0% found this document useful (0 votes)

141 views31 pagesDr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of Jakarta

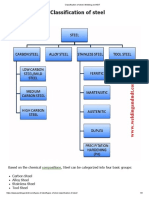

1. This document classifies and describes various types of metal alloys including ferrous alloys, steels, tool steels, stainless steels and their applications.

2. Key alloying elements and properties of each alloy type are discussed. For example, carbon content determines whether an alloy is a steel or cast iron, while chromium provides corrosion resistance in stainless steels.

3. Alloys are grouped according to their intended application such as structural, cutting or high temperature uses. Specific alloy types within groups differ in elements added to achieve desired hardness, strength or other traits for the application.

Uploaded by

CANDRA ANDREAN Mahasiswa PNJCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

141 views31 pagesDr. Vika Rizkia, S.T., M.T Mechanical Engineering State Polytechnic of Jakarta

1. This document classifies and describes various types of metal alloys including ferrous alloys, steels, tool steels, stainless steels and their applications.

2. Key alloying elements and properties of each alloy type are discussed. For example, carbon content determines whether an alloy is a steel or cast iron, while chromium provides corrosion resistance in stainless steels.

3. Alloys are grouped according to their intended application such as structural, cutting or high temperature uses. Specific alloy types within groups differ in elements added to achieve desired hardness, strength or other traits for the application.

Uploaded by

CANDRA ANDREAN Mahasiswa PNJCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd