Professional Documents

Culture Documents

Welding & NDT

Uploaded by

Vijaya Barani0 ratings0% found this document useful (0 votes)

32 views1 pageOriginal Title

WPS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

32 views1 pageWelding & NDT

Uploaded by

Vijaya BaraniCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

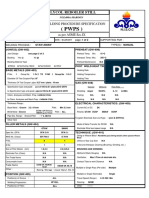

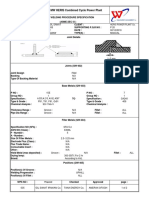

WENDT-WE-FOR-001, R0, Dated: 30/04/2019

WELDING & NDT

QW-482 WELDING PROCEDURE SPECIFICATION (WPS)

(See QW-200.1,Section, IX, ASME Boiler and Pressure Vessel code )

W.P.S. NO. : G-001 Supporting PQR(s) To be qualified POSTWELD HEAT TREATMENT (QW-407) ELECTRICAL CHARACTERISTICS (QW-409)

Revision No.: 0 Welding Process(es): GTAW .1 Ø Type of PWHT: NONE .4 (a) Ø Current (AC or DC): SEE BELOW

Date: 30/04/2019 Type(s): MANUAL .2 (a) Temperature Range :(°C) NA .4 (b) Ø Polarity (EN or EP): SEE BELOW

Equipment Name: Applicable for Welding of PQR No 002 Joint Type: GROOVE/FILLET .2 (b) Time Range:(Minute) NA .8 (a) Ø Amperes (Range): SEE BELOW

JOINTS (QW-402) Method of PWHT: NA .8 (b) Ø Voltage (Range): SEE BELOW

.1 Ø Joint Design: Refer Typical for details Typical: .4 T Limits NONE .12 Ø Tungsten Type:* 2% Thoriated Size (mm): 2.4 mm OR EQUI

.5 + Backing: (Yes/No) NO & YES( IF REQUIRED) Rate Of Heating:(°C/hr) NA .1 > Heat Input : NA

Backing Material (type): NA & BASE/WELD Rate Of Cooling:(°C/hr) NA .3 ± Pulsing Current : NA

.10 Ø Root Spacing 2~4 mm Others : NA Others : NA

.11 ± Retainers : NA GAS (QW-408)

Root face & Included Angle: 1-1.5 mm & 60° P1 G2 P1 G1 .2 (a) Ø Gas(es) .2(b) Ø Mixture & .2 © Ø % Composition .3 Ø Flow rate (LPM)

BASE METALS (QW-403) .2d ± Shielding Gas: ARGON SINGLE (NO CHANGE IN COMPOSITION) 5~15

MATERIAL - 1 MATERIAL - 2 .5 ± Backing Gas or Ø Backing Flow: NA NA NA

.11 Ø P.NO.: 1 P.NO.: 1 .1 ± Trailing Gas or Ø Comp: NA NA NA

.5 Ø Group No.: 2 Group No.: 1 .9 - Backing Gas or Ø Comp : NONE NONE NA

Specification/Grade: SA516GR70 Specification/Grade: SA516GR60 .10 Ø Shielding Trailing gas : NONE NONE NONE

.8 Thickness Range : (mm) TECHNIQUE (QW-410)

Base Metal Groove : 1.5 ~ 20 mm Fillet : NA Tubesheet: NA .1 Ø String/Weave Bead: STRING/WEAVE .3 Ø Gas Cup Size: (mm) 6.3 mm Dia OR EQUI

Pipe Dia Range Groove : ALL Fillet : ALL Ligament: Width : NA .15 Ø Electrode Spacing : NA .11 Ø Closed to out Chamber : NONE

Overlay thickness (Min): NA Tube thickness: NA .10 Ø Multiple/Single Electrode: SINGLE .9 Ø Multi/Single pass (per side): MULTI PASS

.6 T Limits : NA .7 Ø Oscillation: NA .26 ± Peening: NA

FILLER METALS (QW-404) .5 Ø Initial or Interpass WIRE BRUSH OR GRIND/MACHINED ;SURFACE TO BE GROUND

