Professional Documents

Culture Documents

WPS No. ST-CS-02-2

Uploaded by

Hussein Jassim0 ratings0% found this document useful (0 votes)

38 views1 pageCopyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views1 pageWPS No. ST-CS-02-2

Uploaded by

Hussein JassimCopyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

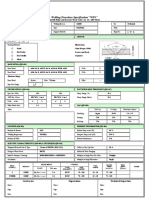

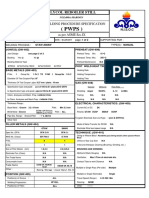

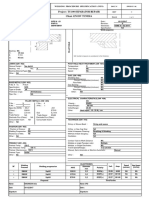

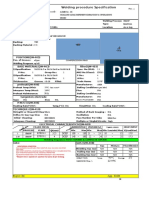

Form No.

AB-WPS-001

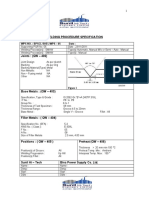

“ eni Iraq b.v. - Zubair Oil Field Development Project”

Work Package of Existing DGS Modification pWPS No.: AB-CS-02 Rev.00

Preliminary WELDING PROCEDURE SPECIFICATION Sheet 1 of 1

Reference Documents: ASME BPV Sec.Ⅸ

PROCESS: GTAW+SMAW TYPE: MANUAL PQR: N.A

JOINT DESIGN (QW-402) BASE METAL (QW-403)

Joint Design: Groove and/or Fillet P-No 1 Group 1 to P-No 1 Group 1

Backing (y/n): GTAW: no / SMAW: yes Type & grade: A 106 Gr. B or Equivalent

Backing/Retainer Material: Weld Metal to type & grade A 106 Gr. B or Equivalent

[ X ] Metal [ ] Nonfusing Metal Thickness range: N.A

[ ] Nonmetallic [ ] Other Pipe diameter range: N.A

Method of Fit Up: Tack weld or fixture Pipe Coupon size : 6”x11mm t

FILLER METAL (QW-404) GTAW SMAW JOINT DESIGN

Spec. No (SFA) A5.18 A5.1

AWS No (Class) ER 70S-3 E 7018-1H4R

750 ±50

F-No 6 4

A-No 1 1

Size Ø2.4 Ø2.5, Ø3.2

Deposited weld metal maximum 6.0 mm 16 mm

Product form Solid Coated Electrode

Consumable trade name BOHLER BOHLER (*)Root Gaps: ³ DN 50 (2”) ~ DN 250 (10”) = 1.5 ~ 2.5 mm

(EML5) ( FOX EV 55) ³ DN 300 (12”) = 2.5 mm ~ 3.0 mm

Electrode/Flux (Class) N.A. N.A.

Flux trade name N.A. N.A.

POSITION (QW-405) PREHEAT (QW-406)

Position(s): 6G Preheat temperature (min): 10°C (50°F) and 50°C (122°F) if ambient

temp. below 5°C(41°F)

Welding direction (up/down): Uphill Interpass temperature(max): 250°C (482°F)

Other: N.A. Other: N.A.

POST WELD HEAT TREATMENT (QW-407) GAS (QW-408)

Heating rate °C/hr: N.A Gas Composition (%) Flow rate (l/min)

Temperature range °C: N.A Shielding: Argon 99.99 12~25

Holding time (h): N.A Trailing: N.A. N.A. N.A.

Cooling rate °C/hr: N.A Backing: N.A. N.A. N.A.

Other N.A. Other: N.A. N.A. N.A.

ELECTRICAL CHARACTERISTICS (QW-409)

Type of current, polarity & Amps/Volts range: see table shown below

Mode of metal transfer for GMAW: N.A. Electrode wire feed speed range: N.A.

Tungsten electrode size & type: Ǿ2.4 mm – EW Th. 2%

TECHNIQUE (QW-410)

String or weave beads: Weave for vertical position Multiple or single pass (for side): Multiple (2 minimum)

Orifice or gas cup size: 8.0~12.5 mm Method of back gouging N.A.

Initial & interpass cleaning: Grinding and/or brushing Peening: N.A.

Multiple or single electrodes: Single Contact tube to work distance: N.A.

Oscillation: N.A. Other: N.A.

LAYER PROCESS FILLER METAL CURRENT VOLTS TRAVEL SPEED Others

No CLASS SIZE TYPE AMPERES (cm/min) (KJ/cm)

1st & 2nd GTAW ER 70S-3 Ø2.4 DCEN 100~200 8~16 N.A N.A

3-n SMAW E 7018-1H4R Ø2.5, Ø3.2 DCEP 80~140 17~25 N.A N.A

Issued Date Prepared by Name DATE SIGN NAME

Reviewed by :

You might also like

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPS 6G CS Pipe CorrectDocument4 pagesWPS 6G CS Pipe CorrectAla ReguiiNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Final WPS - ItdcDocument2 pagesFinal WPS - ItdcsarancivilrajNo ratings yet

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDocument2 pagesBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Glycol Reboiler Still Welding Procedure Specification (PWPSDocument2 pagesGlycol Reboiler Still Welding Procedure Specification (PWPSstdshopNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS Gtaw+smawDocument2 pagesWPS Gtaw+smawAnand GNo ratings yet

