent chain elongation. SAE30-A0 is suitable for the purpose.

Using dropping and brushing method, grease enough between pin-bush-rollr, try to

(2) Align sprocket shaft parallel

(3) lt requires at least 3 teeth for chain-sprocket engagement.

(4) Use take-up to adjust chain elongation.

{5} When using multisle lanes of chains, be sure thatthe teeth are aligned inline.

metal to metal contact.

@®Clean specification

No extraneous mat-

terlol grime, scale)

mesa | Matisse | gees

clean cloth to remove

en

\Wrappedina sheet,

boxe in heavy dy

paper and past

Asuinesssee! | Noewraneousmat- | Pramacetel or

Class 8 parts(SuSt00 or | terfil grime, sate) | Sher malerals No

'5U5400/300 mis) orburrs come direc con

tact wit ean,

Aer assembly chain Aotatmosshere

iswiped oo ana rustagen sade

case | Samorateare | ccsradtramovw ol packaging

regular see and grime. Scale still Boxed in heavy duty.

remain. paper and past

16

Average Tensile Strength 22mcz=

220

oy os000} 000 | soo | 7100 | aso | 500 suo | 200 | 3g | 7.100

py ao] sso | soc | tooo | sao | soo 4900 | 7100 | 5900 | 1000

ov osoo | 7000 | ro00 | 14500 | 7200 | 13,000 zoco | ro000 | 7900 | 14800

py 20} 000 | 11000 | r4s00 | 000 | 12500 roo | 1pg00 | ga | 4500

vy 50} — ao00 | ri000 | r4s00 | 000 | 12500 aco | 10000 | geo | 14500

vy o#oo0 | 000 | 11000 | 14500 | 8000 | r2800 ooo | 19000 | ga00 | 4500

cy 660} ono | t1000 | 14500 | 000 | 2500 nooo | toe00 | 14800 | 14800

py 0000} 11800 | 17000 | 23000 | 11500 | 13000 | 11000 | 23000 | 12800 | 23.000

cy 2 | 13000 | reoc0 | 2e500 | t2000 | p00 | tz800 | 2800 | 13000 | 2500

vy 205} 13000 | 18000 | 24500 | 12000 | 9000 | 12800 | 2as0o | 13000 | 2500

ov 20s} 19000 | 23000 | zes00 | 17.000 | 27000 | 12800 | 2as00 | 19000 | 28500

py +2000} 19.000 | 23000 | zes500 | 17000 | 27000 | 12800 | 2es00 | 19000 | 28500

py 212} 25000 | sz000 | axs00 | 22800 | 6500 | 19000 | apsco | 2no00 | 39500

py 17000} 25000 | 32000 | xs00 | 22800 | 6500 | 19000 | 39800 | 25000 | 39500

py 26000} azo00 | «5000 | saoc0 | anann | noo | 25800 | sno00 | azo00 | 53.000

py 6000} sas00 | sz000 | ss00 | - 5 5 easy | sas00 | 69500

oy szo00| siooo | e000 | tosoon | : : seco | soo | 105.000

py 0000} 51000 | saeco | toecon | 5 5 ‘oseco | «2000 | 106.000

oy 0000} — aosoo | 135000 | 14eo00 | : : ‘ssc | 95000 | 146,000

oy r20000 | 113900 | texo00 | 225000 | 5 5 zoo | 13000 | 225000

7

Standard Conveyor Chain #28 zuioloja2!

R-Roller F-Roller

swmoceet cA

3

oman ot

¥ b 4

P P a |

{88g

OY OS | RFS. cs

by stg | RFS. sooo | somo | 710 | ao | sta | tse | ts | a | | ts | as | 59

ov _cais0 | RF. 10

aoe 500 | p00 | rene | rere] 5 al

OY 5075 5. ® =f =

By 5100 | RF. 5. roo | room | r4sc0 | 100

Oy e100 | RFS. me ye fe fo [wl u fas] as | nz

ae 000] rm | sO ee == 5

OY 0 [RFS M. | e000 | Thomo | vusoo | wore | us| a | mS | ss | we | 25 | as | m2

DY tens [RF S. Mt 15

fy cm [mee m, | 900 | t100 | rusoo] fF | ms] 2 | ws | os | we | 25] as | 2

SW BOR. FSM | a0 Tino | aso | sa B |e aa pte

0 RS 700 == :

oy 10125, s. r1s00 | ram | 23000} 125 | sos) 27

by 0150 | RF. SM. +0 we} Sie yal |

oY 2 [RSM | 13000 | Tyan | masa | toe | ees ef = We

a5 13000 [T4000 | 2500" | 7.1 nr 5 ae

‘OY -@0S| RFS. M.| 19900 | zon | —zas00 | 1824 | S72] @ | 92 | 7 | | a5 ae

DY 17000-[ R: FS. Mt 70

fy ova |eeem, | 19000 | 200] meso] 20 [ws | fw | o | mw | ao 9

oY 22 | RSM | 75000 | aon | aes | te | wae eS PP = wr

Wa RFS a0

oy 17250 | RF.s.M. | 25000 | zon | apso0| 250 | so | uw | oo | 100 | % | 5 | 2 | aor

by 1700 | RFS. M 0

‘oF 26200 So a0 = =

ov 24050 | RF. S. Mt 20

py p40 | RiP. s. m. | $4000 | A8em0 | $HOD | > | yp | go fico | as | oe |e | te | ats

by puso | RIF. S. M 0

oy -3750 su 0 = Ls l= 5

oy auao0 | RFS. 0 me

ov auso | Rie.s.m. | “50 | Seo | 69500) js | ras | se fas | so | a | 7 |

by 36600 | ROFL S. M. 0

oY §200 7 RFS. 0

oy suso | RIF.S. sigoo | sgooo | wosoo | so | wo | os [ua | mm | a | a | ues | sre

ov _§2400 | RF.S. 0

DY 40000 R: FN a0

Dy 40050 | RF. sigo0 | syono | toso00 | 350 | uo | & [uo | mm | | s | us| -

by soo | RF 0

50 EO = =

oy $0490 | R. FN, aosco | 195000 | rwson0 | a0 =

oy saa) REN Siw [7% fim | ms a |

DY Ta000-[ RN 700

ea a ‘raoco | rqo20 | 225000 | St o lm | w ins | as | =

18

“i

‘S(M,N]-Roller

Chain Numbering Example

by 10180 F AZ 1/1

RelerType

- ——4$} chai

+ ve Chain

Le .

Luntkgtrel

| 2) ee)

: > fw | 2 2 ay [ms jas | ar |oma | za | as | aw |e

- - zo | ar | te | *

z 2 pac | aso, wk [9 es esse ua ae fa

iH

: - | a | us wz fn |e |e | see | ose | sz | sa | ae] =

a | aw ||!

5 =a aa, a as ae = So=

Bio) | sat we [itp mas | aS | 06a is |e] 72) ak

we | - | 2 | smo mas [na | ones | ases | aoa [oss | AY [eS a LS

se | se | co | a2

wa [|| eee ||| ae] 8a

0} oo

ae | - | » | smo war fua |r |e | mo | o | a7 | ay | aa | 6s

ao | ea | so | 61

gig} na} 99 wer sy— paras |= | aa

: Seri ssp ase aaes |e a=

se [| 9 ws [ies | 95 | aS | w_| wa _| tee _| es | 92 | 98

Tie | at | a3] 8

zi] - | | 29 us [iss | ans | sus | asa | zo | ME | RE | a | oe

a wf

Bae

us | - | su | sso | soe | ros fois | [ins | me] 7 |e | |

w |w [au [a

er

wa la | | iw

sa | - | s2 | sso | os | m2 |ss2 |r fone | ome] 2 | 2 |S | ie

w |» [a [a

=| ea

a |o |e io | xu

sa | - | w7 | m7 mr | se forse | os | ws |B) 2 |e |B | M

a_|» |» |x

se

: - ian]. na fas fas foo [ims | wis] ao | as | me |:

wn _|w |x | -

aa z

5 n | 7 | wy wo | |ms jas [woe | me | o | st x

6 [4 ze

> e

: so | «| w no | ao | ers fro | rs | as | m | 2

6 | a

w= 8

> | wo fo | wo [soo [rss [is foe | [TE | 2

9

Standard Conveyor Chain Attachment

HES Lwilolof He! OfeHal He

Ar Attachment et

OY GO | RFS | 5 096

oy oa00 | RFS ae | 2 [| M | oo

yao [Rs ORR | To

oS |S i 5 006

or oso lars |r |x|asfa|as| ss | 10| me] oor

or oso [aris | 10 5 x0

mes aA | S| | | Sa | | wo oar

[RFS is || wD] | TY SAGO | 2] MIO | OTe

a DY west RFS Ma |e SO] a | WO | osteo | | moze

1 [RF SM | wu [ wR] so] | | éxeo | 2 [MO | om

a 70 Die

oy 1os0 | RF. SSM | 180 | 01 | oq | oxbal | 12 | oto 020

wae Rs [ow] sm] wm | Te | [we oe

DBAS RF SW | BRAY | AO] P| TOO] FL | OST

wa | RFS HM | 2D v2 oa

” r

oy rao faris.m | zo |™ | | 7 | 1s 15M Toa

ee

We) | RFS | 2D Ta win | Oa

.

oy ro |air.s.m | oo | || | 165 soa) | 18 m2 | 08s

K, Attachment

OY GOS | RFS |S S are

‘

py oso | RFS wo || %| "I os| % 0 | MT on

Wo aR s i

8B |S B S are

or oi lars [ro || mfales| ss || me | on

or ois |rir.s | 10 5 020

Was aT | WO He | as | BOT | | wo

OF) | RF SM | TOs | te | 10] | | Sao | 12 | wo | O36

DY wo] RF SM || Ba | TOO] Tae | FO | asTOON | Te] MOO

DY wo [RFS] TR | a2 | 0] faa] WO] sae | v2 [Mio | OMe

a 70 032

em Le [as | to] x0] | canal | 12 |e | OF

Hae [RSM [OH WO | | Te |S | we | Ose

DY wes [RF Sw | see | a8 | eo] 168 Too] 7a fs [we | OT

oY mod | RFS. M | 20 a O88

oy rao fae som | 20 | % | MO) Sl yes] 7 | M2) a

Daa SM | eee | a | TO] TOE Too asta Tw [we | oe

oo) | RFs. w | 2 0 win} i

vy vaso faies.m | 20 |® ||] yes ssttoa) | 1S mia | 196

20

A, Attachment

OMS RFS | ar) 006

by o3t00 | RF. S ro || wl] % [° |" | oor

wwf Rs One| a | ao | OT Ta [| a

oY as |S 7B =] a 06

or csi |re.s [ro |22fas|or)as| ao) as | s0| me | aor

or oso [Res | s/o a0

ov ms | me [S| | ss | 38 | GH | | WI] TT

[RFS MTS | [50] we | TO wo] oslo | | wiO-| Oe

DY iso RFS MO [ae [SO a] WO wo wale | Ta | MIO a

OY a0 [RFS mM _[ts24 || sO| oe | 90 sO] also) | 12 | io | Om

OY Tie PR. SN feo na a6

by 1o1so | RF. S.M_ | 180 7101 6 | oy | go] S960 | 2 | MIO 020

7a [RSM [ros [a5] mo [wo] TF | | wie | Oe

oY __m5_[s Tait] 35 [oo [75 | [30] 79 | 12 [iO] aa

DY wos R. FSW [Tene [ae [ea] 7H [100] sO] 79 | 18 [we | 8a

DY T00fR. FS. [ato 0) aa

pv 150 |rir.s.m | |% ||” |res|as| 7 [| M| a6

DY 22 [RSM [teed | |S] aw [oO] wo PATO TS [wie | OAT

Oyo PR. FS. [ato 720] mia] 06

pv 1750 |Rir.s.m 20 |||" | 165] 105 ice mi2 | 088

or 2499S. 2 20] wie} a7

py 2650 | Rs. [aso | | |" | ses |r| #0000) | 78 no 1.01

K, Attachment

OW OS RES | Sa a?

X

by 03100 | RFS wo |? ||" | es | ao] | | a7

[RS ors | | w [08 70 | wo | Kaa | Te PMO | cae

oY ems |S 7B Sa ae

oy oso jar s [wo |z|rm| s/s] ao as |r0| me | or

or oss [RFS | 130 s/o 020

Owes eer [Oa ws [a8 | HOT | TE | wa ae

OY «60 RF_S_w_[T016 | ze [100] rem | TO | a] also) | 12 | io] 096

Dy aso | R. FS. M_ [150 | 2H [100/26 90 | oO] ealeor | 12 wiO"| axe

DY | RFS. TeR | we [TOO] Taw| WO | wo] oslo | 2 | wiO-| ave

DY oi0e PR SN fan 7m) @ ow

oy roiso | Rir.s.m |r | ||!) 90 | oo ce el a 040

DY HRS. [VOI [a TO] eww | | 7 | [| a

oy m5 Tait] 35 [e010 | «S| a0] 79 | 12 [wo aa

OY a0s_[-R. FS, w_| 1524 | 38 [120] 1% 100] 60] 79 | 18 | mia | OT

DY Tao PR. FS [a wa] tee

oy tao |RF.s.M [aso |™ ee 165 | 125 Zam he die 122

DY __72_[ R.S.M [1524 |< [10] Tem 100] 60] PaTOOT| 1 | wi | ae

DY PRS [a va] wiz | Tae

by 1750 | R.F.S.M | 250 65 | 190) 19695 125] ee Miz | 1.76

oY 2600S. 7 20] Mia} 1a

by 26250 | R.F.S. M_ | 250 100) 206 45 | 125] 99°91 | * | we | ace

a

A, Attachment

S/5 $|8 § 3/8 $ 8|8 $ 3/8 $ 8/8 2

S| e | = = = =i

a)a)3|8 2

Hele ela ia ls

3/3 3 é 3 £8

gig a|s 8 e[se eles s|s 8 a/8 8

sis ais 8 s[8 8 3|5 = 8[s 2 [= 5

2ls| 3 |e |2 | & [s&s

e[s|e |2 |e 2 ls

3) 8 2 3 e 2 8

ais ols sis 9 s|s 2 sles als &

g

RGR 22809908088

BBs sb 5 esses sR RBS

A, Attachment

is |S Si2 Sisia|s a

|= | 2 | 2 2

2/2/88

Balala ale

plete ta lele

8 |# 3/8 2/8 3/3 |8

Bjess sia sle|

lg|3 |z# | [sis

is} 8] s | = \s\e

ls|}e | 2 |e |s|s

3 | 83 8/8 §|8\s

geeeseg28

15|5 5/5 5/5 5\5|5

22

SA, Attachment

DvOmS | RS |m 2s as

cf elu

Dyasi00 | R.S ‘© |® FL Ml ole] || | cos

bY 490 | R.S iio1s| 376 | S18 zazas)| eit6s)| 40 | 70 | amo | v2 | M10 | ato

DyosI00 | RS fin ole ae

as) 2 | elu

Dyos1s0 | RLS io |S Sl eole| ||" | ow

DY 450 | R.S.M_ |to18| 476 | 607) 2ma6s}| 2or195)| 40 | 7 | 6:60) | 12 | M10] 016

DyoB150 | R.S.M {150 | 461 | 587) 27265)| 2or95)| a | 90 | sa¥6m | 12 | MIO] 020

DY 680 | R.S.M [teal [eo [zee] aiszi] e| wo [avem |e [wie] om

DvTOI00 | R.S. M fin alm ous

1 «x¢a,| 2 | wio

py tots | Resim |i [|S |) M520 oy | e og

DY 24 [R.S.M [ols [| | as | 0] w| a | |we| ox

DY 05 | R.S.M seals [757] 5 | a5 | w/o] ra | |wre| om

Dyi2z00 RSM PM |es los | oss | 5 | 1) oo | s/n] OM

oy 1280 | R.s.M [an 156 oss

DY 212 | R.S.M [sad] © eo |ams)| ea) om | wo jason) ws [wre 08

SK, Attachment

Oa | RS |B a) S a

"

oF ons RS ufo ]oss] ons ]2] 8] 2 [wfw] 28

oY a0] RS i | a | ew | BAT | We ||

OY 100] R.S a] es a

a

oF 00 RS salsa] x | ws [47 S) [uw fwe] oe

YO] RSM [| hw S| | | me eae | S| oa

Oy osis0 | RS. M [O [Ai) S07] cea] ames) | wena] w wo) 00

OY seo | RS. M [| [8 [aso aise) | we eae | wo) Ow

OYTO | RS. w a] ® wD

1 ™

sr tome fee we leg |4[4 [ast] aise] 8) ama |v fone) o8

O20 [R.S.M [ous [| BE] aL ol ww Swe) om

OY ae [R.S.M [muss [P| HE | ms | [w]e [|W] om

By imag RS.M YA Ys Ios | as | as |)" oo | lun] ®

or rs0 | Ris. M ws |s un

ora [RSM [i] | [a oo |eatom) wwe [ae

G, Attachment

by cars | RS BY ely 185, ma jus] 6 | | | Me

or cio lars |w| »

