Professional Documents

Culture Documents

Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S Gouda0 ratings0% found this document useful (0 votes)

15 views1 pageThis welding procedure specification is for a single V-groove joint with backing for piping made of P45 Alloy 20. The joint will be prepared by machining or grinding. Gas tungsten arc welding will be used with argon shielding gas in the manual mode for an uphill progression. Multiple passes will be done with initial cleaning by grinding and brushing and interpass cleaning of grinding and brushing with a stainless steel brush.

Original Description:

Original Title

PP15rev2

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis welding procedure specification is for a single V-groove joint with backing for piping made of P45 Alloy 20. The joint will be prepared by machining or grinding. Gas tungsten arc welding will be used with argon shielding gas in the manual mode for an uphill progression. Multiple passes will be done with initial cleaning by grinding and brushing and interpass cleaning of grinding and brushing with a stainless steel brush.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Date

Uploaded by

S GoudaThis welding procedure specification is for a single V-groove joint with backing for piping made of P45 Alloy 20. The joint will be prepared by machining or grinding. Gas tungsten arc welding will be used with argon shielding gas in the manual mode for an uphill progression. Multiple passes will be done with initial cleaning by grinding and brushing and interpass cleaning of grinding and brushing with a stainless steel brush.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

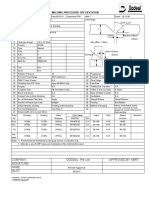

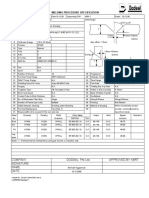

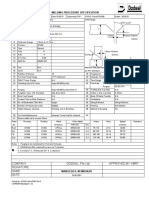

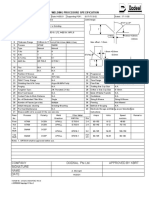

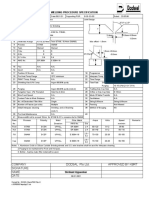

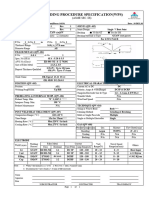

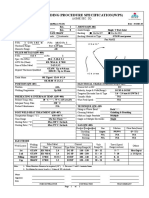

Dodsal Pte Ltd

Q-Chem Ethylene Project

Doha, Qatar

Job No : 7979/G2/010 WELDING PROCEDURE SPECIFICATION

1 7979/WPS/PP/15 Rev.3 12.02.01 Supporting PQR : TO BE QUALIFIED Dated :

2 Joint Design Single "V" Groove Joint Design

3 Backing None 37.5° ± 2.5°

4 Joint Prep. Machining and/or Grinding

5 Base Metal Spec. P45 Alloy 20 T

6 Base Metal B464 N08020, B462 N08020, B366GR.WP20C

B366 GR.WP20 CRW 2-4mm 1.6mm +0.8mm

7 Pipe Dia Range All Other : O-LETS/All size Fillet welds -0.0mm

8 Thickness Range 1.6mm to 14.22 mm Max offset - 1.6mm

9 Process GTAW

10 Type Manual

11 F.No 45 1.6mm +0.8mm

12 A.No 9 37.5°±2.5° -0.0mm

13 S.F.A No. 5.14

14 AWS No. ER NiFeCr-1 T 2-4mm

T

15 Flux N.A.

16 Insert N.A.

17 Position Of Groove All 18 Progression Uphill

19 Pre Heat Temp Range 10°C minimum 20 Interpass Temp. 150°C Max.

21 PWHT Temp. Range N.A. 22 Time Range N.A.

23 Shielding Gas & % Comp Argon 99.99% 24 Flow Rate Shielding 8-12 L/min Purging 10-20LPM

25 Purging Argon 99.99% 26 Trailling Gas Cup Size N.A.

27 Tungsten Type : 2% Thoriated Size Dia 2.4mm 28 Orifice or Gas Cup Size 8-13mm

29 Wire Feed Speed N.A. 30 Mode Of Metal Transfer N.A.

31 Contact Tube to Work Distance N.A. 32 Oscillations N.A.

33 No. of Electrodes/ Filler Wire Single 34 String & Weave String & Weave

35 Number of Passes (per side) Multiple 36 Peening Not Allowed

37 Initial/ interpass cleaning Grinding & Brushing with SS 38 Method of Gouging NA

Brush&Grinding Disc suitable to SS

39 Pre Heat Maintenance N.A. 40

41 Weave width 10mm Maximum.

Pass Process Polarity Weld Filler Metal Amps Volts Speed Remarks

No. Direction AWS No. Dia mm/min

Root GTAW DCEN UPHILL ER 320LR 1.6 85-150 7-13 30-80

Hot GTAW DCEN UPHILL ER 320LR 1.6 85-150 7-13 30-80

F/C GTAW DCEN UPHILL ER 320LR 2.4 85-150 7-13 50-80

Notes 1) PURGING TO BE MAINTAINED FOR ROOT AND HOT PASS.

