Professional Documents

Culture Documents

QW 482 WPS

Uploaded by

smit patelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QW 482 WPS

Uploaded by

smit patelCopyright:

Available Formats

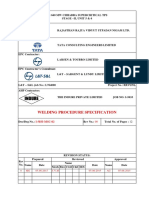

WELDING PROCEDURE SPECIFICATIONS (WPS)

As Per ASME Sec IX QW- 482

Name of Job: Weldability Test (Houldcraft Test) By: SMIT PATEL

Welding Procedure Specification No. SP/WPS/01 Date: 15 sept 2022

Supporting PQR No. (S) N.A Qualified Thickness Range: 0.5t to 2t

Welding Process: MAG Types: Semi-Automatic MAG Welding Machine

JOINTS(QW-402) Details

Joints Design : Double ‘V’ Butt weld 60°

Backing: N.A 4.5mm

Backing Materials (Type) N.A 3mm

(Refer To Both Backing And Retainers) 4.5mm

□ Metal Confusing □ Metal 0.5mm

□ Nonmetallic □ Other

Specimen size : 240×144× 12 mm

Sketches, Production Drawings, Weld Symbols, Or Written Description

Should Show The General Arrangement Of The Parts To Be Welded. Where

Applicable, The Root Spacing And The Details Of Weld Groove May Be 12mm

Specified.

BASE METALS (QW-403)

P-No. : 1 Group No.: 1.2

Or

Specification Type And Grade: MS IS 2062 E 350 BR

Or

Chem. Analysis: N.A

Mech. Prop.: N.A

Thickness : 12 mm

Base Metal: Groove: Yes Fillet: Nil

Other:

*FILLER METALS (QW-404) MAG

Spec. No. (SFA) A 5.18

AWS No. (Class) ER 70 S 6

Input Current (Amp) 180-240

Input Voltage (V) 21 - 25

Size Of Filler Metals Ø1.20 mm

Shielding Gas Co2

‘F’ number 6

Wire Type Solid Wire

Polarity DCEP

Electrode-Flux (Class) No

Flux Trade Name Nil

Consumable Insert Nil

Filer Metal Designation And Make EN ISO 14341-A : G 42 3 M21

3Si1 , ESAB

Section Ix

WELDING PROCEDURE SPECIFICATIONS (WPS)

POSITIONS (QW -405) POST WELD HEAT TREATMENT (QW-407)

Position(S) Of Groove: Flat Horizontal (1G) Temperature Range: N.A

Welding Progression: Down Hand Welding Time Range: N.A

GAS (QW-408)

PREHEAT (QW-406) Percent Composition

Preheat Temperature, Minimum: 5°C Gas Mixture

Interpass Temperature, Maximum: 230°C

Preheat Maintenance: Nil Shielding : Co2 100% Co2

(Continuous Or Special Heating, Where Applicable,

Should Be Recorded) Gas Flow Rate: 15-18 LPM

ELECTRICAL CHARACTERISTICS (QW-409)

Current Ac Or Dc: DC Polarity: DCEP

Amps (Range): 180Amp – 240Amp Voltage (Range): 18V - 34V

(Amps And Volts Range Should Be Recorded For Each Electrode Size,

Position, And Thickness, Etc. This Information May Be Listed In A

Tabular Form Similar To That Shown Below.)

Electrode Size And Type: Ø 1.20mm And Solid Wire

Mode Of Metal Transfer For MAG: Globular

Electrode Wire Feed Speed Range: 170 mm/min

TECHNIQUE (QW-410)

String Or Weave Bead: String Bead

Orifice Or Gas Cup Size: N.A

Initial And Interpass Cleaning (Brushing, Grinding, Etc.): Wire Brush

Method Of Back Gouging: N.A.

Oscillation: N.A

Contact Tube To Work Distance: 15mm-20mm

Multiple Or Single Pass (Per Side): Single Pass

Multiple Or Single Wire: Single wire

Travel Speed (Range): 170 mm/min

Peening : N.A

Torch Angle : 75°-90°

Filler Metal Current Travel Other (E.G., Remarks,

Voltage

Weld Speed Comments, Hot Wire

Process Type/ Amp Range Range

Layer Class Diameter Range Addition, Technique, Torch

Polarity Amp V

in./min Angle, Etc.)

