Professional Documents

Culture Documents

Aic Asf PQR 0121

Uploaded by

AHMED MEDANYOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aic Asf PQR 0121

Uploaded by

AHMED MEDANYCopyright:

Available Formats

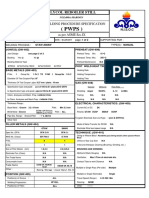

ARABIAN INTERNATIONAL COMPANY

PROCEDURE QUALIFICATION RECORD (PQR)

Procedure Qualification No. : AIC-ASF-PQR-0121 Date: 28/Apr/19

WPS No.: 2019-S-006 Rev.00

Welding Process(es): SAW

Type (Manual, Machine): Machine

Code: ASME IX X API 1104 ASME B31.3 OTHER

JOINTS (QW-402)

a = 80 ⁰

b = 10 mm

c = 4.0 mm

d = 0 mm

BASE METALS (QW-403) POST WELD HEAT TREATMENT (QW-407)

Material Spec. SA516 Grade 60/70 Temperature: N/A

Type / Grade SA516 Grade 60/70 Time: N/A

P-No. 1 Group No. 1, 2 to P-No. 1 Group No. 1, 2 Heating Rate: N/A

Thickness of Test Coupon (Base metal): 8 mm Cooling Rate: N/A

Diameter of Test Coupon: NA Others: N/A

Maximum Pass Thickness: 4 mm

Other: HT# 817554

FILLER METALS (QW-404) GAS (QW-408)

Percent

SAW Gas(es) Flow Rate

Composition

SFA Specification: A5.17 Shielding: None N/A N/A

AWS Classification: F7A2-EM12K Trailing: None N/A N/A

Filler Metal F.No.: 6 Backing: None N/A N/A

Weld Metal Analysis A.No.: 1 Other

Size of Filler Metal: Ø4.0 mm

Filler metal Product Form : Solid/Bare

Supplemental Filler Metal: N/A

Electrode Flux Classification: F7A2-EM12K ELECTRICAL CHARACTERISTICS (QW-409)

Flux Type : Basic Current : DC

Flux Trade Name: Geka ELIFLUX BFB Polarity : EP

Weld Metal Thickness: 8 mm Amps : See table belowVolts : see table below

Electrode Brand: Geka ELIFLUX BFB/Geka S2 SI Tungsten Electrode Size NA

Lot / Batch No 101517-49418/16402174718 Mode of Transfer NA

Others None Heat Input : See table below

Other:

POSITION (QW-405) TECHNIQUE (QW-410)

Position (s) 1G Travel Speed: 490-652 mm/min

Weld Progression (Uphill, Downhill): Uphill String or Weave Bead: String

Other : Cotact tube to work distance 25-40 mm

PREHEAT (QW-406) Multipass or Single Pass: Multiple

Single or Multiple Electrode: Single

Preheat Temperature : 21°C Single / Double side Welding: Single / Double

Interpass Temperature: 185 ⁰C Max Max Weave width N/A

Method of back Gouging

Arc Gouging / grinding

/Grinding

Intial and inter-pass Cleaning Grinding & Brushing

ELECTRICAL CHARACTERISTICS (QW-409)

Voltage Travel

Filler Metal Current Heat Input

Weld Layers Process Range Speed Range

(Passes) Type

Polarity Amp. Range (mm/min) Max (KJ/mm)

Classification Dia. Volts

1(Root) SAW F7A2-EM12K 4.0 mm DCEP 399-436 25-26 652 0.92-1.04

2 (Fill/Cap) SAW F7A2-EM12K 4.0 mm DCEP 525-565 29-30 532 1.72-1.91

3 (BW) SAW F7A2-EM12K 4.0 mm DCEP 489-542 27-28 490 1.62-1.86

FORM-QL-21 Rev.-0 Page 1 of 2

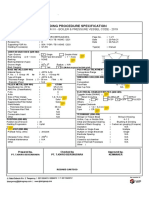

ARABIAN INTERNATIONAL COMPANY

PQR No.: AIC-ASF-PQR-0121

TENSILE TEST (QW-150)

Width Thickness Area Ultimate Total Ultimate Unit Stress Type of Failure and

Specimen No.