Dy os100 RS OO) as n ws | 15 | 10 | | me | Me

py_osso [ars in| @

oY oso [RF sw [| o| a | a | 2 |w|u|e| a [wo

oy 6 [RSM |i) | ae) | masta [se [am [| | [wo

or toi | sm fm]

an | sca | onsen | 0 fe | | [0

py 10180 | R.F.S.M 15 | a iad | st

Dy wos [RF S.M [sa] wo) 7 | | mS [w]e Wz

BY Taian) RF SM |B | ay Be ws | | 1S a | Mie

or rasp | ars. [20 | os

Dy 00 PRS. wham |

py rsa | RF. s. Mm [on | 0] stan |assas)| sss | a | 1s | o | ov |e

py_apo_| RFs. Mm [sm | 10

oy 2600 | RFS. [aD wo

axon | asta | aso | a [| | o [wr

Dy 26650 RF. 5.M [a | 20) | ers

DY 3660 [RF S. What | 2

w|« | « | ws] [ws

‘Dy 36600 | RF. S.M | 600 | 300 ai

by B80 | RFS ) | mS SS | a6) a | 125 | 90 | M20

or soo | ars [a | wm

G, Attachment ae

Dr oie | s/o a “ ) OG

’ |

by 05150 | Ss w | ml S718 |" wo a

Yao | Som [wen To) mw) | os a pw P| wn]

oro | S.M [st | a) &) W/o las) @ |e) we) tae

/ Yas |S. wea wo) | Te Tem | wp wa

H+ py zoo |S. M [an | va] wo] w|i [Re [ a | S| we | woiew

\ja } a oe

Ts ov imo | s.m_|a0 | | | om we |

DY 20 |S. Mad | wa] WO] we | a

- DY 26250 | SM [a0 | 150] 140] m0 | 95 |ugs | me | 15. wi ali

or 20 | s,m |x | | wo | woe |

by sea | SMa | | wa |

oy soo | sm foo | | wf || % | 2] Me il

DYC, The Solution

Standard Conveyor Chain Sprocket #22 zioloj aie! Amz)

Standard sprocket configuration

‘ Auype (Bi awope :

Features

@ Affordable standard series

You have a choice of various types of standard sprockets, Ma~

chining inner diameters allyou need before using it. There are

4 types, 2 materials, 6-12% number of teeth, and induction

heat treatment on the tooth options. And you can get the se-

lected boss type sprocket also withthe shortest delivery pos-

sible.

@ Higher strength, higher toughness

ur sprockets, made of steel, in welded structure, give you

higher strength and higher toughness.

© Precisely machined teeth make backward driving possible

Precision welding and new tooth design with lesser roller gap,

make precise engagement of tooth and chain roller, Ths will

enhance abrasion resistance, and make backward driving pos-

sible. In case of using K attachment, the attached bucket or siat

‘would nat interfere withthe tooth line

@ This design also can be applied to plastic roller and bearing

roller ‘ype chains:

© Please send us inguiy ifthe sprocket is for DY26 or bigger

chain,

Types

@ Atype-I is consist af tooth and flat sprocket body, this can be

bolted to the hub.

@ BW type-Bosses are welded onto each side ofA type sprocket.

© BW1 type-Uni-body boss goes through the A sprocket, and

welded bath sides.

@ CWI type-Uni-body boss goes through the A sprocket, and

welded bath sides, and have each side of boss.

@ Selected boss type-tt the dimension of boss does not match

with the standard sprocket above, you could order your own

specication.

Material

@ General specification

Using carbon steel, and fits for general use.

@ Wear resistance specification

Carbon steet plus induction hardening on the tooth part. This

is used when there's abrasion resistance requirement

Bw ype

cw ype Selected ss

Number of teeth and engagement angle

The minimum numberof engagement for chains 3 and refer to

the following table for engagement angle

Number of teeth

é

TH

e

10

2

Tax

Minimum engagement angle * }

180

me

1

108

30

86

» Every other toth engagement

Every other tooth engaging sprocket

‘The chain engages tthe sprocket with every other teth. This wil

decrease the contact between roller andthe tooth, and increase

fe time, Fr instance, actual number of teeth is 1 but working

numberof teth is 7,

Inner diameter machining

The standard sprockets are pilot-bored. And you need to machine

the inner diameter according to your requirement. Machine the

inner diameter based an the bottom diameter of the tooth tyou

base on the hub diameter, you may mis-pasition the inner diam-

1

And if there's any, please provide your machining tolerance.

Otherwise indicated, the tolerance is as per the following

Inner diameter He

Key way KSB1911

The precision is based on the new standard key way machining

However, when you use parallel conveyer ines, please lel us know

the number of rows, because these need to be machined simul-

taneously,

25

DONGYANG CHAIN INDUSTRY CO., LTD.

KS tapered key dimension

KS parallel key dimension 4

(KSB 1311-77)

(KSB 1311-77) 4

Nominal width « Depth of key way Nominal width x Depth of key way.

Number of teeth Nominal height diameter ‘Nominal height Shaft Boss d +2

be(taett Shaftt! Boss d+t2 beh ‘tT Parallel key Tapered key

ory Woler] awa 7 a5 a

ow 20 420 e | as | te | ona | aay

wow to 30 wor | ke | as | ote | ante

2 wo as a5 wz ow | sis | ae | ona | air

wo© as a5 ww | 6s | as | oan | ane

oar 3 os BB || a |e

oe © ‘ as wz wl a7 | so] oar | ace

7 1 a w mw| we | so| cas | aoe

wo * ae w w| we | so| eas | aan

se + a9 ww | we | s5| ose | aes

To 1 0 i || $0) ass

wer 1 en seo | wea | 40 | ous | ae

rar R an so | own | 70 | owe | ae

wr tee B ans es ow) an | 75] our | aay

wr or 6 ont we | zu __| 90 | ose | aaa

Oar i e155 | as | aaa

ne ww | sans 1 avs ws ow | au | 90 | ose | ane

ws ono | me | r90| oes | asa

‘ nr wr | ganis | to | ira | aa

Chain sprocket model number ser 5x2 no | ee | ato

1a 1S | aed Peo aad | ao

DYO3075R6T- BW var ug tax2e) | 20 | ovtze | detz0

Ss ne ee ee tse 1x2 130 | ea | deat

Trberstesh ype wr we | tax | no] ene | ano

Chain number Rol we ror | esas | iso] aime | aon

@ Selected boss: Intate the dimension ss dareter x bos nth 2 eos aka

@ induction hardening specification: Indicate tne reeuired harness,

Pitch circle diameter of conveyor chain sprocket Zit#|0|OH/21S ADSZl9] DIz|B AS

Ps 6627 7578.1 100 1016 125150 152.8 300350 400450500600

‘ona | 7000 ] e000 | #000 | 1000 | 12000

aria | ao67 | soi | roars | rseu | 19829

rae | aos | 9004 | ri064 | vava | 752

eas | stae | 10a | 1989 | ta066 | 18879

arr | 10033 | 11695 | 10157 | 619 | 17563

gram | 1928 | Tama | SED | ToTaD | 197

rosea | 12129 | urea | 1973 | mer |

vise1 | 13503 | 15455 | 17087 | wate | -

anes | ora | roe | woes] = | -

12536 | 1425 | wri | 1eaog | = | -

tae? | 15729 | T7976 | =

woe | reas |e! - | - | -

et

| 12s | 100 | 1862 | zo00 | a2 | 2500 | 2000 | ame

7 | vs27 | ime | roo | 2ans | 2au2 | 2681 | usr | asi2

1s | wo9 | race | r920 | 2059 | 2ive | sora | aaae | arr

| araz | 60 | zour | 2o1a | 2455 | wee | ar20

9 | ase | 293 | meu | 2920 | 2971 | 55 | ee | wise

| 2S | m7 | aoe | wae | arae | coas | case | oraz

ur | zas2 | 2042 | 2r2 | asus | sane | a7 | size | suas

12 | 7340 | 2098 | sors | aeac | 3926 | ca0 | 5796 | sane

sas | 266s | anne | 3141 | soar | cons | soze | omz | size

1a | 2769 | ata | a2ne | cine | caus | seza | o2ss | ase

uu | ave | aro | asto | 9a | A586 | Soir | ami | aang

as | ata | 3607 | 3757 | cero | ager | oor2 | ras | rax0

we | sav7 | sae | woos | size | szos | 6107 | 689 | rei2 ware |mo| - | - |. | -

a | s6a7 | waar | 4251 | sca | sso9 | oan | area | ern wor | roa) = | = | 2 |:

we | seis | arg | cae | ome | ses | rise | aoas | are was| - | - | - | - | -

a9 | wars | as57 | ance | aare | ar7a | ona | atta | 9259 rn

zo | ane | ave | 99a | aan | oie | suas | ose9 | oraz wal - | - | - |. |]

zy | aus | soa2 | sour | orto | oer7 | e127 | to0en | r0225

zz | sz | sora | saay | m027 | 39 | m39 | 10540 | 19709

za_| aae7 | ssos | sree | rue | raat | m6 | rove | are2

2 | son7 | smb | S984 | 764.1 | 784 | 77¥A | 482 | 67H

vs | sae | smac | o7a2 | rw79 | aioe | eras | r1968 | 12160

go_| ao | rns | ra | 9567 | 90 | 9720 | wise | 1380

Dimension Table for Standard Sprockets #2 4222 x13

®

cane eps pig! ype BW Type Cc Type

Teeth Hig) dL gD dk

1 ¢ ||? [w0> se] 2] 3 [sw] m] ss] ss

a @ [2% >a [ws | | sas | as | | |S

Top a | as [aa | | 8 | S| TO

zw | 6 | wo 7 | | 8 |e] |] aS

e 2 | 15 | a-a0| | | 25 | mao) oS) SF

. ee

jo | a | 35 [a0 | |] 8 [aw] es |] 6

by 03078 12 2 | 45 | 2-50| 75 | 57 | 65 | 25-50] 8S | 70

¢ [m2 (tad | | 2] 3 | | LS

Te] 0 | 28 pass | TO] | eR] | TO] AS

. ee

wo | | as | e-80 | s| ee] 6s || IO] IS

TEP a [68 [aT | S| BS | S| | TO

Tae [ aes | v5-80 | 7S | BS | 8S | | TO

Ce

a @ | a8 | aso | TH | ae | 68 SO | BS | TO

jo | a] 78 | 96-8075 | oe |_| RO] | TOTO

|i ase [es or | e288 | 90 | 7H]

o [a tf ases | TO] Se | 38 | AS | TS |

. @ [2% >a [vad | oe) bs) 80) | TO] BS

P| ofa S| S| BO BS | TO

By 03100 12 20 | 85 75-55 | 85 | Ge | TT B35 | 0 | | Tt

En Ce

fi | TR |S | 80 | 7S | || BY BO

i > @ | ass | as-s0 | Tee] 7 | | ws | |B

sa] ERE 4 To | | 8 | a5-80 | | oe] || |]

| eC

Lo ian | 2 | 2 25-55 | 85 | 7 | | 5-55 | 90 | S| TS

é 20 | 35 | 25-55 | 8 | 71 e 7-85 | 90 | s

BW Type a E [a [65 | aso 9] Te TO 7-8 TOO [BT

io | | 0 90-70. [foo| wi |e | 90-70 [To | 99 |

TEP [| 90-0 | BT P| OTOL | FO

oy ao oa a asa we |S S| LET

Te] 0 | 6 [ao-e0 | 90] 76] 9 | a0-40 [100 | #1

. © | [7S | 0-60 | 90 | 7 | | ae [OO] BOT

To [|| 90-70 | 100 | a || 50-70-10 | 9-7

TE [1 [9050-100 [BT | AO | HOT | TOF 7

ol Tea Hoo | a [20 | 70-0

on

ovosos | s To [a0 | 8 90-70" [100-| BT | TO 30-70 TT |

wpa [9 [90-70 [Foe | a S| ITO | TO | HO Te

Ce

® © | [65 | 0-70 Too | wr | TO a0 70_ [HO] LT

io [| 10 | 90-70 |100| a |e | 50-70 | 10 | FOI

TED 905 75TH TO

@ [a] [aes] 0 | 6 | aOee0 [100 | 8

. eps | a0-70 [roo [a [9 070 [TO | 9] TT

TOP [B90 FOO | TT | HOT | TOFS

CW! Type By 95100 Fea a0=re [TOL aT | 90 [TOF

Ce

TE [6 [20-70 [O| BT || STO | VOT

‘ @ [7 a0-70 [roo Par [at | 30-70 [0] 90 |e

TOO 905 10-1007 | BT S| GOTO TOF

FEI [TO | FT| aT | | [TOO 2s

Fae | a0 te as-76 [TO] | | IS [OTD | Ae

27

1 S| ® | 8 (ea l@la, 2 | en, me

a as Ps ar Pe or

we ase pera ear pe

feb Par bo rate

a

| pe ee oar or ae

i a

ste eff ea |e ps fear] | woo | wo |

ee

i fea Paar eff

i eee

; ee

+E espa pee berber ewer ps

wef eps Psa fa rw) we

a

Alype DY 204 s 0 Ce

espa fr oc sea bo

peo er pep ee mw

a a ear Por

ee Pe rp ae

ee p ee bw eee pe

ofa [saan ores | ee [ww

ees Pae frp ar on ae bo

= ov a fw Pap arb a

ee pep aa oe

1 ee

5 a

|=] |, Gee CSein

i ee

eee Pf ae ag

— 2 oe as [now |e ee [1 ||

ee a

BW Te a eS

a

eee psa fer eee war pw nso

babe par papa ef ee |

ef aaa Par

vores oe ee ee

pepe psa pa ere beef wesw

$e ae bebe a |

oe

eb ge ar afar

weasel eee er pe

ee

wee Psa for oe ewer pe se

ope pe peepee eee ele

a arp arf a fr

we pe pee eee eer pee

fe pe Psa bre beef so

See ae be par ef a |

ee ee

ov 6a ee

espa pss eer ewer pws |e

ope epee fw [re pee fmm |

Pp ae babar aba

soe bape pee era pee before

oe oa fpr at ar bse

ee pe pea berber ewer pes

1a Em) 5-65 [190 [ior |e ono | wo [1s | at

28

rt

i 6) |e] es [m0 | 97 | 0 | ser [reo [too |

Li} é aw [as | 3078 [110 | 97 | 14 | 35-75 [120 | 100 | 15

SHH 3} Toe | asa va TOR | | 95-909 TOS |

"| ov wis weap asta per fa} era [ep

i Co

t 8 @ | 9s | 30-75 | mo | 97 | 15 | 35-75 [120 100 | 16

ee TO @ | w |ase90 | rao | Toa | 22-| 35-00 | 1-105 | 2a

Atype Top [a aes | TeV | | a= aT

ow ph aoa | oe | ve | as00 | 0 [105 | 7

. @ eases p90 [07 | | 0-90 ao 8 |

iz Tow P| |e | | | aI S|

L Te [wp | ooo 150 192 | x | a= 100 | 0-15 PSF

6 @ | é 35-80 | 120 | 9% | 15 3-80 130/108 | 7

es

J) eB I TO wos opine | ae [won| 0-5 aT

V/LEBI o- THE ater eaters ee

oi ee

Ta [we | asa [190 [107 | 26 | e090 fran 8 |

© [wpa asa [9 [OT] BOO OTE | a

To mp ws | ao PT | eo | ao n00 || 15 a

Te [wf | eestor | 160" Tae | 60] a= T00 | 50" 15a

Taw | | woT0o | SO 12a | aE | A010 [180-5 we

ST a a6=r6 | He0 |e a5 [ea HOH | 2

Bw || a0 a0 10ST | 38-80 [Ta OT

5c OO

bv ae Toa] os9s | ao | 120 | 96 [ao t00 || 15 ae

€ pw pt aes [| OO | |S 0_[ TOD | TF

pease foo fe | 8-80 frat 108 | 7

Tow far | aes [13010 | 26] e905 Pa

Towa | aba Tea Wao | 5 [AOD S| IT

Basar [eae fea 00 |g

by ms TO fa | ae Wo Te TOR || 8-8/1] TOS | Te

wp aes fae | ae | eo HO |S

Alpe wipe WTR

¢ | ws | anes | wo [v5 | 25 | 25 | 0-100) 150 [125 | 28

eae | ata t00 | 150 | a5 | 25 | a9 | 0-100 150 [125] 7

To [moat | aero | 1ao| 05 | 25 | 565-170 To 1 3

i2_[-20| se | -s0-120 | 190 [150"| 25 | 01 [50-120] 10-150 90

Ce

aoe | 00 | 50-| | 20 | a0] 80-]125_| a

ov anos TO [20a |-a5110 | 160 9S | 20 | eS AST TOO TS a

72 [20-0 -s0-Fa0 | VwD-| 50 20-|-ee_| 50-120] TeO_[190_|-&F

$m [ | aaess | a0 [v8 | 25 | 27 | 0-100) 160 [125 | 27

Ta | ao | a8 | oto | a0" | 5 PAS a5 | e000 | 0 |es_| 3

Bao | ae | aoton | Ts0-| 5 as || co-100 0 |1a8_ [aT

To [a0 ae | asnn0 | 160 [95 | 25 | 57 e110] 1-15 |

T2—|-a0-|-ea|-s0-ra0|-190|150"| 25 | 26 | 50-120] 19" 150 a5

af 2 [ as] s0mte0 | van 50-| 95 | ae [ 0-120 [a0 [150_| a7

8

9

DONGYANG CHAIN INDUSTRY CO., LTD.

