Professional Documents

Culture Documents

WEP Standard For Reference Only

Uploaded by

Kiran NikateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WEP Standard For Reference Only

Uploaded by

Kiran NikateCopyright:

Available Formats

SPECIFICATION No. HE-POW-WEL-S-008 REV. No.

R0 Page 3 of 39

INDEX

Sr No. Content Page No.

Carbon steel & Low Alloy Steel

1 WEP Tolerance Sheet 5

2 Shell L/S : Shell I.D. ≥ 900 6

3 Shell L/S : Shell I.D. < 900 7

4 Shell C/S : Shell I.D. ≥ 900 9

5 Shell C/S : Shell I.D. < 900 10

6 Shell C/S where rotation not feasible : Shell I.D. ≥ 900 11

7 Shell C/S where rotation not feasible : Shell I.D. < 900 12

8 Shell # Dished End C/S : Shell I.D. ≥ 900 13

9 Shell # Dished End C/S : Shell I.D. < 900 14

10 Tubesheet # Shell C/S 15

11 Tubesheet # Shell C/S where rotation not feasible 17

12 D’End Petals # Petals/Crown L/S & C/S 18

13 Pipe # Pipe & Nozzle # Flange/Spool C/S welds 19

14 Set-On Nozzle welds 20

15 Set-Through Nozzle welds 21

16 Set-Through Nozzle welds with Radiography 22

17 Set-Through Nozzle welds with RF Pad 23

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 4 of 39

INDEX

Sr No. Content Page No.

Stainless Steel, Nickel Alloy & Titanium

19 WEP for Stainless steel 25

20 WEP for Nickel Based material 27

21 WEP for Titanium 28

Other Category joints

22 Tube to Tubesheet Joints 29

23 Overlaid & Clad Joints 32

24 Multi Wall Vessels 35

25 Dissimilar Material C/S weld 36

26 Liner Butt & Liner Attachment Welds 37

27 Tubesheet # Channel C/S for Synloop Boiler 38

28 Nozzle to Hydro blank Joint 38

29 Tubesheet # Shell/Junction Forging for Waste heat boiler 39

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 5 of 39

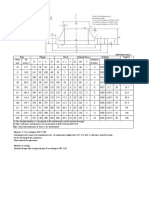

WEP TOLERANCE

GENERAL NOTES:

1. Drawings for all equipment are to be prepared as per this standard.

TOLERANCE

ROOT ANGLE OF

JOINT DETAIL OTHERS

FACE ROOT GAP INDIVIDUAL

(mm) BEVEL

(mm) (Degrees)

(mm)

W1 to W4 -0 -0 -0

+2 +3 +10

-0 -0 -0

W101& W107

+0.5 +1.5 +10

W5 to W15,

-0 -0 -0

W102 to W106,

+0.5 +1.5 +2.5

W108 to W110

-0 -0 -0

N1, N2, N3, N8, N10, N14

+0.5 +1.5 +10

-0 -0 -0

N4, N6, N11, N12

+2 +3 +10

-0 -0

N5, N7, N9, N13

- +6 +2.5

Groove depth:

-0/+0.2 for automatic

Tube to Tubesheet welding

Weld details -0/+0.5 for manual

T1 to T7 welding

Groove radius : -0 / +1.0

Projection : -0.5 / +0.5

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 6 of 39

Shell L/S : Shell ID ≥ 900

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W1

Single V with Chip Back

SMAW

Gas cutting-

(OR) *SAW to be considered only

L/S Shell ≤ 30 ≥ 900 Grinding

SMAW + when base metalThk≥14mm

/Machining

SAW*

W2

Double V with Chip Back

SMAW

Gas cutting-

(OR)

L/S Shell >30–60 ≥ 900 Grinding/Mac

SMAW +

hining

SAW

W4

W3 Single V & straight face with

Double V with Chip Back Chip Back

Gas cutting-

SMAW + For W4 Chip back by machine

L/S Shell >60-80 ≥ 900 Grinding/Mac

SAW grinding only for I.D. > 1200mm

hining

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 7 of 39

Type

Comp- Thickness I.D Welding Method of

of WEP Details Remarks

onent (mm) (mm) Process WEP

weld

W4 W5

Single V & straight face with Double U with Chip Back

Chip Back

Gas cutting- For W4 & W5 Chip back by

SMAW +

L/S Shell >80-200 ≥ 900 Grinding/Mac machine grinding only for

SAW

hining I.D. > 1200mm

Shell L/S : Shell ID < 900

W101

Single V with Single side full

penetration

GTAW+

*SAW to be considered only

SMAW

Gas cutting- when base metalThk≥14mm.

(OR)

L/S Shell ≤ 30 <900 Grinding/Mac

GTAW+

hining For Diameter ≥300 & length of

SMAW +

≤500, W1 can be considered.

SAW*

W102

Compound V with Single side

full penetration

GTAW+

For Diameter ≥300 & length of

L/S Shell >30 - 80 <900 SMAW + Machining

≤500, W7 can be considered

SAW

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 8 of 39

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W103

Compound V with Single side

full penetration

GTAW+

L/S Shell >80-200 <900 SMAW + Machining

SAW

Shell C/S : Shell I.D. ≥ 900

W1

Single V with Chip Back

SMAW

Gas cutting-

(OR) *SAW to be considered only

C/S Shell ≤ 30 ≥ 900 Grinding/Mac

SMAW + when base metalThk≥14mm

hining

SAW*

W2

Double V with Chip Back

Gas cutting-

SMAW +

C/S Shell >30-50 ≥ 900 Grinding

SAW

/Machining

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 9 of 39

Shell C/S : Shell I.D. ≥ 900

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W3 W6

Double V with Chip Back Single U with Chip back

SMAW + Chip back by machine grinding

C/S Shell >50–80 ≥ 900 Machining

SAW W7 only for I.D. > 1200mm

Compound V with Chip Back

W6

Single U with Chip back W8

Compound V with Chip Back

SMAW + Chip back by machine grinding

C/S Shell >80–200 ≥ 900 Machining

SAW only for I.D. > 1200mm

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 10 of 39

Shell C/S : Shell I.D. < 900

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W101

Single V with Single side full

GTAW+ penetration

*SAW to be considered only

SMAW

Gas cutting- when jointThk≥14mm

(OR)

C/S Shell ≤ 30 <900 Grinding

GTAW

/Machining For Diameter ≥300 & length of

+SMAW

≤500, W1 can be considered

+SAW *

W102

Compound V with Single side

full penetration

GTAW

For Diameter ≥300 & length of

C/S Shell >30-60 <900 +SMAW Machining

≤500, W10 can be considered

+SAW

W103 W104

Compound V with Single side Single U with Single side full

full penetration penetration

GTAW Gas cutting- W104 shall be preferred if joint

C/S Shell >60-200 <900 +SMAW Grinding Thk> 80

+SAW /Machining

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 11 of 39

Shell C/S where rotation not feasible : Shell I.D. ≥ 900

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W1

Single V with Chip Back

Gas cutting- Circ seams where shell rotation

C/S Shell ≤ 30 ≥ 900 SMAW Grinding not feasible but root side is

/Machining accessible for Chipback

W9

Compound V with chip back

Circ seams where shell rotation

C/S Shell ≥ 30-60 ≥ 900 SMAW Machining not feasible but root side is

accessible for Chipback

W10

Compound V with chip back

Circ seams where shell rotation

C/S ≥ Shell ≥ 60-200 ≥ 900 SMAW Machining not feasible but root side is

accessible for Chipback

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 12 of 39

Shell C/S where rotation not feasible : Shell I.D. < 900

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W101

Single V with Single side full

penetration

GTAW+ Gas cutting-

C/S * Shell ≤ 30 <900 SMAW Grinding

/Machining

W105

Compound V with Single side

full penetration

GTAW+

C/S * Shell >30-60 <900 Machining

SMAW

W106

Compound V with Single side

full penetration

GTAW+

C/S * Shell >60-200 <900 Machining

SMAW

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 13 of 39

Shell # Dished End C/S : Shell I.D. ≥ 900

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W1

Single V with Chip Back

SMAW (OR) Gas cutting-

Shell#D' *SAW to be considered only

C/S ≤ 30 ≥ 900 SMAW + Grinding

end when base metalThk≥14mm

SAW* /Machining

W1 W2

Double V with Chip Back

Single V with Chip Back

SMAW (OR) Gas cutting-

Shell#D'

