Professional Documents

Culture Documents

Procedure Qualification Record PQR

Uploaded by

Walid BdeirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure Qualification Record PQR

Uploaded by

Walid BdeirCopyright:

Available Formats

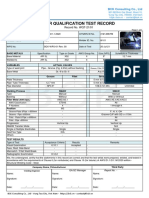

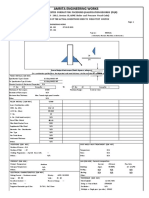

PROCEDURE QUALIFICATION

Page : 1/2

LOGO RECORDS

( PQR ) No : PQR-04

Company Name: GSF CONSTRUCTION COMPANY

Procedure Qalification Record No: PQR-04 Date: 17.10.2020

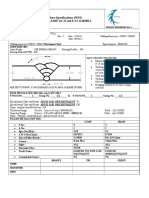

WPS No: WPS-04 Date: 17.10.2020 AWS D1.1 & ASME SEC.IX

Welding Process (es) : SMAW Type (s) : Manuel

JOINTS ( QW-402 ) POST WELD HEAT TREATMENT ( QW-407 )

60 O

Temparature N/A

Time : N/A

Other : N/A

GAS ( QW-408 )

2 3 12 Percent Composition

Gas (es) ( Mixure ) Flow Rate

Shielding N/a N/A N/A

Trailing N/A N/A N/A

Backing N/A N/A N/A

BASE METALS (QW-403 ) ELECTRICAL CHARACTERISTICS ( QW-409 )

Material Spec. A 572 Current: DC

Type or Grade : 50 Polarity : SMAW: ( + )

P. No 1 to P.No 1 Amps.: SMAW (E7016) 100-130 ,SMAW (E7018) :90-120

Thickness of Test Coupon: 12 mm Volts: SMAW : 17 - 30

Diameter of Test Coupon : Plate Tungsten Electrode Size: N/A

Other : None Other: None

FILLER METALS ( QW-404 ) SMAW SMAW

Spec.No. (SFA ) 5.1 5.1

AWS No. ( Class ) E 7016 E 7018

F - No 4 4

A - No 4 4

Size of Filler Metals 2.5 mm 3.2 mm

Weld Metal Thickness : 3.0 mm 9 mm

Other :

POSITIONS ( QW-405 ) PREHEAT ( QW-406 )

Position (s) of Groove: 3G Preheat Temp. None

Welding Progression: Up hill Down Interpass Temp. 250 OC

Other : None

TECHNIQUE ( QW-410 ) SMAW (E7016) SMAW (E 7018)

Travel Speed: 7-15 cm / min 7-15 cm / min.

String or Weave Bead: Weave String and Weave

Oscillation: None None

Multipass or Single pass: Single Multiple

Single or Multiple Electrode Single Single

Other: No pass greater than 12.7 mm

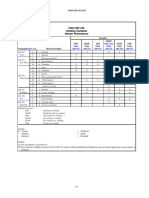

PROCEDURE QUALIFICATION

Page : 2/2

LOGO RECORDS

No: PQR-04

( PQR )

Tensile Test ( QW-150 )

Width Thickness Area Ultimate Total Load Ultimate Unit Stress

Specimen No Type of Failure& Location

( mm ) ( mm ) ( mm2 ) (N) (N / mm2 )

T1 20.3 10.2 207.06 89800 433.7 Ductile /Base Metal

T2 20 9.98 199.60 85500 428.35 Ductile /Base Metal

Guided Bend Test ( QW-160 )

Type and Figure No Result

Side Bend 1(10*12*250) 180 o - Satisfactory

Side Bend 2(10*12*250) 180 o - Satisfactory

Side Bend 3 (10*12*250) 180 o - Satisfactory

Side Bend 4 (10*12*250) 180 o - Satisfactory

Toughness Tests ( QW-170 )

