Professional Documents

Culture Documents

WC9

Uploaded by

Suresh KrishnanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WC9

Uploaded by

Suresh KrishnanCopyright:

Available Formats

WELDING PROCEDURE SPECIFICATION (WPS) (FORM - QW-482) MEI/WPS`/004V

IN ACCORDANCE WITH ASME SECTION IX –QW -200.1 (2021)

Page: 1 of 2

Company / Organization Name : METALLURGICAL ENGINEERING INDUSTRIES

Welding procedure Specification No. : MEI/WPS/004V

Supporting PQR No. : MEI/PQR/004V

Welding process(es) : GTAW (Gas Tungsten Arc Welding)

Type : Manual

Scope : This Producers is used for hard facing overlay welding overlay of P.No. 1 materials without PWHT

and Impact Requirement.

JOINTS: -(QW 402)

Joint Design (Typical)

Joint Design : Overlay Welding

Root spacing (A) : NA

Root land ( B) : NA

Groove angle : NA

Backing : NA

Backing Material : NA

Retainer : Nil

Base metal the (t) : 25 mm (As per relevant / approved drawing.)

BASE METALS (QW 403)

P.No. / Group No. : P.No. 5A Gr. No. 1

Specification Type & Grade : ASME A217 Gr WC9

Chemical Analysis : As per relevant / approved material specification

Mechanical properties : As per relevant / approved material specification

Thickness Range Base Metal : 25

Fillet : NA

Pipe Dia : NA

Fillet : NA

Weld pass thk mm : 1.5 to 3

FILLER METALS (QW 404)

Specification No. (SFA) : SFA: 5.9

AWS No. Classification : ER430

F.No. :6 Consumable insert : Nil

A.No. :6 Change of alloy element : Nil

Size of Electrode/Filler metal : 2.4 mm dia Electrode Flux : N/A

Filler metal product form : Solid wire Supplemental filler metal : Nil

Weld metal Thickness Range - Groove : 25 mm Min to Unlimited Fillet : All Size

POSITIONS (QW 405)

Position of Groove : 1G Flat

Welding Progression : N.A Position of Fillet : N/A

PREHEAT (QW 406)

Preheat Temperature Min. : 150ºC.

Inter pass Temperature Max. : Max 350 ºC Pre heat maintenance: NA

POST WELD HEAT TREATMENT (QW 407): Type: Nil

Temperature Range / Time Range : 620 O C (hr/inch)

Cooling : Furnace Cooled up to 300 O C

WELDING PROCEDURE SPECIFICATION (WPS) (FORM - QW-482) MEI/WPS/004V

IN ACCORDANCE WITH ASME SECTION IX –QW -200.1 (2021)

Page: 2 of 2

GAS (QW 408) (for GTAW) Gas % Composition / Mixture Flow Rate (lpm)

Shielding gas : Argon 99.995 % min ( no mixture ) 20-30 CFH

Trailing : Nil

Backing : Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Filler metal Current Travel Speed Heat Input

Volt

Weld Pass Process Diameter Type & Amps (range) KJ/ mm

Classification (Range)

(mm) Polarity (Range) (mm/min) (max)

AWS A5.14 2.4MM DC-EN 70-180 12-20 75 – 125 1.728

Hard Facing GTAW ERNiCr-3

GTAW AWS A5.14 2.4MM DC-EN 70-180 13-20 75 – 130 1.661

Hard Facing ERNiCr-3

GTAW AWS A5.14 2.4MM DC-EN 70-180 14-20 75 – 140 1.542

Hard Facing ERNiCr-3

Pulsing Current : Nil

Heat Input (max ) : 1.728 KJ / mm as per QW-256.1 & QW-409.26 ( Applicable for 1st Layer only )

Tungsten Electrode Size & type : 2.4 dia & EWTH-2

Mode of metal transfer : N/A

TECHNIQUE (QW 410)

String or weave Bead : Weave

Orifice, Nozzle or Gas cup Size : Gas Cup:6 to 10 mm dia

Initial and Interposes Cleaning : Wire Brushing and Grinding

Method of back gouging : Nil, grinding if required.

Oscillation : Nil

Contact tube to work distance : N/A

Multiple or Single pass (per side) : Multiple pass

Multiple / Single layer : Multiple layer

Multiple or Single electrode : Multiple

Electrode spacing : N/A

Change of process : N/A ( Manual only )

Travel Speed (Range) : Refer table above Peening : Not allowed

Use of thermal process : Nil Transfer mode : N/A

Torch orifice dia : N/A Filler metal delivery : From side of Torch

Prepared by, Reviewed by,

S. SOLAI / TUV SUD

WELDING PROCEDURE QUALIFICATION RECORD (PQR) MEI/PQR/004V

(FORM - QW-483)

IN ACCORDANCE WITH ASME SECTION IX QW - 200.2 (2021) Page: 1 of 2

Company Name : METALLURGICAL ENGINEERING INDUSTRIES

Welder’s Name / Stamp No. : Mr. SathishKumar

Using WPS No. : MEI/WPS/004V

Welder Performance Quln Ref. : MEI/PQR/004V

Welding process(es) : GTAW

Type : Manual Date of Welding : 08/03/2023

JOINTS: -(QW 402)

Joint Design : Overlay Welding Joint design

Root gap / space : NA

Root : NA

Groove angle : NA

Backing : Nil

Backing Material : NA

Retainer : Nil

Base thickness : 25 mm thickness plate

PREHEAT (QW 406)

BASE METALS (QW 403)

Preheat Temperature : 100 ºC

Material Specification : ASME A217 Gr WC9

Inter pass Temperature : Max 350 ºC Others: N.A

Type or Grade : WC 6

In case of interruption in welding, Post heating of 300-350'C for 1hours prior to

P.No. Gr. No. : P.No. 5A Gr. No. 1

natural cooling to room temperature

Thickness of Test Coupon : 25 mm

POST WELD HEAT TREATMENT (QW 407)

Diameter of Test Coupon : NA

Type : Nil

Size (mm) ( l) : 150 X 150 mm

Temperature : N/A

Weld bead thk / pass : 2 – 4 mm

Time Range : N/A

Test Certificate No- 17/22-23 Melt-277

Cooling : N/A

FILLER METALS (QW 404) GAS (QW 408) Gas % Composition Flow Rate (lpm)

SFA Specifications : SFA 5.9 Shielding Gas : Argon 99.99%(No Mixture) 40-30

AWS Classification : AWS A 5.9 ER430 Trailing gas : Nil ----- -----

Filler Metal F.No. :6 Backing gas : Nil ------ ------

Weld Metal Analysis A.No : 6 ELECTRICAL CHARACTERISTICS (QW 409)

Size of Filler Metal : 2.4 mm dia(for all pass/ layers ) Current (A.C. or D.C.) : D.C.

Others : NA Polarity : EN

Filler metal / Powder feed rate: N.A Amps : 70 – 180 A ( for all pass / all layers)

Weld metal thickness : 25 mm Volts : 12 - 20 V ( for all pass / all layers )

Test Certificate: 030178 Heat: 723880 Others: Heat Input (max) : NA

Mode of metal transfer : N/A Weld bead length : N/A

POSITION (QW 405)

Weave form control : N/A Power / Energy : N/A

Position of Groove : 1G

Arc Time : N/A Tungsten Electrode size : N/A

Weld Progression : N/A

Torch Angle : N.A Weld bead thk/pass : 2-4 mm

TECHNIQUE (QW 410)

Travel Speed : 75 -140 mm / min ( for all pass / all layers )

Peening : Nil

String or weave Bead : Both ( Weave width not more than 10mm)

Method of cleaning : Wire brushing (Wire Brush)& Grinding Orifice / nozzle size: N/A

Oscillation : N/A Torch orifice dia : Gas cup 10-20mm Dia

Multi pass or Single pass (per side) : Multi pass Filler metal delivery: N/A

Multiple / Single layer : Multiple layer Method of back gouge: Nil, Grinding only

Single or Multiple electrodes : Single Change of process : Nil ( Manual only )

Gas cup size : N/A Transfer mode : N/A

WELDING PROCEDURE QUALIFICATION RECORD (PQR) MEI/PQR/004V

(FORM - QW-483)

IN ACCORDANCE WITH ASME SECTION IX QW - 200.2 (2021) Page: 2 of 2

TENSILE TEST: (As per QW 150 & QW-462.1a): Report Ref : NA

Specimen No Width mm Thk mm Area mm2 Ultimate Load KN U.T.S (Mpa) Type of failure & loc

NA NA NA NA NA NA NA

Result: Acceptable as per QW-153.

GUIDED -BEND TESTS (As per QW 160 & QW-462.2): Report Ref :NA

Result: Acceptable as per QW-163

FILLET-WELD TEST (QW-180): N.A

Results : N.A

Penetration into Parent metal : N.A

OTHER TESTS

SI No

Type of Examination Acceptance Standard/ Results of Examination

Requirement

1 Radiography As per QW-191.1.2 Acceptable. Refer report No.NA

2 Hardness (HV) As per / ASTM E92-2017, ASTM Acceptable. Refer report No: MI/16210/3/22 23/ Dt 1003 2023

E18-2022

3 Macro Test As per / ASME QW- 53 Acceptable. Refer report No: MI/16210/2/22 23/ Dt 1003 2023

4 Micro As per / ASTM E407 - 2007 Acceptable. Refer report No: ML/16210/1/22-23/ Dt: 10.03.2023

5 Chemical As per / ASTM E3047-2016 Acceptable. Refer report No: ML/16210/13/22-23/ Dt: 10.03.2023

Welder’s Name: Mr. SathishKumar

Stamp No. : NA

Test Conducted By : M/s. Metallurgical Engg Industries.

We certify that the statement in this record is correct and that the test welds were prepared welded and tested in accordance with the

requirements of section IX of ASME Code.

Manufacturer For Witnessed by

S. SOLAI / TUV SUD

WELDER PERFORMANCE QUALIFICATIONS (WPQ) MEI/WQT/004

(FORM QW-484A)

IN ACCORDANCE WITH ASME SECTION IX – QW-301, 302 (2021) Page : 1 of 1

Company Name : METALLURGICAL ENGINEERING INDUSTRIES

Welder’s Name / Stamp No. : Mr. SathishKumar

Using WPS No. : MEI/WPS/004V

Welder Performance Quln Ref. : MEI/PQR/004V

Test conducted on : Test Coupon

Welding date : 08.03.2023

Specification of base metal / Size : ASME A217 GR WC 9 / 25mm

Testing conditions and Qualification limits

Welding Variable (QW-350) Actual Values Range Qualified

Welding process(es) GTAW GTAW

Type (ie., : manual, semi auto) used Manual Manual

Backing (metal, Weld Metal, Double Welded etc.,) Base & Weld Material Base & Weld Material

( ) Plate ( ) Pipe (enter diameter, if Pipe or tube) Plate Plate

Base metal P or S.No to P or S No P. No: 5A P. No: 1 to 15F

Filler metal or electrodes specification(s) (SFA)(info only) 5.9 As per relevant WPS

Filler metal electrodes classification(s) (info only) ER430 As per relevant WPS

Filler metal F.No(s). 2.4 mm As per relevant WPS

Filler type (solid /metal or flux cored/powder) (GTAW or PAW) Solid Wire Solid Wire

Deposit thickness for each process 1.5 mm Maximum as per relevant WPS

Consumable insert (GTAW or PAW ) Nil Nil

Position qualified (2G ,6G,3F,etc) 1G 1G, 1F

Vertical progression (uphill or downhill) N/A N/A

Type of fuel gas (OFW) N/A N/A

Inert gas backing (GTAW,PAW,GMAW) Nil With & Without Backing

Transfer mode (spray/globular or pulse to short circuit- GMAW) N/A N/A

GTAW current type/polarity (AC,DCEP,DCEN) DCEN DCEN

Result

Radiography examination results (QW-191) : Satisfactory & Acceptable. Refer report No. NA

Bend test results (QW 462.2) : Satisfactory & Acceptable. Refer report No. NA

Tensile test conducted by : Satisfactory. Refer report: NA.

