Professional Documents

Culture Documents

Final - WPS PQR 86

Uploaded by

Parag WadekarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final - WPS PQR 86

Uploaded by

Parag WadekarCopyright:

Available Formats

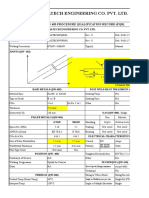

QW -482 WELDING PROCEDURE SPECIFICATIONS (WPS)

SHEET 1 OF 2 (SEE QW – 200.1, SECTION IX, ASME BOILER

AND PRESSURE VESSEL CODE

Company Name : Filteration Engineers India Pvt. Ltd. Rabale, Navi Mumbai

Welding Procedure Specification No: FE/WPS/086 Rev-0 Date: 10/11/2022

Supporting PQR No.(S) : FE/PQR/086 Date: 10/11/2022

Welding Process (es) : GTAW+SMAW Type(s) : Manual

(Automatic, Manual, Machine or semi – Automatic)

JOINTS (QW-402) DETAILS

Joints Design : Single ‘V’ Groove Joint FPW

Root Spacing :

Backing Yes __X__ No: No for Root Layers (GTAW) &

Yes for Subsequent Layer

Backing Material (Type) : Weld Metal for Subsequent Layer

(Refer to both backing & retainers)

Metal Non fusing Metal

Non Metallic Other

* BASE METAL (QW – 403)

P-No. 8 Group no. 1 to P-No. 8 Group no. 1

OR

Specification type and grade: ____________

To specification type and grade: ____________

Chem. Analysis and Mech. Prop ___________NA__________________________

To Chem. Analysis and Mech. Prop ________NA___________________________

Thickness Range:-

Base Metal :- Groove 5 to 32 mm Fillet All thickness, all sizes & all diameters

Other WPS shall be applicable for both without and with backing. Max pass thickness <= ½ in ( 13 mm):Yes

FILLER METALS (QW-404) GTAW SMAW

Spec No. (SFA) SFA-5.9 SFA-5.4

AWS No. (Class) ER-316L E-316L

F-No. 6 5

A-No 8 8

Size of Filler Metals 1.6mm, 2.0mm & 2.5mm 3.2mm & 4.0mm

Filler Metal Product Form Bare Wire is Solid N.A.

Supplemental Filler Metal No N.A.

Weld Metal

Thickness Range

Groove Upto 16 mm max Upto 16 mm max

Fillet All All

Electrode-Flux (Class) N.A. N.A.

Flux Trade N.A. N.A.

Flux Trade Name N.A. N.A.

Consumable Insert None N.A.

Other N.A. N.A.

Prepared By, Checked By, Approved

QW-482 (BACK)

SHEET 2 OF 2 WPS NO : FE/WPS/86 Dated 10/11/2022; REV : 00

POSITION (QW-405)

Position (s) of Groove All

Welding Progression: Uphill for Vertical Down NA

Position (s) of Fillet All

PREHEAT (QW-406) POSTWELD HEAT TERATMENT

Preheat Temp. Min : Ambient Temperature (QW-407)

Interpass Temp. Max : 150˚C Temperature : N.A.

Preheat Maintenance: None Time : N.A.

(Continuous or special heating were Other : N.A.

applicable should be recorded)

GAS (QW-408)

Percentage Composition

GAS(es) (Mixtures) Flow Rate

Shielding : Argon Single 5-10Ltr./min

Trailing : NA NA NA

Backing : Argon Single 5-10Ltr./min

ELECTRICAL CHARCTERISTICS (QW-409)

Filler Metal Wire Energy

Current Travel

Weld Pass Proces Amps Feed or Volts Oth

Classificat Type & Speed

(es) s Diameter (Range) Speed Power (Range) ers

ion Polarity (Range) (Range) (Range)

Root Run

GTAW ER 316L 2 mm DCEN 70-90 N.A. N.A. 8-15 60

(1st Pass)

Hot Pass

GTAW ER 316L 2 mm DCEN 70-90 N.A. N.A. 8-15 60

(2nd Pass)

As required

up to

GTAW ER 316L 2.5 mm DCEN 80-120 N.A. N.A. 8-15 60

10 mm

Deposition

SMAW E 316L 3.2 mm DCEP 90-110 N.A. N.A. 22-28 105

Rest

SMAW E 316L 4 mm DCEP 100-130 N.A. N.A. 22-28 115

Amp and volts range should be recorded for each electrode size, positions and thickness etc.)

Pulsing Current: _DCEN- GTAW & DCEP -SMAW Heat Input Max: GTAW- 1.80 KJ/mm & SMAW- 1.90 KJ/mm

Tungsten Electrodes Size & Type : 2.4 mm, 2% Thoriated Tungsten Electrodes

(Pure tungsten 2% Thoriated etc.)

Mode to metal transfer for GMAW ___________NA _ ______ Others: ___________ NA ___ ____

(Spray arc short circulating arc etc.)

TECHNIQUE (QW-410)

String or weave bead: String &Weave (weaving not more than 12mm size of final pass/capping run).

Orifice or Gas Cup Size : Ceramic Nozzle of 10 mm

Initial and Inter pass Cleaning (Brushing, grinding etc.): Wire Brush, Grinding, Solvent to Remove Dust, Oil, Grease Etc.

Method of Back Gouging __ __NA ________

Oscillation ___ _NA ________

Contact Tube to Work Distance _ __ NA________

Multiple or Single Pass (per side) __ Multiple___

Multiple or Single Electrode Single_____

Electrode Spacing Refer Table-1

Peening Not Allowed

Other NA_____ _

Prepared By, Checked By, Approved

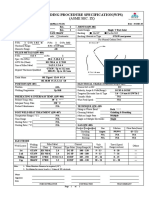

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

SHEET 1 OF 2 (See QW-200.2, Section IX ASME Boiler And Pressure Vessel Code)

Record Actual Variables Used To Weld Test Coupon

Company Name: Filteration Engineers India Pvt. Ltd. Rabale, Navi Mumbai

Procedure Qualification Record No. : FE/ PQR/086 Rev 00 Date: 10/11/2022

WPS No. : FE/WPS/086 Rev -00 Date: 10/11/2022

Welding Process (es) : GTAW + SMAW

Types (Manual, Automatic, Semi-Automatic) : Manual

JOINTS (QW-402)

PLATE SA 240 Gr. Type 316L to SA 240 Gr. Type 316L

Groove Design of Test Coupon

(For combination qualifications, the deposited weld metal thickness shall be recorded for each filler metal or process used)

BASE METAL (QW-403) POST WELD HEAT TREATMENT (QW-407)

Material Spec. : SA 240 to SA 240 Temperature : NA

Type of Grade : Type 316L to Type 316L Time : NA

P-No. ___8____ To P. No. _ 8__ Other : NA

G-No. 1 To G. No. 1 GAS (QW-408)

Thickness of Test Coupon : 16 mm Percentage Composition

Diameter of Test Coupon : N.A. GAS(es) (Mixtures) Flow Rate

Maximum Pass Thickness : <13 mm Shielding : Argon Single 5-10Ltr./min

Heat No.: R09068 TO R09068 Trailing : NA NA NA

Other Backing : Argon Single 5-10Ltr./min

FILLER METALS(QW-404) GTAW SMAW ELECTRICAL CHARACTERISTICS (QW-409)

SFA Specification 5.9 5.4 Process GTAW SMAW

AWS Classification ER 316L E-316L Current DC DC

Filler Metal F-No 6 5 Polarity EN EP

Weld Metal Analysis A-No 8 8 Amps. 70-120 90-130

2.0mm 3.2mm Volts 12-15 22-28

Size of Filler Metal

2.5mm 4.0mm Wave Form Control N.A. N.A.

Filler Metal Product Form Bare Wire N.A. Power or Energy N.A. N.A.

Supplemental Filler Metal NO N.A. Arc Time N.A. N.A.

Electrode Flux Classification N.A. N.A. Weld Bead Length N.A. 105

Flux Type N.A. N.A. Tungsten Electrode Size 2.4mm N.A.

Flux Trade Name N.A. N.A. Mode of Metal Transfer for

GMAW (FCAW) N.A. N.A.

Weld Metal Thickness 8 8

Other Heat Input (KJ/mm) 1.80 1.90

POSITION (QW-405) Others – Tungsten Type - EWTh-2

Position of Groove __Vertical 3G _ TECHNIQUE (QW-410)

Weld Progression (Uphill, Downhill) Up hill Travel Speed (mm/min) GTAW-60 & SMAW-105-115

Others N.A. String or Weave Bead Stringe / Weave _

PERHEAT (QW-406) Oscillation _N.A.___

Preheat Temperature (Min.) Ambient Temperature Multipass or Single Pass (Per Side):_Multipass____

Interpass Temperature (Max.) 1500 C For GTAW & SMAW Single or Multiple Electrodes __Single ______

Other ________________N.A._______________ Other.

