Professional Documents

Culture Documents

Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)

Uploaded by

Saravanan Palanisamy Lakshmi100%(1)100% found this document useful (1 vote)

78 views2 pagesThis document provides a welding procedure specification for a single V-butt joint between SA 240 GR 904L base metals using SMAW with E385 electrodes in the 3G position. It specifies preheat of 10°C, interpass temperature below 150°C, multiple stringer passes with filler metal diameters of 2.5mm and 3.2mm, and current, voltage, and travel speeds within the specified ranges. The WPS does not require post weld heat treatment.

Original Description:

welding Procedure Specification format

Original Title

DRAFT WPS

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a welding procedure specification for a single V-butt joint between SA 240 GR 904L base metals using SMAW with E385 electrodes in the 3G position. It specifies preheat of 10°C, interpass temperature below 150°C, multiple stringer passes with filler metal diameters of 2.5mm and 3.2mm, and current, voltage, and travel speeds within the specified ranges. The WPS does not require post weld heat treatment.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

78 views2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)

Uploaded by

Saravanan Palanisamy LakshmiThis document provides a welding procedure specification for a single V-butt joint between SA 240 GR 904L base metals using SMAW with E385 electrodes in the 3G position. It specifies preheat of 10°C, interpass temperature below 150°C, multiple stringer passes with filler metal diameters of 2.5mm and 3.2mm, and current, voltage, and travel speeds within the specified ranges. The WPS does not require post weld heat treatment.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

Owner :

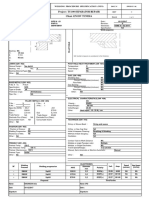

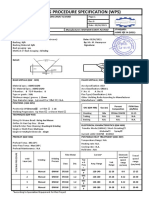

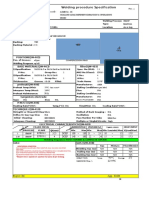

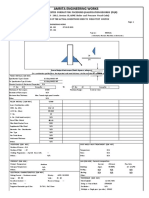

WELDING PROCEDURE SPECIFICATION(WPS)

(As per QW 482 of ASME Section IX)

WPS No (DRAFT) :

Procedure Qualification Record No :

Welding Process(es) : SMAW

Types (Manual, Automatic, Semi-Auto) :Manual

JOINTS (QW-402)

Joint Design : Butt Joint- Single V

Backing : Yes

Backing Material :Base Metal

BASE METALS (QW-403)

P-No 45 Group No to P-No 45 Group No

OR

Specification, Type & Grade :SA 240 GR 904L to SA 240 GR 904L or equivalent

to Specification, Type & Grade :SA 240 GR 904L to SA 240 GR 904L or equivalent

OR

Chemical Analysis and Mech. Properties :

to Chemical Analysis and Mech. Properties :

Base Metal Thickness Range

a) Groove : 1.5mm to 20 mm

b) Fillet : ALL SIZE

FILLER METALS (QW-404)

Process-1 Process-2

Specification No. (SFA) : 5.4

AWS No. (Class) : E385

F- No. :5

A- No. :9

Size of Filler Metal : Ø 2.5 mm & Ø 3.2mm

Weld Metal Thickness Range

a) Groove : max 20 mm

b) Fillet :

Electrode-Flux (Class) : NA

Flux Trade Name : NA

Consumable Insert : NA

Other : NA

POSITION (QW-405) POST WELD HEAT TREATMENT(QW-407)

Position of Groove : 3G Loading Temperature : NA

Welding Progression (Uphill/Downhill) : UPHILL Heating Rate : NA

Position of Fillet : ALL Soaking Temperature : NA

PRE HEAT (QW-406) Soaking Time : NA

Pre heat Temperature (Minimum) : 10 °C Cooling Rate : NA

Interpass Temperature (Maximum) : 150 °C Unloading Temperature : NA

Pre heat Maintenance :

EXHIBIT NO: NSC/1032/QC/W/02 R 0

Owner :

WELDING PROCEDURE SPECIFICATION(WPS)

(As per QW 482 of ASME Section IX)

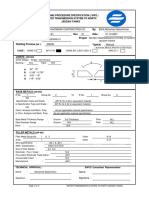

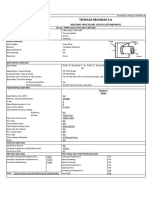

GAS (QW-408)

Gas % Composition (Mixture) Flow Rate

Shielding Gas NA NA NA

Trailing Gas NA NA NA

Backing Gas NA NA NA

ELECTRICAL CHARACTERISTICS (QW-409)

Current : DC

Polarity : DCEP

Amps Range : See Table

Volts Range : See Table

Tungsten Electrode Size and Type : NA

Mode of Metal Transfer (for GMAW) : NA

Electrode Wire Feed Speed Range : NA

TECHNIQUE (QW-410)

String or Weave : String & Weave

Orifice or Gas Cup Size NA

Initial and Inter pass Cleaning : Grinding & Brushing (only SS suitable Material)

Method of Back gouging : Grinding

Oscillation : 3 X Electrode Diameter

Contact Tube to Work Distance : NA

Multiple or Single Pass (per side) : Multiple

Multiple or Single Electrode : Single

Travel Speed (Range) : See Table

Peening : None

Other :

Filler Metal Current

Sl. Speed

Pass Process Dia Volts Remarks

No. AWS Class Polarity Amps mm/Min

(mm)