C/S >30-60 ≥ 900 SMAW + Grinding/Mac

end

SAW hining

W8 W11

Compound V with Chip Back Single U with Chip back

Shell#D' SMAW +

C/S >60-200 ≥ 900 Machining

end SAW

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 14 of 39

Shell # Dished End C/S : Shell I.D. < 900

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W101

Single V with Single side full

GTAW+ penetration

SMAW

Gas cutting-

Shell# (OR) *SAW to be considered only

C/S ≤ 30 < 900 Grinding

D'end GTAW when base metal Thk≥14mm

/Machining

+SMAW

+SAW *

W102

Compound V with Single side

full penetration

GTAW

Shell#

C/S >30-60 < 900 +SMAW Machining

D'end

+SAW

W103 W104

Compound V with Single side Single U with Single side full

full penetration penetration

GTAW Gas cutting- W104 shall be preferred if joint

Shell #

C/S >60-200 < 900 +SMAW Grinding Thk> 80

D'end

+SAW /Machining

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 15 of 39

Tubesheet # Shell C/S

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W1

Single V with Chip Back

TS # Gas cutting-

SMAW+ *SAW to be considered only

Shell/ ≤ 30 ≥ 900 Grinding

C/S SAW* when base metalThk≥14mm

Channel /Machining

W7

Compond V with Chip Back

TS #

SMAW+

Shell/ >30-80 ≥ 900 Machining

C/S SAW

Channel

W8

Compound V with Chip Back

TS #

SMAW+

Shell/ > 80-200 ≥ 900 Machining

C/S SAW

Channel

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 16 of 39

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W101

Single V with Single side full

penetration

TS # GTAW+ Gas cutting-

*SAW to be considered only

Shell/ ≤ 30 <900 SMAW+ Grinding

C/S when base metal Thk≥14mm

Channel SAW* /Machining

W102

Compound V with Single side

full penetration

TS # GTAW+

Shell/ > 30-80 <900 SMAW+ Machining

C/S

Channel SAW

W103

Compound V with Single side

full penetration

TS # GTAW+

Shell/ > 80-200 <900 SMAW+ Machining

C/S

Channel SAW

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 17 of 39

Tubesheet # Shell C/S where rotation not feasible

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W1

Single V with Chip Back

Circ seams where shell rotation

TS # Gas cutting- not feasible

C/S Shell/ ≤ 40 ≥ 900 SMAW Grinding

Channel /Machining Check accessibility for Chipback &

Re-weld

W9

Compound V with chip back

Circ seams where shell rotation

not feasible

TS #

C/S Shell/ > 40-200 ≥ 900 SMAW Machining

Check accessibility for Chipback &

Channel

Re-weld

W101

Single V with Single side full

penetration

TS # GTAW+ Gas cutting-

*Circ seams where shell rotation

C/S * Shell/ ≤ 40 <900 SMAW Grinding

not feasible

Channel /Machining

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 18 of 39

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W105

Compound V with Single side

full penetration

TS #

GTAW+ *Circ seams where shell rotation

C/S * Shell/ > 40-200 <900 Machining

SMAW not feasible

Channel

D’End Petals # Petals/Crown L/S & C/S

W1

Single V with Chip Back

D’End

L/S SMAW (OR) Gas cutting-

(Crown *SAW to be considered only

& ≤ 30 N.A. SMAW + Grinding

& when base metal Thk≥14mm

C/S SAW /Machining

Petals)

W2

Double V with Chip Back

L/S SMAW (OR) Gas cutting-

& D’End > 30 - 80 N.A. SMAW + Grinding/Mac

C/S SAW hining

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 19 of 39

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W7

W3 Compound V with Chip Back

Double V with Chip Back

D’End

L/S SMAW (OR) Gas cutting-

(Crown

& > 80 - 200 N.A. SMAW + Grinding/Mac W7 Preferred for P5A & P5C

&

C/S SAW hining

Petals)

Pipe # Pipe & Nozzle # Flange/Spool C/S welds

W101

Single V with Single side full

penetration

Pipe # GTAW+

Pipe, SMAW

Gas cutting-

(OR) *SAW to be considered only

C/S ≤ 40 <900 Grinding

Nozzle GTAW when base metal Thk≥14mm

/Machining

#Spool/ +SMAW

Flange +SAW *

W102

Compound V with Single side

full penetration

Pipe # GTAW-

Pipe, SMAW

(OR)

C/S > 40 - 200 <900 Machining

Nozzle GTAW-

#Spool/ SMAW -

Flange SAW

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 20 of 39

Set-On Nozzle Welds

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

N1

Single bevel with single side

full penetration

GTAW

Nozzle# Gas cutting-

Nozzle Nozzle (OR)

shell/D' ANY Grinding/Mac RT not feasible

Weld Thk ≤ 35 GTAW+

end hining

SMAW

N2

Single compound bevel with

single side full penetration

Nozzle#

Nozzle Nozzle GTAW+

shell/D' ANY Machining RT not feasible

Weld Thk> 35 SMAW

end

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 21 of 39

Set-Through Nozzle Welds

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

N3

Single bevel withsingle side full

penetration

RT not feasible

Nozzle# Gas cutting-

Nozzle GTAW +

shell/D' All <900 Grinding /

Weld SMAW If Nozzle back side is accessible

end Machining

for Chipback, N4 can be selected.

