Professional Documents

Culture Documents

Welding Procedure Specification for SMAW of Carbon Steel Butt Joints

Uploaded by

tayyabOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification for SMAW of Carbon Steel Butt Joints

Uploaded by

tayyabCopyright:

Available Formats

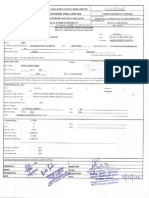

FM-87

Welding Procedure Specification Issue – 01

Date: Feb,12,2015

(WPS) Page 1 of 2

Welding Procedure Specification No WPS-03 Date 20-03-2015 Supporting PQR No. (s) PQR-08 & PQR-09

Revision No. 01 Date 01-01-2019_____ Coupon NO: 03A & 04A

Welding Process (s) SMAW Type(s) Manual

(Automatic, Manual, Machine, or Semi Auto)

JOINTS (QW-402)

Joint Design “V” Grove Butt Joint ,

Backing (Yes) ___________No_________________

Backing Material (Type) N/A

(Refer to Backing and Retainer)

☒ Metal ☐ Nonfusing Metal

☐Non-Metallic ☐Other

Sketches, Production Drawing, Weld Symbols or Written description

Should show the general arrangement of the parts to be welded. Where

applicable , the root spacing and the details of weld groove may be

Specified

(At the option of the Mfg., sketches may be attached to illustrate joint

Design, weld layers and bead sequence may be attached e.g. for notch

Toughness procedure, for multiple process procedures, etc.)

BASE METALS (QW-403)

P. No. 01 Group No. 1,2 to P. No. N/A Group No. N/A .

OR

Specification Type and Grade AISI 4130 .

To Specification Type and Grade N/A .

OR

Chem., Analysis and Mech. Prop Carbon Alloy Steel 70k-85k .

To Chem. Analysis and Mech. Prop.

_________________________________________________________________________

Thickness Range:

Base Metal Groove 1” to Unlimited Fillet N/A .

Pipe Dia Range Grove N/A . Fillet N/A .

Others _N/A____________________________________________________________________________________________

⃰ FILLER METALS (QW-404) Coupon 3A Coupon 4A

Spec. No. (SFA) SFA 5.5 .

SFA 5.5 . E10018-D2 .

AWS. No

E10018-D2 . 04 .

F. No.

04 . A1 .

A. No

A1 . 2.4 - 4 mm .

Size of Filler Metal

2.4 - 4 mm .

Weld Metals

Thickness Range:

Groove 1” to 8” Flange

1” to 8” Flange N/A .

Fillet N/A .

Electrode Flux (Class) E10018-D2

E10018-D2 Atom Arc 10018-MM

Flux Trade Name Atom Arc 10018-MM

Consumable inserts N/A .

N/A . N/A .

Other N/A .

FM-87

Welding Procedure Specification Issue – 01

Date: Feb,12,2015

(WPS) Page 2 of 2

POSITIONS (QW-405) POSTHEAT TREATMENT (QW-407)

Positions of Groove 2G .

Welding Progression: _________UP__________ Temperature Range 646oC±8 ͦ C

Positions of Fillet N/A . Time Range 2 hrs and 2 hrs addition for each

repair with three repair cycle.

PREHEAT (QW-406) GAS (QW-408)

Preheat Temp. Min. 200 C. Percent Composition

Interpass Temp. 300 C. Gases (Mixture) Flow Rate

Preheat Maintenance N/A . Shielded N/A .__________ ________

(Continuous or special heating where applicable should be recorded) Trailing N/A . ________

Backing N/A . _____ ________

ELECTRICAL CHARECTERISTICS (QW-409)

Current AC or DC DC Polarity + .

Amps (Range) 70-220 Volts (Range) 18-38

(Amps and volts range should be recorded for each electrode size, 2.4mm 70-100Amp

Position , and thickness etc. this information may be listed in a 3.2mm 90-160Amp

tabular form similar to that shown below) 4mm 130-220Amp

Tungsten electrode size and type N/A .

