Professional Documents

Culture Documents

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S Gouda0 ratings0% found this document useful (0 votes)

6 views2 pagesOriginal Title

PP02lxls.

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S GoudaCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

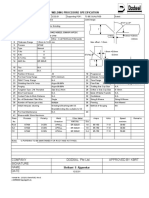

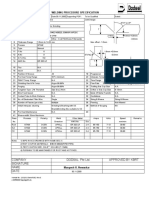

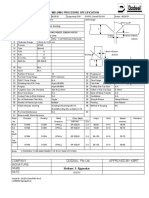

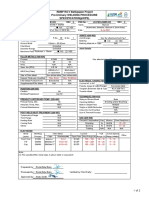

Dodsal Pte Ltd

Q-Chem Ethylene Project

Doha, Qatar

Job No : 7979 WELDING PROCEDURE SPECIFICATION

1 7979/WPS/PP/02 Rev.1 Date:14.05.01 Supporting PQR : DOD/PQR/0101-5 Rev.0 Dated : Sept 01.96

2 Joint Design Single V Groove Joint Design

3 Backing None 37.5° ± 2.5°

4 Joint Prep. Machining and Grinding

5 Base Metal Spec. P1.GRP.1 P1.GRP.2, S.1,GRP.1 T

6 Base Metal A106 GR. B, A234WPB, A672 Gr.C65, A105

2-4mm 1.6mm +0.8mm

7 Pipe Dia >2"NB Others: O-Lets/All Fillets -0.0mm

8 Thickness Range 4.76 to 19.05mm

9 Process SMAW SMAW

10 Type Manual Manual

11 F.No 3 4 1.6mm +0.8mm

12 A.No 1 1 37.5°±2.5° -0.0mm

13 S.F.A No. 5.1 5.1

14 AWS No. E6010 E7018 T 2-4mm

T

15 Flux N.A. N.A.

16 Insert N.A. N.A. Max. mis-alignment as per PFI.

17 Position Of Groove ALL 18 Progression vertical Uphill

19 Pre Heat Temp Range N.A. 20 Interpass Temp. 250°C Max.

21 PWHT Temp. Range N.A. 22 Time Range N.A.

23 Shielding Gas & % Comp N.A. 24 Flow Rate N.A.

25 Purging N.A. 26 Trailling Gas Cup Size N.A.

27 Tungsten Type N.A. 28 Orifice or Gas Cup Size N.A.

29 Wire Feed Speed N.A. 30 Mode Of Metal Transfer N.A.

31 Contact Tube to Work Distance N.A. 32 Oscillations N.A.

33 No. of Electrodes/ Filler Wire Single 34 String & Weave String & Weave

35 Number of Passes (per side) Multiple 36 Peening Not Allowed

37 Initial/ interpass cleaning Grinding/ Brushing 38 Method of Gouging N.A.

39 Pre Heat Maintenance N.A. 40 Electrode storage and baking as per manufactures

41 Weave width not to exceed 3X electrode Dia. Instructions.

Pass Process Polarity Weld Filler Metal Amps Volts Speed

No. Direction AWS No. Dia mm/min

Root SMAW DCEP UPHILL E6010 3.2 75-120 21-26 60-110

Hot SMAW DCEP UPHILL E 7018 2.5 70-110 21-26 50-100

Fill

3.2/

(Multi

4.0

) SMAW DCEP UPHILL E 7018 110-180 21-28 80-120

Cap

3.2/

(Multi

2.5

) SMAW DCEP UPHILL E 7018 70-140 21-28 50-110

Notes :1. WPS to be used for pipe supports/insert plates and lugs for concrete work and miscellaneous structural steel works.

COMPANY DODSAL Pte Ltd. APPROVED BY KBRT

SIGNATURE

NAME A. Shrikant

DATE 14.05.01

Format No : DOD/Q-Chem/F082 Rev 0

c:\DIR00001\wps\pp02

d : Sept 01.96

37.5° ± 2.5°

1.6mm +0.8mm

-0.0mm

per manufactures

Remarks

OVED BY KBRT

You might also like

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Structural Beam ComputationsDocument12 pagesStructural Beam ComputationsJustine LedesmaNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Pipe and fittings document layout guideDocument28 pagesPipe and fittings document layout guidemhreteabNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Harga Sistem Mekanikal (2018) PDFDocument94 pagesHarga Sistem Mekanikal (2018) PDFNisa Najwa76% (33)