ROOT PASS FILL UP PASS(es) COVERING PASS(es) Cleaning: OR POWER WIRE BRUSHED OR MACHINED

.4 Ø F.NO.: 6 6 6 .6 Ø Method of Back Gouging: BY GRINDING IF REQUIRED

.5 Ø A.NO.: 1 1 1 .25 Ø Manual or Automatic MANUAL

Spec No.(SFA): 5.18 5.18 5.18 .64 Ø Use of Thermal Process : NONE

.12 & .33 Ø AWS No.(Class): *ER70S-2 *ER70S-2 *ER70S-2 Others : NA

.3 Ø Size of Filler Metal (mm): 2.4/2.5 2.4/2.5 2.4/2.5 Filler Metal Current Travel Energy or Maximum Minimum

Weld Volt

.23 Ø Filler Metal Product Form: SOLID (BARE) WIRE SOLID (BARE) WIRE SOLID (BARE) WIRE Process Dia. Type & Amp. Speed Power Heat Input Bead Length

Layer(s) Classification (Range)

.50 ± Flux : NA NA NA (mm) Polarity (Range) (mm/min) (Range) (KJ/mm) (mm)

.14± Filler : WITH ADDITION ONLY WITH ADDITION ONLY WITH ADDITION ONLY ALL GTAW ER70S-2 2.4/2.5 DCEN 80-200 10-18 NA NA NA NA

Flux Trade Name: NA NA NA

.22 ± Consumable Insert: NA NA NA

.30 Ø Weld Metal Thk Range: UPTO 20 mm (MAX)

Brand Name/ Batch No: * APPROVED BRAND SHALL BE USED

POSITIONS (QW-405)

.1 + (a) Position(s) of Groove : ALL

.2 & .3 Ø Welding Progression : VERTICAL UPHILL

.1 + (b) Position(s) of Fillet : ALL

Other: NA

PREHEAT (QW-406)

Thickness Range (mm) ≤25

.1 Preheat Temp (MIN)⁰ C : 25 *Tungsten electrode can be identified as : 1)EWTh-2 or WT 20(Red Colour)

.3 Interpass Temp (MAX)⁰ C: 275 NA : NOT APPLICABLE NONE : ESSENTIAL VARIABLE BUT NOT USED

Preheat Maintenance : NA Legend :

Method of measuring .1 & .3 Temperature indicating crayon / Laser gun + Addition > Increase/greater than ↑ Uphill ← Forehand ø Change

-Deletion < Decrease/less than ↓ Downhill → Backhand

PEPARED BY: WELDING ENGINEER REVIEWED BY: WELDING MANAGER APPROVED BY: CLIENT/CUSTOMER/TPI

ASME

DESIGNATOR

NAME: NAME: NAME:

DATE: DATE: DATE: REQ.

NOT REQ.

You might also like

- Bell-John Deere 315 SK Workshop Service Repair PDFDocument733 pagesBell-John Deere 315 SK Workshop Service Repair PDFRonaldWiseman52% (27)

- ASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatDocument1 pageASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatArshadAliNo ratings yet

- Єскаватор PDFDocument65 pagesЄскаватор PDFТарасСкульський100% (3)

- Welding ProcedureDocument11 pagesWelding ProcedureGFDSGSRTGTRH100% (1)

- Welding QA/QC Manual SampleDocument18 pagesWelding QA/QC Manual SampleDanem Halas100% (1)

- Flange Asme ViiiDocument21 pagesFlange Asme Viiizahidwahla1No ratings yet

- DuraGal - Design Capacity Tables For Steel Hollow SectionsDocument187 pagesDuraGal - Design Capacity Tables For Steel Hollow SectionsrichardreddinNo ratings yet

- Basic Fabrication Process FlowchartDocument1 pageBasic Fabrication Process FlowchartMorjhan MJ86% (29)

- Misumi Technical Data PDFDocument1 pageMisumi Technical Data PDFtnchsg100% (1)

- CHEVRON Shell and Tube Exchanger Component Design ConsiderationsDocument42 pagesCHEVRON Shell and Tube Exchanger Component Design Considerationsbabak mir80% (5)

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- AWS Quality Manual Sample No Field InstallationDocument20 pagesAWS Quality Manual Sample No Field InstallationManzar KhanNo ratings yet

- AWS Welders Training Sense - Presentation PDFDocument24 pagesAWS Welders Training Sense - Presentation PDFvonipkoNo ratings yet

- ''Technology Examination Questions (Multi-Cohice Exam - 1)Document4 pages''Technology Examination Questions (Multi-Cohice Exam - 1)Vijaya BaraniNo ratings yet

- Inspection and Test Plan For Structure Steel Erection WorksDocument11 pagesInspection and Test Plan For Structure Steel Erection WorksVijaya BaraniNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya BaraniNo ratings yet

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 pagesRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDocument4 pagesRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksVijaya Barani100% (1)

- NDT Weld Visual Inspection ProcedureDocument4 pagesNDT Weld Visual Inspection Procedureg_sancheti100% (2)

- 2011 VND O&M ManualDocument12 pages2011 VND O&M Manualsequeira.cedric6742No ratings yet

- Glycol Reboiler Still Welding Procedure Specification (PWPSDocument2 pagesGlycol Reboiler Still Welding Procedure Specification (PWPSstdshopNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Part B - CwiDocument5 pagesPart B - CwimobtalaNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- WPS Multi GMAW FCAW PDFDocument2 pagesWPS Multi GMAW FCAW PDFwentroprem75% (4)

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviNo ratings yet

- Welding Technology Exam QuestionsDocument11 pagesWelding Technology Exam QuestionsVijaya BaraniNo ratings yet

- ESAB - Stainless Handbook PDFDocument92 pagesESAB - Stainless Handbook PDFfarshid KarpasandNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- Annex A. Fy 2018 List of Recipient TVL Shs (Sdos and Ius)Document169 pagesAnnex A. Fy 2018 List of Recipient TVL Shs (Sdos and Ius)Bryan SmileNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Document1 pageO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- GTAWDocument1 pageGTAWabdulNo ratings yet

- GS 001 Link 1 PDFDocument1 pageGS 001 Link 1 PDFhichemokokNo ratings yet

- WPS VesselDocument1 pageWPS VesselNaqqash SajidNo ratings yet

- S 001 Link 2Document1 pageS 001 Link 2wael badawiNo ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification: (As Per Asme Sec Ix)Document1 pageWelding Procedure Specification: (As Per Asme Sec Ix)Himanshu SinghNo ratings yet

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- Mathew Associates Hook Up & Weld Services: Welding Procedure SpecificationDocument1 pageMathew Associates Hook Up & Weld Services: Welding Procedure SpecificationHimanshu SinghNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- 347 310 WPSDocument2 pages347 310 WPSBIIS QAQC Babu SivaNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- WPS-035 - (Pno.15e To Pno.7) - 2Document2 pagesWPS-035 - (Pno.15e To Pno.7) - 2Allahyar YekkalamNo ratings yet

- Ce0034-Wps PQR02 E7.62 P01 01 PDFDocument1 pageCe0034-Wps PQR02 E7.62 P01 01 PDFKhaled BouhlelNo ratings yet

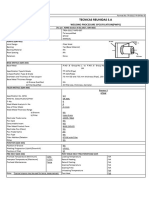

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- WPS For SSDocument1 pageWPS For SSdeepakNo ratings yet

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Project: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Document1 pageProject: Ts 100 Separator Repair: Welding Procedure Specification (WPS)Anonymous 7aUHXY1vWbNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Name: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName: Nihat First Name (S) : WPQ N°: TUR-19-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- Aic Asf PQR 133Document3 pagesAic Asf PQR 133AHMED MEDANYNo ratings yet

- QW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeDocument2 pagesQW-482 Welding Procedure Specification: Section IX, ASME Boiler & Pressure Vessel CodeRamzi ZoghlamiNo ratings yet

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 pagesName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- Welding Procedure Data Sheet for Steel Groups 1-3Document1 pageWelding Procedure Data Sheet for Steel Groups 1-3suronocaturatmojoNo ratings yet

- Aic Asf PQR 0121Document2 pagesAic Asf PQR 0121AHMED MEDANYNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- WPS Proposed CS (2''pwht-01e)Document2 pagesWPS Proposed CS (2''pwht-01e)Rajeev KumarNo ratings yet

- Profile Snapshot: H.Yashik Ahammed B.E., Certified Welding Inspeector-3.1 Qa/Qc Engineer - Pipeline & StructuralDocument5 pagesProfile Snapshot: H.Yashik Ahammed B.E., Certified Welding Inspeector-3.1 Qa/Qc Engineer - Pipeline & StructuralVijaya BaraniNo ratings yet