(Pure Tungsten, 2 % Thoriated, etc)

Mode of Metal Transfer for GMAW Nil .

(Spay Arc, short Circuiting arc, etc)

Electrode Wire Feed Speed Range N/A .

TECHNIQUES (QW-410)

String or Weave Bead ___________Stringer____________________________________

Orifice or gas Cup size N/A .

Initial or interpass cleaning (Brushing, Grinding, Etc) __Yes__

______________________________________________________________________________________________________

Method of Back Gouging _____________________Grinding___________________________________________________

Oscillation N/A .

Contact Tube to work Distance N/A .

Multiple or Single Pass (Per Side) _____________Multiple_______________________________________

Multiple or Single Electrodes_______________Single__________________________________

Travel Speed (Range)__________________3”-9”/min__________________________________

Peening ______________________None___________________________________________

Other_________________________________________________________________________________________________

_________________________________________________________________________________________________

Weld Process Filler Metal Current Volt Travel Other (e.g. Remarks,

Layers Range Speed comments, hot wire,

Class Dia Type Polar Amp Range addition, technique,

mm Range torch angle etc.)

Root SMAW E10018- 2.4mm DCEP(Reverse 70-120 18-22 3”-7”/min Manual

Layer D2 )

Filling SMAW E10018- 3.2mm 90-160 22-28 3”-8”/min Manual

D2 DCEP(Reverse

)

Cappin SMAW E10018- 4mm 130-220 24-38 4”-9”/min Manual

g Layer D2

DCEP(Reverse

)

Prepared By _____________________ Checked By _______________________ Approved By ____________________

You might also like

- AUS Holden Vehicle Communication Software ManualDocument90 pagesAUS Holden Vehicle Communication Software ManualnigilbertoNo ratings yet

- Intro To Eddy CurrentDocument61 pagesIntro To Eddy Currentrealneil_1No ratings yet

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- Carbon Steel: Wps No. Rev. P.No Material PQR Thickness Process PWHT Preheat SR # Filler MaterialDocument6 pagesCarbon Steel: Wps No. Rev. P.No Material PQR Thickness Process PWHT Preheat SR # Filler Materialvipin100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Bolt Torque ASME B16.5 Flanges - Spiral Wound GasketsDocument31 pagesBolt Torque ASME B16.5 Flanges - Spiral Wound Gasketsbakelly100% (5)

- ASME B31.3 CLOSED BOOK PRACTICE QUESTIONSDocument12 pagesASME B31.3 CLOSED BOOK PRACTICE QUESTIONSemaanazeem91% (11)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- SANYO ELEVATORS AND ESCALATORS CO.LTD USER GUIDE Warnings and CautionsDocument158 pagesSANYO ELEVATORS AND ESCALATORS CO.LTD USER GUIDE Warnings and CautionsAliRouyou64% (11)

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- Welder Qualification Test Certificate: Parameters Variables Qualified With Qualified RangeDocument4 pagesWelder Qualification Test Certificate: Parameters Variables Qualified With Qualified RangeSpectex dubaiNo ratings yet

- Wps S - Ea-6gr-01.Doc Rev2 j4662Document1 pageWps S - Ea-6gr-01.Doc Rev2 j4662cisar0007No ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- Electrolux Dish Washer Service ManualDocument117 pagesElectrolux Dish Washer Service ManualJun Aballe100% (6)

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- Asme Sec V Questions and AnswersDocument32 pagesAsme Sec V Questions and AnswersAshwani Dogra100% (6)

- Asme Sec V Questions and AnswersDocument32 pagesAsme Sec V Questions and AnswersAshwani Dogra100% (6)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Interview Guide for Mechanical Inspector CandidatesDocument5 pagesInterview Guide for Mechanical Inspector CandidatesSANUNo ratings yet

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- Sample API 1104 WpsDocument6 pagesSample API 1104 Wpsjacquesmayol100% (2)

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 pageJNK Heaters Co - LTD: Ferrite Test ReportUzorNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Welder Qualification Form for Rana Pratap ChouhanDocument1 pageWelder Qualification Form for Rana Pratap ChouhanMahendra singhNo ratings yet

- Material Flow ChartDocument49 pagesMaterial Flow Charttayyab aliNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- Piping, Hydro QC List-InterviewDocument8 pagesPiping, Hydro QC List-Interviewtayyab100% (1)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- REV Description Date Originated BY Checked BY Approved BY: 01B IFR - Issued For ReviewDocument10 pagesREV Description Date Originated BY Checked BY Approved BY: 01B IFR - Issued For ReviewAbdur RehmanNo ratings yet

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- FCAW Overlay WPSDocument2 pagesFCAW Overlay WPSAsad Bin Ala Qatari100% (1)

- Concept in Milling Tandem in Sugar IndustryDocument10 pagesConcept in Milling Tandem in Sugar IndustryGizachew BeyeneNo ratings yet

- 2016OilSafeCatalog PDFDocument76 pages2016OilSafeCatalog PDFwilmerNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Consumables Control RegisterDocument5 pagesWelding Consumables Control RegisterAli Mhaskar100% (2)

- Failure Mechanisms of C-Steels (API 571)Document90 pagesFailure Mechanisms of C-Steels (API 571)Abdul Gafoor Shaikh50% (2)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Fillet Weid Break and Macroetch Test PlateDocument1 pageFillet Weid Break and Macroetch Test PlatewijiestNo ratings yet

- Toshiba Brazing Procedure SpecificationDocument3 pagesToshiba Brazing Procedure Specificationsheikmoin100% (1)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Qualified Welder List Valid Until - 03-12-2019Document2 pagesQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Welding Procedure Qualification Certificate (EN ISO 15614-1)Document3 pagesWelding Procedure Qualification Certificate (EN ISO 15614-1)mohdfirdausNo ratings yet

- Impact of Molecular Weight and Other Parameters On Centrifugal Compressor's HeadDocument15 pagesImpact of Molecular Weight and Other Parameters On Centrifugal Compressor's HeadJose David De SousaNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 pagesProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- Welder qualification test recordDocument3 pagesWelder qualification test recordTuTuy AnNo ratings yet

- WPQDocument10 pagesWPQayoki100% (3)

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Daily Progress ReportDocument2 pagesDaily Progress ReporttayyabNo ratings yet

- STD-QD-011D Visual Inspection Checklist PipingDocument4 pagesSTD-QD-011D Visual Inspection Checklist PipingtayyabNo ratings yet

- FM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)Document2 pagesFM-87 Welding Procedure Specification WPS (MEC ENERGY's Conflicted Copy 2018-07-10)tayyabNo ratings yet

- STD-INSP-0024 Procedure For Radiographic TestDocument13 pagesSTD-INSP-0024 Procedure For Radiographic TesttayyabNo ratings yet

- Corrosion Fundamentals and Prevention StrategiesDocument101 pagesCorrosion Fundamentals and Prevention StrategiestayyabNo ratings yet

- Welding Technology - Metallurgy BasicsDocument32 pagesWelding Technology - Metallurgy BasicstayyabNo ratings yet

- Weld Mech. QuestionsDocument4 pagesWeld Mech. QuestionservkslmNo ratings yet

- Ferrous Metallurgy: The Chemistry and Structure of Iron and SteelDocument30 pagesFerrous Metallurgy: The Chemistry and Structure of Iron and SteeltayyabNo ratings yet

- 9 IronDocument21 pages9 Ironahmedabdelaziz851647No ratings yet

- Process Validation 1Document1 pageProcess Validation 1tayyabNo ratings yet

- Process Validation 1Document1 pageProcess Validation 1tayyabNo ratings yet

- Api 510 Open 10Document2 pagesApi 510 Open 10tayyabNo ratings yet

- API 570 Part 1 Pipe ComponentsDocument41 pagesAPI 570 Part 1 Pipe ComponentsvajidqcNo ratings yet

