Professional Documents

Culture Documents

Kawasaki ZX11

Kawasaki ZX11

Uploaded by

CA GD100%(1)100% found this document useful (1 vote)

112 views281 pagesmanual kawasaki

Original Title

kawasaki ZX11

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmanual kawasaki

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

112 views281 pagesKawasaki ZX11

Kawasaki ZX11

Uploaded by

CA GDmanual kawasaki

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 281

Kawasaki ZZ-R1100

Motorcycle

Service Manual

Quick Reference Guide

General Information 1

Fuel System 2

Cooling System 3

Engine Top End [4

Clutch 5

Engine Lubrication System 6

Engine Removal/installation 7

Crankshaft/Transmission 8

Wheels/Tires 9

Final Drive 10

Brakes 11

Suspension 12

Steering 13

Frame [14

Electrical System 15

Thia quick reference guido wil ssiet you in Appendix 16

tere he pages back oath he Back tab Supplement — 1999 - 2001 Models | 17

of the desired chapter number with the

black tab on the edge at each table of

contents page.

‘eRefer to the sectional table of contents for

Ine exact pages to locate the specific topic.

required.

LIST OF ABBREVIATIONS.

A ‘ampere(s) Ib pound(s)

ABDC _ | after bottom dead center m meter(s)

AC alternating current min minute(s)

ATDC | after top dead center N newton(s)

BBDC — | bofore bottom dead center Pa pascal(s)

BDC bottom dead cenier PS. horsepower

BTDC | before top dead center psi pound(s) per square inch

6. degroo(s) Colsius ' revolution

pc direct current rpm revolution(s) por minute

F farad(s) TDC top dead center

Fs degree(a) Fahrenheit TR total indicator reading

ft oot, feet v volt(s)

‘orar(s) w watt(s)

h hour(s) o ohms)

liter(s)

This warning may apply to any of the following

components or any aseombly containing one oF

more of these components:

Brake Shoes or Pads

CCluten Friction Material

Gaskets

Insulators

WARNING.

‘CONTAINS SAFETY INSTRUCTIONS

ASBESTOS

ecg Raa eOperate if possible out of doors or in a well

‘Sensor ventilated place

ve heath ePreferably use hand tools or low speed tools

‘equipped, if necessary. with an appropriate dust

extraction facility. If high speed tools are used,

they should slays be so equipped

if possible, dampen before cutting or driling.

@Dampen dust and place it in properly closed

receptacte and dispose of it sately.

Fotow stew

Read OWNER’S MANUAL before operating.

EMISSION CONTROL INFORMATION

To protect the environment in which we all live, Kawasaki has incorporated crankcase emission

(1) and exhaust emission (2) control systems in compliance with applicable reaulations of the

United Statos Environmental Protection Agency and California Air Rosourcos Board. Additionally,

Kawasaki has incorporated an evaporative emission control system (3) in compliance with

applicable regulations of the California Air Resources Board on vehicles sold in California only.

1. Crankcase Emission Control System

This system eliminates the release of crankcase vapors into the atmosphere. Instead, the

vopors are routed through an oil separator to the intake side of the engine. While the engine

Js operating, the vapors are drawn into combustion chamber, where they are burned along

with the fuel and air supplied by the carburetion system.

2. Exhaust Emission Control System

This system reduces the amount of pollutants discharaed into the atmosphere by the exhaust

of this motorcycle, The fual and ignition systems of this motorcycle have beon carsfully

designed and constructed to ensure an efficient engine with low exhaust pollutant levels.

3. Evaporative Emission Control System

Vapors caused by fuel evaporation in the fuel system are not vented into the atmosphere

Instead, fuel vapors ate routed into the running engine to be burned, or stored in a canister

when the engine is stopped. Liquid fuel is cought by a vapor separator and returned to tho

fuel tank.

The Clean Air Act, which is the Federal law covering motor vehicle pollution, contains what is,

commonly referred to as the Act's "tampering provisions.”

"Sec. 203(a) The following acts and the causing thereof are prohibited...

(3)(A)_ for any person to remove or render inoperative any device or element of design installed

on or in a motor vehicle or motor vehicle engine in compliance with regulations under

this tile prior to its sale and delivery to the ultimate purchaser, or for any manufacturer

or dealer knowingly to remove or render inoperative any such device or element of

design after such sale and delivery to the ultimate purchasor.

(3)(B) for any person engaged in the business of repairing, servicing, selling, leasing, or trading

motor vehicles or motor vehicle engines, or who operates a fleet of motor vehicles

knowingly to remove or render inoperative any device or element of design installed on

or in a motor vehicle or motor vehicle engine in compliance with reulations under this,

title following its sale and delivery to the ultimate purchaser..."

(Continued on next page.)

NOTE

© The phrase "remove or render inoperative any device or element of design” has been

generally interpreted as follows:

7. Tampering does net inclide the temporary removal or rendering inoperative of

devices or elements of design in order to perform maintenance.

