0% found this document useful (0 votes)

876 views49 pagesMaterial Flow Chart

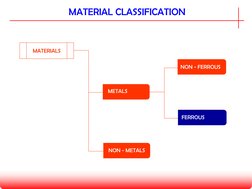

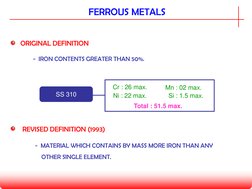

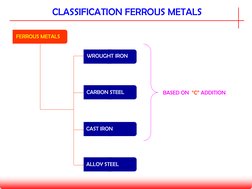

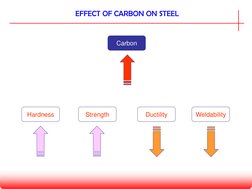

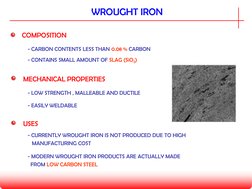

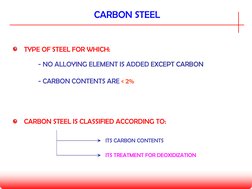

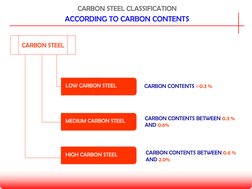

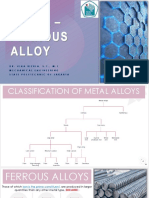

This document provides an overview of industrial and fertilizer materials, including their classification and properties. It discusses ferrous metals such as wrought iron, carbon steel, cast iron, and alloy steels. It also covers non-ferrous metals and non-metals. For carbon and alloy steels, it describes how composition affects properties. Various grades of stainless steel are also outlined, along with their typical applications in fertilizer plants. Finally, common material designation systems are briefly introduced.

Uploaded by

tayyab aliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

876 views49 pagesMaterial Flow Chart

This document provides an overview of industrial and fertilizer materials, including their classification and properties. It discusses ferrous metals such as wrought iron, carbon steel, cast iron, and alloy steels. It also covers non-ferrous metals and non-metals. For carbon and alloy steels, it describes how composition affects properties. Various grades of stainless steel are also outlined, along with their typical applications in fertilizer plants. Finally, common material designation systems are briefly introduced.

Uploaded by

tayyab aliCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd