Professional Documents

Culture Documents

Viii D2 Part As1 PDF

Uploaded by

Farzad SadrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viii D2 Part As1 PDF

Uploaded by

Farzad SadrCopyright:

Available Formats

Part AS

MARKING, STAMPING, REPORTS,

AND RECORDS

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

PART AS

Article S-1 Contents and Method of Stamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

AS-100 Required Marking for Vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

AS-100.1 Units of Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

AS-101 Methods of Marking Vessels With Two or More Independent

Chambers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

AS-101.1 If Markings Are Grouped in One Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

AS-101.2 If Each Independent Chamber Is Marked . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

AS-110 Application of Stamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

AS-120 Part Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

AS-130 Nameplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

AS-131 Stamping of Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

AS-132 Attachment of Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Article S-2 Obtaining and Using Code Stamps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

AS-200 Code Stamps Bearing Official Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

AS-201 Application for Authorization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

AS-202 Issuance of Authorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

AS-203 Inspection Agreement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

AS-204 Quality Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

AS-205 Evaluation for Authorization and Reauthorization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

AS-206 Code Construction Before Receipt of Certificate of Authorization . . . . . . . . . . . . . . . . 270

Article S-3 Report Forms and Maintenance of Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

AS-300 Manufacturer’s Data Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

AS-300.1 Units of Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

AS-301 Distribution and Filing of Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

AS-310 Partial Data Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

AS-320 Maintenance of Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Article S-4 Special Requirements for Layered Vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

AS-400 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

AS-410 Stamping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

AS-420 Manufacturer’s Data Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Figures

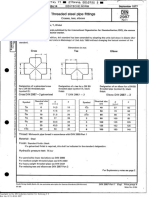

AS-100.1 Official Symbol for Stamp to Denote The American Society of

Mechanical Engineers’ Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

AS-131.1 Form of Stamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

266

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ARTICLE S-1

CONTENTS AND METHOD OF STAMPING

AS-100 REQUIRED MARKING FOR

VESSELS

Each pressure vessel to which the Code symbol is

applied shall be marked with the following:

(a) the official Code symbol, as shown in Fig. AS- FIG. AS-100.1 OFFICIAL SYMBOL FOR STAMP TO

100.1; DENOTE THE AMERICAN SOCIETY OF

(b) name of the Manufacturer of the pressure vessel, MECHANICAL ENGINEERS’ STANDARD

preceded by “certified by”;

(c) design pressure,1,2 psi, at coincident tempera-

ture, °F;

(d) minimum design metal temperature;

(e) Manufacturer’s serial number; tional marking, such as stock space, jacket, tubes, or

(f) year built. channel box, is used to indicate clearly to which

chamber the data apply.

AS-100.1 Units of Measurement. The units of mea-

surement shall be in accordance with AG-151.

AS-110 APPLICATION OF STAMP

AS-101 Methods of Marking Vessels With (a) The Manufacturer who completes the fabrication

Two or More Independent Chambers of the vessel shall have a valid Certificate of Authoriza-

Either of the following arrangements may be used tion for the use of the Code symbol. The Code symbol

in marking vessels having two or more independent shall be applied by the Manufacturer only with the

pressure chambers designed for the same or different acceptance of the Inspector. Such application of the

operating conditions. Each detachable chamber shall Code symbol, together with final certification in accord-

be marked so as to identify it positively with the ance with the rules of this Division, shall confirm that

combined unit. all applicable Code requirements have been fulfilled.

(b) Except as provided in (c) below, the Code symbol

AS-101.1 If Markings Are Grouped in One Loca- shall be applied after the hydrostatic test or pneu-

tion. The markings may be grouped in one location matic test.

on the vessel, provided they are arranged so as to (c) The Code symbol may be preapplied to a name-

indicate clearly the data applicable to each chamber, plate. The nameplate may be attached to the vessel

including the maximum differential pressure for the after the final fabrication and examination sequence

common elements, when this pressure is less than the but before the hydrostatic test or pneumatic test, pro-

higher pressure in the adjacent chambers. vided the procedure for sequence of stamping is de-

AS-101.2 If Each Independent Chamber Is scribed in the Manufacturer’s accepted Quality Control

Marked. The complete required marking may be applied System.