2. Tampering could include:

a. Meladjustment of vehicle components such that the emission standards are

exceeded

b. Use of replacement parts or accessories which adversely affect the performance

: or durability of the motorcycle.

c. Addition of components or accessories that result in the vehicle exceeding the

standards.

d Permanently removing, disconnecting, or rendering inoperative any component

5 or element of design of the emission control systems.

== WE RECOMMEND THAT ALL DEALERS OBSERVE THESE PROVISIONS OF FEDERAL

LAW, THE VIOLATION OF WHICH IS PUNISHABLE 8Y CIVIL PENALTIES NOT

EXCEEDING $10,000 PER VIOLATION.

TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law probibits the following acts or tho causing thereof; (1) The removal or rendering

inoperative by any person other than for purposes of maintenance, repeit, or replacement, of any

device or oloment of design incorporated into any new vehicle for the purpose of noise control prior

{0 its sale or delivery to the ultimate purchaser of whila itis in use, or (2) the use of the vehicle after

such device or element of design hes been removed or rendered inoperative by any person.

Among those acts presumed to constitute tampering are the acts listed below:

‘e Replacement of the original exhaust system of muffler with a component not in compliance with

Federal regulations.

‘Removal of the muffler(s) or any internal portion of the mufiler(s).

‘@ Removal of the air Dox or air box cover.

@ Modifications to the muffler(s) or air intake system by cutting, drilling, or other means if such

‘modifications result in increased noise levels,

Foreword

This manual is designed primarily for use by

trained mechanics in 8 properly equipped shop.

However, it contains enough detail and basic

information to make it useful to the owner who

desires 10 perform his own basic maintenance and

repair work. A basic knowledge of mechanics, the

proper use of tools, and workshop procedures must

bbe understood in order to cary out maintenance and

repair satisfactorily. Whenever the owner has

insufficient experience or doubts his ability to do the

work, ell adjustments, maintenence, and repair

should be carried out only by qualified mechanics.

In order to perform the work efficiently and to

avoid costly mistakes, read the text, thoroughly

familiarize yourself with the procedures before

starting work, and then do tho work carefully in a

clean area. Whenever special tools or equipment are

specified, do not use makeshift tools or equipment.

Precision measurements can only be made if the

proper instruments are used, and the use of substi-

tute tools may adversely afiect safe operation,

For the duration of the warranty period,

we recommend that all repaits and scheduled

maintenance be performed in accordance with this

service manual. Any owner maintenance or repait

Procedure not performed in accordance with this

manual may void the warranty.

To get the longest lite out of your motorcycle.

Follow the Periodic Maintenance Chart in the

Service Manual

‘@8e alert for problems and non-scheduled mainte-

nance.

@Uso propor tools and genuine Kawasaki Motorcy:

cle parts, Special too’s, gauges, and testers that

‘are necessary when servicing Kawasaki motorcy-

cles are introduced by the Special Too! Manual,

Genuine parts provided as spare parts are listed in

the Parts Catalog.

@Follow the procedures in this manual carefully.

Don't take shortcuts.

@Remember to keop complete records of mainte

ance and repair with dates and any new pars

installed.

How to Use This Manual

In prepering this manual, we divided the product

imto its major systems. These systems became the

manual's chapters. All information for a particular

system from edjustment through disassembly and

inspection is located in a single chapter.

The Quick Reference Guide shows you all of the

product’s system and assists in locating their

chapters. Each chapter in turn has its own compre-

hensive Table of Contents.

The Periodic Maintenance Chart is located in the

General Information chapter. The chart gives a time

schedule for roquired maintonance operations.

If you want spark plug information, for example,

90 to the Periodic Maintenance Chart first. The chart

tolls you how frequently to cloan and gap the plug.

Next, use the Quick Reference Guide to locate the

Electrical System chapter. Then. use the Table of

Contents on the first page of the chapter to find the

‘Spark Plug section,

Whenever you seo these WARNING and

CAUTION symbols, heed their instructions! Always

follow safe operating and maintenance practices.

AAWARNING

This warning symbol identifies special

instructions or procedures which. if not

correctly followed, could result in personal

injury, or loss of life.

‘CAUTION

This caution symbol identifies special

instructions or procedures which, if not

strictly observed, could result in damage to

or destruction of equipment.

This manual contains four more symbols (in

addition to WARNING and CAUTION) which will

help you distinguish different types of information.

NOTE

© This note symbol indicates points of partic

ular interest for more efficient and convenient

operation.

‘@lndicates a procacural step or work to be cone.

COlndicates a procedural sub-step or how ta do the

work of the procedural step it follows. It also

precedes the text of a NOTE.

4tIndicates a conditional step or what action to take

based on the results of the test or inspection in the

procedural step or sub-step it follows.

In most chapters an exploded view illustration of,

the system components follows the Table of

Contents. In these illustrations you will find the

instructions indicating which parts require specified

tightening torque, oil, grease or a locking agent

uring assembly.

