Professional Documents

Culture Documents

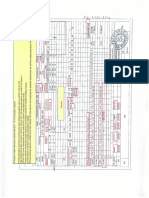

WELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENT

Uploaded by

Ahmed Lepda0 ratings0% found this document useful (0 votes)

337 views1 pageThis document provides a welding procedure specification for gas tungsten arc welding and shielded metal arc welding of single V butt joints for normal carbon steel pipes with wall thicknesses between 19-61.9 mm for the South Pars Gas Field Development project. Key details include the base and filler metals, preheat and interpass temperature ranges, welding positions, parameters for each weld layer, and shielding gas composition and flow rates. Post weld heat treatment is also specified to relieve residual stresses.

Original Description:

Original Title

WPS-ASME-005rev0

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a welding procedure specification for gas tungsten arc welding and shielded metal arc welding of single V butt joints for normal carbon steel pipes with wall thicknesses between 19-61.9 mm for the South Pars Gas Field Development project. Key details include the base and filler metals, preheat and interpass temperature ranges, welding positions, parameters for each weld layer, and shielding gas composition and flow rates. Post weld heat treatment is also specified to relieve residual stresses.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

337 views1 pageWELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENT

Uploaded by

Ahmed LepdaThis document provides a welding procedure specification for gas tungsten arc welding and shielded metal arc welding of single V butt joints for normal carbon steel pipes with wall thicknesses between 19-61.9 mm for the South Pars Gas Field Development project. Key details include the base and filler metals, preheat and interpass temperature ranges, welding positions, parameters for each weld layer, and shielding gas composition and flow rates. Post weld heat treatment is also specified to relieve residual stresses.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

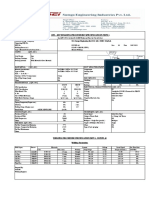

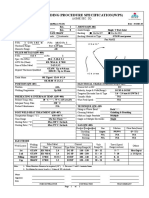

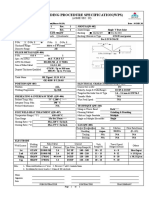

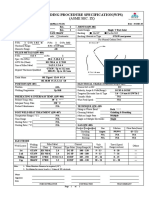

WELDING PROCEDURE SPECIFICATION(WPS)

(ASME SEC. IX)

Project : South Pars Gas Field Development(Phases 9&10) Date : 28 DEC,05

WPS No. CON-WPS-ASME-005 Rev. 0 JOINTS (QW-402)

PQR No. CON-PQR-ASME-006 Rev. 0 Joints Design Single V Butt Joint

Welding Process GTAW-SMAW Backing ■ No for GT ■ Yes for SM

Types Manual □ Semi-Automatic □ Automatic Backing Material or Type GTAW root passes

BASE METALS (QW-403) For Normal Carbon+NACE,Normal Carbon Steel

P-No. 1 G-No. 1&2 to P-No. 1 G-No. 1&2

Thickness Range 19 ≤ t ≤ 61.9 mm

Diameter Range All

FILLER METALS (QW-404)

F-No. 6&4 A-No. 1

Spec. No.(SFA) SFA : 5.18 & 5.1

AWS No.(Class) ER-70S-6 & E 7018

Size of Filler Metal 2.4, 3.2 ,4.0

GTAW: Up to 9.0 mm

Deposit Thickness Qualified

SMAW: Up to 52.9 mm

Trade Name OK Tigrod 12.64 Ø 2.4

OK 48.00 Ø 3.2&4.0

POSITION (QW-405) ELECTRICAL CHARACTERISTICS (QW-409)

Position ALL Current AC or DC DC

Welding Progression Up Hill Polarity, Amps & Volts(Range) DCSP & DCRP

Tungsten Electrode Size & Type 1.6 ~ 2.4 mm & EWTh-2

PREHEATING & INTERPASS TEMP. (QW-406) Transfer Mode N/A

Preheat Temp. Min. 75 º C or 100 º C Note(1) Wire Feed Speed N/A

Interpass Temp. Max. 250 º C

Preheat Maintenance N/A TECHNIQUE (QW-410)

String or Weave Bead Both(Note 3)

POST WELD HEAT TREATMENT (QW-407) Cleaning Method Grinding & Brushing

Temperature Range ( º C ) 610 ±10 °C Multi or Single Pass Multiple

Time Range 1/hr for 25mmNote(2) Single or Multiple Electrodes Single

Heating Rate ( º C ) Max.220˚C / hr/inch

Cooling Rate ( º C ) Max.275˚C / hr/inch GAS (QW-408)

Percent Composition Gas Mixture Flow Rate(l/min)

Shielding Argon 99.99% (9 ~12 )

Trailing N/A N/A N/A

Backing N/A N/A N/A

ELECTRODE

Welding Filler Metal Current Volt Travel Speed

Weld Layers Others

Process Class Dia(mm) Type Polar. Amp Range(A) Range(V) Range(cm/min)

1st GTAW ER 70S-6 2.4 DC SP 130 ~ 170 10 ~ 13 6~9 Heat Input

2 nd GTAW ER 70S-6 2.4 DC SP 180 ~ 230 10 ~ 15 8~ 13 ≥ 13 Kj/Cm

Filling SMAW E7018 3.2&4.0 DCRP 110 ~ 190 21 ~ 24 6 ~ 10

Cap SMAW E7018 3.2 DCRP 120 ~ 140 23 ~ 25 9 ~ 13

Note : 1- Above 25mm thickness of material 2- For over 1" add 2.4 minute/1mm

3- Oscillation for weave bead is < 3 time of OD electrode

Name

Signature

Date

SUBCONTRACTOR CONTRACTOR TPA/COMPANY

Page 1 of 1

You might also like

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocument1 pagePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- Asme Ix - WPS - Gtaw Fcaw Gmaw PDFDocument1 pageAsme Ix - WPS - Gtaw Fcaw Gmaw PDFThe Welding Inspections CommunityNo ratings yet

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocument2 pagesWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Sabari Engineering PQRDocument3 pagesSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Agoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Document3 pagesAgoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Anonymous 7vljJzHNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928Document2 pagesWELDING PROCEDURE SPECIFICATION FOR GTAW+FCAW+GTAW-SA928duyanhNo ratings yet

- Toshiba Brazing Procedure SpecificationDocument3 pagesToshiba Brazing Procedure Specificationsheikmoin100% (1)

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationGodwin A.udo-akanNo ratings yet

- Welder qualification test recordDocument3 pagesWelder qualification test recordTuTuy AnNo ratings yet

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS for Gas Field Development WeldingDocument2 pagesWPS for Gas Field Development WeldingAhmed LepdaNo ratings yet

- NDT Salary Survey 2018 Highlights Continued GrowthDocument27 pagesNDT Salary Survey 2018 Highlights Continued GrowthAhmed LepdaNo ratings yet

- 1 Updated 2159 MergedDocument2 pages1 Updated 2159 MergedAhmed LepdaNo ratings yet

- 5187901TechArticleWebDocLR PDFDocument7 pages5187901TechArticleWebDocLR PDFoggay94No ratings yet

- 6.5. Bolt Installation: 5.1. What Can Be Done To Prevent The Nut From Loosening?Document3 pages6.5. Bolt Installation: 5.1. What Can Be Done To Prevent The Nut From Loosening?Ahmed LepdaNo ratings yet

- 8 FFDDocument129 pages8 FFDAhmed LepdaNo ratings yet

- A Manual For Steel Detailers, Engineers & Fabricators, Containing Working Drawings & Details For Hot-Dip Galvanized StructuresDocument24 pagesA Manual For Steel Detailers, Engineers & Fabricators, Containing Working Drawings & Details For Hot-Dip Galvanized StructuresHowo4DieNo ratings yet

