Professional Documents

Culture Documents

WPS-Shell To Tubesheet (CS-SS)

Uploaded by

suria qaqcOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS-Shell To Tubesheet (CS-SS)

Uploaded by

suria qaqcCopyright:

Available Formats

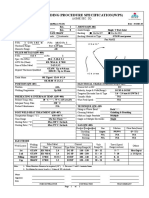

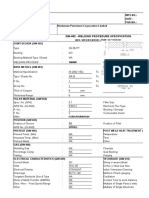

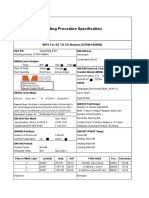

SURIA ENGINEERING

WELDING PROCEDURE SPECIFICATION (WPS)

Client: EPCL Date:

Welding Procedure Specification No.: SE-QC-WPS-CN.2F-02 Project: CN-2F

Revision: 01 Supporting PQR No.: SE-QC-PQR-CN2F-02

Welding Process (es): GTAW Type(s) : Manual

Code / STD: As per ASME Section IX

Note:

Root to be done by GTAW process

Plate Thickness Maximum120mm

Shell to tube sheet

BASE METAL (QW.403) 1

P.NO. 1 Group No. 2 to P.No. 8 Group No.

OR

Specification type and Grade ASTM A-36

to Specification type and Grade SS 304

OR

Base Metal : Groove 2~4mm Tube Sheet: 40mm Thickness. Fillet Fillet All thickness

Base Plate Shell: Thickness 10mm. Fillet

Other: Pipe Dia range unlimited Fillet

FILLER METALS POSTWELD HEAT TREATMENT

(QW.404) (QW.407)

GTAW GTAW

ROOT HOT PASS FILL/CAP ROOT FILL CAP Temperature Range : N/A

Spec. No. (SFA) 5.9 5.9 5.9 Time Range : N/A

AWS No. (Class) ER-309L ER-309L ER-309L Soaking Time at Max Temp : N/A

F.No. 6 6 6

A. No. 8 8 8

Size of Filler Metals 1.6mm/2.4mm 1.6mm/2.4 1.6mm/2.4mm GAS

mm

Weld Metal ER309 ER309 ER309 (QW-408)

Fillet All Thickness All Thickness All Thickness Shielding Gas (es) : Argon

Electrode Flux (Class) BARE METAL Percent Composition (mixture) : 99.90%

Flux Trade Name MAGMAWELD/LINKON / ESSAB Flow Rate : 8 - 10 LIT / P.M

Consumable I n s e r t ` Gas Backing : N/A

Other Trailing Shielding Gas Composition : N/A

Each base & filler metal combination should record individually

QW.482

POSITIONS (QW.405) POSTWELD HEAT TREATMENT (QW.407)

Position(s) of Groove HOR Temperature Range

Welding Position: Up F5 Time Range -

Position(s) of Fillet ALL

PREHEAT (QW.406) GAS (QW.408)

Percent Composition

Preheat Temp. Min. 10 Deg C Gas(es) (Mixture) Flow Rate

Interpass Temp Maintain . 150 Deg C Shielding ARGON 99.90% 8-10 LIT/M.P

Preheat Maintenance (If Required) By Propane Torch Trailing - - -

Baking of electrode Backing - - -

ELECTRICAL CHARACTERISTICS (QW.409)

Current AC or DC DC Polarity GTAW DCEN

Amps. (Range) GTAW 80-140

Volts (Range) 18-28

Electrode wire feed speed range

Tungsten Electrode Size and Type Dia 2.4mm 2% THORATED

TECHNIQUE (QW.410)

String of Weave Bead All String

Orifice or Gas Cup Size 4 - 6 mm

Initial and interpass Cleaning (Brushing, Grinding, etc.) Brushing & Grinding / Power grinding

Method of Back Gouging Power Brush

Oscillation Power Grinding Contact

Tube to Work Distance N/A

Multiple or Single Pass (per side) Multiples

Multiple or Single Electrodes Single

Travel Speed (Range) 3" -6" Penning

Other

Filler Metal Current

Weld Type Amp Volt Travel Other

Layers Process Class Dia. Polar Range Range Speed

ROOT GTAW ER309L 2.4/3.2 DCEN 90 - 120 18-28 3" -4"

FILLING 1 GTAW ER309L 2.4/3.2 DCEN 90 - 120 18-28 3" -4"

FILLING 2(If Req.) GTAW ER309L 2.4/3.2 DCEN 90 - 120 18-28 3" -4"

CAPPING GTAW ER309L 2.4/3.2 DCEN 90 - 120 18-28 3" -4"

Prepared By Reviewed By Approved By

Suria Engineering Suria Engineering EPCL

Name: Altaf Khan Name: Nauman Suria Name:

Signature: Signature: Signature:

Date: Date: Date:

You might also like

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- WPS-Tube To Tube Sheet (SS-SS)Document2 pagesWPS-Tube To Tube Sheet (SS-SS)suria qaqcNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Transmisión Meritor 9 Y10 Velocidades mm99106Document170 pagesTransmisión Meritor 9 Y10 Velocidades mm99106Joel Medina71% (7)

- The Hero ofDocument5 pagesThe Hero ofkhushnood aliNo ratings yet

- Change Pointer in The Material Master in SAP ECCDocument1 pageChange Pointer in The Material Master in SAP ECCTaufik KadarusmanNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- SS Pipe Welding ProcedureDocument5 pagesSS Pipe Welding Procedureamit rajputNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- Acceptance Criteria Asme B31.3 PDFDocument1 pageAcceptance Criteria Asme B31.3 PDFAhmad RizkiNo ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- WPS PQRDocument126 pagesWPS PQRBuditama ChandranegaraNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Soal CswipDocument1 pageSoal Cswipakun jeparaNo ratings yet

- QW 483Document2 pagesQW 483delta lab sangliNo ratings yet

- P91 MaterialDocument15 pagesP91 MaterialelrajilNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- 20G Boiler Steel Pipe PDFDocument5 pages20G Boiler Steel Pipe PDFHeza FirdausNo ratings yet

- Weld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020Document3 pagesWeld Summary: SATIP-W-011-01 SATR-W-2008 30/apr/13 19/04/2020bishalNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- QW-403 6Document1 pageQW-403 6Solikhul HarisNo ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- Radiographic Testing: Inspection ReportDocument2 pagesRadiographic Testing: Inspection Reportsuria qaqcNo ratings yet

- Material Safety Data Sheet: Poly Cell AdhesiveDocument8 pagesMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNo ratings yet

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNo ratings yet

- Welding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Document1 pageWelding Procedure Specification: Wps For Ss To Cs Material (Gtaw+Smaw)Lipika GayenNo ratings yet

- Procedure Qualification Record (PQR) FormDocument1 pageProcedure Qualification Record (PQR) FormEarl HarbertNo ratings yet

- Pretest Piping Punch List (Empty)Document1 pagePretest Piping Punch List (Empty)Jorge GarciaNo ratings yet

- Suria Engineering.: Test Pack For Tt307B PipingDocument16 pagesSuria Engineering.: Test Pack For Tt307B Pipingsuria qaqcNo ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- Acceptable Grade of Plate Material (API 650)Document1 pageAcceptable Grade of Plate Material (API 650)juantamad02No ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 pagesEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaNo ratings yet

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- Welcome To: Training Program On GUIDED TOUR OF Asme CodesDocument120 pagesWelcome To: Training Program On GUIDED TOUR OF Asme CodesDiego HenriqueNo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Welder'S Qualification Test Certificate: Plate TO Plate Plate and Pipe Dia 500Document3 pagesWelder'S Qualification Test Certificate: Plate TO Plate Plate and Pipe Dia 500Er Pralabh ShahNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Asme Sec Ix, Wps-Welding Variables and Data (Smaw-Saw-Gtaw)Document7 pagesAsme Sec Ix, Wps-Welding Variables and Data (Smaw-Saw-Gtaw)Saran Kumar100% (1)

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- Method of Statement PDFDocument7 pagesMethod of Statement PDFSakib AyubNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- WPS002 312Document2 pagesWPS002 312proxywarNo ratings yet

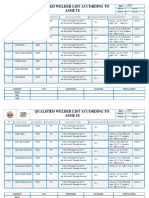

- Qualified Welder List According To Asme IxDocument5 pagesQualified Welder List According To Asme IxAhmad Nabil ElsharkawyNo ratings yet

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pages2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNo ratings yet

- Assure Solutions: Hydro Test ReportDocument1 pageAssure Solutions: Hydro Test ReportKailas NimbalkarNo ratings yet