GENERAL INFORMATION 1-1

General Information

Table of Contents

Before Servicing.

Modol Identification

General Specifications

Periodic Maintenance Chart

Torque and Locking Agent

Special Tools and Sealart ....

Cable, Wire, and Hose Routing

1-2_GENERAL INFORMATION

Before Servicing

Before starting to service a motorcycle, careful reading of the applicable section is recommended to eliminate

unnecessary work, Photographs, diagrams, notes, cautions. warnings. and detailed descriotions have been

included wherever necessary. Nevertheless, even a detailed account has limitations, a certain amount of basic

knowledge is also required for successful work.

Especially note the following:

(1) Din

Bofore removal and disassembly, clean the motorcycle. Any dirt entering the engine or other parts will

work 25 an abrasive and shorten the life of the motorcycle. For the same reason, before installing a new

part, ciean off any dust or metal flings.

(2) Battory Ground

Remove the ground (-) lead from the bettery before performing any disassembly operations on the

motorcycle. This prevents:

(a) the possibilty of accidentally turning the engine aver while partially disassembled.

(b) sparks at electrical connections which will occur when they are disconnected.

(c) damage to electrical parts.

(3) Tightening Sequence

Generally, when installing @ part with several bolts, nuts, or screws, start thom all in their holes and

tighten them to a snug fit. Then tighten them evenly in a cross pattern. This is to avold distortion of the

pert and/or causing gas or oil leakage. Conversely when loosening the bolts. nuts, or sorews, fist loosen

all of them by about a quarter turn and then remove them. Where there is a tightening sequence indication

in this Service Manual, the bolts, nuts, or screws must be tightened in the order and methad indicated.

(4) Torque

‘When torque values are given in this Service Manual, use them. Either ta0 litle or too much torque may

lead to serious damage. Use a good quailty, reliable torque wrench,

(5) Force

Common sense should dictate how much force is necessary in assembly and disessembly. If « part seems

especially difficult to remove or install, siop and examine what may be causing the probiem. Whenever

topping is necessary, tap lightly using a woaden or plestic-faced mallet. Use an impact driver for screws

(particularly for the removal of screws held by a locking agent) in order to avoid damaging the screw heads.

(6) Edges

Wotch for sharp edges, especially during major engine disassembly and assembly. Protect your hands

with gloves or a piece of thick cloth when lifting the engine or turning it over.

(7) High-Flash Point Solvent

'A hiigh-flash point solvent ie recommended to reduce fire danger. A commercial solvent commonly

available in North America is Stoddard solvent (generic name). Always follow manufscturer and container

directions regarding the use of any solvent.

(8) Gasket, O-Ring

‘Do not reuse a gasket or O-ring once it has been in service. The mating surfaces around the gasket

should be free of foreign matter and perfectly smocth to avoid oil or compression leaks.

(8) Liquid Gasket, Non-Permanent Locking Agent

Follow manufacturer's directions for cleaning and preparing surfaces where these compounds will be

used. Apply sparingly. Excessive amounts may block engine oil pessages and cause serious damage. An

example of a non-permanent locking agont commonly available in North America is Loctite Lock'n Seal

(Blue)

(10) Press:

‘A patt installed using @ press or driver, such as a wheel bearing, should first be coated with oil on its outer

‘inner circumference so that it will go into place smoothly.

(11) Ball Bearing and Neadle Beating

Do not remove any ball ot needle bearings that ore pressed in unless it is necessary. Ifthey are removed.

replace them with new ones.

‘When installing a bearing. press it in with the marked side facing out using a suitable driver until it is

botiomed. Bearings should be pressed into place by pushing evenly the bearing race which is affected by

friction.

GENERAL INFORMATION 1-3

(12) Oil Seal and Grease Seal

Replace any oil or grease seals that were removed with new ones, as removal generally damages seals.

When pressing in a seal which has manufacturer's marks, press it in with the marks facing out. Seals

should be pressed into place using a suitable driver, which contacts evenly with the side of seal, until the

face of the seal is even with the end of the hole

(13) Seal Guide

A seal guide is required for certain oll or grease seals during installation to evoid damage to the see! lips.

Before a shaft passes through @ seal, apply a litte high temperature grease on the lips to reduce rubber 10

metal friction.

(14) Circlip, Retaining Ring

Replace any circlips and retaining rings that were removed with new ones, es removal weakens and

deforms them. When installing circlips and retaining rings, take care to compress or expand them only

enough to install them and no more.

(18) Cotter Pin

Roplace any cotter pins that were removed with new ones, as removal deforms and breaks them.

(10) Lubrication

Engine wear is generally at its maximum while the engine is warming up and before all the rubbing

surfaces have an adequate lubricate film. During assembly, oil or grease (whichever is more suitable)

should be applied to any rubbing surface which has lost its ubricatve fim. Old grease and dicy oii should

be cleaned off. Deteriorated grease has lost its lubricative quality and may contain abrasive foreign particles.

