Professional Documents

Culture Documents

Sikadur® 732

Uploaded by

Mary Jean P. MedilloCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sikadur® 732

Uploaded by

Mary Jean P. MedilloCopyright:

Available Formats

Product Data Sheet

Edition No. 07/ 2007

Identification No.

02 04 02 06 001 0 000020

Sikadur® 732

Sikadur® 732

Epoxy Resin Bonding Agent, Epoxy Adhesives & Mortars

Construction

Description A solvent-free, thixotropic, 2-component structural epoxy resin adhesives.

Sikadur 732 provides a perfect bond for new concrete surface to old concrete.

Complies with A.S.T.M.

C 881-78 Type II, Grade 2, Class B + C

Uses n Bond fresh plastic concrete to hardened concrete and steel.

n Grout bolts, dowels and pins, etc.

n Structural adhesive for concrete, masonry, metal, wood, etc.

Characteristics / n High strength bonding / adhesive.

Advantages n Excellent adhesion to most structural materials.

n High early and final strength.

n Insensitive to moisture before, during, and after cure.

n Highly effective, even on damp surfaces.

Coverage 0.3 – 0.8 kg/m², depending on substrate condition.

Instruction for Use

Surface Preparation

Surface must be clean and sound. It may be dry or damp, but free of standing

water, remove dust, laitance, grease, curing compounds, impregnation, waxes,

foreign particles, disintegrated materials.

Preparation work

Concrete – sandblast or use other approved mechanical methods.

Steel – sandblast to white metal finish.

Mixing

Pre-mix each component. Proportion 2 part Component A to 1 part Component

B into a clean pail. Mix thoroughly for 3 minutes with a paddle on low- speed

(400-600 rpm) drill until uniform in colour. Mix only that can be used within its pot

life.

Application

To bond fresh concrete to hardened concrete. Apply by brush, roller or broom,

place fresh concrete while Sikadur 732 is still tacky.

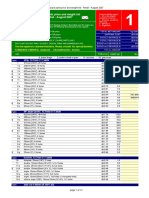

Technical Data

Color Concrete Grey

Mix Ratio Comp A : B = 2 : 1 by weight/ volume

Mix Density 1.45 kg/l

Pot Life 30°C 35 minutes

Tensile Strength 17.65 N/mm²

(ASTM D-638) 28 days

1 Sikadur® 732 1/2

Flexural Strength 38.25 N/mm²

(ASTM D-790) 28 days

Bond Strength

(ASTM C-882)

To concrete, 28 days 3.0 N/mm² (concrete failure)

To Steel, 28 days 11.8 N/mm²

Compressive Strength 62 N/mm² - PSI

(ASTM D-695) 28 days

Coefficient of thermal 50 x 10¯6 per °C

expansion (-20°C to 40°C)

Shelf Life 1 year when unopened

Construction

Packaging 5 kg set

Handling Precautions • Avoid contact with the skin, eyes and avoid breathing itsvapour.

• Wear protective gloves when mixing or using.

• If poisoning occurs, contact a doctor of Poisons Information Centre.

• If swallowed, do NOT induce vomiting. Give a glass of water.

• If skin contact occurs, remove contaminated clothing and wash skin thoroughly.

• If in eyes, hold eyes open, flood with water for at least 15 minutes and see a

doctor.

The information, and, in particular, the recommendations relating to the application and end-use of Sika

Legal Notice products, are given in good faith based on Sika’s current knowledge and experience of the products when

properly stored, handled and applied under normal conditions in accordance with Sika’s recommendations.

In practice, the differences in materials, substrates and actual site conditions are such that no warranty

in respect of merchantability or of fitness for a particular purpose, nor any liability arising out of any legal

relationship whatsoever, can be inferred either from this information, or from any written recommendations,

or from any other advice offered. The user of the product must test the product’s suitability for the intended

application and purpose. Sika reserves the right to change the properties of its products. The proprietary

rights of third parties must be observed. All orders are accepted subject to our current terms of sale and

delivery. Users must always refer to the most recent issue of the local Product Data Sheet for the product

concerned, copies of which will be supplied on request.

Sika Philippines, Inc.