A BW Type ‘CWI Type

of Number of

ChainNo. oller Teeth” kg) d= DyiL a kgf «od Dyk hgh

x [227 { a-100 [160 [125 [a5 [39 | a0-100 [150] 18 | 39

e @ [20 [a6 [a 100 [160 [ras [2s [a [as 110 | 160135 | 00

Toa 7 |S TO af 8-9 |so=t20 180 150 | ae

i 12 —[ 20 | Wo | “80-190 90 || 25-129 | s0-190—[ 190 [160 | 128

+ p20 | aa 100| 60 195-207] 92 a-100 [Aso [125 | st

i r E [2031 | aeNTO [160 198 20 [ aw | ast 160195 | a

i py 12200 To [20 | aa “80-120 160 150-| 20-73 | 0-120 [190 [180-[ 72

I 7 BO | 6 [80-190 | 190 | 760 | 20 [99 | 50-130 | 190 [160 | 98.

Halal [20 2F | a-100 | 160 [108 | 28 [at | ao-too [180 [125 | at

Ta 20 a0 | as-T10 140 [a8 [25 Ps6 | —as=110 [160 [195 |S

i E [20 ae [ae NTO | T6098 5 [ we [ast] 160135 | as

i s TO 07] 80-120 0-180 8-97 | s0=t20 180 SO | He

! iz —[20 | Woo | ~s0-130 190 [60 [25- [ian | soc130 [190 [40 | 32

Ta [PO [TOF | S019 | AHO T6O_| 25-97 [50-120 [190 [101

pao a 1TOT| ea 25—| Beas 110 [4 [as

e @ [2072 | S0-120_| 180 [150 | 25-[ 95 | 50-120 | 190 [150 | 94

AType TO fa [Fes] 50190190 [a0 | far | so=ta0 190 16 | Te

12 [20 | Hse s8-105 | 210 [90 | 25_ [ise | 5-148 [210 [80-197

¢ [20 me | 110 | 160 [a8 | 20-| a5 | as-110 | 160135 | aa

. © [20 ap [0-120 180 150-20" | 7 | s0-120 | 180180 | 72

pyt22s0 To [20 [76 | -s0-190[ 190 [i60-|20-|f06 | s0-120 [190 [140-| 05

SEBO Yow | “sbetas PATO ao | 20" |tas | ssctes [210 ao | Ta

Hy $90 [AsO TO a8 96 [a as TIO |S |

of Ti 2065 | 50-120 | Tad [180-[ 25 [ee | 20-120 [190 [150.| 87

$s | a0] | 80="20 | T8080 25 | 98-120 a0 150 | 97

TO 20 [Tis 80-130 190 160-|25- fica s0-120_ [190 [40 | 142

iz [20 | sen | s8-103 210 tao | 25 or | s5-148 [210 [190-| 201

ee

[2019 | A0-100_| 160 [125 | 25 | 77| ao-100 | 190128 [27

a @ [2026 | aS110 | 60 pias | 5 [az | oto 140" H35 | at

TO P20 [a |Boe1ao 190150" | 25 | ea | s0-T20 [Tao 80 | a7

by 212 7 [20 | $9] “80-190 190 |60_| 25-87 | 0-190 |190-[ 140 [86

[2017 | a-too 50 28-25-29 ao 100 150125 [28

. Baa | AB= TO 1695 96 [ae aso 40 as | a

TO [20] a | “80-120 160150 | 25-| 66 | 50-120 [190 [150

i2 [206 | s0=130 | 190 |60-| 25 [69 | s-130 [190 [140 | 8B

[70 |e [eset 160 [195 [ap [St ase 10 | 10 [135 | 80

a § [2046 | s0-120| 180 [150 [32-[ ao [50-120 | 180 [150 | 85

TOPO [Fo [B03 | [6 | 32 fae | so-T30 [190 [eo Ts

1220 tae [sss 210 go | ae ft s5-148 [210 [90 [178

p20 ar [aso neo ras as | aa ast 60135 [ae

. Baa [80 tAO | T0096 [aw | 510 a0 150-7

py i200 To [207 | 80-130 190 160-|25-| 98-| 0-120 [190 [140 |_¥7

thal 12 a0-| wor | 85-145 | 0 [van | 5 fico | s6-145 [210 190 | tar

$ [20 | -nO | 60 [98 [32 | 88 | ae TI | 16035 | se

Taf 2087 | 80-120 [Yad [80 [ a7 P77 [80-120 180 150-7

$s [20 70| 0-120 180 [150 32-| 90] 50-120 | 180150 | 89

TO 20-| Yow | 5013090 [ a0 at | so=ta0 [190 sO | TaD

i220 | veo “85-103 210 [eo | 32 ftas | s5-105 [210 [a0 | tee

, za [20 [sz [s5-145 | 210-[ 780 [20 fia? | ss-tas [210 [180 | 186

a é 20 | 59 | 50-120 | 180/750 | 32 | 79 | 50-120 | 180/150 | 78

e [20 | tox | 50-130 190-160 [ 32 ze | s0-190 | 190 [140 | 12

TO 20 [se | 55-105 a0 [an | fsa | gs=tas [210 19d | 192

12 [a0 | aa |ss-103 | 210160 | 2 a2 | s5-14s ato [190 zat

[20 [a2 | 0-120] 180 [150-| 25 | oa | 50-120 | 180 [150 | 43

. Bae -s0= ta [19060 95 OO 130 90 [eo | ae

piso To [a0 [aie 88-103 fa feo|25-fis0-| 5-108 [210 [80 [Ta

iz [a0 | tae | soetas 210 80 | 25-five [5-145 [210-190 [t

[20 6 |B-120 | TeO TSOP a2] ws |s0=T20 | 180130 [a

Ta 20-[—95 | S0=Ta0 | 190-[140-[ a7 Hie | —80-130[ 190 [160 | 117

$s [20 joe | 0-130 190 [160-[ 32 faa | -s0-ta0 [190 [140 [132

TO 20 [toe | 5514S 2a | 9-199 | ss=tes [210 180 | 198

i220 | aaa. | 88-3] 210 eo | 2 fae 5-145 [210 [190

a — [a0 }-950-|s5=145 [210 | 160 [32 fs 55-168 1210 [190-1 28d

30

Tee ae S60 |e es or sea |e

oar seep mre rt ee att

Se eS

eee

oe ee

eee

by 17300 @ 2 234 | 55-160 | 230 | 200| 25 | 28! 55-160 | 230 | 200| 287

oH fier Crt serena

Haste tr rl sees

oP r -aee ft mot to aera ae a

ae ee

He Sais se Se

Dy 26200 10 40 116 | 55-145 | 210 10/36 | 150/ 55-145 | 210 | 180] 150

pe eee eee ee ne

oar erate Piet ae eae to

rH 6 | | | 50-130 | 190) 160] a0 | 75] s0-130. | 190 160) 75,

iJ @ co) 85 | 55-145 [210| 180/30 | 130/ 55-145 | 210 | 180] 130

|) & bras pe Gar Hue Se Gee ae ee ae le

4) pees 4) x2 | 40 |_ 190 | $5-160_| 230] 200| 30_| 200] 36-160 | 230 | 200| 240

{ 6 40 ‘7s | 50-130 | 190| 160] 36 | 100! so-130 | 190 | 160| 100

! 8 40 130 | 55-145 | 270| 180/ 36 | 170| 55-148 | 210| 180 170

pata taf mate tot senso at oe

ewe SSeS eee

PL Seat eee

fH etter rel seer ao

SS

y26300 10 40 190 | 55-160 | 230| 200/ 30 | 240| 55-160 | 230 | 200 240

