Professional Documents

Culture Documents

347 310 WPS

Uploaded by

BIIS QAQC Babu Siva0 ratings0% found this document useful (0 votes)

1 views2 pagesOriginal Title

347-310-WPS

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views2 pages347 310 WPS

Uploaded by

BIIS QAQC Babu SivaCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

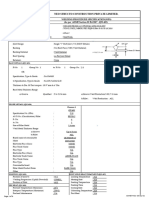

Format No: TR-33117-F-04 Rev 0

TECNICAS REUNIDAS S.A

WELDING PROCEDURE SPECIFICATION(PWPS)

(As per ASME Section IX Ed.2017, QW-482)

WPS No : TRSA-33117-WPS-007

Procedure Qualification Record No : To be qualified

Welding Process(es) : GTAW

Types (Manual, Automatic, Semi-Auto,Machine) : MANUAL

JOINTS (QW-402) 10 mm

6

Joint Design : Fillet Weld

Backing : Yes (Base Material)

Backing Material : NA

Root Spacing : NA

Retainers : None 7.01 mm

BASE METALS (QW-403)

Base Metal : P.NO : 8 Group No: 1 to P.NO : 8 Group No: 2

OR

Specification Type & Grade : TP 347H (Pipe)

to Specification Type & Grade : TP 310 (Plate)

Diameter and Thickness of Test coupon : 73 mm OD and 7.01 mm thickness (Pipe), 150 x 120 x 10 mm thickness (Plate)

Base Metal Thickness Range

a) Groove Qualified : NA

b) Fillet Qualified : All fillet size, thickness, diameter.

FILLER METALS (QW-404)

Process-1

GTAW

Specification No. (SFA) : 5.9

AWS No. (Classification)/Filler : ER 309L

F- No. :6

Weld Metal Analysis A- No. :8

Size of Filler Metal : 2.4 mm

Weld Metal Thickness Range

a) Groove : NA

b) Fillet : Upto 6 mm

Electrode Trade name : ADOR / D&H

Flux type : NA

Consumable Insert : NO

Filler Metal Product Form : BARE (SOLID)

Electrode-Flux (Class) : NA

Flux Trade Name : NA

Flux Type : NA

Filler Addition/Deletion : GTAW with Filler

Other : NA

POSITION (QW-405)

Position of Groove : NA

Welding Progression (Uphill/Downhill) : UPHILL

Position of Fillet : 5F

PRE HEAT (QW-406) POST WELD HEAT TREATMENT(QW-407)

Pre heat Temperature (Minimum) : 10°C Loading Temperature : NA

Interpass Temperature (Maximum) : 175°C Rate of Heating : NA

Pre heat Maintenance : None Rate of Cooling : NA

Soaking Temperature : NA

Soaking Time : NA

Unloading Temperature : NA

Note: Thermal crayons may be used for temp. measurement. Post Heat : NA

Page 1 of 2 EXHIBIT NO: WE-01 R2

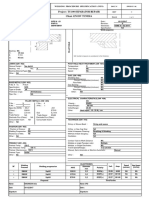

TECNICAS REUNIDAS S.A

WELDING PROCEDURE SPECIFICATION(PWPS)

(As per ASME Section IX Ed.2017, QW-482)

WPS No : TRSA-33117-WPS-007

GAS (QW-408)

Description Gases Percentage Composition Flow Rate

Shielding Gas ARGON 99.995% Pure 14-18 LPM

Trailing Gas None None None

Backing Gas None None None

ELECTRICAL CHARACTERISTICS (QW-409)

Pulsing current or Power source : DC

Current or Polarity : EN (GTAW)

Amps Range : Amps - 115-125

Volts Range : Volts - 15-16

Tungsten Electrode Size and Type : 2.5 mm Dia & 2% Ceriated

Mode of Metal Transfer (for GMAW) : NA

Electrode Wire Feed Speed Range : NA

TECHNIQUE (QW-410)

String or Weave Bead : 1st Stringer/ Rest Pass Weave Bead

Orifice or Gas Cup Size : 6 mm

Initial and Inter pass Cleaning : Grinding/Brushing

Method of Back gouging : NO

Oscillation : ≤3 times electrode diameter

Closed to out Chamber : NA

Electrode Spacing : NA

Contact Tube to Work Distance : NA

Multiple or Single Pass (per side) : Multiple

Multiple or Single Electrode : Single

Travel Speed (Range) : 43-46 mm/min

Peening : NO

Thermal Processes : NONE

Manual Or Automatic : Manual *NA = Not Applicable

Filler Metal Current

S.No Pass Process Volts Tr.Speed mm/Min Remarks

AWS Class. Dia (mm) Polarity Amps Range

Range

1 Root GTAW ER 309L 2.4 DCEN 115-118 15-16 43

2 Hot GTAW ER 309L 2.4 DCEN 115-120 15-16 46

3 Fill up GTAW ER 309L 2.4 DCEN 120-125 15-16 45

4 Final GTAW ER 309L 2.4 DCEN 120-125 15-16 45

Note(s):

1. Weaving shall not be exceeding 3 times electrode dia.

2. Use only Austenitic SS wire brush for cleaning purpose & SS clit shall be used for fit up.

Signature

Name

Date

FOR: TECNICAS REUNIDAS S.A ENGINEERS INDIA LIMITED

Page 2 of 2 EXHIBIT NO: WE-01 R2

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Hazards Identification and Risk Assessment - New FormatDocument2 pagesHazards Identification and Risk Assessment - New FormatBIIS QAQC Babu Siva100% (1)

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- Organization Development Implemented in StarbucksDocument19 pagesOrganization Development Implemented in StarbucksIndiranIn0% (2)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- Oracle EBS R12.2.6 Application Tier Cloning With Step by StepDocument10 pagesOracle EBS R12.2.6 Application Tier Cloning With Step by Stepdoyenblog100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- PWPS WPS CAP 039 PQR 035Document15 pagesPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- Analysis of Business EnvironmentDocument6 pagesAnalysis of Business EnvironmentLapi Boy MicsNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Welding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection WorkDocument10 pagesWelding Procedure Specification (WPS) As Per Asme Sec. Ix: Project Contractor Inspection Workvijayshelke100% (1)

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- RAN Working Paper No.2Document19 pagesRAN Working Paper No.2Rex TyrannosaurNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- GPON - Fundamentals: Technical Team From FTTHDocument56 pagesGPON - Fundamentals: Technical Team From FTTHDaniel VieceliNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- Wps For Ss 304Document3 pagesWps For Ss 304Sajit PillaiNo ratings yet

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Document1 pageO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNo ratings yet

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Form Qw-482 Suggested Format For Welding Procedure Specification (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document10 pagesForm Qw-482 Suggested Format For Welding Procedure Specification (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Prakash PatelNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Document1 pageProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNo ratings yet

- S 001 Link 2Document1 pageS 001 Link 2wael badawiNo ratings yet

- WPS For SSDocument1 pageWPS For SSdeepakNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 pageCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Ex Wps Train 01Document2 pagesEx Wps Train 01aidil30No ratings yet

- Mathew Associates Hook Up & Weld Services: Welding Procedure SpecificationDocument1 pageMathew Associates Hook Up & Weld Services: Welding Procedure SpecificationHimanshu SinghNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- PQR Acero Al CarbonoDocument2 pagesPQR Acero Al CarbonoROBERTO QUESADANo ratings yet

- Wps Blank Form 2sheetDocument4 pagesWps Blank Form 2sheetdidi sudiNo ratings yet

- Welding Procedure Specification: (As Per Asme Sec Ix)Document1 pageWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNo ratings yet

- PWPS 102Document2 pagesPWPS 102Cyril J PadiyathNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design PositionDocument9 pagesWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- WPS-Shell To Tubesheet (CS-SS)Document1 pageWPS-Shell To Tubesheet (CS-SS)suria qaqcNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNo ratings yet

- Details Required For The Vendor RegistrationDocument1 pageDetails Required For The Vendor RegistrationBIIS QAQC Babu SivaNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Biis-Sf-01 Accident RecordDocument1 pageBiis-Sf-01 Accident RecordBIIS QAQC Babu SivaNo ratings yet

- Biis-Sf-02 Personal Protective EquipmentDocument2 pagesBiis-Sf-02 Personal Protective EquipmentBIIS QAQC Babu SivaNo ratings yet

- Biis-Sc-02 Subcontractor Evaluation & Re Evaluation FormDocument2 pagesBiis-Sc-02 Subcontractor Evaluation & Re Evaluation FormBIIS QAQC Babu SivaNo ratings yet

- Biis-Sf-03-Risk Assessment Form-GeneratorDocument3 pagesBiis-Sf-03-Risk Assessment Form-GeneratorBIIS QAQC Babu SivaNo ratings yet

- Risk Assessment Matrix: Consequence (C) Low Risk Moderate Risk High Risk Extreme RiskDocument3 pagesRisk Assessment Matrix: Consequence (C) Low Risk Moderate Risk High Risk Extreme RiskBIIS QAQC Babu SivaNo ratings yet

- Biis-Sc-01 Approved Subcontractor ListDocument2 pagesBiis-Sc-01 Approved Subcontractor ListBIIS QAQC Babu SivaNo ratings yet