(mm) (mm) (Sq.mm) Load (KN) Mpa Location

Ductile

T-1 7.62 18.98 148.72 82.70 571.80 / 82,930

Base metal

Ductile

T-2 7.71 19.03 149.71 84.10 573.20 /83,133

Base metal

Material : A516 Gr 60/70

Test Result : Satisfactory

Refer Fugro-Suhaimi Report # FSL/T&B/1918-2019

GUIDED BEND TESTS (QW-160)

Type and Figure No. Result

Face Bend Test-1 Fig. QW-462.3 (a) Satisfactory

Face Bend Test-2 Fig. QW-462.3 (a) Satisfactory

Root Bend Test-1 Fig. QW-462.3 (a) Satisfactory

Root Bend Test-2 Fig. QW-462.3 (a) Satisfactory

NOTE: Plunger Size 32 mm , Degree of Bend 180⁰ ( Fig QW-.466.1)

No open discontinuity observed in the weld and HAZ on convex surface of the specimens after bending

Refer Fugro-Suhaimi Report # FSL/T&B/1918-2019

TOUGHNESS TESTS (QW-170)

Test

Specimen No. Notch Location Notch Type Impact Drop Weight Break

Temperature

Values % Shear Mills Break (Y/N)

Refer Fugro-Suhaimi Report # FSL/CIT/1919-2019

FILLET WELD TEST (QW-180) (N/A)

Result-Satisfactory: Yes No. Penetration into Parent Metal: Yes No

Macro Results: N/A

OTHER TESTS

Type of Test: RT Report No SOGEC-RT/ 18/111232.

Deposit of Analysis: Impect Test Report Refer to FSL/CIT/1911-2019

Other: Hardness Test Report Refer to FSL/HT/1909-2019 & 1910-2019

Welder's Name: Mario G Ramos Jr Stamp No: 15268

Tests Conducted by: Fugro Suhaimi Ltd Laboratory Test No: FSL/T&B/1908--2019,

FSL/HT/1909-2019 & 1910-2019

FSL/CIT/1911-2019.

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in

accordance with the requirements of Sec.IX of ASME Boiler and Pressure Vessel Code -2017

Organization: Arabian International Company

Prepared By: Prepared By:

Ahmed Medany Zaki Ramadan

Welding Engineer QC Manager

FORM-QL-21 Rev.-0 Page 2 of 2

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- Aic Asf PQR 0122Document2 pagesAic Asf PQR 0122AHMED MEDANYNo ratings yet

- Aic Asf PQR 0119Document2 pagesAic Asf PQR 0119AHMED MEDANYNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- PT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSDocument1 pagePT. TRECONS MITRA GEMILANG PROCEDURE QUALIFICATION RECORDSBudi Setia RahmanNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welding Procedure Specification for Stainless SteelDocument5 pagesWelding Procedure Specification for Stainless SteelVarun Malhotra100% (5)

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Glycol Reboiler Still Welding Procedure Specification (PWPSDocument2 pagesGlycol Reboiler Still Welding Procedure Specification (PWPSstdshopNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WpsDocument2 pagesWpssamer8saifNo ratings yet

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS 10Document2 pagesWPS 10Arab WeldersNo ratings yet

- 4 2WPSDocument2 pages4 2WPSsaravanans18910% (1)

- ASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelDocument3 pagesASME Section IX Welding Procedure Specification for GTAW of ASTM A-36 SteelBudi Setia RahmanNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- PWPS 102 - CopyDocument2 pagesPWPS 102 - CopyCyril J PadiyathNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- AMRITA ENGINEERING WORKS PQRDocument3 pagesAMRITA ENGINEERING WORKS PQRBalkishan DyavanapellyNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- SCES3083 Topic6 Temperature and HeatDocument22 pagesSCES3083 Topic6 Temperature and Heat胡佳玲No ratings yet