Welding qualification conducted by : M/s. Metallurgical Engg Industries.

We certify that the statement in this record is correct and that the test coupons were prepared, welded, and tested in accordance with the

requirements of Section IX of the ASME Boiler & Pressure Vessel Code.

For Witnessed by

S. SOLAI / TUV SUD

You might also like

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- Code of Practice For Electrical Wiring InstallationsDocument82 pagesCode of Practice For Electrical Wiring InstallationsPrithvi RajNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- TA30 G7 SM 05 2007 Manual de Servicio TerexDocument384 pagesTA30 G7 SM 05 2007 Manual de Servicio TerexMoicano P Sánchez100% (2)

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 pagesQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- Wps Format Asme Sec - IxDocument2 pagesWps Format Asme Sec - IxDeepu ChandranNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- WpsDocument2 pagesWpssamer8saifNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Fundamentals, Selection and Sizing of Standby Batteries PDFDocument53 pagesFundamentals, Selection and Sizing of Standby Batteries PDFRajarsi RayNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Is 2309 1989Document72 pagesIs 2309 1989Jagdish PalariyaNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Wps FormatDocument12 pagesWps FormatGohilakrishnan ThiagarajanNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDocument3 pagesASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanNo ratings yet

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocument1 pagePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Ship Hydrodynamics NUMECADocument87 pagesShip Hydrodynamics NUMECACarl FranksNo ratings yet

- BSI Standards Publication: Uninterruptible Power Systems (UPS)Document100 pagesBSI Standards Publication: Uninterruptible Power Systems (UPS)Suresh KrishnanNo ratings yet

- Iec 60076-Part 15Document67 pagesIec 60076-Part 15Suresh KrishnanNo ratings yet

- 2018 01 Green Urban AreaDocument16 pages2018 01 Green Urban AreaCerasella GoiaNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- 0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCDocument2 pages0.1C#PAOLO) Sample PQR-35 For Mock Up Exam 19032016 @PCAshish PatelNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationVISAKHAPATNAM MALAYALEES WELFARE ASSOCIATIONNo ratings yet

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Welding Procedure Specification (AutoRecovered)Document2 pagesWelding Procedure Specification (AutoRecovered)virnmontalesNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- MHC Conveying System Private Limited: JOINTS (QW-402)Document3 pagesMHC Conveying System Private Limited: JOINTS (QW-402)Lipika GayenNo ratings yet

- Verspec WPS WPQDocument6 pagesVerspec WPS WPQgtsi.draftsmanNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Aic Asf PQR 0119Document2 pagesAic Asf PQR 0119AHMED MEDANYNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Procedure Qualification SpecificationDocument4 pagesProcedure Qualification Specificationriyas.hvacworkNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- PROCEDURE FOR HANDLING-Rev.01Document5 pagesPROCEDURE FOR HANDLING-Rev.01Suresh KrishnanNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- 2020 Power Substation GuidebookDocument24 pages2020 Power Substation GuidebookSuresh KrishnanNo ratings yet

- Reaffirmed 2017Document17 pagesReaffirmed 2017Suresh KrishnanNo ratings yet

- Catalogue Havells Consumer CableDocument24 pagesCatalogue Havells Consumer CableneharikaNo ratings yet

- CurrentRatings PDFDocument0 pagesCurrentRatings PDFVirajitha MaddumabandaraNo ratings yet

- Is 3043 1987Document95 pagesIs 3043 1987suresh kumarNo ratings yet

- Is 2551 1982 PDFDocument15 pagesIs 2551 1982 PDFAjay SatputeNo ratings yet

- HTTP Cqir - BhelDocument1 pageHTTP Cqir - BhelSuresh KrishnanNo ratings yet

- Share PricesDocument186 pagesShare PricesHarshul BhatiaNo ratings yet

- EmpgDocument10 pagesEmpgShravanNo ratings yet

- Thesis Generator AppDocument6 pagesThesis Generator Appafcnenabv100% (1)

