Professional Documents

Culture Documents

Arl-Al - WPS-001 PDF

Uploaded by

rajuaji0 ratings0% found this document useful (0 votes)

237 views2 pagesThis welding procedure specification is for gas tungsten arc welding of aluminum alloy P-No #23 to P-No #23. It specifies gas shielding, joint preparation by grinding, preheat and interpass temperatures, filler metal ER4043, and welding parameters. The WPS was approved on February 13, 2018 by AJI RAJU and is intended for use with the associated PQR ARL-AL-WPQ-001.

Original Description:

Original Title

ARL-AL- WPS-001.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis welding procedure specification is for gas tungsten arc welding of aluminum alloy P-No #23 to P-No #23. It specifies gas shielding, joint preparation by grinding, preheat and interpass temperatures, filler metal ER4043, and welding parameters. The WPS was approved on February 13, 2018 by AJI RAJU and is intended for use with the associated PQR ARL-AL-WPQ-001.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

237 views2 pagesArl-Al - WPS-001 PDF

Uploaded by

rajuajiThis welding procedure specification is for gas tungsten arc welding of aluminum alloy P-No #23 to P-No #23. It specifies gas shielding, joint preparation by grinding, preheat and interpass temperatures, filler metal ER4043, and welding parameters. The WPS was approved on February 13, 2018 by AJI RAJU and is intended for use with the associated PQR ARL-AL-WPQ-001.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

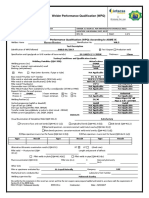

ARL Laboratory Services Pty Ltd WELDING PROCEDURE SPECIFICATION (WPS)

WPS No. ARL-AL- WPS-001 Rev: 0 Date 13-Feb-18

WELDING CODE : ASME-IX-2015, AS 3992-2015 PQR No. ARL-AL-WPQ-001

WELDING PROCESS : GTAW MATERIAL: P-No # 23 to P-No # 23

EDGE PREP.METHOD : Grinding CLEANING METHODE: SS Wire Brush

JOINT TYPE See the attached sketch JOINT POSITION All

Joint Design Gas

Single or Double V,U or J grooves, Fillets, Repairs, Shielding Gas : Argon, 7 to 20 Lit/Min

Build-Up and grooves on engineering drawings or Backing Gas : None

attached sketch on next page. Trailing Shield : None

Joints Preheat (QW-406)

Joint Design See the attached sketch Min. Preheat Temp. 10 Degree Celsius

Backing Optional Max. Interpass Temp. 120 Degree Celsius

Backing Material (Type) Aluminium Preheat Maintenance NA

Base Metal (QW-403) Heating Method: LPG

P-No. Qualified: 23 Temp. check Method: IR Thermometer

Group Number: NA Use of thermal processes

Thickness Qualified in mm: For Groove-1.5 to 20, Fillet-All, Pipe Dia: -All PWHT (QW-407)

Position (QW-405) Temperature Range NA

Position Qualified: All Time Range NA

Weld Progression Uphill when in Vertical Thickness Limit NA

Technique (QW-410)

String/weave Stringer to small Weave Multiple to single pass Multi

Method cleaning SS wire brush Manual or automatic Manual

Method back gouge Grinding/ Plasma arc Peening Not Permitted

Filler Metal Current Travel

Heat Input

Layer No Process AWS Type & Amps Volts (V) Speed

F No. A No. SFA No. Dia kJ/mm

Class Polarity (A) mm/min

1 (Root) 2.4 80-110

1 (Fill) GTAW 23 Nil SFA5.1 ER4043 3.1 AC 90-170 NA 75-200 NA

1 (Fillet) 4 125-275

Note:

Maximum Bead Thichness : 5mm, Convex shape Shielding Gas Cup Size: # 6 to # 12 (10 to 20 ID)

Consumable Insert : Not Permitted Tungsten Size & Type: EWP or EWZr, 2.5 through 4

Pulsed Power Supply : Optional Single or Multi pass per Side : Either

Penetration enhancing Flux : Not Permitted Single or Multiple Electrodes : Single

Intial Cleaning: Remove grease or oil with acetone, toluene, MEK or Paint Thinner. Mechanically clean only

after solvent cleaning,. Stainless steel fine wire brush immediately before note use Cholotinated hydrocarbons

Other : Pre heat to 65 Deg: Celseus if the Base metal is over 6 mm thick is recommended.