- Ground Verify and Neutral Shifting Details for Manual TransmissionDocument1 pageGround Verify and Neutral Shifting Details for Manual TransmissiontvwrightNo ratings yet

- Hyundai Atoz - Part 2. Engine MechanicalDocument22 pagesHyundai Atoz - Part 2. Engine MechanicalDasar GemblungNo ratings yet

- Andsaw For The Lathe: by Dennis HorlerDocument6 pagesAndsaw For The Lathe: by Dennis HorlerJohn BrittonNo ratings yet

- Praveen Kumar. S: ObjectiveDocument2 pagesPraveen Kumar. S: ObjectiveRajesh Krishna0% (1)

- Oil+Air SystemsDocument12 pagesOil+Air SystemsLLNo ratings yet

- J Engstruct 2007 07 008Document12 pagesJ Engstruct 2007 07 008Jaouad OuaâzizNo ratings yet

- ICMF2001 Schnerr SauerDocument13 pagesICMF2001 Schnerr SauermacromoleculeNo ratings yet

- Rss 120-m Recycling Shredder Screener Sell Sheet Pss-1339-00-EnDocument2 pagesRss 120-m Recycling Shredder Screener Sell Sheet Pss-1339-00-Enamolsinha1No ratings yet

- Important QuestionsDocument6 pagesImportant Questionsgibingeorge11No ratings yet

- 2KJ3203Document1 page2KJ3203Banupriya BalasubramanianNo ratings yet

- Ace Catalog 2009Document48 pagesAce Catalog 2009aiyubi2100% (2)

- Air Cooled Split Type Air Conditioners SpecificationsDocument2 pagesAir Cooled Split Type Air Conditioners SpecificationsWare HandokoNo ratings yet

- Hitachi ZX210LC 5 Spec en WebDocument8 pagesHitachi ZX210LC 5 Spec en WebridofambudiNo ratings yet

- Gravitation NotesDocument3 pagesGravitation NotesrajeshdraneNo ratings yet

- Base Equipment 257 496Document240 pagesBase Equipment 257 496Jorge Luis HernándezNo ratings yet

- Yamaha Vf250 SHO Outboard Service Repair Manual Pid Range 6cb-1000001 Current MFG Dec 2009 and NewerDocument0 pagesYamaha Vf250 SHO Outboard Service Repair Manual Pid Range 6cb-1000001 Current MFG Dec 2009 and NewerColey Scott100% (1)

- Basic Electrical Engineering - Synchronous GeneratorDocument82 pagesBasic Electrical Engineering - Synchronous GeneratorlAntiherolNo ratings yet

- Design of AbsorberDocument9 pagesDesign of Absorberhaseeb tahir50% (2)

- Supporting and Design Consideration of Small-Bore PipingDocument4 pagesSupporting and Design Consideration of Small-Bore PipingTUSHAR BANGERANo ratings yet

- Positive Displacement (PD) Meter ExplainedDocument24 pagesPositive Displacement (PD) Meter ExplainedJulius ChavezNo ratings yet

- Is 12818-2010 PDFDocument22 pagesIs 12818-2010 PDFINFOHEPL RCLNo ratings yet

- Heat TransferDocument87 pagesHeat TransferGülgün YenigünNo ratings yet

- ROLLS ROYCE Gasturbines - tcm92-4977Document20 pagesROLLS ROYCE Gasturbines - tcm92-4977Vipin Thathiriyat100% (3)

- Voron: Switchwire Assembly ManualDocument103 pagesVoron: Switchwire Assembly ManualRicardo HaroNo ratings yet

- Flow AssuranceDocument58 pagesFlow AssuranceAbdomatar100% (2)

- PG 23Document1 pagePG 23azeem bilalNo ratings yet

- Mechanics of Materials 7th Edition Beer Solutions Manual 1Document136 pagesMechanics of Materials 7th Edition Beer Solutions Manual 1kimberly100% (45)

- Motion of Particles in FluidsDocument10 pagesMotion of Particles in FluidsMichael Kang'eriNo ratings yet

- Mohit Paper 2Document23 pagesMohit Paper 2mohitNo ratings yet