Professional Documents

Culture Documents

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S Gouda0 ratings0% found this document useful (0 votes)

13 views1 pageOriginal Title

PP29

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S GoudaCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

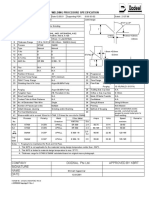

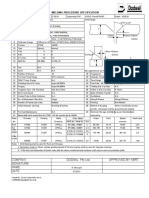

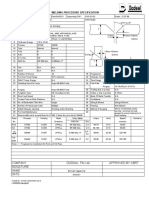

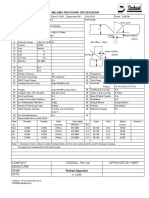

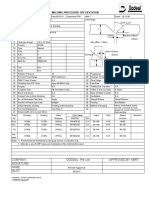

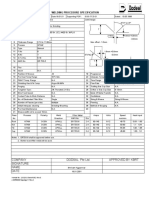

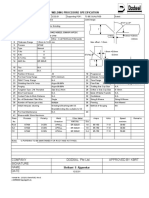

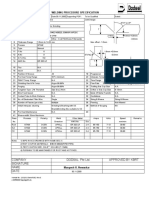

Dodsal Pte Ltd

Q-Chem Ethylene Project

Doha, Qatar

Job No : 7979/G2/010 WELDING PROCEDURE SPECIFICATION

1 7979/WPS/PP/29 Rev.2 Date:06.06.01 Supporting PQR : DOD/Q-Chem/PQR-010 Dated : 26.05.01

2 Joint Design Refer Attachment Joint Design

3 Backing None

4 Joint Prep. Machining and/or Grinding

5 Base Metal Spec. 5BGr.2 to P4

A335 Gr.P91, A182F91, A234WP91, A335P11,

6 Base Metal A234Gr.WP11, A182Gr.F11-CL1,2,3, A387-11-CL1,2 Refer Attachement

7 Pipe Dia Range >2"NB

8 Thickness Range 4.76mm to 25.4mm

9 Process GTAW SMAW

10 Type Manual Manual

11 F.No 6 4

12 A.No 5 5

13 S.F.A No. 5.28 5.5

14 AWS No. ER90S-B9 E 9015-B9

15 Flux N.A. N.A.

16 Insert N.A. N.A.

17 Position Of Groove All 18 Progression Vertical Uphill

19 Pre Heat Temp Range 177°C Minimum 20 Interpass Temp. 300°C Maximum

21 PWHT Temp. Range 732 - 746°C 22 Time Range 2.4 min/mm (4 hrs minimum)

23 Shielding Gas & % Comp Argon 99.99% purity 24 Flow Rate Shielding 20-35 CFH

Purging 20-35 CFH

25 Purging Argon 99.99% purity 26 Trailling Gas Cup Size N.A.

27 Tungsten Type : 2% Thoriated 2% Thoriated 2.4 dia. 28 Orifice or Gas Cup Size 8-13mm

29 Wire Feed Speed N.A. 30 Mode Of Metal Transfer N.A.

31 Contact Tube to Work Distance N.A. 32 Oscillations N.A.

33 No. of Electrodes/ Filler Wire Single 34 String & Weave String & Weave

35 Number of Passes (per side) Multiple 36 Peening Not Allowed

37 Initial/ interpass cleaning Grinding and or Brushing 38 Method of Gouging

where unrestricted access

permits ,root shall be back

39 Pre Heat Maintenance Yes gouged to sound metal prior to

back welding.

41 Weave width not to exceed 10mm for GTAW & 3X the core dia. for SMAW

Pass Process Polarity Weld Filler Metal Amps Volts Speed Remarks

No. Direction AWS No. Dia mm/min

Root GTAW DCEN UPHILL ER90S-B9 2.4 75-105 10-14 40-65

Hot GTAW DCEN UPHILL ER90S-B9 2.4 100-125 10-14 60-80

Fill 2.5 /

(multi) SMAW DCEP UPHILL E9015-B9 110-135 20-28 70-105

3.2

Cap 2.5 /

(multi) SMAW DCEP UPHILL E9015-B9 80-105 20-28 70-105

3.2

Notes 1. Purging to be maintained for root and hot pass.

2. Bohler brand filler metal will be used on production welds.

COMPANY DODSAL Pte Ltd. APPROVED BY KBRT

SIGNATURE

NAME MANGESH H. NEWASKAR

DATE 06.06.2001

Format No : DOD/Q-Chem/F082 Rev 0

c:\DIR00001\wps\PP29Rev2.xls

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project Welding Procedure SpecificationDocument1 pageEthylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Q-Chem Ethylene Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Welding Procedure SpecificationS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project GTAW Welding Procedure QatarDocument1 pageEthylene Project GTAW Welding Procedure QatarS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS Ethylene Project QatarDocument1 pageWPS Ethylene Project QatarS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project Fillet Weld PQRDocument1 pageEthylene Project Fillet Weld PQRS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTDocument1 pageWELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTAhmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Ethylene Project Welding Procedure SpecificationDocument1 pageEthylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- In Millions USD: Balance Sheet 2020 2021 2022Document4 pagesIn Millions USD: Balance Sheet 2020 2021 2022Trần Ngọc Quỳnh ChiNo ratings yet

- 10 Steps To Dream Building: - A Publication of Center My CenterDocument19 pages10 Steps To Dream Building: - A Publication of Center My CenterRamalakshmi100% (2)

- Facilitate Training Session Powerpoint PresentationDocument16 pagesFacilitate Training Session Powerpoint Presentationscribdhie100% (2)

- The Bank and The Mundhra AffairDocument14 pagesThe Bank and The Mundhra AffairAmbika MehrotraNo ratings yet

- Abdulbasit MohammedDocument170 pagesAbdulbasit MohammedGooftilaaAniJiraachuunkooYesusiinNo ratings yet

- Cis Bin Haider GRP LTD - HSBC BankDocument5 pagesCis Bin Haider GRP LTD - HSBC BankEllerNo ratings yet

- Ir 2101Document14 pagesIr 2101Willard DmpseyNo ratings yet

- Response of Hollow-Core Slab Floors To Concentrated LoadsDocument16 pagesResponse of Hollow-Core Slab Floors To Concentrated LoadsJuan Carlos GonzálezNo ratings yet

- A Study On Consumer Changing Buying Behaviour From Gold Jewellery To Diamond JewelleryDocument9 pagesA Study On Consumer Changing Buying Behaviour From Gold Jewellery To Diamond JewellerynehaNo ratings yet

- Manual Micro DNC 2dDocument31 pagesManual Micro DNC 2dDiego GarciaNo ratings yet

- Benetton CaseDocument23 pagesBenetton CaseNnifer AnefiNo ratings yet

- Plastic PackagingDocument47 pagesPlastic PackagingRajaSekarsajja100% (1)

- Describe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementDocument3 pagesDescribe The Financial and Non-Financial Benefits of Strategic Management 4.1 Financial Benefits of Strategic ManagementAlemayehu Demeke80% (5)

- What is Cultural Heritage and Why it's ImportantDocument3 pagesWhat is Cultural Heritage and Why it's ImportantMiguel A. González LópezNo ratings yet

- Bank Account Details and Contact NumbersDocument38 pagesBank Account Details and Contact NumbersD-Blitz StudioNo ratings yet

- Mil STD 1686CDocument18 pagesMil STD 1686CNam NguyenNo ratings yet

- Pangilinan, Zobel de Ayala, Sy Sr., Dangote, Rupert, Jameel - Power and influence of business leaders in Asia and AfricaDocument20 pagesPangilinan, Zobel de Ayala, Sy Sr., Dangote, Rupert, Jameel - Power and influence of business leaders in Asia and AfricaGwenNo ratings yet

- The Beatles Album Back CoverDocument1 pageThe Beatles Album Back CoverSophia AvraamNo ratings yet

- Metsec Purlin Technical ManualDocument88 pagesMetsec Purlin Technical ManualAnbalaganV100% (2)

- CIVL 222 AXIAL MEMBERSDocument27 pagesCIVL 222 AXIAL MEMBERSskhan247100% (1)

- NTPC Limited: (A Government of India Enterprise)Document7 pagesNTPC Limited: (A Government of India Enterprise)Yogesh PandeyNo ratings yet

- DP8 Series Manual - English PDFDocument48 pagesDP8 Series Manual - English PDFluis enrique de la rosa sanchezNo ratings yet

- Agni Free PDF - 2 For Sbi Clerk Mains 2024Document18 pagesAgni Free PDF - 2 For Sbi Clerk Mains 2024supriyo248650No ratings yet

- Hydrogen Plant For The New MillenniumDocument21 pagesHydrogen Plant For The New Millenniumapi-3799861100% (2)

- AfghanistanLML OnlinDocument117 pagesAfghanistanLML Onlinعارف حسینNo ratings yet

- Lorenzo Tan National High School 2018-2019 Federated Parent Teacher Association Officers and Board of DirectorsDocument4 pagesLorenzo Tan National High School 2018-2019 Federated Parent Teacher Association Officers and Board of DirectorsWilliam Vincent SoriaNo ratings yet

- Osha CFR 1910Document16 pagesOsha CFR 1910CI Amilcar100% (3)

- Penetron Admix FlyerDocument2 pagesPenetron Admix Flyernght7942No ratings yet

- Dee ChuanDocument4 pagesDee ChuanBurn-Cindy AbadNo ratings yet