- Perforated Expanded Catalog NewDocument16 pagesPerforated Expanded Catalog NewAhmed LepdaNo ratings yet

- Simultaneous Operations (SIMOPS)Document156 pagesSimultaneous Operations (SIMOPS)Ahmed Lepda100% (3)

- What Every Engineer Should Know AboutDocument217 pagesWhat Every Engineer Should Know AboutGurpreet Singh DhunnaNo ratings yet

- Cafco Fendolite Mii Application Guidelines PDFDocument23 pagesCafco Fendolite Mii Application Guidelines PDFTanmay GorNo ratings yet

- Structural ShapesDocument21 pagesStructural ShapesjeefryNo ratings yet

- Animal Signal Sheet PDFDocument2 pagesAnimal Signal Sheet PDF유웃No ratings yet

- Cafco Fendolite Mii - Data Sheet - LRDocument3 pagesCafco Fendolite Mii - Data Sheet - LRMohammed Ahtesham100% (1)

- Cafco ® Fendolite Mii: Application GuideDocument27 pagesCafco ® Fendolite Mii: Application GuideAhmed LepdaNo ratings yet

- 24 Sample ChapterDocument14 pages24 Sample ChapterRomyMohanNo ratings yet

- Astm A 153 PDFDocument4 pagesAstm A 153 PDFmahmoud hegazy100% (5)

- Cafco Fendolite Mii - Data Sheet - LRDocument3 pagesCafco Fendolite Mii - Data Sheet - LRMohammed Ahtesham100% (1)

- 24 Sample ChapterDocument14 pages24 Sample ChapterRomyMohanNo ratings yet

- Design and MaterialDocument40 pagesDesign and MaterialRavishankarNo ratings yet

- Parts of Speech Cheat Sheet: A, An, and The Are Articles That Precede Nouns. We Generally Classify Them As AdjectivesDocument2 pagesParts of Speech Cheat Sheet: A, An, and The Are Articles That Precede Nouns. We Generally Classify Them As AdjectivesMaria AndreeaNo ratings yet

- AISC - Bolts TCQ Up Side or DownDocument1 pageAISC - Bolts TCQ Up Side or DownAhmed LepdaNo ratings yet

- Steel WiseDocument5 pagesSteel WisepicottNo ratings yet

- Add To Favorites Contact Us SearchDocument4 pagesAdd To Favorites Contact Us SearchAhmed LepdaNo ratings yet

- MTC 17022021063931Document1 pageMTC 17022021063931Ahmed LepdaNo ratings yet

- Astm A 563 14pdf PDFDocument18 pagesAstm A 563 14pdf PDFSathish KumarNo ratings yet

- Addressing Anchors (Steelwise Article On Anchor Bolt Fixes)Document3 pagesAddressing Anchors (Steelwise Article On Anchor Bolt Fixes)Justin UyarNo ratings yet

- Carbon and Alloy Steel Nuts (Metric) : Standard Specification ForDocument9 pagesCarbon and Alloy Steel Nuts (Metric) : Standard Specification ForAhmed LepdaNo ratings yet

- A 325M - 03 PDFDocument7 pagesA 325M - 03 PDFsergioNo ratings yet

- English Math Revision KG1: Math Numbers & Shapes LinksDocument9 pagesEnglish Math Revision KG1: Math Numbers & Shapes LinksAhmed LepdaNo ratings yet

- Capacitors Discharge Stud SpecificationsDocument2 pagesCapacitors Discharge Stud SpecificationsNajib KiwanNo ratings yet

- ASME BPVC 2021 - Key Changes PresentationDocument68 pagesASME BPVC 2021 - Key Changes PresentationOmar Shahin100% (4)

- STR1 T080 8Document1 pageSTR1 T080 8Suntech Testing Limited STLNo ratings yet

- Butt Weld Tee Dimension - Penn MachineDocument1 pageButt Weld Tee Dimension - Penn MachineEHT pipeNo ratings yet

- ITP-40Document10 pagesITP-40Wijayanto BekasiNo ratings yet

- BOC185ACDC Manual v2Document32 pagesBOC185ACDC Manual v2beachboy12No ratings yet

- Manual de Servicio dv26Document505 pagesManual de Servicio dv26Servi PadNo ratings yet

- Code Requirements: Post Weld Heat Treatment: Asme Sec-Iii: Div.-1Document22 pagesCode Requirements: Post Weld Heat Treatment: Asme Sec-Iii: Div.-1Vinu RaveendranNo ratings yet

- RT Rejection Rate (Each Welder) : Period: ALLDocument6 pagesRT Rejection Rate (Each Welder) : Period: ALLspnx13No ratings yet

- CatalogDocument2 pagesCataloglangtu2011No ratings yet

- Dilution and Microsegregation in Dissimilar Metal Welds Between Super Austenitic Stainless Steel and Nickel Base AlloysDocument10 pagesDilution and Microsegregation in Dissimilar Metal Welds Between Super Austenitic Stainless Steel and Nickel Base AlloysPrasanth M CoolNo ratings yet

- (AWS A5.20 E71T-1) : Technical ReportDocument2 pages(AWS A5.20 E71T-1) : Technical ReportRyu RyuNo ratings yet

- Tüvis: AD 2000-MerkblattDocument10 pagesTüvis: AD 2000-MerkblattUfuk ÇİMENNo ratings yet

- Manual em Ingles e Bem Explicado Tig 200 AcdcDocument16 pagesManual em Ingles e Bem Explicado Tig 200 AcdcMarcelo CarnicelliNo ratings yet

- 2011 VND O&M ManualDocument12 pages2011 VND O&M Manualsequeira.cedric6742No ratings yet

- 370 PDFDocument78 pages370 PDFsipasit1518No ratings yet

- 2022-Post Railing Systems Typical Product CatalogueDocument51 pages2022-Post Railing Systems Typical Product CatalogueStructural TenderNo ratings yet

- CSWIP WIS 5 General Quiz: TWI Training & Examination ServicesDocument64 pagesCSWIP WIS 5 General Quiz: TWI Training & Examination Serviceshaoues23No ratings yet

- Variables de Sistema FANUCDocument770 pagesVariables de Sistema FANUCLakisha Blevins50% (4)

- Handicraft Macrame and Basketry CGDocument10 pagesHandicraft Macrame and Basketry CGjenemie betache0% (1)

- Sample Moldflow ReportDocument16 pagesSample Moldflow ReportmubarakNo ratings yet

- WORKSHOP LESSON Viva QuestionsDocument3 pagesWORKSHOP LESSON Viva QuestionsVenkateshYadavCivarlaNo ratings yet

- VLBS LOAD RING User InstructionsDocument3 pagesVLBS LOAD RING User InstructionsGianluca PiccinettiNo ratings yet

- ASTM G150 99 (04) Critical Pitting Temperature of SSDocument13 pagesASTM G150 99 (04) Critical Pitting Temperature of SSRifki RuriardiNo ratings yet

- Catalogo Placas Antidesgaste CDP PDFDocument12 pagesCatalogo Placas Antidesgaste CDP PDFoscarlopez12345No ratings yet

- QA&QC Earthing SystemDocument6 pagesQA&QC Earthing SystemMuhammadZahirKhanNo ratings yet

- Pc228us Uslc-3#30001 Sebm030501 U0303Document579 pagesPc228us Uslc-3#30001 Sebm030501 U0303Сергей Москвин100% (2)

- The Welding Journal 1958 4Document226 pagesThe Welding Journal 1958 4Alexey100% (2)

- Operating Instructions Tcbeadmaking Rev02 AlphasensorsDocument22 pagesOperating Instructions Tcbeadmaking Rev02 AlphasensorsfabrikaNo ratings yet

- Heat Treatment Procedure GuideDocument4 pagesHeat Treatment Procedure GuideDemir Alp IlıkobaNo ratings yet