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- WPS-Shell To Tubesheet (CS-SS)Document1 pageWPS-Shell To Tubesheet (CS-SS)suria qaqcNo ratings yet

- WPS-Nozzle With Reinforcement Pad (CS-CS) .Document1 pageWPS-Nozzle With Reinforcement Pad (CS-CS) .suria qaqcNo ratings yet

- WPS-Nozzle Without Reinforcement Pad (CS-CS) .Document1 pageWPS-Nozzle Without Reinforcement Pad (CS-CS) .suria qaqcNo ratings yet

- WPS-Shell To Shell Joint (CS-CS) .Document1 pageWPS-Shell To Shell Joint (CS-CS) .suria qaqcNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- PWPS WPS CAP 039 PQR 035Document15 pagesPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNo ratings yet

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Document1 pageO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNo ratings yet

- Daily Inword Gate Pass (D)Document195 pagesDaily Inword Gate Pass (D)suria qaqcNo ratings yet

- Short Description of 10years Professional Journey: Covering LetterDocument1 pageShort Description of 10years Professional Journey: Covering Lettersuria qaqcNo ratings yet

- Tle-01 Dossier.Document39 pagesTle-01 Dossier.suria qaqcNo ratings yet

- TT-307B Dossier.Document41 pagesTT-307B Dossier.suria qaqcNo ratings yet

- TT306 Dossier.Document29 pagesTT306 Dossier.suria qaqcNo ratings yet

- Suria Engineering.: Test Pack For Tt307B PipingDocument16 pagesSuria Engineering.: Test Pack For Tt307B Pipingsuria qaqcNo ratings yet

- Suria Engineering.: Test Pack For Tt307B PipingDocument18 pagesSuria Engineering.: Test Pack For Tt307B Pipingsuria qaqcNo ratings yet

- BOQ PIPING Total DetailDocument16 pagesBOQ PIPING Total Detailsuria qaqcNo ratings yet

- Tle-02 Dossier.Document40 pagesTle-02 Dossier.suria qaqcNo ratings yet

- Sub Station Structure.Document33 pagesSub Station Structure.suria qaqcNo ratings yet

- Ovr Dossier.Document93 pagesOvr Dossier.suria qaqcNo ratings yet

- E1461 Dossier.Document46 pagesE1461 Dossier.suria qaqcNo ratings yet

- DSQ Dossier.Document62 pagesDSQ Dossier.suria qaqcNo ratings yet

- Weekly HSE ReportDocument1 pageWeekly HSE Reportsuria qaqcNo ratings yet

- GF-304CR Dossier.Document35 pagesGF-304CR Dossier.suria qaqcNo ratings yet

- Suria Engineering: Tool Box Talk FormDocument1 pageSuria Engineering: Tool Box Talk Formsuria qaqcNo ratings yet

- Suria Engineering Staff List: Doc No: Rev By: DateDocument3 pagesSuria Engineering Staff List: Doc No: Rev By: Datesuria qaqcNo ratings yet

- Safe Work Practices: Doc No: Rev By: DateDocument1 pageSafe Work Practices: Doc No: Rev By: Datesuria qaqcNo ratings yet

- PPEs Issue ListDocument1 pagePPEs Issue Listsuria qaqcNo ratings yet

- Task Instructions (Ti) : Date: Time: Dept: PTW No Location: Emergency No: What Is The Task Today?Document2 pagesTask Instructions (Ti) : Date: Time: Dept: PTW No Location: Emergency No: What Is The Task Today?suria qaqcNo ratings yet

- Bill of Material For Cn2F Dish Heads: Part No. Description Material Thickness-Mm Size-Mm Qty. RemarksDocument1 pageBill of Material For Cn2F Dish Heads: Part No. Description Material Thickness-Mm Size-Mm Qty. Remarkssuria qaqcNo ratings yet

- Suria Engineering SR/EPCL/-01/21: Piping Test Package For Tt307B PipingDocument18 pagesSuria Engineering SR/EPCL/-01/21: Piping Test Package For Tt307B Pipingsuria qaqc100% (1)

- Short Description of 09years Professional Journey: Covering LetterDocument7 pagesShort Description of 09years Professional Journey: Covering Lettersuria qaqcNo ratings yet