Don't use just any oil or grease. Some oils and greases in particular should be used only in carain

applications and may be harmful if used in an epplication for which they are not intended. This manual

makes reference to molybdenum disulfide grease (MoS: ) in the assembly of certain engine and chassis

parts, Always check manufacturer recommendations before using such special lubricants

(17) Electrical Wires

Al the elecvical wires are either single-color or two-color and, with only 2 few exceptions, must be

connected to wires of the samo color. On any of the two-color wires thare is a greator amount of one color

and a lesser amount of a second color, so a two-color wire is identified by first the primary color an then

the secondary color. For example, a yellow wire with thin red stripes is referred to as.a "yellow/red” wit

it would be a “red/yellow" wiea if the colors wore reversed to make red the main color.

‘Wire (cross-section) Name of Wire Color

Red

Wire Strands

Yellow/ Red

Yellow

Red

(18) Replacement Fans

When there is a replacement instruction, replace these parts with new ones every time they are removed,

These replacement parts will be damaged or lose thoir original function once removed.

(18) Inspection

When paris have been disassembled, visually inspect these parts for the following conditions or other

damage. If there is any doubt es to the condition of thom, replace them with new ones.

Abrasion rack Hardening Warp

Bent Dent Scratch Wear

Color change Deterioration Seizuro

(20) Specifications

Specification terms are defined as follows:

"Standards": Show dimensions or porformancos which brand-naw parts or systems have.

“Service Limits”: Indicate the usable limits. If the measurement shows excessive wear or deteriorated

performance, repiace the damaged parts

1-4 GENERAL INFORMATION

Model Identification

2X1100-D1 (US and Canadian Models) Left Side View:

2X1100-D1 (US and Canadian Models) Riaht Side View:

GENERAL INFORMATION 1-5

2X1100-D1 (European Model) Right Side View:

2X1100-D1 (European Model) Right Side View:

1-6 GENERAL INFORMATION

Item 2x1100-D1-

Dimensions:

Overall length 2165 mm, (Gi (N) (S) (SW) (GR) 2180 mm

Overall wth 730 mm

Overallheignt 4205 mm

Wheelbase 1495 mm, D3 ~: (G)[EU)'SP)INLY 1 )(FUK)IN)(GR) 1500 mm

Road elearance 110mm

‘Seat heignt 780 mm

Dry mass: 233 kg. (Cal) 233.5 ko

Curbmass: Front 190 kg

Rear 139 kg, (Cal) 139.5ko

Fuol tank capacity 240

Performance:

Minimurn turning radius 20m

Engine:

Type

‘Coating system

Bore and stioke

Displacoment

‘Compression ratio

‘Maximum horsepower

Maximum torque

Carburetion system

Starting sysiom

Ignition system

Timing advance

Ignition timing

4-stroke, DOHC, +-cylinger

Liquid-cooled

76.0 x58.0 mm

4052 mL.

VOE1 (F)IO.N

4108 kW (147 PS) @ 10500 ¢/min (rpm),

JAR) (K) 74 KW (190 PS) @9000 ¢/min (1pm),

(F) 75.1 kW (-) @8509 din (rom) (UTAC'S norm),

03~:75.1 KW (-) @8400 rimin (rpm) {UTAGS norm),

(S) $5 kW (75 PS) @6000 r/min (rom),

(SW) 68 KW (@2 PS) @8500 r/min (rpm),

(u)-.

(UK) 92 KW (-~) @9500 r/min (rom) (ISO4106),

DB: 108 KW (147 PS) @ 10500 renin (rpm)

(G) 74 KW (100 PS) @9000 rmin (rpm) (DIN)

Ds: (G) 74 kW (100 PS) @9500 rimin (rpm) (DIN)

Dé ~: (G) 72 kW (98 PS) @9300 r/min (1pm) (DIN)

440. Nem (11.2 kgm, 81 ft1B) @ 8500 e/min (pm).

(AR) (&) 90 Nem (9.2 kgm, 67 feb) @ 7000 rimin (Pm),

(FU) (UK) ~,

(5) 90 Nem (9.2 kg-m, 67 fulb) @5500 rimin (rpm),

(SW) 86 Nom (8.8 kgm, 64 f-lb) @4500 rimin (rpm),

(G) 30NN-m (9.2 kgm, 67 t-bo)

©7000 s/min (pr) (DIN)

Ds ~: (G) 93 N-m (9.5 ko-m, 69 ft-lb)

{©5000 r/min (pm) (DIN)

Carburetors, Keihin CVK:D 40 x 4

Electric starter

Battery and coll (vansistorized)

Electronically advanced

From 10° BTDC @1000 r/min (rpm) to

40” BTDC @6000 r/min (rpm)

(Cal) From 75° BTDG @ 1200 rimin (rpm) to

40° BTDC @6000 vin (rom)

(S),D8 ~ () From 7.5" BTOC 6 1300 ¢/min (1pm) to

40° BTDC @6000 ymin (rpm)

