Professional Documents

Culture Documents

(P1) NSC-1020-TR-0102-1.1-WPS-06

Uploaded by

BIIS QAQC Babu SivaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(P1) NSC-1020-TR-0102-1.1-WPS-06

Uploaded by

BIIS QAQC Babu SivaCopyright:

Available Formats

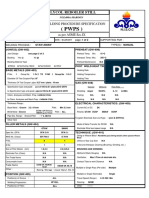

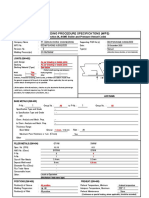

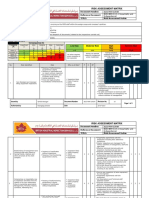

NEO STRUCTO CONSTRUCTION PRIVATE LIMITED.

WELDING PROCEDURE SPECIFICATION(WPS)

(As per ASME Section IX Ed.2017 , QW-482)

WPS No : NSC-1020-TR-0101-1.1-WPS-05 Rev:4 Dtd: 02.04.2019

: TOYO/NSCL/MBOP/PIP/PQR-01 Rev.0 dt: 05.10.2010

Procedure Qualification Record No

Welding Process(es) : GTAW

Types (Manual, Automatic, Semi-Auto,Machine) : MANUAL

JOINTS (QW-402)

Joint Design : Single "V" Butt Joint ( W1 JOINT Details) 70° ± 5°

Backing : No (Root Pass)/YES (Weld Material)

1.6mm ± 0.4mm

Backing Material : Weld Material t=5.08/7.11 mm

Root Spacing : As Per Joint Detail

Retainers : None 1.6 mm ± 0.8 mm

BASE METALS (QW-403)

P-No 1 Group No 1 to P-No 1 Group No : 2/1

OR

Specification, Type & Grade : SA 106GrB

to Specification, Type & Grade : SA 105/SA234 Gr.B

Thickness & Dia. Of Test coupon : 10.97 mm & 6" Dia

Base Metal Thickness Range

a) Groove Qualified : 5 to 21.94 mm a)Groove:Weld Production:5.08/7.11 mm

b)Fillet : Weld Production : ALL

FILLER METALS (QW-404)

Process-1

GTAW

Specification No. (SFA) : 5.18

AWS No. (Classification)/Filler : ER70S-2

F- No. : 6

A- No. : 1

Size of Filler Metal : 1.6 mm

Weld Metal Thickness Range

a) Groove : Up to 8 mm

b) Fillet : ALL

Brand name of consumable : ULTIMATE-18

Make : HONAVAR

Electrode-Flux (Class) : NONE

Flux Trade Name : NONE

Flux Type : NA

Electrode-Flux (Class) : NA

Electrode Trade Name : ADOR/D & H

Flux Trade Name : NA

Flux Type : NA

Consumable Insert NA

Filler Metal Product Form : BARE (Solid)

Other : NA

POSITION (QW-405) POST WELD HEAT TREATMENT(QW-407)

Position of Groove : ALL Loading Temperature : NA

Welding Progression (Uphill/Downhill) : UPHILL Heating Rate : NA

Position of Fillet : ALL Soaking Temperature : NA

PRE HEAT (QW-406) Soaking Time : NA

Pre heat Temperature (Minimum) : 10˚C Cooling Rate : NA

Interpass Temperature (Maximum) : 250°C- Unloading Temperature : NA

Pre heat Maintenance : NA Post Heat : NA

Page 1 of 6 EXHIBIT NO: WE-01 R2

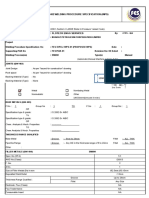

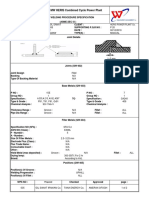

NEO STRUCTO CONSTRUCTION PRIVATE LIMITED.

WELDING PROCEDURE SPECIFICATION(WPS)

(As per ASME Section IX Ed.2017 , QW-482)

WPS No : NSC-1020-TR-0101-1.1-WPS-05 Rev:4 Dtd: 02.04.2019

Note: Thermosticks may be used for temp. measurement.

GAS (QW-408)

Gas % Composition (Mixture) Flow Rate

Shielding Gas ARGON 99.995% Pure 10-12 LPM

Trailing Gas NONE NONE NONE

Backing Gas NONE NONE NONE

ELECTRICAL CHARACTERISTICS (QW-409)

Pulsing current or Power source : DC

Current or Polarity : EN(GTAW)

Amps Range : 125-165

Volts Range : 14-18

Tungsten Electrode Size and Type : 2.4 mm dia & 2% Thoriated

Mode of Metal Transfer (for GMAW) : NA

Electrode Wire Feed Speed Range : NA

TECHNIQUE (QW-410)

String or Weave : 1st Pass String Bead / Rest passes weave

Orifice or Gas Cup Size : 6 to 8 mm

Initial and Inter pass Cleaning : Grinding/ Brushing

Method of Back gouging : No

Oscillation : <=3 times electrode diameter

Closed to out Chamber : NA

Electrode Spacing : NA

Contact Tube to Work Distance : NA

Multiple or Single Pass (per side) : Multiple

Multiple or Single Electrode : Single

Travel Speed (Range) : 41-52

Peening : NO

Thermal Processes : NONE

Manual Or Automatic : Manual * NA=Not Applicable

Filler Metal Current

Sl. Volts

Pass Process AWS Amps Remark

No. Dia (mm) Polarity Range Tr.Speed mm/Min

Class. Range

1 Root GTAW ER 70S 2 1.6 DCEN 125-130 14-16 44

2 Hot GTAW ER 70S 2 1.6 DCEN 155-160 16-17 52

3 GTAW ER 70S 2 1.6 DCEN 127-132 15-18 41

Sub-

4 Sequent GTAW ER 70S 2 1.6 DCEN 128-133 16-18 44

Pass

5 GTAW ER 70S 2 1.6 DCEN 150-165 15-17 47

Note (s): 1. Weaving not exceeding 3 times electrode dia.

Signature

Name

Date

Welding Engineer Quality Manager Client/Inspection/TPI

Page 2 of 6 EXHIBIT NO: WE-01 R2

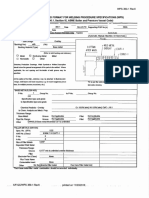

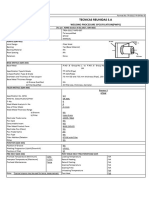

NEO STRUCTO CONSTRUCTION PRIVATE LIMITED.

WELDING PROCEDURE SPECIFICATION(WPS)

(As per ASME Section IX Ed.2017 , QW-482)

WPS No : NSC-1020-TR-0101-1.1-WPS-06 Rev:4 Dtd: 02.04.2019

Procedure Qualification Record No : TOYO/NSCL/MBOP/PIP/PQR-01 Rev.0 dt: 05.10.2010

Welding Process(es) : GTAW+SMAW

Types (Manual, Automatic, Semi-Auto,Machine) : MANUAL

JOINTS (QW-402)

Joint Design : Single "V" Butt Joint (W2.1 JOINT Detail)

Backing : No (Root Pass) / YES (Weld Material)

Backing Material : Weld Material

Root Spacing : As Per Joint Detail

Retainers : None

BASE METALS (QW-403)

P-No 1 Group No : 1 to P-No 1 Group No : 2

OR

Specification, Type & Grade : SA 106GrB

to Specification, Type & Grade : SA 105

Thickness & Dia. Of Test coupon : 10.97 mm & 6" Dia

Base Metal Thickness Range

a) Groove Qualified : 5 mm to 21.94 mm(Note 1) a)Groove:Weld Production Thk : 5.08/15.24 mm

b)Fillet : Weld Production: ALL

Other : t pass > 13 mm (for SMAW):NO

FILLER METALS (QW-404)

Process-1 Process-1

GTAW SMAW

Specification No. (SFA) : 5.18 5.1

AWS No. (Classification)/Filler : ER70 S-2 E 7018

F- No. : 6 4

A- No. : 1 1

Size of Filler Metal : 1.6 mm 2.5 mm

Weld Metal Thickness Range

a) Groove : Up to 8 mm Up to 13.94mm

b) Fillet ALL ALL

Electrode-Flux (Class) : NA NA

Electrode Trade Name : ADOR /D & H

Flux Trade Name : NA NA

Flux Type : NA NA

Consumable Insert NO NA

Filler Metal Product Form : BARE (Solid) NA

Other : NA NA

POSITION (QW-405) POST WELD HEAT TREATMENT(QW-407)

Position of Groove : ALL Loading Temperature : NA

Welding Progression (Uphill/Downhill) : UPHILL Heating Rate : NA

Position of Fillet : ALL Soaking Temperature : NA

PRE HEAT (QW-406) Soaking Time : NA

Pre heat Temperature (Minimum) :10˚C Cooling Rate : NA

Interpass Temperature (Maximum) : 250°C- Unloading Temperature : NA

Pre heat Maintenance : NA Post Heat : NA

Note: Thermosticks may be used for temp. measurement.

Page 3 of 6 EXHIBIT NO: WE-01 R2

NEO STRUCTO CONSTRUCTION PRIVATE LIMITED.

WELDING PROCEDURE SPECIFICATION(WPS)

(As per ASME Section IX Ed.2017 , QW-482)

WPS No : NSC-1020-TR-0101-1.1-WPS-06 Rev:4 Dtd: 02.04.2019

GAS (QW-408)

Gas % Composition (Mixture) Flow Rate

Shielding Gas ARGON 99.995% Pure 10-12 LPM

Trailing Gas NONE NONE NONE

Backing Gas NONE NONE NONE

ELECTRICAL CHARACTERISTICS (QW-409)

Pulsing current or Power source : DC

Current or Polarity : EN(GTAW) & EP(SMAW)

Amps Range : 125-160 (GTAW) ; 80-90 (SMAW)

Volts Range : 14-17 (GTAW) ; 22-26 (SMAW)

Tungsten Electrode Size and Type : 2.4 mm dia & 2% Thoriated

Mode of Metal Transfer (for GMAW) : NA

Electrode Wire Feed Speed Range : NA

TECHNIQUE (QW-410)

String or Weave : 1st Pass String Bead / Rest passes Weave

Orifice or Gas Cup Size : 6 to 8 mm

Initial and Inter pass Cleaning : Grinding/ Brushing

Method of Back gouging : No

Oscillation : <=3 times electrode diameter

Closed to out Chamber : NA

Electrode Spacing : NA

Contact Tube to Work Distance : NA

Multiple or Single Pass (per side) : Multiple

Multiple or Single Electrode : Single

Travel Speed (Range) : 44-52 (GTAW) ; 41-47 (SMAW)

Peening : NO

Thermal Processes : NONE

Manual Or Automatic : Manual * NA=Not Applicable

Filler Metal Current

Sl. Volts Tr.Speed

Pass Process AWS Amps Remark

No. Dia (mm) Polarity Range mm/Min

Class. Range

1 Root GTAW ER 70S 2 1.6 DCEN 125-130 14-16 44

2 Hot GTAW ER 70S 2 1.6 DCEN 155-160 16-17 52

3 SMAW E7018 2.5 DCEP 80-84 22-24 41

Sub-

4 Sequent SMAW E7018 2.5 DCEP 86-90 23-26 44

Pass

5 SMAW E7018 2.5 DCEP 84-87 23-25 47

Note (s): 1. For pressure piping , use of this WPS shall be limited to thickness upto 19.0 mm only

2. Weaving not exceeding 3 times electrode dia.

Signature

Name

Date

Welding Engineer Quality Manager Client/Inspection/TPI

Page 4 of 6 EXHIBIT NO: WE-01 R2

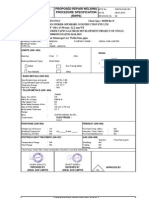

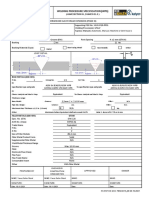

NEO STRUCTO CONSTRUCTION PRIVATE LIMITED.

WELDING PROCEDURE SPECIFICATION(WPS)

(As per ASME Section IX Ed.2017 , QW-482)

WPS No : NSC-1020-TR-0101-1.1-WPS-11 Rev:2 Dtd: 02.04.2019

Procedure Qualification Record No : TOYO/NSCL/MBOP/PIP/PQR-01 Rev.0 dt: 05.10.2010

Welding Process(es) : GTAW

Types (Manual, Automatic, Semi-Auto,Machine) : MANUAL

JOINTS (QW-402)

Joint Design : Single "V" Socket Joint (W3 JOINT Detail)

Backing : No (Root Pass) / YES (Weld Material)

Backing Material : Weld Material

Root Spacing : As Per Joint Detail

Retainers : None

BASE METALS (QW-403)

P-No 1 Group No : 1 to P-No 1 Group No : 2

OR

Specification, Type & Grade : SA 106Gr B to SA105

to Specification, Type & Grade : A105

Thickness & Dia. Of Test coupon : 10.97 mm & 6" Dia

Base Metal Thickness Range

a) Groove Qualified : 5 to 21.94 mm a) Socket Weld :Weld Production -5.08 MM

b) Fillet : Weld Production:ALL

Other : t pass > 13 mm (for SMAW):NA

FILLER METALS (QW-404)

Process-1

GTAW

Specification No. (SFA) : 5.18

AWS No. (Classification)/Filler : ER70 S-2

F- No. : 6

A- No. : 1

Size of Filler Metal : 1.6 mm

Weld Metal Thickness Range

a) Groove : Up to 8 mm

Electrode-Flux (Class) : NA

Electrode Trade Name : ADOR /D & H

Flux Trade Name : NA

Flux Type : NA

Consumable Insert NO

Filler Metal Product Form : BARE (Solid)

Other : NA

POSITION (QW-405) POST WELD HEAT TREATMENT(QW-407)

Position of Groove : ALL Loading Temperature : NA

Welding Progression (Uphill/Downhill) : UPHILL Heating Rate : NA

Position of Fillet : ALL Soaking Temperature : NA

PRE HEAT (QW-406) Soaking Time : NA

Pre heat Temperature (Minimum) : 10˚C Cooling Rate : NA

Interpass Temperature (Maximum) : 250°C- Unloading Temperature : NA

Pre heat Maintenance : NA Post Heat : NA

Note: Thermosticks may be used for temp. measurement.

Page 5 of 6 EXHIBIT NO: WE-01 R2

NEO STRUCTO CONSTRUCTION PRIVATE LIMITED.

WELDING PROCEDURE SPECIFICATION(WPS)

(As per ASME Section IX Ed.2017 , QW-482)

WPS No : NSC-1020-TR-0101-1.1-WPS-11 Rev:2 Dtd: 02.04.2019

GAS (QW-408)

Gas % Composition (Mixture) Flow Rate

Shielding Gas ARGON 99.995% Pure 10-12 LPM

Trailing Gas NONE NONE NONE

Backing Gas NONE NONE NONE

ELECTRICAL CHARACTERISTICS (QW-409)

Pulsing current or Power source : DC

Current or Polarity : EN

Amps Range : 125-160

Volts Range : 14-17

Tungsten Electrode Size and Type : 2.4 mm dia & 2% Throiated

Mode of Metal Transfer (for GMAW) : NA

Electrode Wire Feed Speed Range : NA

TECHNIQUE (QW-410)

String or Weave : 1st Pass String Bead / Rest passes Weave

Orifice or Gas Cup Size : 6 to 8 mm

Initial and Inter pass Cleaning : Grinding/ Brushing

Method of Back gouging : No

Oscillation : <=3 times electrode diameter

Closed to out Chamber : NA

Electrode Spacing : NA

Contact Tube to Work Distance : NA

Multiple or Single Pass (per side) : Multiple

Multiple or Single Electrode : Single

Travel Speed (Range) : 44-52 (GTAW)

Peening : NO

Thermal Processes : NONE

Manual Or Automatic : Manual * NA=Not Applicable

Filler Metal Current

Sl. Volts Tr.Speed

Pass Process AWS Amps Remark

No. Dia (mm) Polarity Range mm/Min

Class. Range

1 Root GTAW ER 70S 2 1.6 DCEN 125-130 14-16 44

2 Hot GTAW ER 70S 2 1.6 DCEN 155-160 16-17 52

3 GTAW ER 70S 2 1.6 DCEN 127-132 15-18 41

Sub-

4 Sequent GTAW ER 70S 2 1.6 DCEN 128-133 16-18 44

Pass

5 GTAW ER 70S 2 1.6 DCEN 150-165 15-17 47

Note (s): 1. Weaving not exceeding 3 times electrode dia.

Signature

Name

Date

Welding Engineer Quality Manager Client/Inspection/TPI

Page 6 of 6 EXHIBIT NO: WE-01 R2

You might also like

- p94-1738 Instrumentation t2000Document6 pagesp94-1738 Instrumentation t2000AaronNo ratings yet

- Hazards Identification and Risk Assessment - New FormatDocument2 pagesHazards Identification and Risk Assessment - New FormatBIIS QAQC Babu Siva100% (1)

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- The Champion Legal Ads: 03-30-23Document49 pagesThe Champion Legal Ads: 03-30-23Donna S. SeayNo ratings yet

- DL1 Dragons of DespairDocument38 pagesDL1 Dragons of DespairHeath Page100% (1)

- HUD Settlement Statement - 221-1993Document4 pagesHUD Settlement Statement - 221-1993Paul GombergNo ratings yet

- Glycol Reboiler Still Welding Procedure Specification (PWPSDocument2 pagesGlycol Reboiler Still Welding Procedure Specification (PWPSstdshopNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- WELDING PROCEDURE SPECIFICATIONSDocument6 pagesWELDING PROCEDURE SPECIFICATIONSMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielNo ratings yet

- (Nick Lund - Grenadier) Fantasy Warriors Special RulesDocument11 pages(Nick Lund - Grenadier) Fantasy Warriors Special Rulesjasc0_hotmail_it100% (1)

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- Sample SHARKS Worksheet PDFDocument10 pagesSample SHARKS Worksheet PDFAmruta Chhajed100% (2)

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- PWPS WPS CAP 039 PQR 035Document15 pagesPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Document1 pageO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- 347 310 WPSDocument2 pages347 310 WPSBIIS QAQC Babu SivaNo ratings yet

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Form WPS for MIG Welding ProcedureDocument10 pagesForm WPS for MIG Welding ProcedurePrakash PatelNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Ex Wps Train 01Document2 pagesEx Wps Train 01aidil30No ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- WPS For SSDocument1 pageWPS For SSdeepakNo ratings yet

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- Welding Procedure Specification: (As Per Asme Sec Ix)Document1 pageWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- S 001 Link 2Document1 pageS 001 Link 2wael badawiNo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- PWPS 102 - CopyDocument2 pagesPWPS 102 - CopyCyril J PadiyathNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- Welding & NDTDocument1 pageWelding & NDTVijaya BaraniNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- GTAWDocument1 pageGTAWabdulNo ratings yet

- Balajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Document2 pagesBalajee Tanks & Vessels: QW 482 Welding Procedure Specifications (WPS)Eswara Rao BodduNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- Details Required For The Vendor RegistrationDocument1 pageDetails Required For The Vendor RegistrationBIIS QAQC Babu SivaNo ratings yet

- Biis-Sc-02 Subcontractor Evaluation & Re Evaluation FormDocument2 pagesBiis-Sc-02 Subcontractor Evaluation & Re Evaluation FormBIIS QAQC Babu SivaNo ratings yet

- Biis-Sf-02 Personal Protective EquipmentDocument2 pagesBiis-Sf-02 Personal Protective EquipmentBIIS QAQC Babu SivaNo ratings yet

- Biis-Sf-01 Accident RecordDocument1 pageBiis-Sf-01 Accident RecordBIIS QAQC Babu SivaNo ratings yet

- Biis-Kpi-01-Key Performance Indicator-Rev-01-17-07-2019Document1 pageBiis-Kpi-01-Key Performance Indicator-Rev-01-17-07-2019BIIS QAQC Babu SivaNo ratings yet

- Biis-Sf-03-Risk Assessment Form-GeneratorDocument3 pagesBiis-Sf-03-Risk Assessment Form-GeneratorBIIS QAQC Babu SivaNo ratings yet

- Biis-Sc-01 Approved Subcontractor ListDocument2 pagesBiis-Sc-01 Approved Subcontractor ListBIIS QAQC Babu SivaNo ratings yet

- British Industrial Crane AssessmentDocument4 pagesBritish Industrial Crane AssessmentBIIS QAQC Babu SivaNo ratings yet

- BIIS invoice details letterDocument1 pageBIIS invoice details letterBIIS QAQC Babu SivaNo ratings yet

- Risk Assessment Matrix: Consequence (C) Low Risk Moderate Risk High Risk Extreme RiskDocument3 pagesRisk Assessment Matrix: Consequence (C) Low Risk Moderate Risk High Risk Extreme RiskBIIS QAQC Babu SivaNo ratings yet

- Biis CL 46 Storage Rack InspectionDocument2 pagesBiis CL 46 Storage Rack InspectionBIIS QAQC Babu SivaNo ratings yet

- WPS 012Document11 pagesWPS 012BIIS QAQC Babu SivaNo ratings yet

- CriticalAppraisalWorksheetTherapy EffectSizeDocument2 pagesCriticalAppraisalWorksheetTherapy EffectSizeFitriArdiningsihNo ratings yet

- Common Phrasal VerbsDocument2 pagesCommon Phrasal VerbsOscar LasprillaNo ratings yet

- RNYM02-1120A-12Document2 pagesRNYM02-1120A-12bastian silvaNo ratings yet

- A Day With Maria Becerra (1) - 2Document2 pagesA Day With Maria Becerra (1) - 2FelipeNo ratings yet

- Geospatial Assessment of Climatic Variability and Aridity in Katsina State, NigeriaDocument11 pagesGeospatial Assessment of Climatic Variability and Aridity in Katsina State, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 6 1 Reducing Rational Expressions To Lowest TermsDocument21 pages6 1 Reducing Rational Expressions To Lowest Termsapi-233527181No ratings yet

- Seven Tips For Surviving R: John Mount Win Vector LLC Bay Area R Users Meetup October 13, 2009 Based OnDocument15 pagesSeven Tips For Surviving R: John Mount Win Vector LLC Bay Area R Users Meetup October 13, 2009 Based OnMarco A SuqorNo ratings yet

- South-Goa v1 m56577569830512348 PDFDocument16 pagesSouth-Goa v1 m56577569830512348 PDFXavierBoschNo ratings yet

- Electronic Skin PPT 2Document12 pagesElectronic Skin PPT 2Sunitha AteliNo ratings yet

- Tds CPD Sika ViscoCrete 2100 Us PDFDocument2 pagesTds CPD Sika ViscoCrete 2100 Us PDFSamirHashimNo ratings yet

- LPG Cylinder Market Player - Overview (Bangladesh)Document5 pagesLPG Cylinder Market Player - Overview (Bangladesh)ABID REZA KhanNo ratings yet

- STDM Course OutlineDocument11 pagesSTDM Course OutlineTp RayNo ratings yet

- RSSC IntroductionDocument31 pagesRSSC Introductioncalamus300No ratings yet

- Nick Bradbeer Thesis Master v11 Corrections REDACTEDDocument276 pagesNick Bradbeer Thesis Master v11 Corrections REDACTEDbatra_763079313No ratings yet

- Inorganic Polymers: Classification and PropertiesDocument46 pagesInorganic Polymers: Classification and PropertiesGokul KannanNo ratings yet

- Showcase your talent and skills at Momentum 2021Document48 pagesShowcase your talent and skills at Momentum 2021Tanishq VermaNo ratings yet

- Pod Graphics Processor Users GuideDocument71 pagesPod Graphics Processor Users GuideAsmaNo ratings yet

- CS 70 Discrete Mathematics and Probability Theory Spring 2016 Rao and Walrand Note 2 1 ProofsDocument8 pagesCS 70 Discrete Mathematics and Probability Theory Spring 2016 Rao and Walrand Note 2 1 ProofsAyesha NayyerNo ratings yet

- CH 6 SandwichesDocument10 pagesCH 6 SandwichesKrishna ChaudharyNo ratings yet

- Marketing Plan: Walton NextDocument26 pagesMarketing Plan: Walton NextAnthony D SilvaNo ratings yet

- Jewett CrisisManagementPlan 2021Document30 pagesJewett CrisisManagementPlan 2021Musadiq HussainNo ratings yet

- Principles of Synthetic BiologyDocument21 pagesPrinciples of Synthetic BiologyOpale PapaleNo ratings yet

- Transfer Taxes and Basic SuccessionDocument59 pagesTransfer Taxes and Basic SuccessionARC SVIORNo ratings yet

- Coaching Can Be Defined As The Process of MotivatingDocument5 pagesCoaching Can Be Defined As The Process of MotivatingDaniel DowdingNo ratings yet