- Scribd For IphoneDocument3 pagesScribd For IphoneScribd50% (2)

- CSP Networking 5g EbookDocument14 pagesCSP Networking 5g EbookLeopoldo Lopez QuinteroNo ratings yet

- Mathematical Modeling Performance Evaluation of Electro Hydraulic Servo ActuatorsDocument24 pagesMathematical Modeling Performance Evaluation of Electro Hydraulic Servo ActuatorsZyad KaramNo ratings yet

- Inventaris Barang LaboratoriumDocument52 pagesInventaris Barang Laboratoriumlaboratorium rsparagonNo ratings yet

- Online Interview Questions AnswersDocument4 pagesOnline Interview Questions AnswersafiloteNo ratings yet

- Surface roughness modelling in super duplex stainless steel turningDocument16 pagesSurface roughness modelling in super duplex stainless steel turningfatinNo ratings yet

- Lubricator L26 Economist™ L27 Atomist™: Specifi CationsDocument2 pagesLubricator L26 Economist™ L27 Atomist™: Specifi CationsJacobo SuarezNo ratings yet

- V2 Progression Pathways by CS IT and DL-with-CT-refs PDFDocument1 pageV2 Progression Pathways by CS IT and DL-with-CT-refs PDFsramsahaNo ratings yet

- AVIC-Z150BH, X950BH, X850BT Firmware Update InstructionsDocument4 pagesAVIC-Z150BH, X950BH, X850BT Firmware Update InstructionsEnlight Lab AlbaniaNo ratings yet

- NetworkDocument3 pagesNetworkNikhil kushwahaNo ratings yet

- S7 Communication Between SIMATIC S7-1500 and SIMATIC S7-300: Step 7 V16 / Bsend / BRCVDocument45 pagesS7 Communication Between SIMATIC S7-1500 and SIMATIC S7-300: Step 7 V16 / Bsend / BRCV9226355166No ratings yet

- 2001 Bookmatter HandbookOfPrintMedia PDFDocument20 pages2001 Bookmatter HandbookOfPrintMedia PDFShakhawat SopanNo ratings yet

- Product Group Codes: Pump SealsDocument15 pagesProduct Group Codes: Pump SealsJesus PicaluaNo ratings yet

- A Study On Consumer Behaviour Towards Led TV: in Comibatore DistrictDocument11 pagesA Study On Consumer Behaviour Towards Led TV: in Comibatore DistrictNithishNo ratings yet

- Netwrix Effective Permissions Reporting Tool Quick Start GuideDocument20 pagesNetwrix Effective Permissions Reporting Tool Quick Start GuideAaronNo ratings yet

- MK9906 enDocument2 pagesMK9906 enZarko DramicaninNo ratings yet

- RRB Clerk Main - 11Document42 pagesRRB Clerk Main - 11EliteNo ratings yet

- Catia v5 6r2014 For Engineers and Designers PDF FreeDocument2 pagesCatia v5 6r2014 For Engineers and Designers PDF FreeJasmeet SinghNo ratings yet

- Artificial Lift Methods GuideDocument38 pagesArtificial Lift Methods Guide000No ratings yet

- ESBWR Natural Circulation Fact SheetDocument1 pageESBWR Natural Circulation Fact SheetmanuvildaNo ratings yet

- Introduction To Qualitative Research MethodsDocument8 pagesIntroduction To Qualitative Research MethodsBast JordNo ratings yet

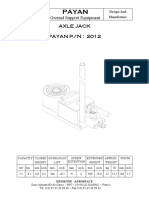

- Payan: Axle Jack PAYAN P/N: 2012Document38 pagesPayan: Axle Jack PAYAN P/N: 2012gmailNo ratings yet

- .Uksitesdefaultfiles2023 10Pages20from20LOCOMOTION20report20part201 PDFDocument109 pages.Uksitesdefaultfiles2023 10Pages20from20LOCOMOTION20report20part201 PDFdfjpennington1No ratings yet