Use of a balanced wave power supply is recommended. A slightly convex bead is preferred

APPROVALS: ARL Laboratory Services Client

Name: AJI RAJU (AWS-SCWI # 06071191)

Siganture:

Date: 13-02-18

ARL-AL- WPS-001 Page: 1 of 2

ARL Laboratory Services Pty Ltd WELDING PROCEDURE SPECIFICATION (WPS)

ARL-AL- WPS-001 Page: 1 of 2

You might also like

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- UT Formula SheetDocument2 pagesUT Formula SheetOktayKulNo ratings yet

- An Overview Of: Piping Material SpecificationDocument60 pagesAn Overview Of: Piping Material SpecificationNeeraj Bora100% (10)

- Radiography Testing - NDT Inspection - TWIDocument5 pagesRadiography Testing - NDT Inspection - TWIKolusu SivakumarNo ratings yet

- Basic DPTDocument56 pagesBasic DPTrajuajiNo ratings yet

- Powder Metallurgy: Introduction ToDocument268 pagesPowder Metallurgy: Introduction ToBhavya SumaNo ratings yet

- Api Ut Thickness Procedure PDFDocument7 pagesApi Ut Thickness Procedure PDFShreekanthKannath100% (1)

- BS EN 1011 - 8 - 2003 - DraftDocument22 pagesBS EN 1011 - 8 - 2003 - DraftMichael Andrews100% (2)

- Centrifugally Cast "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) PipeDocument5 pagesCentrifugally Cast "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) PipeShaker Qaidi100% (1)

- List of NDT Standards 10 2015 CorrDocument16 pagesList of NDT Standards 10 2015 CorrAymeeen100% (2)

- Nozzles - UT in Place of RTDocument7 pagesNozzles - UT in Place of RTVicky GautamNo ratings yet

- Intertek Caleb Brett Tank Calibration Services WebDocument2 pagesIntertek Caleb Brett Tank Calibration Services WebrajuajiNo ratings yet

- Dacon PAUT PresentationDocument20 pagesDacon PAUT Presentationbacabacabaca100% (1)

- Visual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support SystemsDocument2 pagesVisual Inspection Checklist For Piping Systems: Connected Mechanical Equipment, Instrumentation, and Pipe Support SystemsrajuajiNo ratings yet

- Lloyd S Register NBIC Part 3 2017 Edition Key ChangesDocument21 pagesLloyd S Register NBIC Part 3 2017 Edition Key ChangessreekanthsreedharaNo ratings yet

- Req. For Welder Qualification Testing Center Rev7Document29 pagesReq. For Welder Qualification Testing Center Rev7FongJeremyNo ratings yet

- Api 653 Quiz-3Document3 pagesApi 653 Quiz-3rajuajiNo ratings yet

- Deviations During PWHT and ResponseDocument2 pagesDeviations During PWHT and ResponseEIL NDT100% (1)

- Astm E2491-06Document13 pagesAstm E2491-06Andi DaudNo ratings yet

- Intro To RadiographyDocument37 pagesIntro To RadiographySaleemSahabNo ratings yet

- Acceptance Standards UtDocument3 pagesAcceptance Standards UtAhmed GomaaNo ratings yet

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyNo ratings yet

- Iso18563 1 2022Document54 pagesIso18563 1 2022baurzhannNo ratings yet

- Phased Array Ut Procedure For WeldsDocument12 pagesPhased Array Ut Procedure For WeldsMohd Salleh Zainal100% (7)

- Oilite CatalogDocument40 pagesOilite CatalogPurdue03bNo ratings yet

- The Automotive Chassis - Engineering PrinciplesDocument50 pagesThe Automotive Chassis - Engineering PrinciplesSimplice KengneNo ratings yet

- UT Procedure PDFDocument14 pagesUT Procedure PDFAbhayNo ratings yet

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Welding Defect - ISO6520Document3 pagesWelding Defect - ISO6520manojballaNo ratings yet

