Professional Documents

Culture Documents

Adcos NV - TFE - Purinject 1C 115 Eco

Uploaded by

Florin RazvanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adcos NV - TFE - Purinject 1C 115 Eco

Uploaded by

Florin RazvanCopyright:

Available Formats

PURINJECT 1C 115 ECO TDS

One component, solvent free, polyurethane injection system ideally suitable for crack injection/water leaks in concrete and masonry structures.

Reaction with water yields a semi-rigid polyurethane foam (slightly flexible). To be injected with a one-component pump. Use with 6 to 10% catalyst.

HOW DOES PURINJECT 1C 115 ECO WORK? PACKAGING

Reaction with water yields a polyurethane semi-rigid foam (slightly Standard packaging:

flexible). The formation of CO2 makes the foam penetrate very well into

the cracks. The reaction speed can be adapted easily by varying the • 25 kg resin and 2,5 litre catalyst

accelerator or catalyst content from 6% to 10%. The more catalyst is Pallet: 600 kg resin and 60 litres of catalyst

added, the faster the reaction velocity. The end product neither shrinks • 10 kg resin and 1 litre catalyst

nor swells. A good compression strength is obtained in a very short Pallet: 750 kg resin and 75 litres of catalyst

time. Free expansion: +4000%.

Other type of packaging available on request. Can be supplied under

private label.

APPLICATION PRESCRIPTIONS

Shake the catalyst well. Mix the resin and the accelerator in a ratio of

STORAGE

6% to 10% in function of the desired reaction speed. For injection: use

packers and a 1 component pump (manual or automatic). PURINJECT To avoid problems, it is very important to understand that these

1C 115 ECO is very hygroscopic and packed under dry atmosphere. Use materials are both temperature and moisture sensitive. Therefore,

opened containers as soon as possible or recap under dry nitrogen. materials should be stored in an area with temperatures not exceeding

Pumps should be cleaned with PURCLEAN, a cleaning product specially 30°C or not lower than 10°C. The maximum shelf life is one year. All

developed for cleaning of polyurethane injection pumps. partly used drums should be covered by nitrogen and resealed to

prevent the ingress of moisture.

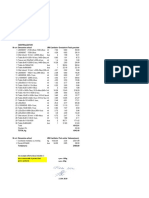

TECHNICAL DATA

SAFETY AND HEALTH PRECAUTIONS

Physical characteristics of the uncured polyurethane prepolymer

Subject Value Norm Do not breathe dust/fume/gas/mist/vapours/spray.

Density 1,158 g/cm³ EN ISO 2811-2:2002 In case of inadequate ventilation wear respiratory protection.

Viscosity 96 mPa.s EN ISO 3219:1994 Wear protective gloves/clothing and eye/face protection.

Isocyanate 18,1 M.-% EN 1242:2006 If in eyes: Rinse cautiously with water for several minutes. Remove

Flash point > 150 °C contact lenses, if present and easy to do. Continue rinsing.

Colour Brown If on skin or hair: Take off immediately all contaminated clothing. Rinse

skin with water/shower.

Physical characteristics of the catalyst For more information, consult the safety data sheet.

Subject Value Norm

Density 0,889 g/cm³ EN ISO 2811-2:2002

Viscosity 21 mPa.s EN ISO 3219:1994

Flash point > 150 °C

Colour Transparent

REACTION TIME

Quantity of catalyst Reaction Polymerisation

6% 15 seconds 70 seconds

8% 12 seconds 55 seconds

10% 9 seconds 45 seconds

Indication at 20 °C. Free expansion: 4000% of starting volume.

All information is given in good faith and without any warranty. The application, use and processing of these products are beyond our control and therefore entirely your responsibility.