- Heat Treatment Procedure GuideDocument4 pagesHeat Treatment Procedure GuideDemir Alp IlıkobaNo ratings yet

- Technology 2Document9 pagesTechnology 2Vijaya BaraniNo ratings yet

- Carbon Equivalent Ploblem SolvedDocument1 pageCarbon Equivalent Ploblem SolvedJon LawsonNo ratings yet

- Cwi ToolsDocument5 pagesCwi ToolsMohamedGhanemNo ratings yet

- Guide Lines For Preparation of QAP by VendorsDocument1 pageGuide Lines For Preparation of QAP by VendorsFaiyaz KhanNo ratings yet

- Material Data Sheets For Piping: 1 ForewordDocument50 pagesMaterial Data Sheets For Piping: 1 ForewordhsdeNo ratings yet

- Form 29Document1 pageForm 29jacobpulikodenNo ratings yet

- 476 NR - 2018 01Document26 pages476 NR - 2018 01魏永涛No ratings yet

- MPI Reference Guide 2011Document20 pagesMPI Reference Guide 2011Telo VendoNo ratings yet

- Metrode Duplex Welding EWDDocument7 pagesMetrode Duplex Welding EWDClaudia MmsNo ratings yet

- Ss 1145Document2 pagesSs 1145wholenumberNo ratings yet

- Bhaduri2001 PDFDocument11 pagesBhaduri2001 PDFakhileshNo ratings yet

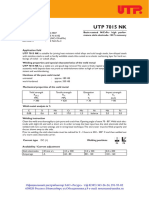

- Utp 7015 NKDocument1 pageUtp 7015 NKsergey.pu4kaNo ratings yet

- AQSIQ Notice No.151 (2012) PDFDocument12 pagesAQSIQ Notice No.151 (2012) PDFarbor02No ratings yet

- SMAW Facilitator's Guide Provides Safety Tips for Welding Fumes and Electric Shock HazardsDocument62 pagesSMAW Facilitator's Guide Provides Safety Tips for Welding Fumes and Electric Shock HazardsAJ AcuñaNo ratings yet

- API 653 Calculation TestsDocument20 pagesAPI 653 Calculation TestsAnuradha Sivakumar100% (4)

- Wel 12 DDocument7 pagesWel 12 DWilly UioNo ratings yet

- AASHTO D1.5 welding procedure specificationDocument1 pageAASHTO D1.5 welding procedure specificationViswanath SreepadaNo ratings yet

- PCH Welding Repair ProcedureDocument8 pagesPCH Welding Repair Proceduremohd as shahiddin jafriNo ratings yet

- Esab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)Document1 pageEsab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNo ratings yet

- Welding Level 3 5e Courseplanningtools PDFDocument25 pagesWelding Level 3 5e Courseplanningtools PDFFerl Sadrid0% (1)

- Machine Frames, Bolted Connections, and WeldedDocument19 pagesMachine Frames, Bolted Connections, and WeldedwinstonsequeiraNo ratings yet

- Manual de Servicio dv26Document505 pagesManual de Servicio dv26Servi PadNo ratings yet

- VR7000 Wire Feeder ManualDocument55 pagesVR7000 Wire Feeder Manualfzr989No ratings yet

- Description S.NO.: Produced by An Autodesk Educational ProductDocument1 pageDescription S.NO.: Produced by An Autodesk Educational ProductAshar HassanNo ratings yet

- SSR DataDocument251 pagesSSR DataVenkata KrishnaNo ratings yet

- Duplex Beaune 2010Document10 pagesDuplex Beaune 2010aliNo ratings yet

- Cty CP Que hàn điện Việt Đức Chứng chỉ ISO 9001-2008Document48 pagesCty CP Que hàn điện Việt Đức Chứng chỉ ISO 9001-2008Binh Hung OngNo ratings yet

- Catalogo Placas Antidesgaste CDP PDFDocument12 pagesCatalogo Placas Antidesgaste CDP PDFoscarlopez12345No ratings yet

- Welding Hand BookDocument434 pagesWelding Hand BookavmrNo ratings yet

- MAG Digital High-Performance Ultrasonic GeneratorDocument4 pagesMAG Digital High-Performance Ultrasonic GeneratorAladin ZeribiNo ratings yet

- Wheel Up English Presentation 5Document17 pagesWheel Up English Presentation 5Omar Mendoza LegardaNo ratings yet