Lateral Exp. Drop Weight

Specimen Test Temp. Impact

Notch Location Notch Type

No ( OC ) Value kg-m % Shear Mils. Break No Break

None None None None None None None None None

Fillet Weld Test ( QW-180 )

Result - Satisfactory Yes No X Penetration into Parent Metal Yes No X

Macro - Result None

Other Tests

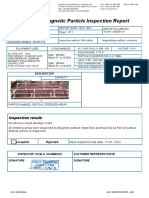

Radiographic Test MIQIAS Report No :MQS-GSF-RT-02, Dated 11.10.2020

Deposit Analysis None

Macro Test Satisfactory

Hardness Test None

Other None

Welder's Name : Stamp No:

Test Conducted by : Mahmoud Salah Laboratory Test No: MQS-GSF-WPQR-01 Rev.1,Dated 15.10.2020

We certify that the statements in this record are correct and that the test welds were prepared , welded , and tested in

accordance with the requirements of section IX of the ASME Code and AWS D1.1

Prepared by Checked by Approved by Customer or (Third Party)

Name Name Name Name

Date 17.10.2020 Date 17.10.2020 Date 17.10.2020 Date

Signature Signature Signature Signature

KAL.f.009 REV:01 01.07.2002

You might also like

- Tools Automotive Body RepairDocument78 pagesTools Automotive Body RepairOtto H. SubiantoroNo ratings yet

- O'Bannon Well Servicing Tools-1Document28 pagesO'Bannon Well Servicing Tools-1Praveen ChoudharyNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Mpi Pipe Rack PR 03-1.Document1 pageMpi Pipe Rack PR 03-1.Khalil ChabbouhNo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- Welder Qualification Test Record for NDBDocument1 pageWelder Qualification Test Record for NDBAli HammoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Welding Consumables Handling Procedure.Document5 pagesWelding Consumables Handling Procedure.Mohammed Kamal78% (23)

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- Table - Qw-416 Welding Variables For Welder PerformanceDocument1 pageTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- Q4 IA EIM 11 Week3Document4 pagesQ4 IA EIM 11 Week3Harold Vernon Martinez50% (2)

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationWaranya Musika100% (1)

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocument2 pagesWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 pagesP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonNo ratings yet

- ADCO Amendments 30-99-12-3207 Rev.1 To DEP 31.38.01.31 Steel Piping 2013...Document22 pagesADCO Amendments 30-99-12-3207 Rev.1 To DEP 31.38.01.31 Steel Piping 2013...aymanNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- AccreditationDocument40 pagesAccreditationWalid BdeirNo ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Tanstia Industry Members - Msme1Document258 pagesTanstia Industry Members - Msme1Devasyruc100% (2)

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- Magnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Document2 pagesMagnetic Particle Inspection Report: TEM INSPECTED: Assembly (X Over 2",pipes 2",elbows)Khalil ChabbouhNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Dokumen - Tips Wqt-FormatDocument2 pagesDokumen - Tips Wqt-FormatMr Pie100% (1)

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- Dayang Enterprise Inspection and Test PlanDocument3 pagesDayang Enterprise Inspection and Test PlanAmyNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Ronald C. Longakit ResumeDocument2 pagesRonald C. Longakit ResumeRonald Longakit100% (1)

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Method of Statement PDFDocument7 pagesMethod of Statement PDFSakib AyubNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Document Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Document1 pageDocument Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Ed FangNo ratings yet

- INSPECTION REPORT TITLEDocument7 pagesINSPECTION REPORT TITLEABEC Trombay siteNo ratings yet

- Job Safety Analysis For Internal Corrosion Monitoring PDFDocument2 pagesJob Safety Analysis For Internal Corrosion Monitoring PDFVineet AgrawalNo ratings yet

- Fit Up Welding Visual Inspection ReportDocument2 pagesFit Up Welding Visual Inspection Reportgst ajah100% (1)