Se ee

Eee ee

ee eee re

Pt eee

fH Hi tease resto

ope ae ee esate tet ee fa et

aoe

oo Te Lees

BY 98800 10 40 210 | 75-190 | 270| 240] 32 | 300| 75-190 | 270| 240| 300

aH tte ete re seam a

Pee Creat aot eta terete tae oe

uv

Boss

BW Type

Boss Length

Max Boss Diameter

| | 80 | 25-40 | 25-08 vw [12 py oss | 90 | 1s | tao | 170 | 210 | 250

me | | 58 | 20s | 2500 13 | 16 by osteo | 130 | 170 | 190 | 250 | s10 | 30

7B) 50 | 60 | 25-50 | 25-45 1 | 20 by ao | 130 | 170 | 190 | 290 | a10 | a0

as | 88 | 70 | 25-38 | 25-80 2 | 30 by oso | — | — | 12 | 16s | 200 | —

3) 60) TS | 25-60 | 5-85 29 | 34 By osteo | 120 | 140 | 180 | 2u0 | 300 | 220

Too | 6 |e | soe | 0-00 as | 47 Dy osis | 135 | 220 | mo | azo | sco | a0

no | 7 | 90 | 30-75 | 30-70 54 | 60 by osis0 | 200 | 270 | 290 | 390 | u90 | 520

12 | 80 | 100 | 35-80] 35-75 |carton| 67 | Be py mm | = | — | 0 | ts | 0 | =

tao | as | 10s | 35-08 | as-e0 | steel | aa | toe by 40 | 120 | 10 | two | 230 | 300 | 00

wo | 9s | 115 | ao95 | vo-90 tos | ia Dy osiz5 | 16 | 220 | 230 | a10 | a9 | «20

150 | 100 | 125 | 40-100 132 | 164 Dy 08130 | 200 | 270 | 290 | 90 | 490 | S20

w fo | ws | ano 163, | 200 by «0 | 20 | 270 | 20 | 390 | wo | 520

tao | 20 | 150 | s0-i20 25 | 261 py tio | 115 | — | 170 | 20 | 290 | —

to | 130 | 10 | S030 24 | a7 Dy 10125 | 150 | 20 | 20 | 300 | a0 | «0

aio | 4s | 190 | S815 372 | 462 by iso | 195 | 240 | 290 | azo | veo | 510

230 | 140 | 200 | s5-160 500 | Go py ms | = | — | 10 | 1m | mo | =

by 24 | 1a | — | veo | 240 | 200 | —

by «05 | 15 | 250 | 260 | 370 | «70 | soo

Dy 12700 | 260 | 340 | 390 | 520 | 440 | 60

by 12230 | 300 | 470 | sto | eo | a0 | 80

by 712 | 1 | — | m0 | 3m | uo | —

Dy 17200 | 250 | 250 | 370 | soo | wo | 80

by 17230 | aso | céo | soo | oso | 810 | 70

Dy 17800 | 420 | s70 | «0 | #20 | 1.000 [1070

32

Bucket Elevator Chain (B type) +2 wa1wioies a12uee)

Bucket elevator chainiB typel, which consists ofa conveyor chain with

buckets fitted to its attachments and circulates along a vertical path,

is for vertical conveyance of bulk or powdered materials, being excel

lent in both wear resistance and impact resistance.

Sco east

po

a x mr | 6 | ® BM

Bios | 1 sc) itso | 7000

@ iaine=-s | 152 a

tae | we | om om | as | ow | ws | os] a SS) yom | caso

B iTia0-5 | 200 ite

Bie | ef a ste | soe | as fotos | sis) oe | | cso | aaseo

B 2eza0-N | 200 782

Bron | = | ss | 52 | ws | ss | SP HL nay | emo | $8000

8 asino-n | 300 vas | as a9

8 a60-N | 250 ar 6 ar

Bawwo-n | wo | 2 | wr | m2] nz | ig n | ® | 21] aso | esse

8 abis0-n | 380 206

B saxo-N | 200 aT

Baso-n | a9 | 70 n | 9 | 27 | m w | u | ms | com | t0%000

8 voimo-n | 400 2a

B s0I50-N | 350 59

ieee ae | we we fae | tons) es | BE | aso | tesoon

ey2eu-N | ao | || es) eas |e

Bucket Elevator Chain (B type)

B 36i00-N- 6 36350-N 300-350 % 8 a teh 2

B 6fi00-N- 8 650-N- 8 GOMG0-N | 300-380-000 | a5 e # 176 @

1 90350-N- B 90:00-N "380-400 2 wos | 101s 204 16

BR0409-N= 8 36300-N 200 Ee 20

B

Attachment

G-bAttachment ‘G-GaAttachment (Double Plate Assembled)

G-4 Attachment

Fs 15

ais | | mo | = | 7m | a

aiae-s | ie | ef =| wa

B 12200-S. 200 cs 100 0 " #8 a 5 ” Ms 10

aime-s | mo | me} wo | 0 | 8 wie)

8 17280-S. 0 180 40 100 8 #8 2 ” ~ Mie 18

3 2@0-N [af ep ea ae Mig

B 26250-N 0 180 0 100 38 “ ca ” ” Mie ”

aun | wo | m0 | we | | a7 | @ |» |» | © | me | 9

G-4 Attachment (Double Plate Assembled)

sam-N | m0 | me | m | w | 2 | « |» | x | © | mo | x

Fr }

axon | a0 | 20 | mo | m | 2 | 2 | w | » | w | mm | x

amon | m0 | ae} me || 2 | 7 | | «| | wa | a

aeson | x | 2@ | aw | m | 2 | 7 | o | w | w | mm | ao

secon | a | wo | a | m |» | w | » | » | o | mm | w

aast-N | a0 [2a fae | me ps || fee]

avon | a | mo | ao | m | wv | ws | o | » | wo | mo | o

sromo-n | ao | ao | ao | mo | | es | so | a | © | woo | os

DYC, The Solution

Flow Conveyor Chain #2¢ auioloi a2! C

Flow conyer hin coms powdered ater 3 sae cs,

whieh prevents dispersal or loss of the materials and is efficient for

pollution control, Ithas many alternative attachments to choose from

according to the kind of materials to be conveyed. We have narmal

specification and extra heavy duty specification.

General Type Flow Conveyor Chain

US SSP wloloj ale!

a Travel

35

OF St is) | oie i a ae “a 90 | 74sa0

a ey

‘Type Chain ‘Type 2 Chain

Dimension Diagram of Bushed Chains

chain Pitch Break Bushing Pin Link late Weight

Chain No ‘Streng

Type mm in Ming) D w é ry u T HO katim

ov | 2 | 6627) 209 520 | se 20 | via2 | a0 | i580 | 63 | ms | se

aves eee 3000 | se [es | [eae]

owe 2 | 6627) 209 e000 | zse mes | vio | si9 | a7t_| 63) tes | su

oe aa Tes00_[ aia aie eas a9] a

avaasd |_| Toro | 00 14500 | 3650) is) Sae_| S12] 79) ms | Toa

rae [ahaa 14500] 680 | ad Ras | Seas | a

Bushed Chain Attachments

fe: (Ee

« \:1

fe

‘Type 3 Chain Type 4 Chain Type § Chain Type 6 Chain Type 7 Chain

Dimension Diagram of Attachments

: Chain Dimensions Weight

‘Attachment No, Chain No,

Te os & & 8 Cc F £0 T _ kstm

Ova a | 0 | 00 | i530 | m0 | sis | 0 | - | os | 40 | ta

yet two [ois [ats ao tae eis [| as [79] a

id < [too | 950 | %50_| so] 1940 | wo | | eo | 79) ts

w rae Sa = eo

read [seo oe [ane | aoa | aaa) oe

Ha rae 7 = [=| me | mea] a | tee [72 | 98 | 6

mae read 7 Es

62

Bushed Roller Chain

‘Type 8 chain ‘Type 9 chain

Dimension Diagram of Bushed Roller Chains

ri | man | sors [waco | sis | 101 | 1580 | anos | sas | a0 | 190 | 102

ori | 6 | 0x0 | oss | sromo | asus | «1 | zz | s7o | 60 | 127 | suo | me

ress «| woz | dos | sooo | mas | 2 | maa | x0 | wo | 127 | so | zs

oats 7 [mae [ ano 9s | oa | as | 7s | m0 | so | 4a | at | 2

prize + | wie | com | room | soe | azo | wr | a7 | we | 79 | aes | vio

its ¥ [tors [000 | 1ss00 | soa [me | ws | es | 1 | 7s | ms | 7

riiaa > | waa | coo | 14000 | a5 | a74 | wos | aes | oss | 6a | s0# | 120

orriee a [wea [som | sero | rez | ace | mara | eo | sao | os | sow | tea

ste ‘|

A EEE ESS

“Se wr o

We fet

‘Type 10 chain, ‘Type 11 chain ‘Type 12 chain

Dimension Diagram of Bushed Roller Chains

res | en | 30% | ss | a8 | a71 | ta | as | os | 79 | m1 | 100

orig Ww [tee [waco | iva00 [mez | gat [tame | war | stw | too | son | ma

rea 2 | tse | 6000 | t2sc | os | coo | To | vr | Se | 95 | m9 | 2h0

rete mf tore | como | ttaoo | eas | s30s | tse | ee | on | to | a | 0

reais i | wes | 9000 | mo | m2 | wo | zo | wo | seo | os | Gs | tad

63

Dimension Diagram of A22 or A42 Attachments

Tye] | wz | ovis | soe | seo | ma | mer | wr | v7 | 159

A ma [ ona | so | oa | ma | as | we | ao | me

aa | onm | soa | so | ms | eo | wa | v7 | v7

ret

fH na [own [ua | wo | we [us [ur | wo | wa

ToL mia | oveiee | 742 | oo | v5 | soe | 7s | 180 | 20s

ot

82 Attachment |Ad2 Attachment Kt Attachment

Dimension Diagram of Attachments

15 oats | so | - | me | cass | 7 | v0 ns | 95 a

me Dia =| m2 | wo | na me ws [wo | ms

esa

Ki onm | as | - | mo | wo “8? | tao | to | as ue

Flight Wing Attachments

D

p

Dimension Diagram of Flight Wing Attachments (C-Type)

a a1 | tao | so7 | ms | ua | as | mo | at | tt | m7 | 79 | 79 | out

1c ws | m9 | 96 | me | ta | S08 | 70 | sy | 14O | 10 | 79 | 95 | O50

Te soo | 150 | 350 | ma | 111 | eo | 10 | m2 | 130] 11 | #9 | 80 | 0M@

Chains of UK Type for Sugar Plants

ay . Mat oo

es

i. \ |

tH

Ht ;

"i ae

im wl

‘ye csi syneBchan

Dimension Diagram of Chains of UK Type

oor | a | ore | sos | are | wns | ru | us | 29 | tas0 407 olololo

ows | ae | tee | ors | 65 | a0 | 53 | sos | 95 | tas 14s olololo

cw | ae | wee | oe | aa | 190 | 5a | oe | 98 | zia00 1aer of[ofofo

omer | ae | wee | os | os | 190 | 993 | sz | 95 | sae 186 ° °

vw | 8 | tsze | ose | 36s | 222 | 1000 | sae | 95 | 65400 | Attachment Ony °

oes | A | tse | 742 | 365 | 220 | iors | ers | 103 | e350 °

65

3. A 4

¢

wl vane

2

4 L

2 Atacment

Dimensions Diagram of Attachment

a 290% m0 us 35 7 | 687 318 366 79

a 0906 2088 a | _es | as aa 762 95

a 09060 2068 36 a7 | 1s | aa 72 35

w 708 258 Be a7 | ea |e aa 762 35

Ke 908 19.36 es 98 or | ear aa abs 79

a 0908 2 Be a7 | a | aa 72 35

Ke 09060 270 6 mr | wea | as aa 762 95

@ 908% 250 a 7 | ies |e aa 762 35

ie 09088 7158 358 m7 | Wea |e us 762 103

@ vso0 7088 36 7 | 730 a3 762 35

g (

ETtyr EE

“4

ss herne sso pace

Dimensions Diagram of Attachment

A Ce Oe

a2 2908 8 78 Te 35 413 us| lors 19

452 2906 706 en 127 a3 os | 1a 79

as2 09060 7306 we) Tl 127 a3 sos | 14a 79

co 9068 Be w|i 127 aa me | aa 7

‘A820 0908 : ai 24 95 Be #0 20 a

1S 0906 5 jaa | ied | a mI a ae 7

‘A820 09060 : jaa | 1080 127 381 953 na 79

66

PALM OIL MILL CHAIN #ewu «2

2

DYC, The Solution

Ss s—

CoE

Pp

Solid Pin chain

a a a

ove mae rey flee, ern ete rate

ChainNo, Strength) a in Toye” Thickness Thickness NUM er Meter

Ukgfl tm) (ra) kg)

vvoses | nom [ins | as | wo | wa | «a | so | we [70

ovasee | mon a7 | me ma | 90 | 79 | soe | tao

t=

Solid Pin with Extended Pin and Lock Nut

Pp

cys : cate wage

ove “te rues Ser, ter Pn gat ‘Huts ae Pate eh

ChainNo, Str Dae ep Size ueNut Thickness Thickness MIS" Per Meter

Ukaf Ic) my (ra) Akg)

neers | tem [wie | aa [a | va [we] w [oe [ se pn [te

onaes | ame [wee [wa [me | ze [mew | [pee [ee

67

DONGYANG CHAIN INDUSTRY CO., LTD.

Parking Building Chain =#w23 a2

Escalator Chain oiAzalolets ale!

Escalator chain must provide a high degree of safely and be of high pre-

cision to ensure a smooth ride.

68

DYC, The Solution

Water Treatment Facility Chain #x2 221 a2!

DSS Chain

Water treatment plant chain is made of specially selected stainless steel

whichis precision press formed and subjected to special heat treatment.

Ithas high dimensional precision, and despite ts light weight, its strong

and also exceptionally resistant to corrosion and wear

‘aver

manne, petal Sinimame DW tn eshte Pank at

(gd Strengthikat) Fa Lao Ce (TI LHL (Ta ET

oss ras | ee [asm] aison | wae wef wf | To

69

‘SF4 Attachment

% | 1% | ® | 2 | ®

bss TST vas | 100 12

bs mF % | o7 | 2 [ms | 1m | 6 | 2 | @ 1

bss 155 % | om | 2 | as | im | 6 | % | ® 1

ed ~ | | s [mo [i | se | = | © 16

A, Attachment a

D2, Attachment

=

gf a | '

gee

055

Sh = ms isin [a] |e [oe] wpe] aT

oss iss [35 | «2 [iss [one] © fu [| om

55

tszss | a | 72 [tes |one|ss2| 14 ft | 070

DSC Chain

seo CAL

2

ie eo

4 | 08 | 02 mi |

sc we2is-s. F | 15240 | 15000] 19500 vii | 0 | 310 | 240

DSc Te2i9-S. F | tsea® | wooo | 1700 | es | €0 | a9 | SOs | soz | 143 | Tas | a8 | WS | wi | a

sc Teeaa-S. F | ts240 | amooo | 5500 | 93 | 10 | a9 | ao | ami | 89 | ws | WO | Ms | ws | 79

dsc weas-5. fF | tse40 | saooo | as000 | we | tea | 97 | moo | amt | ieos| ms | as | sao | soe | 95

SC T5248 rszaa | sooo] ojo | we | - | ms | - | s2| m2 | vies | sa | wa | 5 | 95

psc wis | a) |S 7 | a

psc iaiy | Me) |S 7 [>

bsc tim | 0 | a |e em

sc ms | mo | | sf

n

DONGYANG CHAIN INDUSTRY CO., LTD.

DSC Chain D2, Attachment

‘Chain No. Lh & 4 ' ‘1 Weight

a tes

Ds i219 | 328] 590] 5] M2] Ma] 1 | om

Ds fez | OO) BO] S| NM) S| | on

psc 15285 | M45] 740) TaO| NIB] SAS] 6 | On

DSC Chain T, Attachment

Dimensions ‘Additional

fae Fy yg

se 15240 | 10 | | 3 | 0 | 12

dsc i219 | 1240 | toe | 85 | 9) a | ta

psc ise | iso | ue | im | @ |) | ze

DSc sas | sea ps | ae | mae

sc 2K

A; Attachment

Chain. P ‘Weight

se 15240 CE ed

Ds

psc

sc

Tie] 0 | woo] || was] Os

16240) 60 | et | 60 | 100) 38 | @/79| a0

T5246) 6 | ws | 60 | 100) S| vw) 9s| O55

2

Water Treatment Plant Chain Drive +#2 3418 75 “12!

De 120 si | 223 | sa | a7 | ms | sis | wo | @ | 5 | toc | tim] 68

Bo ws | 0 | em | mis | ms | amo | sw | | 40 | tom | tom | 95

a 1a somo | zee | av70 | 17 | aus | ws | @ | = | ¢ | reson | vom | 109

18 200 an | sa | a0 | 20 | 6s | os | * | = | 9 | nso | om | 7

De 20 m0 | a4 | a | wa | ss | rs | as | as | 0 | woo | som | za

B

Water Treatment Chain Sprocket #42! ale!s AZ=2!