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- WC9Document5 pagesWC9Suresh KrishnanNo ratings yet

- QW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeDocument2 pagesQW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeRamzi ZoghlamiNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- GTAW Welding Process ParametersDocument12 pagesGTAW Welding Process Parametersmiteshpatel191No ratings yet

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Document1 pageProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNo ratings yet

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (2)

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- LOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONDocument5 pagesLOGOS ENGINEERING WELDING PROCEDURE SPECIFICATIONKAMALNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- WPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsDocument3 pagesWPS for Manual SMAW Welding of 316L Stainless Steel Butt JointsAmjad PathanNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Document1 pageO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNo ratings yet

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Micro Digital Media 2e Lab Book-3Document101 pagesMicro Digital Media 2e Lab Book-3string440% (1)

- Air Entraining CementDocument14 pagesAir Entraining CementBashairu WaseemNo ratings yet

- Material (Young's Modulus, Modulus of Elasticity) - E - - σ - σDocument14 pagesMaterial (Young's Modulus, Modulus of Elasticity) - E - - σ - σyoshefus caffaso hautamaNo ratings yet

- Bahasa Inggris Kelas XI IPA/ XI IPS: Name: Class: DateDocument7 pagesBahasa Inggris Kelas XI IPA/ XI IPS: Name: Class: DateChristevanNo ratings yet

- Technical Documentation For Pagel Grout: MAN-material-no.: 11.72125-0035 Manufacturer: PAGELDocument23 pagesTechnical Documentation For Pagel Grout: MAN-material-no.: 11.72125-0035 Manufacturer: PAGELOunna PechNo ratings yet

- Presentation 6Document9 pagesPresentation 6Priyotamo NandiNo ratings yet

- Improvements in Gold Ore Cyanidation by Pre-OxidatioDocument4 pagesImprovements in Gold Ore Cyanidation by Pre-Oxidatioboanerges wino pattyNo ratings yet

- Tall Oil Production and ProcessingDocument11 pagesTall Oil Production and Processinggauravjuyal1988No ratings yet

- 25 Tack Welder - ABSDocument7 pages25 Tack Welder - ABSvudinhnambrNo ratings yet

- Tectyl 502 CDocument2 pagesTectyl 502 CKARTHIGEYAN.RNo ratings yet

- Drilling Fluids ExercisesDocument17 pagesDrilling Fluids ExercisesJohn Kevin De CastroNo ratings yet

- The Effect of Storage at Various Temperatures On Blood Alcohol ConcentrationDocument7 pagesThe Effect of Storage at Various Temperatures On Blood Alcohol ConcentrationRosaniza KamarudinNo ratings yet

- DR Hugo Touchette (NITheP Stellenbosch)Document11 pagesDR Hugo Touchette (NITheP Stellenbosch)Rene KotzeNo ratings yet

- Amburgey & Amirtharajah 2005 Strategic Filter Backwashing TechDocument13 pagesAmburgey & Amirtharajah 2005 Strategic Filter Backwashing TechJoseNo ratings yet

- RGD 32Document1 pageRGD 32abhi7112No ratings yet

- Arachis Hypogeal (Peanut Seed Oil) PH Eur MonographDocument2 pagesArachis Hypogeal (Peanut Seed Oil) PH Eur Monographthe docsproviderNo ratings yet

- Gear Beam and Wear StrengthDocument46 pagesGear Beam and Wear StrengthNisarg MistryNo ratings yet

- Composite AssignmentDocument4 pagesComposite AssignmentAmna QureshiNo ratings yet

- CH 01Document26 pagesCH 01Sue Anne KohNo ratings yet

- Heat Transfer-Literature ReviewDocument84 pagesHeat Transfer-Literature Reviewnewcastle74No ratings yet

- JSW Casting EquipDocument23 pagesJSW Casting EquipArnab GhoshNo ratings yet

- Catalog Metal RotameterDocument12 pagesCatalog Metal RotameterNibinNo ratings yet

- 5061 10023 1 SMDocument7 pages5061 10023 1 SMNadya Rahmawati PutriNo ratings yet

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationyazNo ratings yet

- Carbohydrates of Sub Bab 15Document8 pagesCarbohydrates of Sub Bab 15dilla daniahNo ratings yet

- Level Management EHandbook - Chemical ProcessingDocument14 pagesLevel Management EHandbook - Chemical ProcessingAzar Deen100% (1)

- Project Report On Mass Balance of RR3 Grade of GreaseDocument116 pagesProject Report On Mass Balance of RR3 Grade of GreaseAkash Dhobale100% (2)

- Le Problème Inverse de Conduction de La Chaleur: P O U R E N S A V O I R P L U SDocument2 pagesLe Problème Inverse de Conduction de La Chaleur: P O U R E N S A V O I R P L U SZeinab Ben RomdhaneNo ratings yet

- Review FfsDocument12 pagesReview FfsMustafa AkbarNo ratings yet

- Astm C1097Document1 pageAstm C1097pfta_No ratings yet