Prepared By, Checked By, Approved

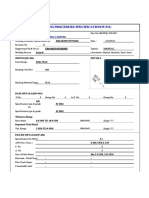

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

SHEET 2 OF 2 (See QW-200.2, Section IX ASME Boiler And Pressure Vessel Code)

Record Actual Variables Used To Weld Test Coupon

QW -483 (Back) TENSILE TEST (QW – 150)

Specimen No. Width Thickness Area mm2 Ultimate Total Ultimate Unit Type of Failure and Location

mm mm Load KN Stress Mpa

T-1 19.00 16.00 304.00 178.00 585 Ductile on Parent Metal

T-2 19.00 16.08 305.52 176.50 578 Ductile on Parent Metal

GUIDED-BEND TESTS(4T) (QW-160)

Type and Figure No. Result

Face Bend ( FB -1 ) AS PER QW 462.2 Satisfactory

Face Bend ( FB -2 ) AS PER QW 462.2 Satisfactory

Root Bend ( RB -3 ) AS PER QW 462.2 Satisfactory

Root Bend ( RB -4 ) AS PER QW 462.2 Satisfactory

IMPACT TEST / TOUGHNESS TESTS (QW-170)

Test Impact Values - Joules LE PS

Specimen Notch Location

Temperature 1 2 3 Avg. (mm) (%)

Specimen Size 10 X 7.5 X 55

Weld SMAW 1.5 mm from Top Surface -196 °C 78 72 68 73 ― ―

HAZ –SMAW 1.5 mm from Top -196 °C 98 90 100 96 ― ―

Weld GTAW 1.5 mm from BOTTOM -196 °C 76 86 82 81 ― ―

HAZ – GTAW 1.5 mm from Bottom -196 °C 94 88 86 89 ― ―

Specimen Size 10 X 2.5 X 55

Weld SMAW - Midway -196 °C 48 42 40 43 ― ―

SMAW HAZ – Midway -196 °C 36 34 30 33 ― ―

Weld GTAW Midway -196 °C 34 32 38 34 ― ―

GTAW HAZ – Midway -196 °C 32 38 36 35 ― ―

FILLET –WELD TEST (QW-180)- NOT DONE

Result – Satisfactory Yes _________No. ________Penetration into Parent Metal Yes ______ No. __

Macro – Results - NA

OTHER TESTE

MECHANICAL TESTING : IGC PRACTICE ‘E’ TEST

MAGNIFICATION RESULT

20 X NO IGC FISSURES OR CRACKS OBSERVED

250X NO IGC FISSURES OR CRACKS OBSERVED

TYPE OF TEST: HARDNESS TEST (IN HV-10)

Location LHS PARENT METAL LHS HAZ WELD METAL RHS HAZ RHS PARENT METAL

TOP 188 218, 216, 213 213,216, 216 215, 216, 216 187

MIDDLE 193 221, 221, 222 221,219, 216 221, 218, 218 185

BOTTOM 196 228, 227, 225 233, 228,225 224, 222, 222 191

Deposit Analysis - NA

Radiography test conducted and acceptable: - Report No:- JIS/RT/22-23/088H Dated: 17.06.2022

Welder’s Name Shri. Dhananjay Yadhav Clock No. : FE/W/10 Stamp. No.10

Test Conducted by GEO Chem Laboratories Pvt. Ltd Laboratory Test No. MET/22/07/03569 Dated: 16/07/2022

Welding Supervised by Filteration Engineers India Pvt. Ltd

We certify that the statements in this record are correct and that the test coupons were prepared, welded

and tested in accordance with the requirements of Section IX of the ASME Boiler & Pressure Vessel Code

For Filteration Engineers India Pvt. Ltd : Mr. Narendra Verma

Date: ____________ Certified By :________________

Prepared By, Checked By, Approved

You might also like

- WPSDocument3 pagesWPSSagar GourNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- WPS SUMMARYDocument10 pagesWPS SUMMARYbhavin178No ratings yet

- CALTECH ENGINEERING PQR PROCEDUREDocument8 pagesCALTECH ENGINEERING PQR PROCEDURESrikant GanjiNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- PQR Procedure Qualification RecordsDocument6 pagesPQR Procedure Qualification RecordsDaniel CamposNo ratings yet

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- PQR (52a) ModelDocument1 pagePQR (52a) ModelSIDDHARTH BEHERAYNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- METALS INSPECTION SERVICES WELDING PROCEDUREDocument6 pagesMETALS INSPECTION SERVICES WELDING PROCEDURELuis MuñozNo ratings yet