Established liability if any, through bad application or any other reason, for any damages, is always limited to the value of the goods supplied by ADCOS nv. The products and systems are

manufactured under total quality management (01/06/2016)

You might also like

- PARATHERM 600 HEAT RESISTING FINISHDocument2 pagesPARATHERM 600 HEAT RESISTING FINISHyarth880% (1)

- Water ProofingDocument30 pagesWater ProofingMuhammad Irfan ButtNo ratings yet

- Unibar Shopprimer LV: BarilDocument2 pagesUnibar Shopprimer LV: BarilFlori SmăduNo ratings yet

- SteelKote EP ZN HS: High-Build Zinc-Rich Epoxy PrimerDocument3 pagesSteelKote EP ZN HS: High-Build Zinc-Rich Epoxy Primerprasanth cp100% (1)

- How Does PURINJECT 1C Multiflex Work?Document3 pagesHow Does PURINJECT 1C Multiflex Work?Abdou BidaouiNo ratings yet

- How Does PURINJECT 1C Multiflex Work?Document3 pagesHow Does PURINJECT 1C Multiflex Work?Abdou BidaouiNo ratings yet

- Injection Systems PURINJECT 1C 55 LV TFE Versie2!17!04 2009Document3 pagesInjection Systems PURINJECT 1C 55 LV TFE Versie2!17!04 2009Abdou BidaouiNo ratings yet

- PURINJECT 1C 55 LV Polyurethane Injection SystemDocument3 pagesPURINJECT 1C 55 LV Polyurethane Injection SystemAbdou BidaouiNo ratings yet

- BETA PTC - 1982 PDF (New)Document2 pagesBETA PTC - 1982 PDF (New)Vaittianathan MahavapillaiNo ratings yet

- Luxaprime1501 Etch PrimerDocument2 pagesLuxaprime1501 Etch PrimerGurdeep Sungh AroraNo ratings yet

- Araldite Kit K134: Araldite Kit K134 Part A 100 PBW Araldite Kit K134 Part B 40 PBWDocument5 pagesAraldite Kit K134: Araldite Kit K134 Part A 100 PBW Araldite Kit K134 Part B 40 PBWVaibhav GuptaNo ratings yet

- Simacover EP Unicoat 2401-00: Product Data SheetDocument3 pagesSimacover EP Unicoat 2401-00: Product Data SheetParan baenNo ratings yet

- Interzone 101Document4 pagesInterzone 101Trịnh Minh KhoaNo ratings yet

- SteelkobeDocument3 pagesSteelkobealexamaigutNo ratings yet

- Protective & Marine Coatings: Magnalux 40VDocument2 pagesProtective & Marine Coatings: Magnalux 40VMd Usama100% (1)

- Dulux Epoxy Holding Primer Two Pack - R580-2058Document3 pagesDulux Epoxy Holding Primer Two Pack - R580-2058Arif RusyanaNo ratings yet

- b1) Zincanode330 6548Document2 pagesb1) Zincanode330 6548Syed FaridNo ratings yet

- LUXAPRIME 1200 Alkyd QD Primer SpecsDocument2 pagesLUXAPRIME 1200 Alkyd QD Primer SpecsGurdeep Sungh AroraNo ratings yet

- DSA 2011 01590 - HEMPADUR ZINC 15343 DatasheetDocument2 pagesDSA 2011 01590 - HEMPADUR ZINC 15343 DatasheetMehedi HasanNo ratings yet

- Sun PU GardDocument2 pagesSun PU GardUmeshchandra PatilNo ratings yet

- 20240116TD AquaRoute HB - TTP1952 - CCode - GMMYDocument2 pages20240116TD AquaRoute HB - TTP1952 - CCode - GMMYJelian Grace Gonti�asNo ratings yet

- 3 Component Epoxy MortarDocument1 page3 Component Epoxy MortarVietpapayaNo ratings yet

- Luxaprime1801 Chromate Free Etch PrimerDocument2 pagesLuxaprime1801 Chromate Free Etch PrimerGurdeep Sungh AroraNo ratings yet

- TDS Tankguard 412 English (Uk) Issued.22.05.2009Document4 pagesTDS Tankguard 412 English (Uk) Issued.22.05.2009Ahmed NabilNo ratings yet

- Epoxy Primer - Epilux610 - 4079Document2 pagesEpoxy Primer - Epilux610 - 4079GautamNo ratings yet

- I1) Luxol 1000Document2 pagesI1) Luxol 1000Chan zxNo ratings yet

- Technical Data SheetDocument2 pagesTechnical Data SheetBenjaminNo ratings yet

- 2024TDS AquaRoute N GMMYDocument2 pages2024TDS AquaRoute N GMMYJelian Grace Gonti�asNo ratings yet

- Material Safety Data Sheet: Section 1. Identification of The Material and SupplierDocument5 pagesMaterial Safety Data Sheet: Section 1. Identification of The Material and SupplierJoel Leon VillaNo ratings yet

- Pds Simathane Gloss 9-1Document2 pagesPds Simathane Gloss 9-1Aulia RahmahNo ratings yet

- enDocument2 pagesenSalih HasNo ratings yet

- PC 1262 - Asian Epoxy HB CoatingDocument3 pagesPC 1262 - Asian Epoxy HB CoatingHithayathulla KhanNo ratings yet

- Luxaprime1300 Alkyd Zinc Chromate PrimerDocument2 pagesLuxaprime1300 Alkyd Zinc Chromate PrimerGurdeep Sungh AroraNo ratings yet

- Enviroline 222LT+ds+eng PDFDocument4 pagesEnviroline 222LT+ds+eng PDFMohamed NouzerNo ratings yet

- aE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1260 - Eng - A4 - 20150205Document4 pagesaE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interchar - 1260 - Eng - A4 - 20150205Annas QahharNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- Cleverproof™ 2Kw Pu: Two Component Polyurethane Based, Solvent-Free, Liquid Waterproofing Membrane For Water TanksDocument2 pagesCleverproof™ 2Kw Pu: Two Component Polyurethane Based, Solvent-Free, Liquid Waterproofing Membrane For Water TanksAarif TanwarNo ratings yet

- PDS - Berger Weathercoat 345 - StdRev 9Document2 pagesPDS - Berger Weathercoat 345 - StdRev 9Aru VijayNo ratings yet

- Hyperdesmo®-Ady 610 - enDocument3 pagesHyperdesmo®-Ady 610 - enMajd M. KhalilNo ratings yet

- KCC DataSheet WH3350 (ENG)Document2 pagesKCC DataSheet WH3350 (ENG)Trịnh Minh KhoaNo ratings yet

- k1) Luxatherm1600 3171Document2 pagesk1) Luxatherm1600 3171Syed FaridNo ratings yet

- Crayglue: Product Data SheetDocument2 pagesCrayglue: Product Data SheetYASHICA VAITTIANATHANNo ratings yet

- R 50 CP TDSDocument2 pagesR 50 CP TDSVenkatesh KumarNo ratings yet

- TDS-PDF-Interchar 1290 Eng A4 20170228Document4 pagesTDS-PDF-Interchar 1290 Eng A4 20170228shameelNo ratings yet

- WeldOn Low 810 PB Sep08Document3 pagesWeldOn Low 810 PB Sep08geverett2765No ratings yet

- Interclene 245: TBT Free AntifoulingDocument4 pagesInterclene 245: TBT Free AntifoulingTrịnh Minh KhoaNo ratings yet

- Solvented Epoxy Primer for ConcreteDocument2 pagesSolvented Epoxy Primer for ConcreteEng-Medrar AlkateryNo ratings yet

- Luxaprime1500 Etching Wash PrimerDocument2 pagesLuxaprime1500 Etching Wash PrimerGurdeep Sungh AroraNo ratings yet

- Cantesco® Eco Antispatter Ready To Use - ConcentrateDocument1 pageCantesco® Eco Antispatter Ready To Use - ConcentrateRys Multiventas SacNo ratings yet

- Medium Clear PVC Solvent CementDocument2 pagesMedium Clear PVC Solvent Cementguevara170188No ratings yet

- 2401-00 Simacover EP UnicoatDocument3 pages2401-00 Simacover EP UnicoatSAEFUDDIN SAEFUDDINNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsMuthuKumarNo ratings yet

- d2) Epilux218 4267Document2 pagesd2) Epilux218 4267Syed FaridNo ratings yet

- Berger: Product SpecificationsDocument2 pagesBerger: Product SpecificationsAabhas UpadhyayaNo ratings yet

- High Solids Coal Tar Epoxy Product SpecificationsDocument2 pagesHigh Solids Coal Tar Epoxy Product SpecificationsAbuhurairah MunshiNo ratings yet

- Tiger Brand Thinner MSDS Provides Safety DetailsDocument5 pagesTiger Brand Thinner MSDS Provides Safety DetailsNur Fatihah Mohd RaffikNo ratings yet