N4

Single bevel with chip back

If shell Diameter is >1.5meter

inside V shall be preferred.

Nozzle# Gas cutting-

Nozzle

shell/D' ≤ 40 ≥ 900 SMAW Grinding / RT not feasible

Weld

end Machining

In case of tangential/radial nozzle

N3 shall be preferred

N5

Single bevel with backing strip If shell Diameter is > 1.5meter

inside V shall be preferred.

SMAW RT not feasible

Nozzle# Gas cutting-

Nozzle (OR)

shell/D' >40 ≥ 900 Grinding */

Weld SMAW + SAW only when

end Machining

SAW 1) Shell I.D > 1.2 meter &

2) Nozzle OD > 300 mm

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 22 of 39

Set-Through Nozzle Welds with Radiography

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

N6

Single V (Lip type joint)

SMAW

Nozzle# Gas cutting-

Nozzle (OR) Where RT/Recordable UT

shell/D' ≤ 40 ≥ 900 Grinding/Mac

Weld SMAW + required

end hining

SAW

N7 If shell Diameter is >1.5meter

Single V with Chip back inside V shall be preferred.

(Lip type joint)

Where RT/Recordable UT

SMAW required

Nozzle# Gas cutting-

Nozzle (OR)

Weld

shell/D' > 40 ≥ 900 Grinding *

SMAW SAW only when

end /Machining

+SAW 1) Shell I.D > 1.2 meter &

2) Nozzle OD > 200 mm

*Gas cutting-Grinding for shell

side only

N8

Single V (Lip type joint)

GTAW +

SMAW

Nozzle# Gas cutting-

Nozzle (OR) Where RT/Recordable UT

shell/D' ≤ 40 <900 Grinding/Mac

Weld GTAW + required

end hining

SMAW +

SAW

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 23 of 39

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

N9

Single V (Lip type joint)

GTAW +

SMAW

Nozzle# Gas cutting-

Nozzle (OR) Where RT/Recordable UT

Weld

shell/D' > 40 <900 Grinding/Mac

GTAW + required

end hining

SMAW +

SAW

Set-Through Nozzle Welds with RF pad

N10

SSFP with Reinforcement pad

Nozzle# Gas cutting-

Nozzle GTAW + RT not feasible

Weld

shell/D' ALL <900 Grinding *

SMAW

end /Machining

N11 N12

SSFP with Reinforcement pad DSFP with Reinforcement

pad&chipback

Nozzle# Gas cutting-

Nozzle

Welds

shell/D' ≤ 40 ≥ 900 SMAW Grinding * RT not feasible

end /Machining

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 24 of 39

Set-Through Nozzle Welds with RF pad

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

N13

Single bevel with backing strip

&Reinforcement pad

If shell Diameter is >1.5meter

SMAW inside V shall be preferred.

Nozzle# Gas cutting-

Nozzle (OR)

shell/D' >40 ≥ 900 Grinding */

Welds SMAW + RT not feasible

end Machining

SAW

N14

P without Chipback & with

Reinforcement pad

RT not feasible

Nozzle# Gas cutting-

Nozzle GTAW +

shell/ ALL ≥ 900 Grinding * /

Welds SMAW N10 shall be used for Nozzle

D'end Machining

OD < 200mm

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 25 of 39

WEP for Stainless Steel

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W101

Single V with Single side full

GTAW + penetration

SMAW

Gas cutting-

L/S (OR)

ANY ≤ 30 ANY Grinding/

C/S GTAW +

Machining

SMAW +

SAW

W105

Compound V with Single side

full penetration

GTAW +

SMAW

L/S (OR)