1 Root SMAW E 385 2.5 DCEP

2 Hot SMAW E 385 3.2 DCEP

3 Fill up SMAW E 385 3.20 DCEP

4 Fill up SMAW E 385 3.2 DCEP

5 Final SMAW E 385 2.5 DCEP

Note(s):

Signature

Name

Date

Contractor Client Inspection Authority

EXHIBIT NO: NSC/1032/QC/W/02 R 0

You might also like

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Document1 pageProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- WPS PQR CompleteDocument49 pagesWPS PQR CompleteGulfam HussainNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- WPS PQRDocument126 pagesWPS PQRBuditama ChandranegaraNo ratings yet

- Aic Asf PQR 0119Document2 pagesAic Asf PQR 0119AHMED MEDANYNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Mechanical Engineering M.Abdul GhoziDocument4 pagesMechanical Engineering M.Abdul GhoziRizaldy PhoenksNo ratings yet

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiNo ratings yet

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 pageCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDDocument2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVANDvahid mobiniNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- 347 310 WPSDocument2 pages347 310 WPSBIIS QAQC Babu SivaNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

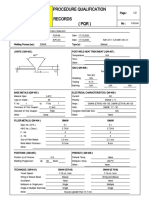

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Criteria Based WorksheetDocument3 pagesCriteria Based Worksheetarun iyer BitcoinminerandmathematicianNo ratings yet

- Pyro-Bloc M Module Manual DD 31052016Document20 pagesPyro-Bloc M Module Manual DD 31052016thoavitNo ratings yet

- Large-Particle CompositesDocument25 pagesLarge-Particle CompositesLexNo ratings yet

- Project TopicsDocument2 pagesProject TopicsBala GopalNo ratings yet

- Total ResultDocument29 pagesTotal Resultali aridiNo ratings yet

- Q1 Week 56 MatterDocument5 pagesQ1 Week 56 MatterJohannah SuraitNo ratings yet

- U-4 - Design of Riveted Joint - SRMDocument87 pagesU-4 - Design of Riveted Joint - SRMsiddharth GautamNo ratings yet

- Data 1Document3,440 pagesData 1Amitash DeganNo ratings yet

- Piping QC Chart-1Document1 pagePiping QC Chart-1Muthu SubramanianNo ratings yet

- Absorption - Mass TransferDocument34 pagesAbsorption - Mass TransferAnonymous 0zrCNQNo ratings yet

- Oil & Grease TestDocument16 pagesOil & Grease TestRohini GadhaweNo ratings yet

- Plasma Laser CuttingDocument5 pagesPlasma Laser Cuttingibrahim syedNo ratings yet

- Bills of Quantities PDFDocument53 pagesBills of Quantities PDFAlvin ClintNo ratings yet

- Construction and Building Materials: Reza Bani Ardalan, Alireza Joshaghani, R. Douglas HootonDocument7 pagesConstruction and Building Materials: Reza Bani Ardalan, Alireza Joshaghani, R. Douglas HootonCarlos CameroNo ratings yet

- Summary of Hot Mix Asphalt Preparation by Marshall Method: Mixing, Compaction, and Stability and FlowDocument7 pagesSummary of Hot Mix Asphalt Preparation by Marshall Method: Mixing, Compaction, and Stability and FlowlabgggcNo ratings yet

- Loctite PC 7210™: Technical Data SheetDocument4 pagesLoctite PC 7210™: Technical Data Sheetangga alvianNo ratings yet

- Mineral Resources of Nepal and Their Present StatusDocument26 pagesMineral Resources of Nepal and Their Present StatusSanjay KarkiNo ratings yet

- BSB Opzv SeriesDocument2 pagesBSB Opzv SeriesEris Osman RifkiNo ratings yet

- BEHAVIOUR AND STRENGTH ASSESSMENT OF Masonry PrismsDocument42 pagesBEHAVIOUR AND STRENGTH ASSESSMENT OF Masonry Prismsmanish_shashikantNo ratings yet

- Piping Manual EnglishDocument75 pagesPiping Manual EnglishbachieuNo ratings yet

- DIY Modern Chicken Coop Plans Printable PDFDocument10 pagesDIY Modern Chicken Coop Plans Printable PDFPim Durieux100% (1)

- CAS NO 61791-53-5 - Duomeen-TdoDocument2 pagesCAS NO 61791-53-5 - Duomeen-TdoVirender KumarNo ratings yet

- Anchor HiltiDocument324 pagesAnchor HiltiRuben GutierrezNo ratings yet

- Woodcraft Magazine USA April May 2013 PDFDocument84 pagesWoodcraft Magazine USA April May 2013 PDFalex2010_23100% (3)

- Fire Tech and Arson InvestigationDocument24 pagesFire Tech and Arson InvestigationMagus Flavius91% (23)

- Ria Final ChaitanyaDocument10 pagesRia Final ChaitanyaChaitanya WalkeNo ratings yet

- Composition of Suspension and Suspending Agents.Document4 pagesComposition of Suspension and Suspending Agents.hira khanNo ratings yet

- Tylose For Emulsion PolymerizationDocument4 pagesTylose For Emulsion Polymerizationhenriquefxs2926No ratings yet

- R2 - RevADocument12 pagesR2 - RevAChirag ShahNo ratings yet

- C1 - PCCDocument8 pagesC1 - PCCkjj7760No ratings yet