DSC Chain Sprocket

7 | we | ass | a | ai | sc] om | a | 1m | 9 | m6

ose ASS RE | wee | soe | se | ose | ic | mo | o | im | os | @

7 [teak | SE |e] ae too seo ato)

Osc 15228-S.RF n | wee | soe | ss | st | oc | no | ms | 1m | tm | se

ta | wee | ous | | om | oc | ns | wo | wo | wo |

ye) SB) wm) S|) OSS)

Osc 1525-5. nf wee | soe | se | so | oc | ons | os | tao | zo |

ss | wee | oe | ws | ws | oc | ws | ws | mm | we |

DSC Chain Sprocket

a

055 1828-85. un |soe | se | os | se | oc | ons | wm | io | wo |

on | sm | ss | so | # | c | wo | o | wo | |

a

055 18219-8.5..F n | sop | so | sa | sw | c | ms | ow | to | wo |

on | sm | s7 | so | se | c¢ | mw | m | m | w | o

a

055 1825-8.5..F nj soe | se | se | sa | oc | ms | wm | two | wo | oo

os | wo | su | se | c | mm | m | vm | w | so

ip sae [se || ee] aoe

osstes-esRF | a | si | su | se | sm | c | ms | oo | ws | we |

Ie

Carrying Chain carrying a2!

For Automatic filtering systems of coaling water at thermal power plants,

the material should be selected according to environmental conditions at the plant

eq oe oe

[eee |

65 so | | 8 | a | = | 6 || ws

era sane eee

vr am | «| | |» | | xe

a aime eee

vara a0 [ we || we

a aa [ eee

no

x

oO

oO

2

9

og

a

Q

=>

2.

a

>

[ul

In

=

u

Q

re

Wis 102 72,700 1z0 35 38 19.98 Bh 1 1

Ws 106 23000 ime 35 ai 5 12 1 1

wsi10 000 my 35 ey 18.05 34 210 200

wee 73000 a2 35 as waar a m2 0

wsa0 000 7032 727 ss 700 78 5 230

6

DONGYANG CHAIN INDUSTRY CO., LTD.

Installation & Maintenance x) || OHI) Tt (utaxy * © Length Bush Nut Bolt Screw Rangelkgtm]

NUMBER ‘(H10)

DyTLamo wee

7| w] a] | m] os] as] as] 7|- fafa | ao -

oyn.z002 Pio

OFT 25-1 05

wv) alelalalefelal ele |o]a] a - | ws

orn ms

OTL wae 2076

wlalelelalw |e lalwls ls] 2] » - | we

oynaso2 m5 a5.182

OFT. ws | 8 wants

w| ala) el} mia |slalwie|-| or] fio | we

ovr.sos2 os | oes $0.09

ori ws | or)

ve] w|im| | wa | 7 | a2] af es| - | 7 | ns #15 | mio

ovum pis | Spe nem

avr. 1046 wios | wi w-0

| m|aw} mw) ns|az| 2 |s fa}. fa] uw | us Pus | mie

orn. 02% ms | doce cov

oe wis | M26 som

so} im|ae| ue) |a0 |uels fa] - [a] a | we rs | as

ormiers eo _| Spes 220-400

86

MEMO,

HEAD OFFICE

24, Yeongdong-gi, Yangsan-si, Gyeongsangnam-do, 50571, Republic of Korea

tel, $82-55-383-1112-4 fax, +82-55-383-1115

E-MAIL : dychain @dongyangchain co kr

BUSAN OFFICE

56, Sinsanbukcto, Sahe-gu, Busan, 49421, Republic of Korea

tel +82-51-316-2208-8 fax +82-51-316-2210

GYEONGG! OFFICE

67, #707-4, 1-na, Siwa Industial Complex, Gongdan 1-a00,

‘Sheung-s, Gyeongg-do, 15085, Republic of Korea

tel 48231-487-9566-7 fax, +82-081-487-9568

http:/Awww.dongyangchain.co.kr/en

‘SEOUL OFFICE

2-107, Guro Industrial Tool Shopping Center,

188, Gurojungang0, Guro-gu, Seou, 08212, Republic of Korea

tel +82-2-9667-9566-7 fax. +82-2.9667-9568

DAEGU OFFICE

#17-20,1F, Indust Material Center,

416, Yutongdani1o, Buk-gu, Daegu, 41518, Republic of Korea

tel +82-53:384-0038-9 fax. +82-53-384-0040

So DONGYANG CHAIN INDUSTRY CO.,LTD.

Ver 201708

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Sipart ManualDocument160 pagesSipart ManualJuan Ramón Hernandez MendozaNo ratings yet

- Techsupport #63: Properties and ProcessingDocument4 pagesTechsupport #63: Properties and ProcessingNguyễn Linh100% (1)

- Mobile Jaw Crusher PDFDocument7 pagesMobile Jaw Crusher PDFNguyễn LinhNo ratings yet

- Enoise Control Sound Curtains Brochure PDFDocument6 pagesEnoise Control Sound Curtains Brochure PDFNguyễn LinhNo ratings yet

- Ash CoolerDocument8 pagesAsh CoolerthiyagarajankNo ratings yet

- Sound Curtain Enclosure Windows Datasheet1 PDFDocument1 pageSound Curtain Enclosure Windows Datasheet1 PDFNguyễn LinhNo ratings yet

- UNC25 Sound Curtain Datasheet1 PDFDocument1 pageUNC25 Sound Curtain Datasheet1 PDFNguyễn LinhNo ratings yet

- B Blla Ac CK KD Diia Am Mo On ND DDocument6 pagesB Blla Ac CK KD Diia Am Mo On ND DNguyễn LinhNo ratings yet

- Purchase Specification For Sludge DryerDocument84 pagesPurchase Specification For Sludge DryerNguyễn LinhNo ratings yet

- Ash CoolerDocument5 pagesAsh CoolerNguyễn LinhNo ratings yet

- DA102-13 Damper Torque PDFDocument3 pagesDA102-13 Damper Torque PDFNguyễn LinhNo ratings yet

- Conveyor Chain Data SheetDocument24 pagesConveyor Chain Data SheetNguyễn LinhNo ratings yet

- Technical Data Sheet GM24A-SR-TPDocument6 pagesTechnical Data Sheet GM24A-SR-TPNguyễn LinhNo ratings yet

- Installation Operation Man GTXDocument20 pagesInstallation Operation Man GTXNguyễn LinhNo ratings yet

- Carbon Steel TubesDocument3 pagesCarbon Steel Tubesreall0ve24No ratings yet

- Industrial PDFDocument8 pagesIndustrial PDFNguyễn LinhNo ratings yet

- Mech7350 11 Fans PDFDocument10 pagesMech7350 11 Fans PDFRavi ShankarNo ratings yet

- Spec PL e 2014Document47 pagesSpec PL e 2014Nguyễn LinhNo ratings yet

- SCM 440Document2 pagesSCM 440weldmindNo ratings yet

- ControlDampers CatalogDocument20 pagesControlDampers Catalogdaviko313100% (1)

- Cone StandardDocument16 pagesCone StandardNguyễn LinhNo ratings yet

- Technical Data Sheet: Sound Curtain Enclosure UN-10 CV WindowsDocument1 pageTechnical Data Sheet: Sound Curtain Enclosure UN-10 CV WindowsNguyễn LinhNo ratings yet

- Quilted Sound Barrier/Sound Absorber CurtainDocument1 pageQuilted Sound Barrier/Sound Absorber CurtainNguyễn LinhNo ratings yet

- Sound Curtains: Specializing in Acoustics, Noise & Vibration ControlDocument6 pagesSound Curtains: Specializing in Acoustics, Noise & Vibration ControlNguyễn LinhNo ratings yet

- FTang - Pitot Type L - 02 04 19Document3 pagesFTang - Pitot Type L - 02 04 19Nguyễn LinhNo ratings yet

- Schenck Balancer ManualDocument1 pageSchenck Balancer ManualNguyễn LinhNo ratings yet

- Ash+Extractor - PDD GOC120200 331RA 00 PDFDocument109 pagesAsh+Extractor - PDD GOC120200 331RA 00 PDFNguyễn Linh100% (1)

- 11 CVC 01 INLET VANE CONTROL DAMPER Flamgard Calidair Product Data Sheet1Document2 pages11 CVC 01 INLET VANE CONTROL DAMPER Flamgard Calidair Product Data Sheet1Nguyễn LinhNo ratings yet

- ACAT Screw Press Brochure Rev001Document4 pagesACAT Screw Press Brochure Rev001Nguyễn LinhNo ratings yet