ANY > 30 – 50 <900 Machining

C/S GTAW +

SMAW +

SAW

W9

W2 Compound V with chip back

Double V with Chip Back

SMAW

L/S ANY > 30 – 50 ≥ 900 (OR) Machining

SMAW +

SAW

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 26 of 39

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W9

Compound V with chip back

SMAW

C/S ANY > 30 – 50 ≥ 900 (OR) Machining

SMAW +

SAW

L/S

ANY ≥ 50 ANY - Machining Consult Welding engineer for WEP

C/S

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 27 of 39

WEP for Nickel based material

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W107

Single V with Single side full

penetration

Gas cutting-

L/S GTAW +

ANY ≤ 20 ANY Grinding/

C/S SMAW

Machining

L/S

ANY > 20 ANY - - Consult Welding engineer

C/S

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 28 of 39

WEP for TITANIUM

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W101

Single V with Single side full

penetration

L/S,

ANY ≤ 10 N.A GTAW Machining

C/S

W108

Double V double side full

penetration

L/S,

ANY > 10- 25 N.A GTAW Machining Without Chipback

C/S

W109 W110

Single U with Single side full Double U with double side full

penetration penetration

L/S, W112 for Shell I.D < 900

ANY > 25 N.A GTAW Machining

C/S W113 for Shell I.D ≥ 900

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 29 of 39

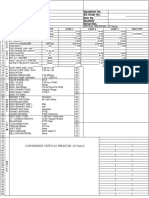

Tube to Tubesheet Joints

Tube

Sr No Joint configuration Material Projection (P) Notes Remarks

thickness

C.S

S.S

1) Adopt only for strength welding

INCONEL P=t

T1 t >=1.6 2) For t < 5 : Min 2 Pass

MONEL (5 Max)

t ≥ 5 : Min 3 Pass

LAS

TITANIUM

P - L ≥ 1mm,

Where L = Ligament

C.S

Adopt only for strength welding in

S.S

T2 t <= 1.6 P = 0.5 to 1 special cases, in consultation with

LAS

welding engineering

TITANIUM

1) joint preferred for thin

C.S

tubes

S.S

T3 t <= 2 P = 0.5 t Autogenousseal Weld

LAS

2) Not applicable for

TITANIUM

dissimilar material

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 30 of 39

Tube

Sr No Joint configuration Material Projection (P) Notes Remarks

thickness

1) Suitable for automatic welding

>0.5-1.0 0

C.S only& not applicable for dissimilar

>1.0-1.2 0.5

S.S material

>1.2-1.5 1

T4 LAS

>1.5-1.8 1.5

MONEL 2) Welding engineer shall be

>1.8-2.0 2

INCONEL consulted prior to adopting this on

>2.0-2.3 2.5

drawing

1) Single side full penetration

joints for

C.S

T5 ANY - RG & SG Boilers

LAS

2) Tolerance for root face ± 0.2

1) Only for internal bore welding

C.S

T6 3.6 Max. -

LAS

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 31 of 39

Tube

Sr No Joint configuration Material Projection (P) Notes Remarks

thickness

1) Only for internal bore welding

C.S

T7 T >3.6 -

LAS

Urea Stripper

5 (Top side) 1) Suitable for automatic welding

17 (Bottom side) only not applicable for dissimilar

material For Snaprogatty Urea

T8 S.S ANY

Equipment only

Carbamate 2) Contact welding engineer prior

Condenser: to adopting this on drawing

6

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 32 of 39

WEP for Overlay & Clad Joints

WEP Numbers

SELECT WO1 details for W101, W102, W103, W104, W105, W106

SELECT WO2 details for W1, W7, W8, W9, W10, W11

SELECT WO3 details for W2, W3, W5

SELECT WO4 details for W4, W6

Notes:

1. Clad Type 2 can be given where Shell I.D control is required for tube bundle insertion. Designer to account for the groove depth in base

material.

Non-Overlaid Overlaid Clad Type 1 Clad Type 2

Inside Inside Clad Inside Clad

Inside O/L For SMAW, GTAW, GMAW &

FCAW : X =5 mm

For ESW :

30 W strip : Y = 27(+3,- 0)

60 W strip : Y = 55(+3,- 0)

WO1

Consult welding engineer prior

2R 2R 2R to adopting dimensions on

Typ. Typ. Typ. drawing.

For ‘Z’ Dimension consult

welding engineer

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 33 of 39

Non-Overlaid Overlaid Clad Type1 Clad Type 2

Inside Inside Clad Inside Clad

Inside O/L

For SMAW, GTAW, GMAW &

FCAW : X =5 mm

For ESW :

30 W strip : Y = 27(+3,- 0)

2R 60 W strip : Y = 55(+3,- 0)

2R 2R

WO2 Typ. Typ.

Typ. Consult welding engineer prior

to adopting dimensions on

drawing.

For ‘Z’ Dimension consult

Chip back to Chip back to welding engineer

Chip back to

Sound metal Sound metal

Sound metal

& reweld & reweld

& reweld

Non-Overlaid Overlaid Clad Type 1 Clad Type 2

Inside Inside Clad Inside Clad

Inside O/L For SMAW, GTAW, GMAW &

FCAW: X =5 mm

For ESW :

30 W strip : Y = 27 (+3,- 0)

60 W strip : Y = 55 (+3,- 0)

WO3

2R 2R 2R Consult welding engineer prior

Typ. Typ. Typ. to adopting dimensions on

drawing.