- Mr-85 en Sds AerosolDocument11 pagesMr-85 en Sds AerosolBala KrishnanNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- Result of Inspection: ConclusionDocument5 pagesResult of Inspection: ConclusionBayu Aringga putraNo ratings yet

- 2G +5GDocument1 page2G +5GRahul Moottolikandy0% (1)

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallDocument1 pageSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun AkkayaNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- 5FPipe to plate welding procedureDocument2 pages5FPipe to plate welding procedureTrudie0% (1)

- AMRITA ENGINEERING WORKS PQRDocument3 pagesAMRITA ENGINEERING WORKS PQRBalkishan DyavanapellyNo ratings yet

- STS ProfileDocument13 pagesSTS ProfileWalid BdeirNo ratings yet

- API Spec 5Document1 pageAPI Spec 5Walid BdeirNo ratings yet

- API Spec 5Document1 pageAPI Spec 5Walid BdeirNo ratings yet

- API Spec 5Document1 pageAPI Spec 5Walid BdeirNo ratings yet

- STS ProfileDocument13 pagesSTS ProfileWalid BdeirNo ratings yet

- STS Profile Rev-04Document19 pagesSTS Profile Rev-04Walid BdeirNo ratings yet

- Flydubai Important InformationDocument3 pagesFlydubai Important InformationRaju LamaNo ratings yet

- Silver DetailsDocument6 pagesSilver DetailsWalid BdeirNo ratings yet

- STS Profile Rev-04Document19 pagesSTS Profile Rev-04Walid BdeirNo ratings yet

- Repair Welding of The Massive castvol17AFE2 2017pp5 8Document5 pagesRepair Welding of The Massive castvol17AFE2 2017pp5 8Walid BdeirNo ratings yet

- STS ProfileDocument13 pagesSTS ProfileWalid BdeirNo ratings yet

- 1.1 ISO CertificatesDocument4 pages1.1 ISO CertificatesWalid BdeirNo ratings yet

- Anthony Baber Uvjd2pDocument2 pagesAnthony Baber Uvjd2pWalid BdeirNo ratings yet

- Silver Villa Safety Pin Bow Shackle Test CertificateDocument1 pageSilver Villa Safety Pin Bow Shackle Test Certificatebash bashNo ratings yet

- Fitting List NPT 1Document3 pagesFitting List NPT 1Walid BdeirNo ratings yet

- Safety Induction: Operational Excellence One Team, One Goal, Incident-Free Operations (IFO)Document9 pagesSafety Induction: Operational Excellence One Team, One Goal, Incident-Free Operations (IFO)Walid BdeirNo ratings yet

- Silver Villa Safety Pin Bow Shackle Test CertificateDocument1 pageSilver Villa Safety Pin Bow Shackle Test Certificatebash bashNo ratings yet

- AZI-IMSP-05 REV 2management ReviewDocument6 pagesAZI-IMSP-05 REV 2management ReviewWalid BdeirNo ratings yet

- AZI-IMSP-26 Safety InductionDocument8 pagesAZI-IMSP-26 Safety InductionWalid BdeirNo ratings yet

- Fitting List HP 1Document1 pageFitting List HP 1Walid BdeirNo ratings yet

- HSE PolicyDocument1 pageHSE PolicyWalid BdeirNo ratings yet

- AZI-IMSP-07 Environmental ImpactDocument6 pagesAZI-IMSP-07 Environmental ImpactWalid BdeirNo ratings yet

- Driving Policy Standard: Driver Training and QualificationDocument1 pageDriving Policy Standard: Driver Training and QualificationWalid BdeirNo ratings yet

- Conflict of Interest PolicyDocument2 pagesConflict of Interest PolicyWalid BdeirNo ratings yet

- Procurement PolicyDocument1 pageProcurement PolicyWalid BdeirNo ratings yet

- AZI-IMSP-05 REV 2management ReviewDocument6 pagesAZI-IMSP-05 REV 2management ReviewWalid BdeirNo ratings yet