- Api 510 Open 7Document2 pagesApi 510 Open 7tayyabNo ratings yet

- Process Validation 1Document1 pageProcess Validation 1tayyabNo ratings yet

- Process Validation 1Document1 pageProcess Validation 1tayyabNo ratings yet

- Api 510 Open 5Document5 pagesApi 510 Open 5tayyabNo ratings yet

- Process Validation 1Document1 pageProcess Validation 1tayyabNo ratings yet

- Api 510 Open 10Document2 pagesApi 510 Open 10tayyabNo ratings yet

- Api 510 Open 6Document22 pagesApi 510 Open 6tayyabNo ratings yet

- Autonomous Vehicle Implementation Predictions: Implications For Transport PlanningDocument19 pagesAutonomous Vehicle Implementation Predictions: Implications For Transport PlanningLethal11No ratings yet

- A Coordination Framework For Sales and Operations PlanningDocument20 pagesA Coordination Framework For Sales and Operations PlanningprasannaNo ratings yet

- Hydraulic Overload Protection: The Silent SentinelDocument7 pagesHydraulic Overload Protection: The Silent SentinelSerdar FildisNo ratings yet

- Debug 1214Document3 pagesDebug 1214Ana Esther Martinez RoncalloNo ratings yet

- Belgium TemperingDocument14 pagesBelgium TemperingInes Kurfirst-VukušićNo ratings yet

- Contoil VZF IIDocument2 pagesContoil VZF IIMuhammad ZainNo ratings yet

- Requara. H. Wickens Fundamentals of Rail Vehicle Dynamics Guidance and StabiliteDocument42 pagesRequara. H. Wickens Fundamentals of Rail Vehicle Dynamics Guidance and Stabilitetesfaye awelNo ratings yet

- Asme Section II A-2 Sa-649 Sa-649mDocument6 pagesAsme Section II A-2 Sa-649 Sa-649mAnonymous GhPzn1xNo ratings yet

- Narayana - 20!06!2022 - Outgoing SR - Jee Main Model Gtm-15 - SolDocument18 pagesNarayana - 20!06!2022 - Outgoing SR - Jee Main Model Gtm-15 - SolShreyas VedantiNo ratings yet

- Colorado High Country LeafletDocument2 pagesColorado High Country LeafletDanangAjiPrasetiaNo ratings yet

- Chinese Code Implementation 2Document19 pagesChinese Code Implementation 2Partha Pratim RoyNo ratings yet

- Electrical Safety 3 Steps To Test Your RCCB PosterDocument1 pageElectrical Safety 3 Steps To Test Your RCCB PosterGoogool YNo ratings yet

- Chris Hanian - ResumeDocument1 pageChris Hanian - Resumeapi-438788011No ratings yet

- Lesson 1 - Position and Position Lines Learning OutcomesDocument23 pagesLesson 1 - Position and Position Lines Learning OutcomesMico SantosNo ratings yet

- DropboxDocument28 pagesDropboxVetylis MolinaNo ratings yet

- Deutz Lube OilDocument15 pagesDeutz Lube OilMuhammad rizkiNo ratings yet

- Document Numbering Procerdure Rev 1Document1 pageDocument Numbering Procerdure Rev 1Mohammed AshrafNo ratings yet

- Andis BGR ManualDocument24 pagesAndis BGR ManualRebeca BookerNo ratings yet

- Engine SensorsDocument6 pagesEngine SensorsVaibhav Vithoba NaikNo ratings yet

- Amherst Rental Bylaw EnforcementDocument10 pagesAmherst Rental Bylaw EnforcementLarry KelleyNo ratings yet

- SMEP Questionaire For HelidecksDocument2 pagesSMEP Questionaire For HelidecksIlyas Rangga RamadhanNo ratings yet

- Tembungomol pump vibration measurement guideDocument1 pageTembungomol pump vibration measurement guidefazzlieNo ratings yet