For ‘Z’ Dimension consult

welding engineer

Chip back to Chip back to

Chip back to

Sound metal Sound metal

Sound metal

& reweld & reweld

& reweld

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 34 of 39

Non-Overlaid Overlaid Clad Type 1 Clad Type 2

Inside Inside O/L Inside Clad Inside Clad

For SMAW, GTAW, GMAW &

FCAW: X =5 mm

For ESW :

30 W strip : Y = 27 (+3,- 0)

60 W strip : Y = 55 (+3,- 0)

WO4 2R 2R

2R Consult welding engineer prior

Typ. Typ. Typ.

to adopting dimensions on

drawing.

For ‘Z’ Dimension consult

welding engineer

Chip back to Chip back to Chip back to

Sound metal Sound metal Sound metal

& reweld & reweld & reweld

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 35 of 39

Multi Wall Vessels

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W12Single U with Chip Back

SMAW+

C/S Shell All N.A. Machining Multi wall Circ seam

SAW

W13 Single U with Chip Back

SMAW+

C/S Shell All N.A. Machining Multi wall Circ seam – Closing seam

SAW

W14 Single U with Chip Back

Shell

#D’en SMAW+

C/S All N.A Machining Multi to Mono wall Circ seam

d/Flan SAW

ge

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 36 of 39

Dissimilar Material C/S welding

Type Dia-

Comp- Thickness Welding Method of

of meter WEP Details Remarks

onent (mm) Process WEP

weld (mm)

W111

Single V with Buttering

Pipe #

GTAW+

Pipe,

SMAW

Gas cutting-

(OR)

C/S Nozzle ≤40 ALL Grinding Buttering Thk : 6mm Minimum

GTAW

#Spoo /Machining

+SMAW

l/Flan

+SAW *

ge

W112

Compound V with Buttering

Pipe #

GTAW-

Pipe,

SMAW

(OR)

C/S Nozzle > 40-200 ALL Machining Buttering Thk : 6mm Minimum

GTAW-

#Spoo

SMAW -

l/Flan

SAW

ge

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 37 of 39

Liner attachment & Liner butt joint for Urea Equipment

L1Liner Attachment weld

Liner For buttering by ESW :

L/S,

Attach- ALL N.A GTAW Grinding 30 W strip : Y = 27 (+3,- 0)

C/S

ment 60 W strip : Y = 55 (+3,- 0)

L2Liner Butt weld

L/S, Liner

All N.A. GTAW Grinding

C/S Butt

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 38 of 39

Type Thickne Dia-

Comp- Welding Method of

of ss meter WEP Details Remarks

onent Process WEP

weld (mm) (mm)

Tubesheet # Channel C/S for Synloop Boiler

W113

GTAW +

TS #

C/S All N.A. SMAW + Machining

Channel

SAW

Nozzle to Hydro blank Joint

W114

Nozzle

to GTAW +

C/S All N.A. Machining L to be decided by designer

Hydro SMAW

Blank

W115

Nozzle

to GTAW +

C/S All N.A. Machining L to be decided by designer

Hydro SMAW

Blank

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

SPECIFICATION No. HE-POW-WEL-S-008 REV. No. R0 Page 39 of 39

Type Thickne Dia-

Comp- Welding Method of

of ss meter WEP Details Remarks

onent Process WEP

weld (mm) (mm)

Tubesheet # Shell/Junction Forging for Waste heat boiler

Root offset due to ovality.Max

W116 allowed offset is 10mm

Tubesheet ID to be kept 6mm more

than the shell ID

TS # Drawing/operation card to indicate

GTAW +

Junction shell ID machining stage after shape

C/S All N.A. SMAW + Machining

forging/ correction if any. Ovality readings of

SAW

Shell LHS & RHS Tubesheets to be

considered before M/c

Shell ovality shall be restricted to

10mm(max). Ovality>10mm will

require shape correction.

W117

Channel should be designed with

extra thickness for ID machining

Channel ID machining/grinding to be

carried out after completion of

GTAW +

Channel channel assembly fabrication & after

C/S All N.A. SMAW + Machining

# Shell having the ovality readings.

SAW

Drawing/operation card to indicate

the same

Max permissible offset shall be 2mm

This document is the property of Larsen & Toubro Limited and

must not be copied or lent without their permission in writing.