- Sample Wps Carbon Steel GTAW SMAW PDFDocument2 pagesSample Wps Carbon Steel GTAW SMAW PDFirwanNo ratings yet

- Sample WPS for Carbon Steel GTAW+SMAW WeldingDocument2 pagesSample WPS for Carbon Steel GTAW+SMAW WeldingAmanSharmaNo ratings yet

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocument1 pagePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- WELDING PROCEDURE SPECIFICATION FOR FILLET WELDSDocument2 pagesWELDING PROCEDURE SPECIFICATION FOR FILLET WELDSAhmed saberNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- CV AkshayDocument3 pagesCV AkshayParag WadekarNo ratings yet

- SR (CV)Document3 pagesSR (CV)Parag WadekarNo ratings yet

- Dinesh-CV 01Document4 pagesDinesh-CV 01Parag WadekarNo ratings yet

- Vododara to bandra terminusDocument2 pagesVododara to bandra terminusParag WadekarNo ratings yet

- 5.2 PAUT TeamDocument1 page5.2 PAUT TeamParag WadekarNo ratings yet

- QA Manager YogeshDocument4 pagesQA Manager YogeshParag WadekarNo ratings yet

- PAUT Roles & ResponsibilitesDocument1 pagePAUT Roles & ResponsibilitesParag WadekarNo ratings yet

- PCN RTFI Roles & ResponsibilitesDocument2 pagesPCN RTFI Roles & ResponsibilitesParag WadekarNo ratings yet

- Invoice - December - 2022Document1 pageInvoice - December - 2022Parag WadekarNo ratings yet

- Corrections Track Record Cum PTR SheetDocument11 pagesCorrections Track Record Cum PTR SheetParag WadekarNo ratings yet

- IVR-DYC.M.1.22.0004-Sr - No. 41 - Rev 00Document6 pagesIVR-DYC.M.1.22.0004-Sr - No. 41 - Rev 00Parag WadekarNo ratings yet

- Sr. No. Name Designation OrganizationDocument4 pagesSr. No. Name Designation OrganizationParag WadekarNo ratings yet

- QMS Manual IS 9001 2015Document28 pagesQMS Manual IS 9001 2015Parag WadekarNo ratings yet

- MOU-Dev ElectricalDocument3 pagesMOU-Dev ElectricalParag WadekarNo ratings yet

- Fe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Document10 pagesFe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Parag WadekarNo ratings yet

- MRH Competence Skill Matrix - To CheckDocument7 pagesMRH Competence Skill Matrix - To CheckParag WadekarNo ratings yet

- Fe-Gen-St-Xxxxx-Weld Repair ProcedureDocument3 pagesFe-Gen-St-Xxxxx-Weld Repair ProcedureParag WadekarNo ratings yet

- QMS-F-19 Blank Job Risk Analysis 2019Document1 pageQMS-F-19 Blank Job Risk Analysis 2019Parag WadekarNo ratings yet

- Inventory Record - FinalDocument6 pagesInventory Record - FinalParag WadekarNo ratings yet

- Hrd-f-06 Blank Training FeedbackDocument1 pageHrd-f-06 Blank Training FeedbackParag WadekarNo ratings yet

- Hrd-f-06 Blank Training FeedbackDocument1 pageHrd-f-06 Blank Training FeedbackParag WadekarNo ratings yet

- Dycint Mumbai Surendra Kumar JaiswarDocument5 pagesDycint Mumbai Surendra Kumar JaiswarParag WadekarNo ratings yet

- Job Risk AnalysisDocument1 pageJob Risk AnalysisParag WadekarNo ratings yet

- Hrd-f-06 Blank Training FeedbackDocument1 pageHrd-f-06 Blank Training FeedbackParag WadekarNo ratings yet

- ANWARDocument4 pagesANWARParag WadekarNo ratings yet

- Job Risk AnalysisDocument1 pageJob Risk AnalysisParag WadekarNo ratings yet

- QA Engineer Vinay Pachat ContactDocument25 pagesQA Engineer Vinay Pachat ContactParag WadekarNo ratings yet

- Daksh CP 19-12-2022Document20 pagesDaksh CP 19-12-2022Parag WadekarNo ratings yet

- Helping Others Through Shutdown and Revamp ProjectsDocument85 pagesHelping Others Through Shutdown and Revamp ProjectsParag WadekarNo ratings yet

- Mf5101 Advances in Manufacturing Technology: For Syllabus, Question Papers, Notes & Many MoreDocument2 pagesMf5101 Advances in Manufacturing Technology: For Syllabus, Question Papers, Notes & Many MoreNandha Gopal SenthilnathanNo ratings yet

- Assessment of Grain Threshers and Dryer Machines in West Java Rice FarmingDocument14 pagesAssessment of Grain Threshers and Dryer Machines in West Java Rice FarmingfitriajiNo ratings yet

- Review Manufacture of Polymeric Foam Cores For Sandwich Structures of Complex ShapeDocument35 pagesReview Manufacture of Polymeric Foam Cores For Sandwich Structures of Complex ShapeMustafa SenolNo ratings yet

- CE Lecture 8 (Plain Concrete Finishing Works)Document42 pagesCE Lecture 8 (Plain Concrete Finishing Works)Hammad AmjadNo ratings yet

- MUDA English v1 (Small2.4) 202301Document87 pagesMUDA English v1 (Small2.4) 202301peaceNo ratings yet

- Aluminium Conductor Composite Core ACCCDocument5 pagesAluminium Conductor Composite Core ACCCAmlanshankar Deb BarmaNo ratings yet

- Replacement of Lime With Industrial Wastes in HotDocument10 pagesReplacement of Lime With Industrial Wastes in HotAtish GoswamiNo ratings yet

- Grommet Plastic ms21266Document1 pageGrommet Plastic ms21266RhianNo ratings yet

- Cost API 650 Vs API 620Document3 pagesCost API 650 Vs API 620johnNo ratings yet

- 08 Selection of Present EconomyDocument15 pages08 Selection of Present EconomyMitch TechsNo ratings yet

- Airbus: Process and Material SpecificationDocument25 pagesAirbus: Process and Material SpecificationJorge OrtegaNo ratings yet

- Turner: 2 SemesterDocument62 pagesTurner: 2 SemesterirshadNo ratings yet

- Sae J1701Document5 pagesSae J1701Marco NiNo ratings yet

- Up Dated Industries List ESIPL-Sitarganj1456809456Document8 pagesUp Dated Industries List ESIPL-Sitarganj1456809456UDGGAMNo ratings yet

- Just in TimeDocument9 pagesJust in TimeFerenc balázsNo ratings yet

- Ways of Separating MixturesDocument2 pagesWays of Separating MixturesPretty SwanNo ratings yet

- Destillador de Agua - Water Distiller - Distillateur D'eaurDocument63 pagesDestillador de Agua - Water Distiller - Distillateur D'eaurYrvin Emanuel BusnegoNo ratings yet

- Technical Sheet Racloflex NTDocument2 pagesTechnical Sheet Racloflex NTAnthony AngNo ratings yet

- Materials 15 01612 v2Document23 pagesMaterials 15 01612 v2karthicfinconNo ratings yet

- S_MachineToolsGeneralCatalogDocument11 pagesS_MachineToolsGeneralCatalogadrienbridel80No ratings yet

- Catloge (PEACOCK) PDFDocument6 pagesCatloge (PEACOCK) PDFSundarNo ratings yet

- Kilian: Bearings & AssembliesDocument4 pagesKilian: Bearings & AssembliesLuis Angel Rivera MacielNo ratings yet

- Pis Taski Spiral HDDocument2 pagesPis Taski Spiral HDMaddyNo ratings yet

- D 5497 - 94c R00 RDU0OTCDocument3 pagesD 5497 - 94c R00 RDU0OTCJuanNo ratings yet

- CNC Router Research PaperDocument7 pagesCNC Router Research Paperafeawqynw100% (1)

- A-1-10-Specification For FRP Vessels and TanksDocument17 pagesA-1-10-Specification For FRP Vessels and TanksbecemNo ratings yet

- Caustic Recovery PlantsDocument37 pagesCaustic Recovery PlantsCaustic Recovery PlantsNo ratings yet

- Quick Installation Guide GPON ONT GN256VHDocument1 pageQuick Installation Guide GPON ONT GN256VHKarloff AutencioNo ratings yet

- W3 Concrete and IBS ConstructionDocument86 pagesW3 Concrete and IBS ConstructionSyazwani ArifahNo ratings yet

- ASTM A992/A572 Grade 50 Steel Beam and ChannelDocument7 pagesASTM A992/A572 Grade 50 Steel Beam and ChannelAlbert SebanNo ratings yet