Heat Input : 1.33

Single MAG G3Si 1 1.20 mm DCEP 180-240 18-34 91-512

Torch Angle : 75°- 90°

You might also like

- V5750maintance ManualDocument114 pagesV5750maintance ManualJoe Gozinia100% (2)

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- CIGWELDDocument244 pagesCIGWELDrodastrid5653100% (1)

- Welding Procedure For BOXNR Wagon (WPS)Document8 pagesWelding Procedure For BOXNR Wagon (WPS)Shekher Nikhil100% (1)

- Alu WpsDocument4 pagesAlu WpsdselvakuuNo ratings yet

- WELDING PROCEDURE FOR STEERING BRACKETSDocument1 pageWELDING PROCEDURE FOR STEERING BRACKETSViktorNo ratings yet

- Design Guide 26 Design of Blast Resistant StructuresDocument175 pagesDesign Guide 26 Design of Blast Resistant Structurespaarth93100% (6)

- Pyramidal Horn Antenna Design GuideDocument38 pagesPyramidal Horn Antenna Design GuideJocaNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- Stainless steel welding procedure qualification recordDocument1 pageStainless steel welding procedure qualification recordchandraNo ratings yet

- Ahp 2X660 (WPS) )Document17 pagesAhp 2X660 (WPS) )Hema NandhNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- Saudi Aramco WPS Procedure ApprovalDocument7 pagesSaudi Aramco WPS Procedure ApprovalAkansha SharmaNo ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- WELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111Document15 pagesWELDING PROCEDURE SPECIFICATION FOR TANK TK 5109/5110/5111surya1960No ratings yet

- 385 2 Internal Gtaw+SmawDocument2 pages385 2 Internal Gtaw+Smawsubash1688No ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- Welders Performance Qualification Record: Actual Values Range QualifiedDocument13 pagesWelders Performance Qualification Record: Actual Values Range QualifiedErick AguadoNo ratings yet

- Shielded Metal Arc WeldingDocument39 pagesShielded Metal Arc Weldingعزت عبد المنعم100% (1)

- 1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016Document64 pages1515-WD .Weld Procedures and Welder Qualifications 19 Aug 2016ivan sulistianNo ratings yet

- Welders CertDocument11 pagesWelders CertAhmed GomaaNo ratings yet

- Wps PQRDocument7 pagesWps PQRsobariNo ratings yet

- Welding Drying OvenDocument2 pagesWelding Drying OvenAsad AliNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Welding & NDE Summary Sheet (BE)Document12 pagesWelding & NDE Summary Sheet (BE)MulPXNo ratings yet

- By RPS Welding ConsultantsDocument41 pagesBy RPS Welding ConsultantsvairavnNo ratings yet

- Wps Non PWHTDocument193 pagesWps Non PWHTMaxwell G SihotangNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- 2017 Welding School CatalogDocument34 pages2017 Welding School CatalogDiego AlonsoNo ratings yet

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- Hot Work Procedures: Fire ControlDocument10 pagesHot Work Procedures: Fire ControlSiraj KuvakkattayilNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Data SheetDocument2 pagesWelding Procedure Data SheetAmanSharmaNo ratings yet

- RESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceDocument11 pagesRESPONSIBILITY: G - Galvanized D - Designer B - Builder/Fabricator S - Steel Type/SurfaceLaxit100% (1)

- PWPS - GTSM-73 Rev-ADocument5 pagesPWPS - GTSM-73 Rev-AVimin PrakashNo ratings yet

- Wel 13 HDocument8 pagesWel 13 HWilly Uio100% (1)

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- Welder Performace Qualification Report 2014..Document132 pagesWelder Performace Qualification Report 2014..Kayra Riri ChirulNo ratings yet

- Handle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsDocument1 pageHandle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsSAKTHIVEL ANo ratings yet

- WQTR 004-2Document2 pagesWQTR 004-2walitedisonNo ratings yet

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaDocument5 pagesDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- ITP Inspection and Test Plan for Aqaba Screening Project Steel FabricationDocument3 pagesITP Inspection and Test Plan for Aqaba Screening Project Steel FabricationKhaled GamalNo ratings yet

- Poster Welding P VoxXa PDFDocument1 pagePoster Welding P VoxXa PDFAd Man GeTigNo ratings yet

- WPS & PQR Summary List for Structure Reference ProjectsDocument8 pagesWPS & PQR Summary List for Structure Reference ProjectsFerdie OS100% (1)

- W-55 PLATE ID CARDDocument6 pagesW-55 PLATE ID CARDKrishnan TnNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Poposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015Document12 pagesPoposed Welding Procedure Specification (PWPS) : ASME Section IX, ASME Boiler and Pressure Code Ed.2015MulPXNo ratings yet

- WPS List PDFDocument2 pagesWPS List PDFNAVANEETH NAVANINo ratings yet

- Surface Preparation & Painting ProcedureDocument9 pagesSurface Preparation & Painting ProcedureRam ThevarNo ratings yet

- Lesson 14 WelderQuals - New2Document80 pagesLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Course Module 4Document6 pagesCourse Module 4Makise AghataNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- ASMEDocument38 pagesASMEshazanNo ratings yet

- Define of WPS & PQRDocument16 pagesDefine of WPS & PQRThanh Hua100% (1)

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Chapter 9 PLCCDocument26 pagesChapter 9 PLCCpruddviNo ratings yet

- Name of Learner: - Grade & SectionDocument9 pagesName of Learner: - Grade & SectionAxel Nicerio RoveloNo ratings yet

- Mathematical Modeling of Spherical Storage TanksDocument7 pagesMathematical Modeling of Spherical Storage TanksMihaela NastaseNo ratings yet

- Multicomponent Distillation CalculationsDocument5 pagesMulticomponent Distillation CalculationsPatricia DavidNo ratings yet

- DC Pandey Objective - 19Document40 pagesDC Pandey Objective - 19M Basava PunnaiahNo ratings yet

- Design of Machine Elements - IDocument109 pagesDesign of Machine Elements - ISam prabhakarNo ratings yet

- Duct SizingDocument13 pagesDuct SizingEugene MicarandayoNo ratings yet

- Fischerscope X-Ray Xan 220Document4 pagesFischerscope X-Ray Xan 220varun sachdevaNo ratings yet

- Caracteristicas ChillerDocument21 pagesCaracteristicas ChillerJoe Israel V-Red SkidNo ratings yet

- Temperature Metrology PDFDocument122 pagesTemperature Metrology PDFSuryanarayan YadavNo ratings yet

- Questions Bank On ElectrostaticsDocument2 pagesQuestions Bank On Electrostaticsashok PradhanNo ratings yet

- Atomic Structure Knowledge Organiser - Foundation and HigherDocument2 pagesAtomic Structure Knowledge Organiser - Foundation and HigheranqelineeNo ratings yet

- Solving Quadratic FactoringDocument4 pagesSolving Quadratic FactoringMonica GrapeNo ratings yet

- Today:: + Cos + Sin ,:, Arg Arg + Arg +Document20 pagesToday:: + Cos + Sin ,:, Arg Arg + Arg +IbrahimNo ratings yet

- What Is HPLC Column Conditioning - How Long To EquilibrateDocument5 pagesWhat Is HPLC Column Conditioning - How Long To EquilibrateMubarak PatelNo ratings yet

- Erapol E90A: Technical DatasheetDocument2 pagesErapol E90A: Technical Datasheetmgamal1080No ratings yet

- As 23a WavesDocument42 pagesAs 23a WavesHany ElGezawyNo ratings yet

- Sturm AW97I22N Protel Schematic & Footprints & PCB PictureDocument5 pagesSturm AW97I22N Protel Schematic & Footprints & PCB PicturehosseinarevanNo ratings yet

- Ultra Low Freezer (Tower) ManualDocument53 pagesUltra Low Freezer (Tower) Manualadnan_hashmi786100% (1)

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- Particle Packing in Concrete 30-04-20Document49 pagesParticle Packing in Concrete 30-04-20b ramachandraNo ratings yet

- Nota Ringkas KimiaDocument2 pagesNota Ringkas KimiaZulhilmil Zul100% (7)

- 6.3 Magnetic Torque, Moment, MagnetizationDocument42 pages6.3 Magnetic Torque, Moment, Magnetizationannambaka satishNo ratings yet

- A Wide Tuning Range Dual-Core Quad-Mode Orthogonal-Coupled VCO With Concurrently Dual-Output Using Parallel 8-Shaped ResonatorDocument15 pagesA Wide Tuning Range Dual-Core Quad-Mode Orthogonal-Coupled VCO With Concurrently Dual-Output Using Parallel 8-Shaped ResonatorQiuFengNo ratings yet

- MATH115A LECTURE NOTES ON VECTOR SPACESDocument59 pagesMATH115A LECTURE NOTES ON VECTOR SPACESShela RamosNo ratings yet

- Sub Module 3.9 Capacitance FinalDocument26 pagesSub Module 3.9 Capacitance FinalInterogator5No ratings yet

- Ac Cassette 1Document1 pageAc Cassette 1Surya LiemNo ratings yet