- ASME P NumbersDocument6 pagesASME P NumbersAbdul KharisNo ratings yet

- ASME U StampDocument12 pagesASME U StampShaheen Andre ChikkuNo ratings yet

- Radiographic Testing Report: EGB-S-RT-0002Document4 pagesRadiographic Testing Report: EGB-S-RT-0002Tuấn ĐậuNo ratings yet

- NDT RT PDFDocument13 pagesNDT RT PDFck19654840No ratings yet

- Saic M 2004Document6 pagesSaic M 2004Hussain Nasser Al- NowiesserNo ratings yet

- GE Mentor EM Weld BrochureDocument6 pagesGE Mentor EM Weld BrochuredimachampionNo ratings yet

- MDR Form A-1Document2 pagesMDR Form A-1Yuvraj ThoratNo ratings yet

- Pws Convention PresentationDocument93 pagesPws Convention Presentationbenj100% (1)

- PWHT ProcedureDocument6 pagesPWHT ProcedurevictorbirlanNo ratings yet

- ISOndtDocument8 pagesISOndtNooruddin SheikNo ratings yet

- Chhatisgarh SIDDocument3 pagesChhatisgarh SIDbijayaceNo ratings yet

- UT Examination of Welds - BS StandardDocument16 pagesUT Examination of Welds - BS StandardramalingamNo ratings yet

- List of Questions EN 13445 - 2014Document11 pagesList of Questions EN 13445 - 2014kamal615No ratings yet

- Se 797Document7 pagesSe 797donaldoguerreroNo ratings yet

- 24 Practical Visual InspectionDocument5 pages24 Practical Visual InspectionMai Anh TaiNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Liquid Penetrant (Lev1el-I-level - II''Document100 pagesLiquid Penetrant (Lev1el-I-level - II''Chandresh100% (1)

- Ut ReportDocument6 pagesUt ReportVijay PandeyNo ratings yet

- Welder Performance Qualification (WPQ) According To ASME IX Hassan HussienDocument1 pageWelder Performance Qualification (WPQ) According To ASME IX Hassan HussienMahmoud shawkyNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- E2700-09 Standard Practice For Contact Ultrasonic Testing of Welds Using Phased ArraysDocument9 pagesE2700-09 Standard Practice For Contact Ultrasonic Testing of Welds Using Phased Arrayskenvn100% (1)

- PWHT On Tube To Tubesheet Welds - ASME (Mechanical) Code Issues - Eng-TipsDocument2 pagesPWHT On Tube To Tubesheet Welds - ASME (Mechanical) Code Issues - Eng-Tipsharan2000No ratings yet

- Welding - Fissures DefectDocument12 pagesWelding - Fissures DefectthanhNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Scope:: Area of Sample To Be Tested All Surfaces, Weld and Heat Affected Zone, Including Dimensions of HAZDocument2 pagesScope:: Area of Sample To Be Tested All Surfaces, Weld and Heat Affected Zone, Including Dimensions of HAZAnna PariniNo ratings yet

- Liquid Penetrant Testing ProcedureDocument2 pagesLiquid Penetrant Testing ProcedureManivannanMudhaliarNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- Is 9902 2004 PDFDocument11 pagesIs 9902 2004 PDFAgniva DuttaNo ratings yet

- General Requirements For Qualification and PCN Certification of NDT PersonnelDocument26 pagesGeneral Requirements For Qualification and PCN Certification of NDT PersonnelPedro OliveiraNo ratings yet

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingDocument14 pagesMobile Offshore Drilling Units 2008: Rules For Building and ClassingmfazioliNo ratings yet

- Air Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsDocument4 pagesAir Compressor Guide AICIP and CAAA - Guidelines and Requirements For Asset Management of Pressure VesselsTim WilsonNo ratings yet

- DMTA 20006 01EN - Rev - B COBRA - Scanner Users - Manual PDFDocument80 pagesDMTA 20006 01EN - Rev - B COBRA - Scanner Users - Manual PDFDanny Milton Silva VasquezNo ratings yet

- Alphagage + Manual - v5Document80 pagesAlphagage + Manual - v5JC Schwartz100% (2)