- Drugs and Alcohol Policy SummaryDocument2 pagesDrugs and Alcohol Policy SummaryWalid BdeirNo ratings yet

- Local Hiring PolicyDocument1 pageLocal Hiring PolicyWalid BdeirNo ratings yet

- Procurement PolicyDocument1 pageProcurement PolicyWalid BdeirNo ratings yet

- Djf21012 - Foundry Workshop: Worksheet ReportDocument11 pagesDjf21012 - Foundry Workshop: Worksheet ReportSakinah KamalNo ratings yet

- Introduction to Power Screws and Welded JointsDocument23 pagesIntroduction to Power Screws and Welded JointssathiaNo ratings yet

- DVS GradesDocument1 pageDVS GradesDev ShahNo ratings yet

- Oib Technical Spec 21,22,23Document586 pagesOib Technical Spec 21,22,23kali highNo ratings yet

- GXT Mobile Shear Shear Jaw Armor™: Field Installation ManualDocument24 pagesGXT Mobile Shear Shear Jaw Armor™: Field Installation ManualPrudzNo ratings yet

- Write Up On Crusher HouseDocument3 pagesWrite Up On Crusher HouseKumaraswamyNo ratings yet

- 07 Rawlbolts Plugs AnchorsDocument1 page07 Rawlbolts Plugs AnchorsLincolnNo ratings yet

- Mould TechnologyDocument71 pagesMould TechnologyS Karthick KeyanNo ratings yet

- AWS Certified Welder ApplicationDocument2 pagesAWS Certified Welder Applicationhanz bermejoNo ratings yet

- Chinese Aluminium Price Stays FirmDocument8 pagesChinese Aluminium Price Stays FirmAnver AkperovNo ratings yet

- 'Identifying Basic Hand Tools and Test Equipment: General ClassificationDocument15 pages'Identifying Basic Hand Tools and Test Equipment: General ClassificationGaming AmbinNo ratings yet

- PLP SA VARI-GRIP DEAD-END Installation Instruction 26112013Document9 pagesPLP SA VARI-GRIP DEAD-END Installation Instruction 26112013Carlos SatoNo ratings yet

- P-193 - Pipeline Pump Station and Terminal Valves in Crude Oil Service (API 6D Valves)Document34 pagesP-193 - Pipeline Pump Station and Terminal Valves in Crude Oil Service (API 6D Valves)MatteoNo ratings yet

- Tubeandpipejournal202106 DLDocument58 pagesTubeandpipejournal202106 DLLeo CarrascoNo ratings yet

- ELECRODE STORAGeDocument4 pagesELECRODE STORAGeGuruchell ChellguruNo ratings yet

- Theory of Lathe MachinesDocument12 pagesTheory of Lathe MachinesAman KumarNo ratings yet

- SHOP THEORY-Drilling ProcessesDocument28 pagesSHOP THEORY-Drilling ProcessesDaxNo ratings yet

- Inspecting Hand Tools for Safety and DefectsDocument11 pagesInspecting Hand Tools for Safety and DefectsGen GonNo ratings yet

- Submitted BY: Jatin Arora Mohit Gupta Mukul GuptaDocument38 pagesSubmitted BY: Jatin Arora Mohit Gupta Mukul GuptaJatin AroraNo ratings yet

- Guide To Sspc-Vis 3: SSPC: The Society For Protective CoatingsDocument4 pagesGuide To Sspc-Vis 3: SSPC: The Society For Protective CoatingsTeymur RegenmaisterNo ratings yet

- Item Rate Boq: Without MaterialsDocument8 pagesItem Rate Boq: Without Materialssuresh gNo ratings yet

- Die Casting ProcessDocument23 pagesDie Casting ProcessshayarigurunitinNo ratings yet

- TCEWDocument14 pagesTCEWJose AquinoNo ratings yet

- Ksa MorDocument10 pagesKsa MorSadik ShaikhNo ratings yet