Unit A & B

888 Marcos Alvarez, Ave. Tel.no. : 800 1818

Talon, Las Piñas City 1747 Fax. no : 806 2378

Philippines www.sika.com.ph

2 Sikadur® 732 2/2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Construction Schedule For Transmission LineDocument17 pagesConstruction Schedule For Transmission LinePradeep Jha50% (4)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASHRAE 0-2013 - Guideline The Commissioning ProcessDocument8 pagesASHRAE 0-2013 - Guideline The Commissioning Processhehehe heheheheheheNo ratings yet

- Sequence of Operation for Fire PanelDocument2 pagesSequence of Operation for Fire PanelAhmed Sweet100% (1)

- Structural Design of Staircase According To Eurocode2Document11 pagesStructural Design of Staircase According To Eurocode2prakash100% (1)

- BluCem 511 TDS 2017Document4 pagesBluCem 511 TDS 2017Mary Jean P. MedilloNo ratings yet

- High Dose Vitamin D (Cholecalciferol) Capsules, Consumer Medicines InformationDocument3 pagesHigh Dose Vitamin D (Cholecalciferol) Capsules, Consumer Medicines InformationWaqar GhoryNo ratings yet

- QS607 220310Document3 pagesQS607 220310Jet ToledoNo ratings yet

- QS 504 190516Document2 pagesQS 504 190516Mary Jean P. MedilloNo ratings yet

- Quicseal 106Document2 pagesQuicseal 106Mary Jean P. MedilloNo ratings yet

- Astm C 76-19Document12 pagesAstm C 76-19Carlos Manuel Ampié BerriosNo ratings yet

- Buenos Aires City HallDocument8 pagesBuenos Aires City HallSenouiiNo ratings yet

- Report of Testing: Certificate No. DateDocument2 pagesReport of Testing: Certificate No. DatePhilippe PandyNo ratings yet

- HANGER BAR DESIGN - 3fDocument6 pagesHANGER BAR DESIGN - 3fGanesh Prabu100% (1)

- Spare Parts Price and Weight List Retail - August 2007Document12 pagesSpare Parts Price and Weight List Retail - August 2007komenasaiNo ratings yet

- High Modulus Asphalt (EME2) Pavement Design: Technical Note 142Document12 pagesHigh Modulus Asphalt (EME2) Pavement Design: Technical Note 142Syed MubashirhussainNo ratings yet

- DATA BOOK FOR CONSTRUCTION PROJECTSDocument66 pagesDATA BOOK FOR CONSTRUCTION PROJECTSvishnukesavieam10% (1)

- Copper PRDocument17 pagesCopper PRSaadAminNo ratings yet

- Audit of PPE-2Document2 pagesAudit of PPE-2Josha Mae PerezNo ratings yet

- ANALISA JALAN BETON Fc'30 Mpa TEBAL 20 CMDocument52 pagesANALISA JALAN BETON Fc'30 Mpa TEBAL 20 CMnixonNo ratings yet

- Sor Water 2014Document37 pagesSor Water 2014Aswad TonTongNo ratings yet

- Elevis 4 No. 2 Bed ApartmentDocument90 pagesElevis 4 No. 2 Bed ApartmentNana BarimaNo ratings yet

- Introduction To Chapter 3-Wiring Methods and MaterialsDocument145 pagesIntroduction To Chapter 3-Wiring Methods and MaterialsTerry wei shengNo ratings yet

- RA-RP FG ConveyorsDocument17 pagesRA-RP FG ConveyorsNadeem AhmedNo ratings yet

- (L5 - 025) SOLN-SD-DR-MSI-BB623-L5-00397 - SD-04.1 (HW-4H.1) at LEVEL 5 0 - B APPROVED WC 0Document1 page(L5 - 025) SOLN-SD-DR-MSI-BB623-L5-00397 - SD-04.1 (HW-4H.1) at LEVEL 5 0 - B APPROVED WC 0Michael TugawenNo ratings yet

- Sample DrawingDocument1 pageSample DrawingCassy AbulenciaNo ratings yet

- Metal WorkDocument7 pagesMetal WorkchandankollamNo ratings yet

- Experimental Investigation of Mud Blocks Stabilized With Lime and CementDocument19 pagesExperimental Investigation of Mud Blocks Stabilized With Lime and CementChandrashekhara JainNo ratings yet

- Concrete Specification StandardsDocument1 pageConcrete Specification StandardszeeshanNo ratings yet

- INTEGRAL ROOF BATHROOM WATER TANK EXTERNAL WALLSDocument56 pagesINTEGRAL ROOF BATHROOM WATER TANK EXTERNAL WALLSSenthilkumar Narayanan100% (1)

- Precast Technology With The Case Study of BWSLDocument93 pagesPrecast Technology With The Case Study of BWSLer_hvpatelNo ratings yet

- New EBCS 6 Part 1-2 - SECUREDDocument108 pagesNew EBCS 6 Part 1-2 - SECUREDSitotaw AlemuNo ratings yet

- Underwater Concreting Report 2Document8 pagesUnderwater Concreting Report 2Amey KadulkarNo ratings yet

- National Building Code AdoptedDocument10 pagesNational Building Code AdoptedPISALBO, JEXTER P.No ratings yet

- Tpbo Paper-2Document32 pagesTpbo Paper-2RaghuNo ratings yet

- Stability CertificateDocument1 pageStability CertificateUmesh ChikhlikarNo ratings yet