- Enviroline 222+ds+eng PDFDocument4 pagesEnviroline 222+ds+eng PDFMohamed NouzerNo ratings yet

- MSDS Duco Color DC-12211 HV Grey P429C 90ivsmDocument4 pagesMSDS Duco Color DC-12211 HV Grey P429C 90ivsmAjiWidyartaNo ratings yet

- b3) Zincanode685 4586Document2 pagesb3) Zincanode685 4586Syed FaridNo ratings yet

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEFrom EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENo ratings yet

- Oferta Capac Metalic Transformator (003) .PDF - RomtehDocument1 pageOferta Capac Metalic Transformator (003) .PDF - RomtehFlorin RazvanNo ratings yet

- Name S20 Undercounter Washbasin: Product Code: 6039B003-0012Document1 pageName S20 Undercounter Washbasin: Product Code: 6039B003-0012Florin RazvanNo ratings yet

- Assembly Instruction: Schäfer Cubicle Type SVF30/S AltusDocument16 pagesAssembly Instruction: Schäfer Cubicle Type SVF30/S AltusFlorin RazvanNo ratings yet

- FDocument21 pagesFPradeep ReddyNo ratings yet

- Platbanda Alama - Grosime 5mmDocument1 pagePlatbanda Alama - Grosime 5mmFlorin RazvanNo ratings yet

- FDocument1 pageFB.JAYAPRAKASHNo ratings yet

- Fisa Tehnica Manere HEWI-PVCDocument1 pageFisa Tehnica Manere HEWI-PVCFlorin RazvanNo ratings yet

- Ancore I.am - 2Document12 pagesAncore I.am - 2Florin RazvanNo ratings yet

- FDocument3 pagesFAngelito DioquinoNo ratings yet

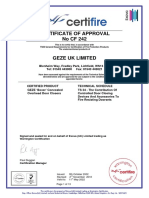

- Certificate of Approval No CF 242Document13 pagesCertificate of Approval No CF 242Florin RazvanNo ratings yet

- Proget Ninz Doors: Fire Rated VersionDocument17 pagesProget Ninz Doors: Fire Rated VersionFlorin RazvanNo ratings yet

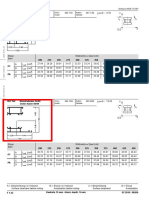

- 2-FT MD.32.3.2 11mch@15mcaDocument7 pages2-FT MD.32.3.2 11mch@15mcaFlorin RazvanNo ratings yet

- Features: The Multipurpose Door in A Class of Its OwnDocument3 pagesFeatures: The Multipurpose Door in A Class of Its OwnFlorin RazvanNo ratings yet

- FDocument3 pagesFFlorin RazvanNo ratings yet

- Instructions For Use and Handling of Stone Wool Products Manufactured by Petralana Scan A058 PDFDocument1 pageInstructions For Use and Handling of Stone Wool Products Manufactured by Petralana Scan A058 PDFFlorin RazvanNo ratings yet

- Instructions For Use and Handling of Stone Wool Products Manufactured by Petralana Scan A058 PDFDocument1 pageInstructions For Use and Handling of Stone Wool Products Manufactured by Petralana Scan A058 PDFFlorin RazvanNo ratings yet

- Fisa Technica Fibran20mmDocument6 pagesFisa Technica Fibran20mmFlorin RazvanNo ratings yet

- 2-FT MD.32.3.2 11mch@15mcaDocument7 pages2-FT MD.32.3.2 11mch@15mcaFlorin RazvanNo ratings yet

- PDFDocument1 pagePDFFlorin RazvanNo ratings yet

- Schüco AutomotiveFinish - Brilliant metallic design for PVC-U windows and doorsDocument4 pagesSchüco AutomotiveFinish - Brilliant metallic design for PVC-U windows and doorsFlorin RazvanNo ratings yet

- 13265FRo Plan CofrajDocument1 page13265FRo Plan CofrajFlorin RazvanNo ratings yet

- 322450Document1 page322450Florin RazvanNo ratings yet

- PDFDocument1 pagePDFFlorin RazvanNo ratings yet

- 01 Catalogue Cable Entries PDFDocument58 pages01 Catalogue Cable Entries PDFFlorin RazvanNo ratings yet

- Memorie AcerDocument1 pageMemorie AcerFlorin RazvanNo ratings yet