(U) (C) From 75" BTDG @ 1000 r/min (rpm) to

40" BTDC 6900 r/min (rpm)

GENERAL INFORMATION 1-7

tem zx1100-01 ~

‘Spark plug NGK CAGE 07 ND U27ESR-N

Cylinder numbering method Lett to right, 1-2-3-4

Firing ordor 1.243

Vaive timing:

Inlet Open 40° BTDC. (F) 20°

Close 70) ABDG, (F) 50°

Duration 290" (F) 260"

Exhaust Open 63° BBDC. (F) 45°

Close 43° ATDC, (F) 25°

Duration 286° (F) 250°

Lubrication system

Forced lubrication (wet sump with elor)

Engine

Grade SE,SF, oF SG class

Viscosity SAE1OW.40, 10W-50, 20W.-£0, or 20W-50

Capacity 35L

Drive Train:

Primary reduction system

Type Gear

Reduction ratio 1.637 (98/58)

Clutch type Wet muti disc

Transmission:

Type 6-speed, constant mesh, retum shit

Geerratos: 1st 2,800 (42/15)

2nd 2.055 (37/10)

ard 1.890 (35/22)

ath 1.238 (32/24)

‘th 1.183 (8028)

ath 1.035 (29/28)

Final drive system:

Type Chain drive

Reduction ratio 2.647 (45/17), DS ~: (GFUK)(GF)(N\EU)SPHINL) 1) 2588 (44/17)

Qveral crive ratio

Frame:

Type

Caster (rake angie)

Trail

Fronttire: Type

Size

Rear tio: Type

size

Front suspension: Type

Wheel travel

ear suspension: Type

Wheel travel

Brake type Front

Fear

4.490 @ Top gear D3~: ()(FYUK)(GA)N)IEUYEPHNLY |) 4.990

@Top gear

Tupuiar, double cradle

255°

107 mm

Tupeiess

320/70 ZR17

Tuboless

180155 ZR17

‘Telesconic fork

420 mm

‘Swing arm (uni-trak)

112mm

Dual dice

Single disc

1-8 GENERAL INFORMATION

tem 2x4100-01 -

Electrical Equipme

Battery r2V12 An

Headlight: Type ‘Semisealed beam

Bulb 2V60/55W (quartz-halogen)

Tailorake light 42.V/5/21 W x2 (C) (Cal) (U) 12V8/27W x2

Aternator: Type Three-phase AC

Rated output 28.6 A 6000 r/min (rem), 14

Spectications subiect to change without notics, and may not apply to every country.

(AS) + Australia Modal (8) = Switzerlana

(AR) = Austria Mode! (GA): South Africa Modo!

(©) = Canada Model (SW): Sweden Model

(Cal) + California Model (WU) » USA. Modo!

©): France Model (UK): UK Mode!

(@) + Germany Model (EU): Europe Model

(GR) : Greece Mode! (SP): Span Model

(1) = Maly Model (NL): Netherlands Model

(N)_ = Norway Model (6): Korea Mode!

Periodic Maintenance Chart

GENERAL INFORMATION 1-9

Tho scheduled maintenance must be done in accordance with this chart to keep the motorcycle in good running

condition. The initial maintenanes is vitally important and must not be neglected.

iahever IN

PELUEY wri ay TODOMETER READING

Efs [s/s /§

4 Ss [S/S] 8 (S/S) 5

OPERATION S /E/E/S /E/E/S

trey [/s /e/e/e (efe/e

Spark plug -clean and gap" elelefelele

Valve cloaranes - check” e e ° e

‘Ar suction valve - check" elelelelele

Ar leaney element and air vent filer- clear ° ° °

Air cleaner element and air vent fiter- replace |S cleaning °

Throtle op play - check * . e . .

Tele spoad- chock * elelelelelele

Engine vacuum Synchronization - check e@lelejelelele

Fuel system - check * e . °

Fuel hoses, connections ~ check = elelelelele

Coolant change 2years °

Evaporative omiasion contol syaien

(Cal) -check” SASS ETS sR.

Engine ol change years | © ° . =

‘Oi tier = repiace [le ° e °

Radiator hoses. connections - chack * _years | © e e °

Fuel fiter-replace . . .

Fuel hose replace ayears

‘Clutch fuid level - check ™ month |e [elelelelel|e

‘Guutch tid charge 2years °

(Cluteh hose and pipe - replace a years

‘Clutch master cylinder cup and dust seal replace | 2 years

‘Ciutch slave cylinder piston seal - replace. 2years

Dive chain woar -cheok ™ elelelelele

Dive chain ~ lubricate OOK

| Drive chain slack - check * 800 km

Brake ped wear - check = elelelelele

Brake fuidlevel- check” month |e [ele|elelele

Brake fuid- change: years ° |

Brake nose - replace years

Brake hoses, connections ~ check" elelelelele

Brake master cylinder cup and dust seal replace | 2 years

Caliper piston seal and dust seal - replace 2 years

Brake light awitch - check * Lelelelelelele

Steering check * elelelelelele

Steering stem bearing - lubricate 2years °

Front fork cil~ change . :

Tite wear - check" —— =| elelelelele

‘Swing arm pivot, unitrak inkage lubricate ° ° °

Battery electrolyte level - check ™ month | @ [elelelelele

General lubrication - perform T elelelelele

Nuts, boli, and fasteners tighin@ss Gheok = ° ° ° e

Coolant fiter- clean “Tyee |

F: For higher odometer readings, repeat at the frequency interval established here.