- OT Request FormDocument1 pageOT Request FormBIIS QAQC Babu SivaNo ratings yet

- Biis-Kpi-01-Key Performance Indicator-Rev-01-17-07-2019Document1 pageBiis-Kpi-01-Key Performance Indicator-Rev-01-17-07-2019BIIS QAQC Babu SivaNo ratings yet

- Biis CL 46 Storage Rack InspectionDocument2 pagesBiis CL 46 Storage Rack InspectionBIIS QAQC Babu SivaNo ratings yet

- WPS 012Document11 pagesWPS 012BIIS QAQC Babu SivaNo ratings yet

- Mobile Crane AssessmentDocument4 pagesMobile Crane AssessmentBIIS QAQC Babu SivaNo ratings yet

- Industrial Control 11)Document33 pagesIndustrial Control 11)Arindam LayekNo ratings yet

- Laptop HP 15Document4 pagesLaptop HP 15Carlos RechepNo ratings yet

- Effect of Mechanical Properties On Multi Axial Forged LM4 Aluminium AlloyDocument6 pagesEffect of Mechanical Properties On Multi Axial Forged LM4 Aluminium AlloySharath P CNo ratings yet

- SDK-Python Interface ENG V1.0Document32 pagesSDK-Python Interface ENG V1.0Chandru ChristurajNo ratings yet

- VP Marketing Product Development in NYC Resume Sherri SwihartDocument2 pagesVP Marketing Product Development in NYC Resume Sherri SwihartSherriSwihartNo ratings yet

- TN680 MHTC 96 Drop CalorimetryDocument9 pagesTN680 MHTC 96 Drop CalorimetryMiruna PetriaNo ratings yet

- Schott Brochure Schott Vials English Us 20092017Document28 pagesSchott Brochure Schott Vials English Us 20092017Tomena ÁkosNo ratings yet

- EVCO-EVDrive UserManualDocument44 pagesEVCO-EVDrive UserManualMelanie InglishNo ratings yet

- Business Account Executive in NH Resume Shayna Malool-JuneauDocument2 pagesBusiness Account Executive in NH Resume Shayna Malool-JuneauShaynaMaloolJuneauNo ratings yet

- Restricted Earth Fault ProtectionDocument3 pagesRestricted Earth Fault ProtectionFatima MirNo ratings yet

- M SC Petroleum Engineer 2Document3 pagesM SC Petroleum Engineer 2anouari2014No ratings yet

- Gleh1642fs 31 Cu FT Laundry CenterDocument20 pagesGleh1642fs 31 Cu FT Laundry Centeredison mauricio alarcon acostaNo ratings yet

- TLWG Question BankDocument18 pagesTLWG Question BankSuchitharaNo ratings yet

- Astm 1735Document3 pagesAstm 1735jchemNo ratings yet

- Assignment No.1 Title-Case Study Based Assignment On Method StudyDocument4 pagesAssignment No.1 Title-Case Study Based Assignment On Method Studyshreyas mithariNo ratings yet

- How Thought Leadership Drives Demand Generation: 2019 Edelman-Linkedin B2B Thought Leadership Impact StudyDocument27 pagesHow Thought Leadership Drives Demand Generation: 2019 Edelman-Linkedin B2B Thought Leadership Impact StudyDiego TellezNo ratings yet

- Licensed To Arun Kumar Das: Concrete Masonry Units - SpecificationDocument14 pagesLicensed To Arun Kumar Das: Concrete Masonry Units - SpecificationIndira BanerjeeNo ratings yet

- Cisco1300APBridge Spec WebDocument14 pagesCisco1300APBridge Spec Webahfuoahrf0384No ratings yet

- Wing Design ParametersDocument5 pagesWing Design ParametersMakam VenkateshNo ratings yet

- HLeiteDocument6 pagesHLeiteLê Trung DũngNo ratings yet

- Analysis of Two Area Power System With Battery Energy StorageDocument5 pagesAnalysis of Two Area Power System With Battery Energy StoragezahidNo ratings yet

- History N Development ICEDocument5 pagesHistory N Development ICEAneesh KumarNo ratings yet

- 5 X 7 LED Matrix Display ProjectDocument8 pages5 X 7 LED Matrix Display Projectsiddkula89No ratings yet

- 2010 Peugeot 508 508 SW Brochure NL NovemberDocument12 pages2010 Peugeot 508 508 SW Brochure NL NovemberFelipe FragosoNo ratings yet

- Yamaha FC7 Volume Pedal Manual M - 151552Document5 pagesYamaha FC7 Volume Pedal Manual M - 151552FREIMUZICNo ratings yet