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- SAE Steel Grades - WikipediaDocument12 pagesSAE Steel Grades - WikipediaprabuNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Production of Synthetic Natural GasDocument21 pagesProduction of Synthetic Natural GasMạnh BùiNo ratings yet

- Industrial Arts 6: Week 1Document9 pagesIndustrial Arts 6: Week 1arielle domingoNo ratings yet

- Analysis of Geopolymer Concrete ColumnsDocument10 pagesAnalysis of Geopolymer Concrete ColumnsRodick AndyNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ferrite Measurement PDFDocument2 pagesFerrite Measurement PDFESWARANM91No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project Welding Procedure SpecificationDocument1 pageEthylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project GTAW Welding Procedure QatarDocument1 pageEthylene Project GTAW Welding Procedure QatarS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project Fillet Weld PQRDocument1 pageEthylene Project Fillet Weld PQRS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS Ethylene Project QatarDocument1 pageWPS Ethylene Project QatarS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Ethylene Project Welding Procedure SpecificationDocument1 pageEthylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Q-Chem Ethylene Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Engineering Properties AggregatesDocument4 pagesEngineering Properties AggregatessuryakantameNo ratings yet

- Aleación Aluminio SilicioDocument7 pagesAleación Aluminio SilicioEmanuelRomeroGNo ratings yet

- Effect of DMPA & MW of Polyurethane DispersionDocument15 pagesEffect of DMPA & MW of Polyurethane Dispersionichsan hakimNo ratings yet

- Basic Materials, Tools and Processes For Arts and Design FormDocument85 pagesBasic Materials, Tools and Processes For Arts and Design FormHanna Clarisse BangayanNo ratings yet

- Estimate PlasteringDocument11 pagesEstimate PlasteringJohnNo ratings yet

- MP 25 PDFDocument8 pagesMP 25 PDFAshraf TomizehNo ratings yet

- Appropriate Building Technology Lecture 4Document19 pagesAppropriate Building Technology Lecture 4Nahum HabtamuNo ratings yet

- STYLE 4400 / 4000 / 4100 SPECIFICATIONS: With Dow EcolibriumDocument4 pagesSTYLE 4400 / 4000 / 4100 SPECIFICATIONS: With Dow EcolibriumEfrain LangaricaNo ratings yet

- Chemical CompoundsDocument17 pagesChemical CompoundsKalu ChouhanNo ratings yet

- Aws American Welding Society ﺎﻜﯾﺮﻣآ شﻮﺟ ﻦﻤﺠﻧا دراﺪﻧﺎﺘﺳا: Pdf Created With Pdffactory Pro Trial VersionDocument33 pagesAws American Welding Society ﺎﻜﯾﺮﻣآ شﻮﺟ ﻦﻤﺠﻧا دراﺪﻧﺎﺘﺳا: Pdf Created With Pdffactory Pro Trial VersionAli SASSINo ratings yet

- Some Important Prestressed Silos and Reservoirs in ScandinaviaDocument17 pagesSome Important Prestressed Silos and Reservoirs in ScandinaviaRolando RojasNo ratings yet

- 29-01-2022 Saleesh Nattika-1Document10 pages29-01-2022 Saleesh Nattika-1Nidhin PDNo ratings yet

- Jun 12Document20 pagesJun 12phin easNo ratings yet

- Chemistry 100 Questions EM FinalDocument4 pagesChemistry 100 Questions EM FinalJUDE GamingNo ratings yet

- FMDS0830Document9 pagesFMDS0830hh0% (1)

- Documents - Pub - Keeping The Resistance in Basf Dispersions Pigments Solutions and High QualityDocument24 pagesDocuments - Pub - Keeping The Resistance in Basf Dispersions Pigments Solutions and High QualityLong An ĐỗNo ratings yet

- T Mech Clamp CatalogueDocument29 pagesT Mech Clamp CatalogueKABIR CHOPRANo ratings yet

- 18 - 2017 - Covering Material PDFDocument4 pages18 - 2017 - Covering Material PDFvjdj100% (1)

- Rosner DuoCryl Profi ENDocument2 pagesRosner DuoCryl Profi ENKhushal JangidNo ratings yet

- Suzuka Thailand Trowel StoneDocument7 pagesSuzuka Thailand Trowel StoneDear SelfNo ratings yet

- 0620 w17 QP 22 PDFDocument16 pages0620 w17 QP 22 PDFyuke kristinaNo ratings yet

- Separation and Purification of Organic Compounds-DistillationDocument17 pagesSeparation and Purification of Organic Compounds-DistillationMarie Maraniag100% (1)