(Cal) : California Mode! only

Replace, add, adjust, clean, or torque i necessary.

1-40 GENERAL INFORMATION

(Other than U.S.A. and Canada Models)

Whichever ODOMETER READING

FREQUENCY ey a

<

ever Lf is

Brey > Ag

‘Spark plug -clean and G20" e

Vawe learance check” ° e

“Airsucton valve = check = °

‘cleaner element and ai vent fitar clean

Throtle gp play - check * ° °

ide speed - check * e e

‘Carburetor synonronization - check °

Fual hoses. connections - chek” °

Coolant = change 2yeare e

Engine oll- change Sronhs| © felelelelele

Oilfiter -replace ° e e e

adhator hoses, connections - check °

Cich fu evel - check * Tom |e [elelelelele

‘Giuteh uid chenge Byears e

Cluich hose and pipe - replace a years

‘utch mastor cylinder cup and dust seal

years

= replace

Glutch stave cylinder piston seal- replace ‘Tyears

Drve chan wear = check elelelelele

Drive chan -lubicate BOOK

Drive chain slack - chook = 7000 «re

Brake pad wear check." e[elelelele

Brake fluid level - check * month | @ |e@|e|el/elele

Brake uid - change 2 years °

‘Brake hoses, connections - check elelelelele

[aia otro eed seat a

Caliper pston seal and dust seal replace a years

Brake fight switch - check” @l[el[elelelele

Steering - check” elfelelelelele

‘Soaring stem baaving -Wbicate 2 years e

Front fork ol - change 2 years Oo

Front fork oll leak Check” ° ° °

ear shock absorber oll eak check ° e °

Tire wear - check" elelelelele

Swing arm pivot, uni tak kage — lubricate ° ° °

Battery electroyte level -check™ Srontns elelelelele

‘General lubrication - perform e| Te °

Nuts, Gots, and fasteners ighinass - cveck™ ° ° ° °

Coolant fiter= clean year

T : For higher odometer readings, repeat at the frequency interval established here.

* + Replace, add, adjust. clean, or torque if necessary.

GENERAL INFORMATION 1-17

Torque and Locking Agent

The following table list the tightening torque for the msjar fasteners, and the pats requiring use of @ non-permanent

focking agent or liquid gasket

Letters used in the “Remarks” column mean:

L: Apply a non-permanent locking agent to the threads,

0: Appian cil to the threads, seated surface, or washer

'S = Tighten tho fasteners following the specified sequence.

SS: Apply sifcone sealant to the threads.

Fastener Torque Remarks

Nm kgm ft-lb

Cooling System:

Fen switch 18 18 139

Water temperature sensor 15 15 110 ss

Bleed valve 78 | 080 69 in-tb

Water pump cover bolts 98 10

Water pump drain plug 98 10

Engine Top End:

Camshaft cap bolts 12 12 s

Rocker shaft end bolts 5 25

Oil hose fitting 22 2.2

Oil hose banjo bolt 25 25

Carburetor holder bolts qua! =A L

Cylinder head bolts: 11 mm dia. 51 52 os

10 mm dia. 38 40 | as

6mmdia 98 10 87 in-tb

Cylinder bolts 15 4B Sao

Upper chain guide mounting bolt - - =< il) oa

Rear chain guide mounting bolts 0 20 145 L

Chain tensioner mounting bolts 98 10 87 in-lb

Camshaft sprocket bolts 15 15 110 L

Clutet

Clutch hose banjo bolts 26 25 18.0

Clutch pipe nipple 18 18 130

Clutch lever pivot nut 59 0.60 52 in-lb

Clutch master cylinder clamp bolts 4 14 95 in-b 8

Clutch slave cylinder bolts - - - LQ)

Bleed valve 78 080 89 inl

Right cover bolts = - La)

Right cover damper boks - - - L

Clutch spring bolts " 14 95 in-ib

Clutch hub nut 130 135 98

Engine Lubrication Syster

Oil hose banjo bolts (14 mm dia.):