- BOQ PIPING Total DetailDocument16 pagesBOQ PIPING Total Detailsuria qaqcNo ratings yet

- QIP TT 307 PIPING WORK - RevisedDocument2 pagesQIP TT 307 PIPING WORK - Revisedsuria qaqcNo ratings yet

- Sepsis and Pneumonia v1.3Document2 pagesSepsis and Pneumonia v1.3Luis HANo ratings yet

- Dirk Kruger MacroTheoryDocument308 pagesDirk Kruger MacroTheoryGurjot SinghNo ratings yet

- Guias ESC para Insuficiencia Cardiaca CronicaDocument128 pagesGuias ESC para Insuficiencia Cardiaca CronicaKarla HernandezNo ratings yet

- Psychometric Evaluation of The Albanian Version of Tosca 3 To Measure Shame and GuiltDocument6 pagesPsychometric Evaluation of The Albanian Version of Tosca 3 To Measure Shame and GuiltMirela Cojocaru StetcoNo ratings yet

- Rigid Rotor WikipediaDocument8 pagesRigid Rotor WikipediaAtropospNo ratings yet

- Marginal CallDocument3 pagesMarginal Calllexredondo22No ratings yet

- Indian Institute of Technology Delhi: Semester Schedule For Semester II 2019-20 (Proposed)Document5 pagesIndian Institute of Technology Delhi: Semester Schedule For Semester II 2019-20 (Proposed)karan tanwarNo ratings yet

- Assignment 1 - Time Dose Fractionation TDF ConceptsDocument3 pagesAssignment 1 - Time Dose Fractionation TDF Conceptsapi-299138743No ratings yet

- Astro Tips & Techniques How To'sDocument8 pagesAstro Tips & Techniques How To'stsampounas100% (1)

- Katalog Pintu Bajaa FenturaDocument18 pagesKatalog Pintu Bajaa FenturaAgung YanaNo ratings yet

- A 109 - A 109M - 16 PDFDocument9 pagesA 109 - A 109M - 16 PDFأسامة وحيد الدين رمضانNo ratings yet

- 4 Curriculum StructureDocument19 pages4 Curriculum StructurealiyazahirNo ratings yet

- De Contemptu Mundi A Medieval SatireDocument3 pagesDe Contemptu Mundi A Medieval SatireachielliesNo ratings yet

- English 1-2-1Document7 pagesEnglish 1-2-1Arlene Suan Paña SevensixfourzeroNo ratings yet

- Problems On MergerDocument7 pagesProblems On MergerSUNILABHI_APNo ratings yet

- Grabar FTPDocument6 pagesGrabar FTPSergio Martín CorderoNo ratings yet

- OCSPDocument3 pagesOCSPgayathrisanNo ratings yet

- Cisco Catalyst Blade Switch 3020 For HP Getting Started GuideDocument36 pagesCisco Catalyst Blade Switch 3020 For HP Getting Started GuideAlgor333No ratings yet

- Earth Sheryn ReanaDocument10 pagesEarth Sheryn ReanaSHERYN REANA A/P KUMARASAMY MoeNo ratings yet

- Book ReviewDocument5 pagesBook ReviewMANOHAR SIVVALA 20111632No ratings yet

- Abhaya Mudra: "Abhaya" Means "Fearless". Abhaya Mudra Represents Protection, Peace, Benevolence, and Dispelling of FearDocument9 pagesAbhaya Mudra: "Abhaya" Means "Fearless". Abhaya Mudra Represents Protection, Peace, Benevolence, and Dispelling of FearIon ConstantinNo ratings yet

- NSTP 2Document21 pagesNSTP 2chloeNo ratings yet

- Lighting Global Standardized Specifications Book: Manufacturer: Component Family NameDocument4 pagesLighting Global Standardized Specifications Book: Manufacturer: Component Family NamemagaliNo ratings yet

- Table of Specifications in Grade 7 ScienceDocument2 pagesTable of Specifications in Grade 7 ScienceBillones Rebalde MarnelleNo ratings yet

- Macintosh Developer's Guide To The Wacom TabletDocument29 pagesMacintosh Developer's Guide To The Wacom TabletnqrcNo ratings yet

- Proj Quake TowersDocument4 pagesProj Quake TowersMacky CometaNo ratings yet

- Job AnalysisDocument16 pagesJob AnalysisThulasi BrindhaNo ratings yet