Professional Documents

Culture Documents

Welding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVAND

Uploaded by

vahid mobini0 ratings0% found this document useful (0 votes)

24 views2 pagesOriginal Title

wps-06 butt tichk

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views2 pagesWelding Procedure Specification (WPS) : Manufacturer: NAHADIN SANAT ALVAND

Uploaded by

vahid mobiniCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

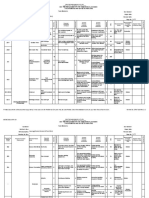

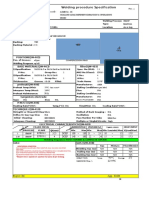

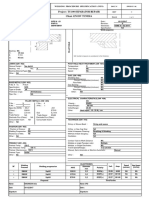

WELDING PROCEDURE SPECIFICATION (WPS)

Author:Hasanpour Project: NAHADIN SANAT ALVAND Page:1

Drawing N.R:

Rev:0

Date: 09/06/2021

CLIENT: WPS NO:01 Manufacturer: NAHADIN SANAT ALVAND STANDARD:

WELDING PROCESS(ES) : GMAW ASME SEC IX (2021)

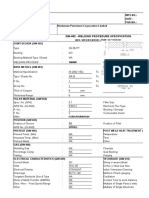

JOINTS(QW-402)

Joint Design : Single Groove weld ( V Groove) Date: 09/06/2021

Backing: N/A By: Mr. M. Hasanpour

Backing Material: N/A Signature:

Back gouging : yes

Method of Back Gouging : Grinding

Detail:

BASE METALS (QW - 403) FILLER METALS ( QW-404)

Material spec.: ASME SA240 Aws Specification: A5.9

TO Material Spec.: ASME SA240 Aws Classification: ER316-L

P Number: 8 TO P Number: 8 F .No: 6 A .No: 8

Type or grade : 316L Flux Type( Classification ): N.A

Thickness range ( groove ): 12mm Other :Holding Rods According to Manufacturer

Pipe diameter range ( groove or fillet ): N.A. Manufacturer : AMA

POSITONS ( QW-405)

Percent FIOW Rate

GAS (QW-408) Gas (es)

Position(s) OF(Groove or Fillet ): 1G Composition (Lit/Min)

Welding Progression: Up Ward or Down Ward

Shielding Mix 95%Ar+5%CO2 12-15

TECHNIQUE (QW-410)

Trailing N.A. N.A. N.A.

String Or Weave Bead : String And Weave Backing N.A. N.A. N.A.

Orifice Or Gas Cup Size : 15 mm

Initial & Inter Pass Cleaning: Brushing & Grinding ELECTERICAL CHARACTERISTICS (QW-409)

Single or Multi Pass: Multi pass Transfer Mode (GMAW) Short-Circuiting

Single Or Multiple Electrode : Single Globular Spray

Current :AC DCEP DCEN

PREHEAT (QW-406) POSTWELD HEAT TREATMENT (QW-407)

Temperature Range: N.A

Preheat Temp.: Min 10°C Heating rate: N.A.

Inter Pass Temp: Max 150°C Cooling rate : N.A.

Preheat Maintenance : N.A. Hold time : N.A

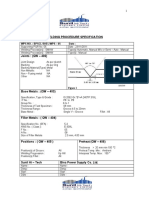

WELDING PROCEDURE

Filler Metal Current* Electrode Travel

wire feed

weld Welding

Typ

speed

Welding speed.

Layer (es) Process range

e& Volt. range

Class Dia. Amp. Range (cm/min)

Pola Range (m/min)

r.

DCE

1 Manual GMAW ER316l 1.2 120-140 22-26 6-8 15-25

P

DCE

2 Manual GMAW ER316l 1.2 120-160 24-28 8-12 20-30

P

DCE

3 Manual GMAW ER316l 1.2 140-180 24-28 8-12 20-40

P

DCE

4 Manual GMAW ER316l 1.2 140-180 24-28 8-12 20-40

P

*According to Specialized Equipment for this Project

You might also like

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- Pfi Es-24Document10 pagesPfi Es-24kingstonNo ratings yet

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Process Improvement in Pressure Vessel Fabrication Approach To DMAIC Methodology Case in Small and Medium Industries in IndonesiaDocument5 pagesWelding Process Improvement in Pressure Vessel Fabrication Approach To DMAIC Methodology Case in Small and Medium Industries in IndonesiaAbuhurairah MunshiNo ratings yet

- Inspection and Testing RequirementsDocument10 pagesInspection and Testing Requirementsnaoufel1706No ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- Workshop Welding ShopDocument80 pagesWorkshop Welding ShopBhaskar KandpalNo ratings yet