Coolor side 26 26 180

Oil pan side 34 35 25

Gil hose banjo bolti& mm ia.) 15 15 110

Gil pan bolts = - 2 Lay

Drain plugs 29 30 22

il pressure switch 6 15 11.0 ss

Gil pen plug 20 20 145 L

Crankcase mein oil pessage plug 18 18 130

Crankcase plug 18 18 130

1-12 GENERAL INFORMATION

Fastener Torque Remarks

Nem ko-m ft-lb

Oil pipe banjo bolts(12 mm cia.) B 25 180

Oil pimp gear holder screws - - - L

Oil pump mounting boks 12 12 108 in-Ib ig

Oil fiter bolt 20 20 145

Engine Removal/Installati

Engine mounting nuts. = 8mm 20 20 148

10mm 44 45 33

Down tube mounting bolts 4a 45 33

Crankshaft/Transmission:

Crankshaft cap bolts 2 33 24

Balancer shaft guide pin plate bolt - - - L

Balancer shaft clamp lever mounting bolt - - - L

Alternator shaft chain tensioner bolts - - = L

Crankcase botts: 9mm dia 2 33 24 s

3 mm dia ) Sey 28 20

Timea, ||| 9B 48 130

6 mm dia. 18 18 11.0

Connecting 1od big end cap nuts See p8-11

‘Altemator shaft chain sprocket bolt 25 26 180

Altenator shaft nut 89 60 43

Alternator shaft boit 2 25 180

One-way clutch bolts 12 12 104 in-Ib L

Shift drum bearing holder bolts - = - L

External shift mechanism return spring pin 23 30 22 L

External shift mechanism cover bolts 98 10 87 in-lb Lay

Neutral switch 15 15 11.0

Wheels/Tires:

Front axle nut 145; 150 110

Front axle clamp bolts 20 2.0 145

Rear axle nut 110 10 80

Final Drive:

Engine sprocket nut 125 130 94

Engine sprocket cover damper bolts - - - L

Rear sprocket nuts 74 78 54

Rear sprocket studs - - = L

Chain adjuster clamp boks 39 40 29

Brakes:

Brake lever pivot nut 88 0.90 78 in-Ib

Front moster cylinder clamp boits " 1. 95 in-tb s

Brake hose banjo bolts 25 25 180

Bleed valves 78 0.80 69 in-Ib

Caliper mounting bolts: Front 34 35 25

Rear 25 25 18

Front caliper assembly bolts a 24 150

Brake disc mounting bolts 23 23 165

Brake pedal pivot bolt 88 0.90 78 in-ib

Rear master cylinder mounting bolts 23 23 165

Push rod nut 18 18 130

Torque link bolts/nut 25 25 18.0

GENERAL INFORMATION 1-13

Fastonor Torque Remarks

Nm kgm ftlb

‘Suspension:

Front fork top plugs 23 23 165

Front fork clamp bolts(Upper) 2B 29 2

Front fork clamp nuts(Lower) a 24 150

Front fork bottom Allen bolts a 62 45 L

Front axle clamp bolts 20 20 145

Rear shock absorber mounting nuts 59 60 43

‘Swing arm pwvot nut 8 9.0 65

Rocker arm pivot nut 59 60 43

Tie-rod bolts 59 60 43

Steering:

Handlebar weight bolts - - - i

Handlebar holder bolts 20 20 145

Steering stem head nut 39 40 29

Stooring stom nut 49 050 43 in-tb

Frame:

Downtube bolts a4 45 33

Side stand switch sorews - - - L

Center stand spring hook bolts - = - L

Side stand bracket mounting bolts 49 50 26 L

Side Stand Bolt a“ 35 25

Electrical System:

Spark plugs 14 14 400

up coil cover bolts, - - - L2)

iming rotor bolt 6 25 180

Pickup coil holder bolts L

Alternator mounting bolts 25 25 180

Alternator coupling bolts 98 10 87 in-lo

Alternator cover nuts, 44 0.45 39 in-to

Aterator cover studs 8g 090 18 in-Io

The table below, relating tightening torque to Basic Torque for General Fasteners

thread diameter, lists the basic torque for the bolts Frege dia, To

and nuts, Use this table for only the bolts and nuts pa

which do not require a specific torque value. All of fore Naw fem Fe

the values are for use with dry solvent-cleaned 6 | 94-49 [035~050 | 30~ 43 in-tb

threads. 6 | &9~78 |0.80 ~ 0.80) 62 ~ 69 in-ib

8 ta~19 | 14-19 | 100~135

10 | 25~34 | 26~35 | 190~250

12 «| 44-61 | 45~62 | 33 ~45

14 | 73~98 | 74~100| 54 ~72

16 [115 ~155/11.5~160| 63~115

1g |165~ 225] 17.0~ 230) 125 ~ 165

20__|225~325| 23~33 | 165 ~240

4-14 GENERAL INFORMATION

Special Tools and Sealant

Bearing Puller Adapter: 5701-138

@

‘Compression Gauge: §7001-221

@

‘Steering Stem Bearing Driver. §7001-137

Valve Spring Compressor Assembly: 5701-241

=.