You might also like

- KB Coupling CatalogueDocument2 pagesKB Coupling CatalogueGaurav BedseNo ratings yet

- Canalta Orifice Fitting Parts & Accessories: Precision Machined Accuracy Reliability PerformanceDocument90 pagesCanalta Orifice Fitting Parts & Accessories: Precision Machined Accuracy Reliability Performanceray mojicaNo ratings yet

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocument2 pages2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebNo ratings yet

- 2020 Lepin Cold and Hot Aisle ContainmentDocument31 pages2020 Lepin Cold and Hot Aisle ContainmentLunick Fabrice100% (1)

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- SN398 2008-04 eDocument4 pagesSN398 2008-04 ewasim_akp9885No ratings yet

- Low-Pressure Hoselines SN 544: Double Nipple Welding NippleDocument2 pagesLow-Pressure Hoselines SN 544: Double Nipple Welding NippleNaveen Kumar Chauhan100% (1)

- Weld MapDocument1 pageWeld MapFerdie OSNo ratings yet

- Check Safety Requirements For Clutch Door According To ASMEDocument3 pagesCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533No ratings yet

- Dish Head TypesDocument6 pagesDish Head TypesJohn MaldonadoNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Gasket Installation: DurlonDocument3 pagesGasket Installation: Durlonlorenzo100% (1)

- Material Selection GuideDocument1 pageMaterial Selection Guidesuresh_vikiNo ratings yet

- Din Flange Din 2627: (Dimensions in MM.)Document12 pagesDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNo ratings yet

- API 650 (US) EN 14015 (Europe) GOST 31385-2016 (Russia, CIS) X - Tick As NecessaryDocument3 pagesAPI 650 (US) EN 14015 (Europe) GOST 31385-2016 (Russia, CIS) X - Tick As NecessaryBilel NajjarNo ratings yet

- Delta Industrial Knife Gate ValvesDocument28 pagesDelta Industrial Knife Gate ValvesAlin AllinNo ratings yet

- GIC Pressure GaugeDocument2 pagesGIC Pressure GaugeSUSOVAN BISWASNo ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- API 650 Tank Nozzle Stand Out - EditableDocument20 pagesAPI 650 Tank Nozzle Stand Out - EditableShaaban NoamanNo ratings yet

- Weight CalculatorDocument2 pagesWeight CalculatorenjoygurujiNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- Comments Resolution Sheet For Commented QAPDocument10 pagesComments Resolution Sheet For Commented QAPSuraj ShettyNo ratings yet

- Interview Type Question Manufacturing PDFDocument4 pagesInterview Type Question Manufacturing PDFSourav KayalNo ratings yet

- Belt Conveyor Draw FinishDocument1 pageBelt Conveyor Draw FinishRizki FauziNo ratings yet

- 4 2500 (F347H)Document2 pages4 2500 (F347H)siddhesh_guessNo ratings yet

- Sa 420Document10 pagesSa 420Widya widyaNo ratings yet

- Rationalise List Welding ConsumablesDocument19 pagesRationalise List Welding ConsumablesMayank SadaniNo ratings yet

- 1018 Mechanical PropertiesDocument2 pages1018 Mechanical PropertiesjangaswathiNo ratings yet

- Pn16 - FlangeDocument2 pagesPn16 - FlangeJebranNo ratings yet

- Fiberstrong Wavistrong: Flange GuideDocument1 pageFiberstrong Wavistrong: Flange Guidesiva8000No ratings yet

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- B Jack Nos For Cs Ss MaterialDocument12 pagesB Jack Nos For Cs Ss MaterialfahadfiazNo ratings yet

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- Brosur REVCO WPA GEAR REDUCER PDFDocument52 pagesBrosur REVCO WPA GEAR REDUCER PDFtisna drafterNo ratings yet

- Presentation Rekuluvo Counter-Flow Air Preheater Technologie" Gea-Ecoflex GMBH Dr.-Ing. Olivier BrasseurDocument29 pagesPresentation Rekuluvo Counter-Flow Air Preheater Technologie" Gea-Ecoflex GMBH Dr.-Ing. Olivier BrasseurdeepchotiNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- Ladder Rung Calc.Document1 pageLadder Rung Calc.Azwan ShahNo ratings yet

- 2 PN40 (WCB)Document2 pages2 PN40 (WCB)siddhesh_guessNo ratings yet

- Grating Weight - CalculationDocument1 pageGrating Weight - CalculationMuthuram NNo ratings yet

- Ewf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDocument1 pageEwf - Technical Sheet - Calculation of Preheat Temperature For Butt WeldsDries VandezandeNo ratings yet