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Fmea Sfe47.005 WeldingDocument8 pagesFmea Sfe47.005 Weldingkumaraswamy.kNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Oil Penetration Leak Test Procedure Rev ADocument4 pagesOil Penetration Leak Test Procedure Rev AAzuwan MohamadNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- JPSC-230-41-PCD-4-101-00 HSE PlanDocument23 pagesJPSC-230-41-PCD-4-101-00 HSE PlanYosuaNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667No ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- 1044 Plant Inspection Career Poster March 2015 PDFDocument1 page1044 Plant Inspection Career Poster March 2015 PDFHoque Anamul100% (1)

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Caterpiller Engine Manual SVMDocument661 pagesCaterpiller Engine Manual SVMJuan I. Meza Lozano92% (12)

- WPS PQRDocument126 pagesWPS PQRBuditama ChandranegaraNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Technical Standards & Specifications Including Safety Standards For City or Local Natural Gas Distributions NetworksDocument91 pagesTechnical Standards & Specifications Including Safety Standards For City or Local Natural Gas Distributions Networkspravesh sharma80% (5)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- QP-STD-L-009 R1 TechSpecfor Corrosion Monitoring SystemDocument36 pagesQP-STD-L-009 R1 TechSpecfor Corrosion Monitoring Systemsamynathan_bvsNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Arl-Al - WPS-001 PDFDocument2 pagesArl-Al - WPS-001 PDFrajuajiNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Causes of Failure and Repairing Options PDFDocument17 pagesCauses of Failure and Repairing Options PDFSubhash AhujaNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- WPS PQR CompleteDocument49 pagesWPS PQR CompleteGulfam HussainNo ratings yet

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Document1 pageProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNo ratings yet

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateDocument3 pagesJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanNo ratings yet

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad BilalNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- Aic Asf PQR 0119Document2 pagesAic Asf PQR 0119AHMED MEDANYNo ratings yet

- Welding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001Document4 pagesWelding Procedure Specification (WPS) : WPS-KNM-001 PQR-KNM-001sreejithr86No ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Procedure Specification Pipe 6G PDFDocument3 pagesWelding Procedure Specification Pipe 6G PDFchepurthiNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxDocument4 pagesWelding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxLipika GayenNo ratings yet

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Welding Procedure Specification (AutoRecovered)Document2 pagesWelding Procedure Specification (AutoRecovered)virnmontalesNo ratings yet

- Aic Asf PQR 0120Document2 pagesAic Asf PQR 0120AHMED MEDANYNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- WPS 01 WQT PDFDocument1 pageWPS 01 WQT PDFkiki270977No ratings yet

- Internship Report - HRM - Central Railway Workshop, Mysore - Final To PrintDocument68 pagesInternship Report - HRM - Central Railway Workshop, Mysore - Final To PrintshashankNo ratings yet

- Murex Mig Poster 2008 PDFDocument1 pageMurex Mig Poster 2008 PDFPCNo ratings yet

- 012 HIRARC Driving of 175mm X 175mm PileDocument4 pages012 HIRARC Driving of 175mm X 175mm PilebdieyNo ratings yet

- A426A426MDocument5 pagesA426A426Msandeep acharNo ratings yet

- Urea Paper 2c BartelliDocument7 pagesUrea Paper 2c BartelliSai PrasathNo ratings yet

- Grade 11: Automotive ServicingDocument39 pagesGrade 11: Automotive ServicingBe MotivatedNo ratings yet

- Broco BR-20 Welding StingerDocument2 pagesBroco BR-20 Welding Stingercomsindo commodity survey indonesiaNo ratings yet

- VSB6 Vehicle RegulationDocument35 pagesVSB6 Vehicle Regulationct0720054858No ratings yet

- Sifat Mekanik Dan Struktur Mikro Aluminium Aa1100 Hasil Pengelasan Friction Stir Welding Dengan Variasi Feed RateDocument8 pagesSifat Mekanik Dan Struktur Mikro Aluminium Aa1100 Hasil Pengelasan Friction Stir Welding Dengan Variasi Feed RateNamira Putri AuliaNo ratings yet

- Ultracore 360 C71: Conformances Key FeaturesDocument3 pagesUltracore 360 C71: Conformances Key FeaturesYousab CreatorNo ratings yet

- HR MicrofinishDocument96 pagesHR MicrofinishSuresh Babu ReddyNo ratings yet

- 2.2 Weld Joint TerminologyDocument1 page2.2 Weld Joint TerminologyAbdülHak ÖZkaraNo ratings yet

- Consumables For Repair WeldingDocument8 pagesConsumables For Repair WeldingbernardohbgNo ratings yet

- Svetsaren 2002-2 PDFDocument55 pagesSvetsaren 2002-2 PDFVijo JoseNo ratings yet

- Special Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0Document1 pageSpecial Metal Korea Co., LTD.: File No: SMK-DS-SM-308L Rev.0son ambaritaNo ratings yet

- Astm A 494Document7 pagesAstm A 494Rodrigo BarrosNo ratings yet

- AME-26 Rev 1Document46 pagesAME-26 Rev 1Gyanr BNo ratings yet