NO

Inside Circlip Pliers: §7001-143

Bearing Puller Adapter: 57001-317

Bozring Puller: 57001-1658

Piston Pin Puller Assembly: 7001-910

Hand Tester: 87001-1394

GENERAL INFORMATION 1-15

il Seal & Bearing Remover: 67001-1058

Piston Ring Compressor Grip: 67001-1095,

oS

TS

Le

Steering Stem Bearing Driver Adapter: 57001-1074

Piston Ring Compressor Belt, 067 ~ 979: 57001-1097

hoa

Head Pipe Outer Race Press Shatt: 57001-1075

‘Steering Stem Nut Wrench: 57001-1100

Head Pipe Outer Race Driver. 57001-1076

Head Pipe Outer Race Remover, 57001-1107

|

les

Head Pipe Outer Race Driver 57001-1077

Valve Seat Cutter. 45" ~ 0275: 57001-1114

©

1-16 GENERAL INFORMATION

Valve Seat Cutter, 45° ~ 082; 67001-1116

Valve Seat Cutter, 32° - 933: 57001-1199

2

©

Valve Seat Cutter, 32° - 30: 57001-1120

Valve Spring Compressor Adapter, 22: 57001-1202

2

&

Valve Seat Cutter, 60° - 30: 57001-1123

Valve Guide Arbor, @5: 57001-1203

©

a

Valve Seat Cutter Holder Bar. 87001-1128

Valve Guide Reamer, 05: 57001-1204

a

oe

Bearing river Set §7001-1129

Valve Seat Cutter Holder, @5: 67001-1208

se

GENERAL INFORMATION 1-17

Fork Outer Tube Weight: 57001-1218

Piston Base, 96: 57001-1263

Front Fork Oil Seal Driver: 67001-1219

Bearing Removor Shatt: 57001-1285

Coil Tester: 57001-1242

Bearing Remover Head, 15x O17: 57001-1267

&

‘Spark Plug Wrench, Hex 16: 57001-1262

Fork Oil Level Gauge: 97001-1290

s-

Jack: 57001-1238

Bearing Remover Head, ©20 x ©22: 57001-1293

&

1-18 GENERAL INFORMATION

‘Compression Gauge Adapter, M10 X 1.0: 57001-1317

Kewasaki Bond (Liquid Gasket ~ Black): 92104-1003

=

foe

Valve Seat Cutter, 60° — 33: 57001-1334.

Kawasaki Bond (Liquid Gasket - Stver): 92104-002

8

gy

\

Hexagon Wrench, Hex 29: 57001-1335

&

=

Vacuum Gauge: 57001-1369

Kawacaki Bond (Silicone Sealant): 58019-120

“Ba

ioe

ee

GENERAL INFORMATION 1-19

Cable, Wire, and Hose Routing

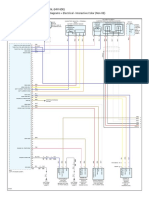

3, Main Hames

4. Water Temp. Sensor Leads

5. Ground Load

8. Fan Motor Lead

7. #2,3 Ignition Coil Leads

8, Right Hom Lead

9. Alternator Lead

10. Pickup Coil Leod

411. Battery (-) Lead

12. Oil Pressure Switch Lead

13. Rear Brake Switch Lead.

14, Junction Box Load,

15. Fuel Level Gauge Lead

16. Tail/Brake Light Lead

17. Right Turn Signal Lead

18. Licence Light Lead

19. Left Turn Signal Lead

20. Tum Signal Relay Lead

21. Rectifier Lead

22.1C Igniter Lead

23. Starner Relay Lead

24. Fuel pump Relay lead

25, Side Stand Switch Lead

28. Noutral Switch Load

1

2. Cable passing in Right Hole

27.

28,

29.

30.

31

32

33

34.

36.

Cables passing in Left Hole

Throwtle Cable

Choke Cable

Ignition Switch Leacs

Left Switch Case Leeds

Main Hames

Right Switch Case Leads

Cooling Fan Switch Lead

Loft Horn Lead

Loft Hendleber Switch Lead

Right Handlebar Switch Lead

Ignition Switch Leads

Clamp

White Color Tape Wound

‘on Main Harness

#1, 4 Ignition Coil Leads

Fuel Pump Lead

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Caja Manual SentraDocument126 pagesCaja Manual SentraCA GDNo ratings yet

- 2021 Chevrolet Camaro Owners ManualDocument354 pages2021 Chevrolet Camaro Owners ManualCA GDNo ratings yet

- Versa 2019 Engine ControlDocument5 pagesVersa 2019 Engine ControlCA GDNo ratings yet

- zx9r PDFDocument307 pageszx9r PDFCA GDNo ratings yet

- C90 PDFDocument186 pagesC90 PDFCA GDNo ratings yet

- Ducati Superbike: Owner's ManualDocument122 pagesDucati Superbike: Owner's ManualCA GDNo ratings yet

- V5 PV776 370 99197 3 EngineECU VolvoS12C VN B5 99Document5 pagesV5 PV776 370 99197 3 EngineECU VolvoS12C VN B5 99nancy100% (3)