- BS 5996 (1993) Specification ForAcceptanc Levels For Internal Imperfections in Steel Late, Strip and Wide Flats, Based On Ultrasonic TestingDocument14 pagesBS 5996 (1993) Specification ForAcceptanc Levels For Internal Imperfections in Steel Late, Strip and Wide Flats, Based On Ultrasonic TestingZoltán PálfyNo ratings yet

- NDT Level 2 in Leak - TestingDocument9 pagesNDT Level 2 in Leak - TestingRichard MitchellNo ratings yet

- Asme NDT MethodDocument1 pageAsme NDT Methodkinglordofato100% (1)

- Guidelines For Automated Ultrasonic Inspection Austenitic WeldsDocument10 pagesGuidelines For Automated Ultrasonic Inspection Austenitic WeldsDurgamadhaba MishraNo ratings yet

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- 2400-2420 enDocument3 pages2400-2420 enrajuajiNo ratings yet

- Assembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62Document12 pagesAssembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62rajuajiNo ratings yet

- Studying The Effect of Tramp Elements in Scrap On Industrial Recycled Steel Processing and QualityDocument8 pagesStudying The Effect of Tramp Elements in Scrap On Industrial Recycled Steel Processing and QualityDominic TanNo ratings yet

- Presentation JanakDocument108 pagesPresentation JanakJanakNo ratings yet

- Arc SprayingDocument6 pagesArc SprayingAshok KumarNo ratings yet

- Materials AlturasDocument66 pagesMaterials AlturasDonald ToledoNo ratings yet

- Bavaria en BA-TIG 310Document1 pageBavaria en BA-TIG 310cocoNo ratings yet

- QCS 2010 Section 1 Part 22 Part 22 New Technologies and Innovations PDFDocument3 pagesQCS 2010 Section 1 Part 22 Part 22 New Technologies and Innovations PDFbryanpastor106No ratings yet

- Site Mate Complete Brochure 2019 PDFDocument286 pagesSite Mate Complete Brochure 2019 PDFAnonymous WFlvDUNu5ONo ratings yet

- Parker FittingsDocument40 pagesParker FittingsqcselvaNo ratings yet

- T/SP/CW/5: Specification ForDocument40 pagesT/SP/CW/5: Specification ForJames TaylorNo ratings yet

- BuhlmannDocument27 pagesBuhlmannGeorge GhitaNo ratings yet

- KLH Timber Concrete Composites PDFDocument12 pagesKLH Timber Concrete Composites PDFBasaraba Dragos100% (1)

- M.arch. Fibre Reinforced ConcreteDocument18 pagesM.arch. Fibre Reinforced ConcreteSaloniNo ratings yet

- FerrocementDocument25 pagesFerrocementNandhini NallasamyNo ratings yet

- Portland Cement: Wednesday, March 25, 2015Document35 pagesPortland Cement: Wednesday, March 25, 2015EFRA BININo ratings yet

- Sigma Fasteners & U BoltsDocument7 pagesSigma Fasteners & U BoltsmaxhoNo ratings yet

- 2010 Masterformat Sample JobCost Codes + NotesDocument11 pages2010 Masterformat Sample JobCost Codes + NotesYay B. GicoNo ratings yet

- Format Boq & Est - Harga PertashopDocument5 pagesFormat Boq & Est - Harga PertashopBima Agung100% (13)

- Common Pipe Terminology and AcronymsDocument7 pagesCommon Pipe Terminology and AcronymsDGWNo ratings yet

- Piping Classes - Rev07Document39 pagesPiping Classes - Rev07Sali NdjiddaNo ratings yet

- Schedule 40 PipeDocument2 pagesSchedule 40 Piperasnowmah2012No ratings yet

- ASTM F 467m-03aDocument9 pagesASTM F 467m-03aJORGE ARTURO TORIBIO HUERTANo ratings yet

- Requirement: 261 Sets. List of Fittings For Steel Channel Sleeper (One Set) List of FittingsDocument1 pageRequirement: 261 Sets. List of Fittings For Steel Channel Sleeper (One Set) List of FittingsBWS JALANDHARNo ratings yet

- Hardness TestDocument2 pagesHardness TestGurdeep KohliNo ratings yet