COMPANY DODSAL Pte Ltd. APPROVED BY KBRT

SIGNATURE

NAME Shrikant S Ajgaonkar

DATE 12.02.01

Format No : DOD/Q-Chem/F082 Rev 0

c:\DIR00001\wps\pp03.xls

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project GTAW Welding Procedure QatarDocument1 pageEthylene Project GTAW Welding Procedure QatarS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS Ethylene Project QatarDocument1 pageWPS Ethylene Project QatarS GoudaNo ratings yet

- Q-Chem Ethylene Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project Welding Procedure SpecificationDocument1 pageEthylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP41 Rev.3Document1 pagePP41 Rev.3Ashish ChackoNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project Fillet Weld PQRDocument1 pageEthylene Project Fillet Weld PQRS GoudaNo ratings yet

- Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06Document1 pageFormat No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp06S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- WPS & PQR VVSPLDocument3 pagesWPS & PQR VVSPLBhargav BbvsNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- PRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWDocument8 pagesPRELIMINARY WELDING PROCEDURE AND QUALIFICATION FOR GTAWmegantara maromNo ratings yet

- Ethylene Project Welding Procedure SpecificationDocument1 pageEthylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Q-Chem Ethylene Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Tube To Tube Sheet Mock UpDocument5 pagesTube To Tube Sheet Mock UpKushalNo ratings yet

- Section VIII Div. 1 - UG-119 PDFDocument1 pageSection VIII Div. 1 - UG-119 PDFEsapermana RiyanNo ratings yet

- GratingsDocument3 pagesGratingssaurabhsubhuNo ratings yet

- A 1018 - A 1018M - 02 QtewmtgtmdiDocument5 pagesA 1018 - A 1018M - 02 QtewmtgtmdiGsuslionelNo ratings yet

- Industrial Training Report ContentsDocument32 pagesIndustrial Training Report ContentsArtur SilvaNo ratings yet

- Structural Steel Plate and Strip To EN 10025Document4 pagesStructural Steel Plate and Strip To EN 10025Ibrahim BashaNo ratings yet

- ASNT Level II Study Guide PTDocument114 pagesASNT Level II Study Guide PTNitesh Srivastava100% (2)

- Noss Matrix: H-024-1 Jurukimpal Arka Logam BerperisaiDocument4 pagesNoss Matrix: H-024-1 Jurukimpal Arka Logam BerperisaiNorazzah AbdullahNo ratings yet

- SMAW 9 - Q1 - W2 - Mod2Document29 pagesSMAW 9 - Q1 - W2 - Mod2Romeo Dela RosaNo ratings yet

- L 08092 9Document5 pagesL 08092 9DmitryNo ratings yet

- Automotive Tools and EquipmentDocument24 pagesAutomotive Tools and EquipmentRaymund DowasoNo ratings yet

- 2 Bulk Deformation ProcessesDocument67 pages2 Bulk Deformation ProcessesAsadNo ratings yet

- 4 Growth & DevelopmentDocument7 pages4 Growth & Developmentphoenix eastwoodNo ratings yet

- A866Document4 pagesA866Deepak JNo ratings yet

- Vacuum-Treated Carbon and Alloy Steel Forgings For Turbine Rotors and ShaftsDocument8 pagesVacuum-Treated Carbon and Alloy Steel Forgings For Turbine Rotors and ShaftsMahsaNo ratings yet

- Super Vulcaseal: General Purpose Polychloroprene-Based SealantDocument2 pagesSuper Vulcaseal: General Purpose Polychloroprene-Based SealantAdam Mark LegaspiNo ratings yet

- Inspection Certificate: (EN10204 3.1/ISO 10474 3.1)Document1 pageInspection Certificate: (EN10204 3.1/ISO 10474 3.1)Faishal Khairul UmamNo ratings yet

- DIN 17440 (2001) (Technical Delivery Condition For Stainless Steel Drawn Wire)Document12 pagesDIN 17440 (2001) (Technical Delivery Condition For Stainless Steel Drawn Wire)TomasB22No ratings yet

- Vessel Sample External Inspection ReportDocument3 pagesVessel Sample External Inspection ReportabdellahNo ratings yet

- Table Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Document1 pageTable Pw-39 Mandatory Requirements For Postweld Heat Treatment of Pressure Parts and Attachments (Conrd)Panchal ShaileshNo ratings yet

- Waste Water Treatment ProcessDocument4 pagesWaste Water Treatment ProcessDengAwutNo ratings yet

- Dissimilar WeldingDocument24 pagesDissimilar WeldingVishnupriya SunilNo ratings yet

- Standard Test Methods For Bend Testing of Material For Ductility PDFDocument12 pagesStandard Test Methods For Bend Testing of Material For Ductility PDFJuan VanegasNo ratings yet

- Agglomeration of Iron OresDocument41 pagesAgglomeration of Iron OresAnonymous NxpnI6jC100% (1)

- Melina S 30Document2 pagesMelina S 30HydbbNo ratings yet

- A Presentation On "3D Printing Technology"Document22 pagesA Presentation On "3D Printing Technology"YOUNES KABBAJ0% (1)

- Transistor - Substitutions 2023Document80 pagesTransistor - Substitutions 2023senthilnathan srinivasanNo ratings yet

- Liner - QuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service ManualDocument4 pagesLiner - QuickServe Online - (4021528) GTA38, K38, K50, QSK38, and QSK50 Service ManualAvir YadavNo ratings yet

- MIG Welding MachineDocument7 pagesMIG Welding MachineSAATISH0% (1)

- Manufacturing ScienceDocument89 pagesManufacturing ScienceVokNo ratings yet