to each independent pressure chamber, provided addi-

1

When a vessel is expected to operate at more than one pressure AS-120 PART MARKING

and temperature condition, other values of coincident pressure and

design temperature may be added (see Table AD-120.1). Parts of pressure vessels for which Partial Data

2

Not required on parts for which the parts manufacturer does not Reports are required in AS-310 shall be marked by

prepare a Manufacturer’s Design Report. the parts manufacturer with the following:

267

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

AS-120 2001 SECTION VIII — DIVISION 2 AS-132

(a) the official Code symbol shown in Fig. AS-100.1

above the word “Part”;

(b) name of the Manufacturer of the pressure vessel, Certified by

preceded by the words “certified by”;

(Name of Manufacturer)

(c) Manufacturer’s serial number;

(d) design pressure,3 psi, at coincident tempera- psi at °F

(Design pressure)

ture, °F.

This requirement does not apply to such items as °F

(Min. design metal temperature)

handhole covers, manhole covers, and accessories.

HT (if postweld

heat treated) (Manufacturer’s serial number)

AS-130 NAMEPLATE

(Year built)

(a) The marking required in AS-100 shall be applied

to a separate nameplate permanently attached to the

vessel. The nameplate shall be located within 30 in.

FIG. AS-131.1 FORM OF STAMPING

(762 mm) of the vessel and shall be attached by suitable

means. Removal shall require the willful destruction

of the nameplate or its attachment system.

(1) Nameplates may be attached by either welding, the Code symbol, shall be cast, etched, or stamped

brazing, or soldering. and this marking need not be witnessed by the Inspector.

(2) Nameplates may be attached by tamper- The additional nameplate shall be marked “duplicate.”

resistant mechanical fasteners of suitable metal con-

struction.

AS-131 Stamping of Nameplate

(3) Nameplates may be attached with pressure-

sensitive acrylic adhesive systems, provided that, in The Code symbol and the Manufacturer’s serial

addition to the requirements of this paragraph, those number shall be stamped on the nameplate, but the

of Appendix 23 are met. other required data may be stamped, etched, cast, or

The marking shall not be stamped directly on the impressed thereon. The data shall be in characters not

vessel, except that steel stamping shall be permitted less than 5⁄32 in. (4 mm) high. The arrangement shall

be substantially as shown in Fig. AS-131.1.

on the head section of vessels over 1⁄2 in. (13 mm)

thick having 1⁄4 in. (6 mm) greater thickness than the

design requirements for the head; such stamping shall AS-132 Attachment of Nameplate

be done with “low stress” stamps as commercially If the nameplate is marked before it is affixed to

available (see AF-102.1). the vessel, the Manufacturer shall ensure that the name-

(b) An additional nameplate may be installed on the plate with the correct marking has been applied to the

skirt, supports, jacket, or other permanent attachment vessel to which it applies and the Inspector shall satisfy

to a vessel. All data on the additional plate, including himself that this has been done. The nameplate shall

be permanently attached by a method which will not

3

Not to be included on parts for which the parts manufacturer does affect the integrity of the vessel (see AF-102.1 and

not prepare a Manufacturer’s Design Report. AF-670).

268

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Porous CeramicsDocument65 pagesPorous CeramicsFarzad SadrNo ratings yet

- Safety Data Sheet: Dykem Steel Red SprayDocument10 pagesSafety Data Sheet: Dykem Steel Red SprayFarzad SadrNo ratings yet

- Flange For Not Subject To Pressure Vessel DIN 28034Document3 pagesFlange For Not Subject To Pressure Vessel DIN 28034Farzad Sadr0% (1)

- DIN (2987) FittingDocument2 pagesDIN (2987) FittingFarzad SadrNo ratings yet

- Boundary Layer TheoryDocument32 pagesBoundary Layer TheorySubhasish MitraNo ratings yet

- ISO 49 StandardDocument42 pagesISO 49 StandardFarzad Sadr100% (1)

- Rotordynamic Capabilities in ANSYS Mechanical PDFDocument3 pagesRotordynamic Capabilities in ANSYS Mechanical PDFFarzad SadrNo ratings yet

- ISO 7-1 Pipe ThreadsDocument11 pagesISO 7-1 Pipe ThreadsFarzad SadrNo ratings yet

- Iso 261Document5 pagesIso 261Farzad SadrNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)