- Knife Gate Valve - AVKCMSDocument2 pagesKnife Gate Valve - AVKCMSjuantamad02No ratings yet

- Din en 10216-2Document2 pagesDin en 10216-2vishal.nitham100% (1)

- Virgo Trunnion Ball ValveDocument16 pagesVirgo Trunnion Ball ValveKamalNo ratings yet

- ST 35.8 (Germany / DIN) : Material PropertiesDocument3 pagesST 35.8 (Germany / DIN) : Material Propertiesmohammad zareiNo ratings yet

- Manhole. API 650-2021Document3 pagesManhole. API 650-2021jose luisNo ratings yet

- B.W.G. Chart PDFDocument1 pageB.W.G. Chart PDFSaqib AliNo ratings yet

- Compresor EinhellDocument1 pageCompresor Einhellmih4iNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- WEP NormsDocument40 pagesWEP NormskumarNo ratings yet

- Atc Q-Bridge Thermal ConductorDocument4 pagesAtc Q-Bridge Thermal ConductorwjsynNo ratings yet

- Accessories AV-ACCS ENDocument16 pagesAccessories AV-ACCS ENTeressia SilalahiNo ratings yet

- Technical Datasheet Gearbox Triple Offset Butterfly ValveDocument6 pagesTechnical Datasheet Gearbox Triple Offset Butterfly ValveBenny 37No ratings yet

- Sub-D Feedthroughs: Three Versions For Different Technical RequirementsDocument2 pagesSub-D Feedthroughs: Three Versions For Different Technical RequirementsDeaNo ratings yet

- Ok Tubrod 14.30a PDFDocument1 pageOk Tubrod 14.30a PDFqaNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument2 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 78D05A UnisonicTechnologiesDocument10 pages78D05A UnisonicTechnologieshermesHEDNo ratings yet

- 250 Tab-In TypeDocument1 page250 Tab-In TypeNgoc NguyenNo ratings yet

- Dss Booklet PDFDocument63 pagesDss Booklet PDFInaamNo ratings yet

- 01-Samss-016, 11.05.2018Document16 pages01-Samss-016, 11.05.2018Rami ELLOUMINo ratings yet

- Calibration of InstrumentsDocument163 pagesCalibration of InstrumentsKiran NikateNo ratings yet

- Saes-A-206 DT 09 April 2020Document18 pagesSaes-A-206 DT 09 April 2020Kiran NikateNo ratings yet

- 04 Samss 035 PDFDocument19 pages04 Samss 035 PDFnadeem shaikhNo ratings yet

- Reportslist Aspx?mpgid 24Document126 pagesReportslist Aspx?mpgid 24Kiran NikateNo ratings yet

- US Market CrashesDocument14 pagesUS Market Crashesjohn2ma2No ratings yet

- Position Size by Trading LabDocument2 pagesPosition Size by Trading LabKiran NikateNo ratings yet

- ASNT Ultra Sonic TestingDocument98 pagesASNT Ultra Sonic TestingKiran NikateNo ratings yet

- Granger StockmarketDocument11 pagesGranger StockmarketHadis BajricNo ratings yet

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Philip - Fisher - Checklist For Stock SelectionDocument3 pagesPhilip - Fisher - Checklist For Stock SelectionKiran NikateNo ratings yet

- Ongc WPS 1 of 2Document4 pagesOngc WPS 1 of 2Kiran NikateNo ratings yet

- ISO Standards On Mech Test of MetalsDocument1 pageISO Standards On Mech Test of MetalsKiran NikateNo ratings yet

- ISO Standards On Mech Test of MetalsDocument4 pagesISO Standards On Mech Test of MetalsDaniel MoreNoNo ratings yet

- Autocad-Parametric DrawingDocument30 pagesAutocad-Parametric DrawingTiberiu ScarlatNo ratings yet

- Warren Buffett Way PDFDocument8 pagesWarren Buffett Way PDFIsrael ZepahuaNo ratings yet

- Udaykumar KamuniDocument3 pagesUdaykumar KamuniKiran NikateNo ratings yet

- Warren Buffett Way PDFDocument8 pagesWarren Buffett Way PDFIsrael ZepahuaNo ratings yet

- Is 2007 - 1974Document15 pagesIs 2007 - 1974Kiran NikateNo ratings yet

- Modify Objects 2011 AutocadDocument12 pagesModify Objects 2011 AutocadTiberiu ScarlatNo ratings yet

- Fiber OpticsDocument24 pagesFiber OpticsKiran NikateNo ratings yet